Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

S |

|---|

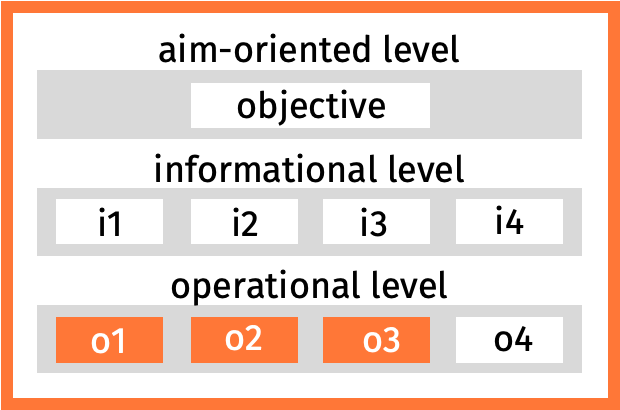

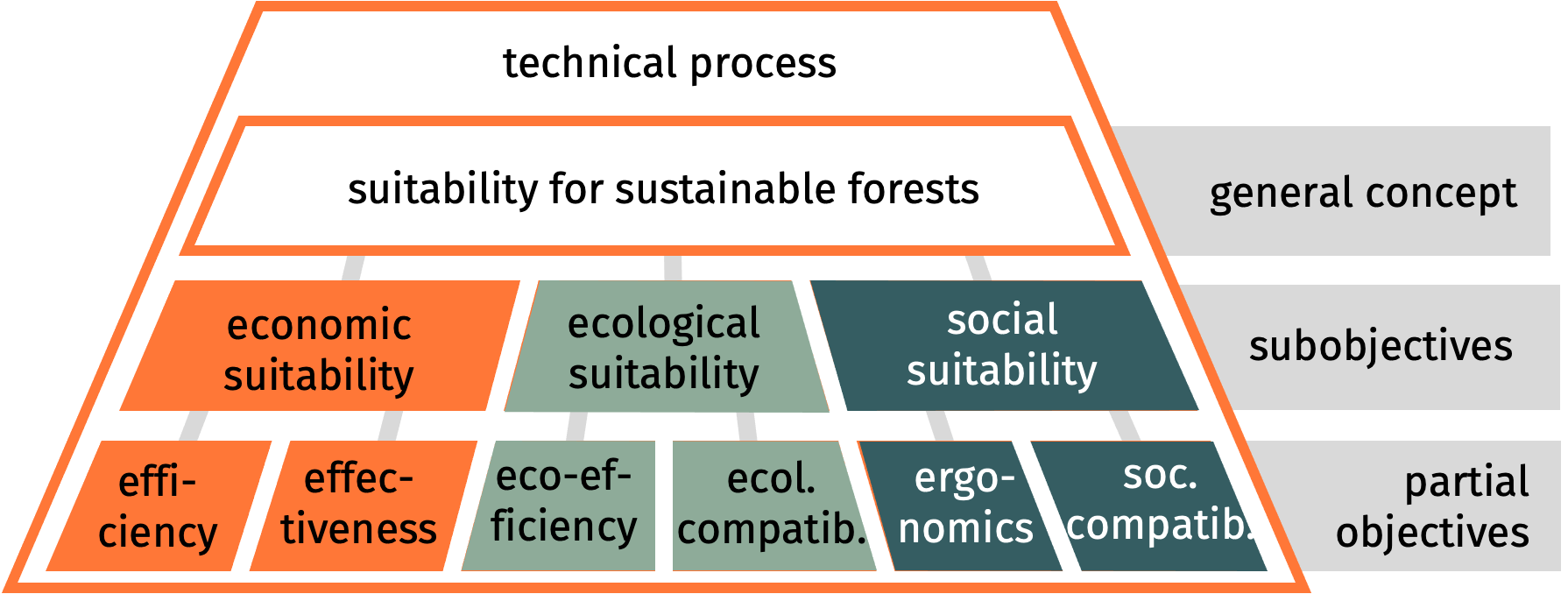

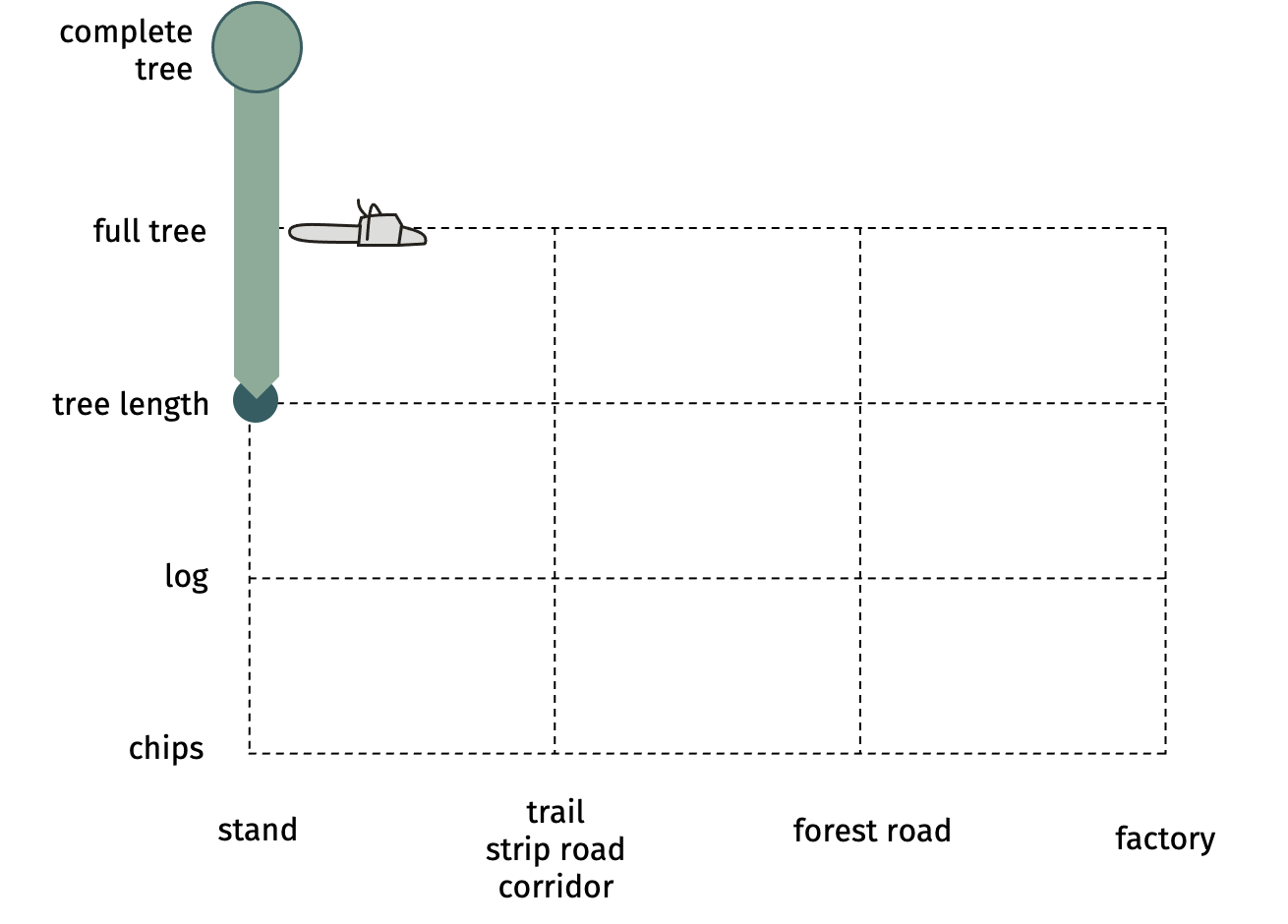

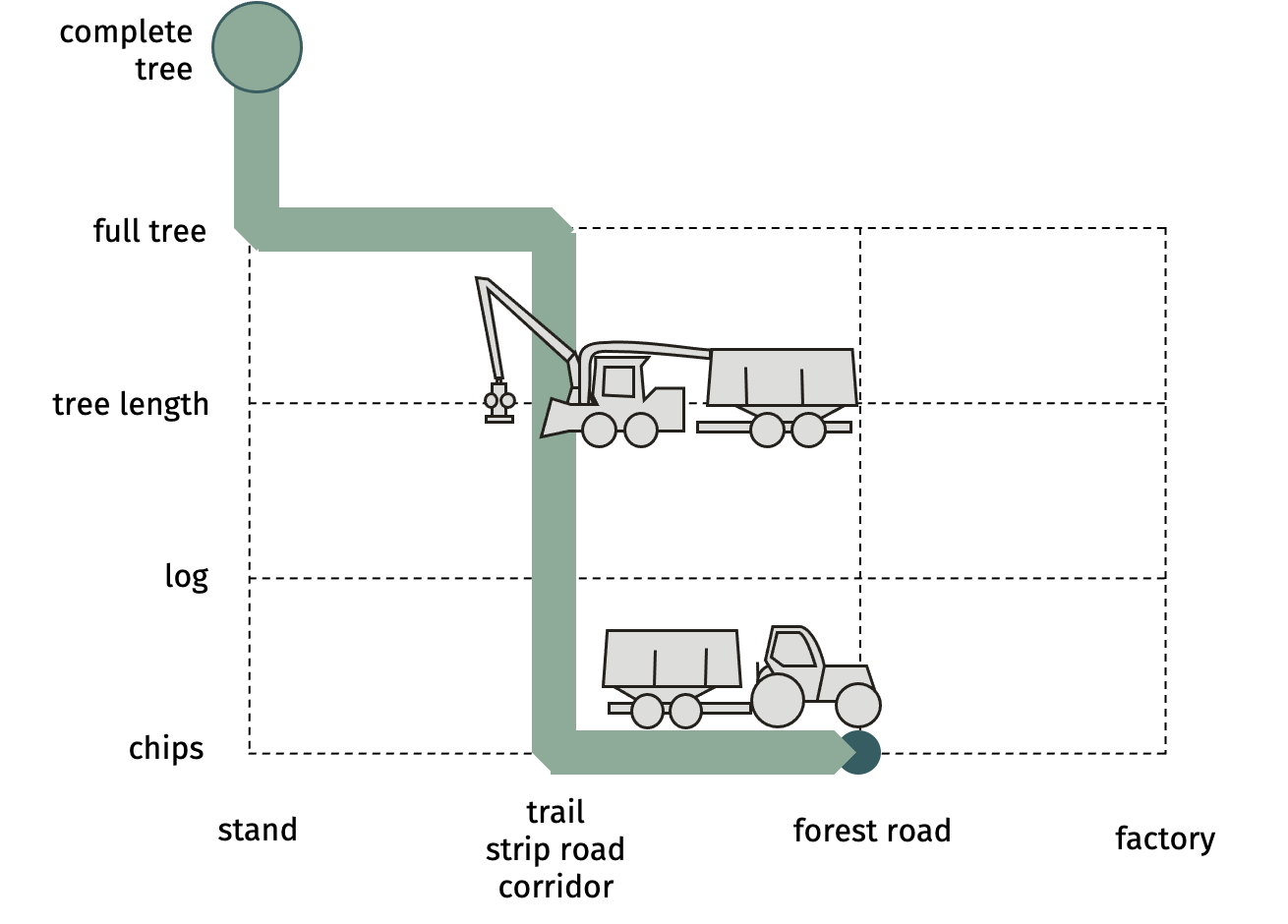

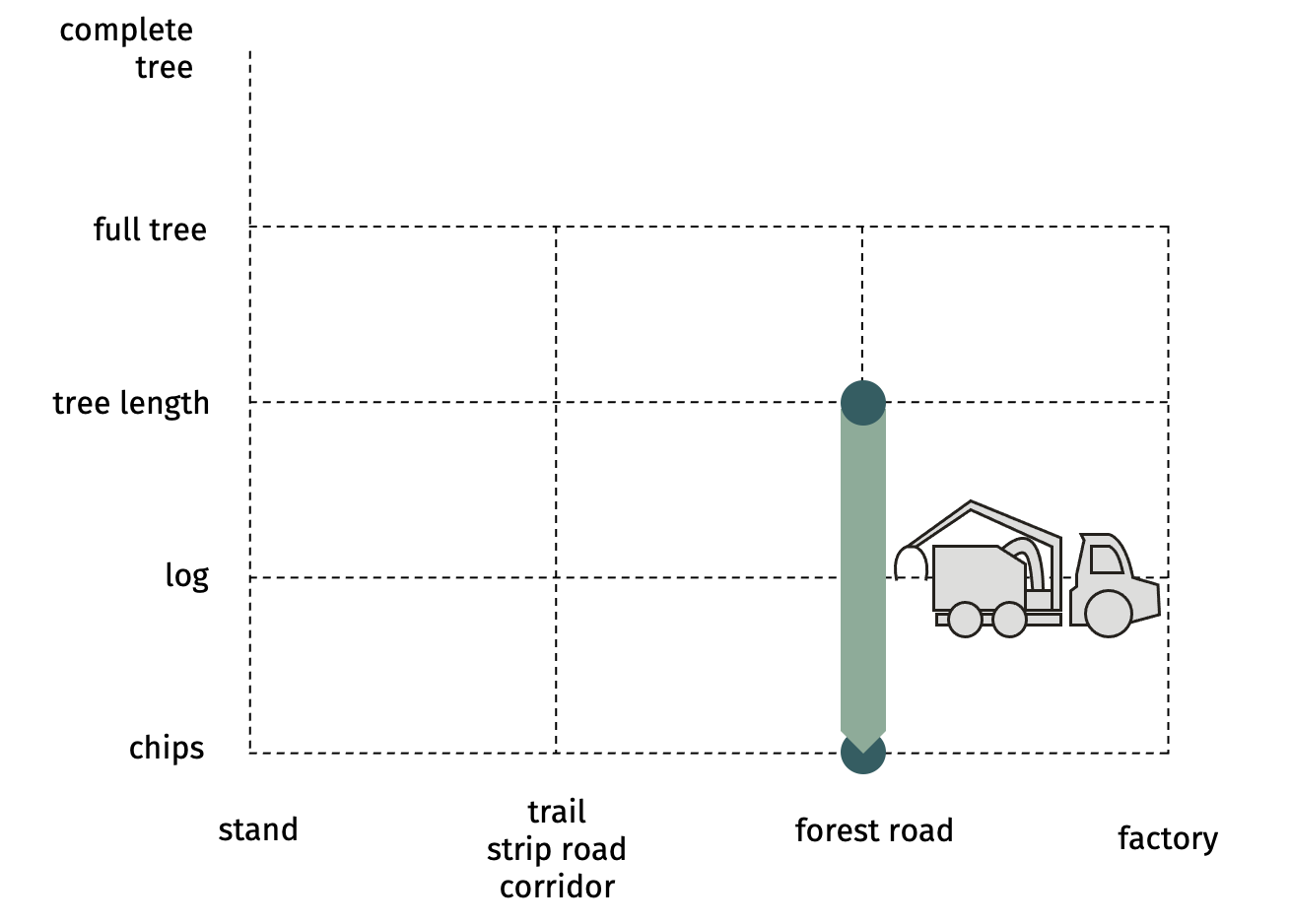

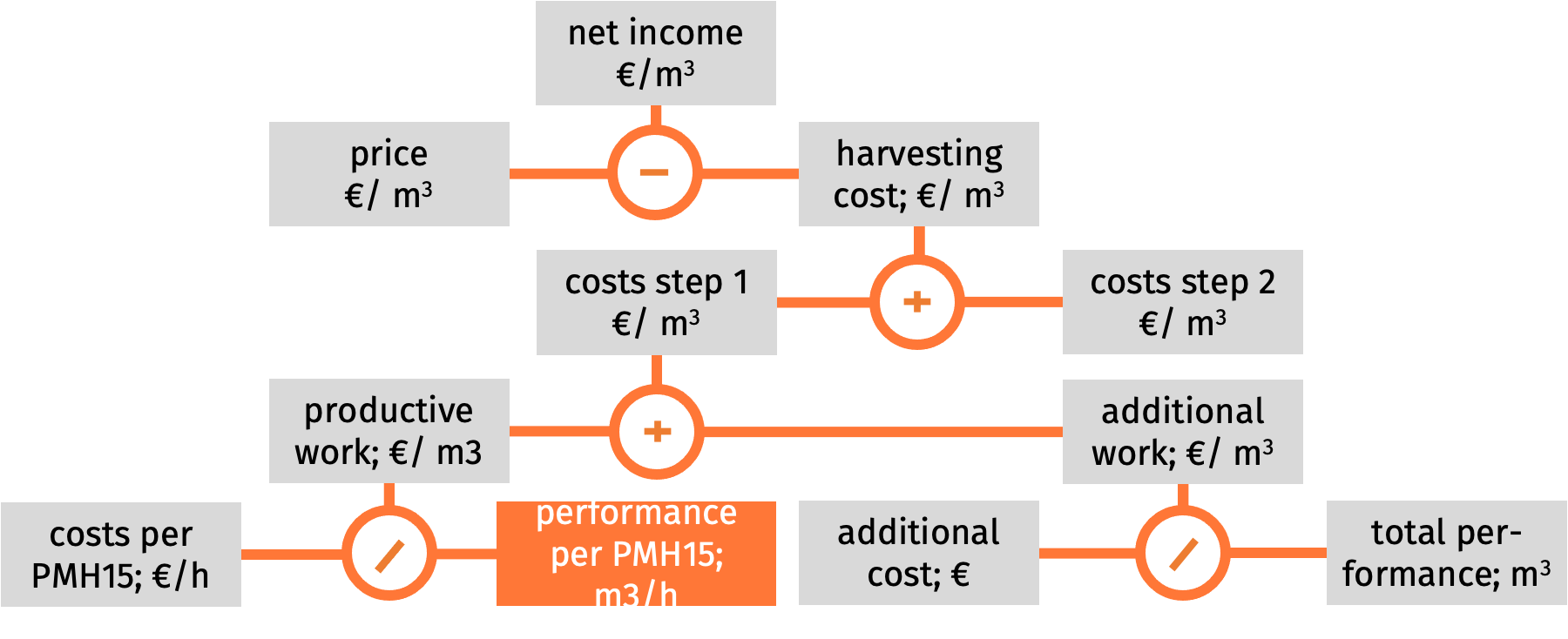

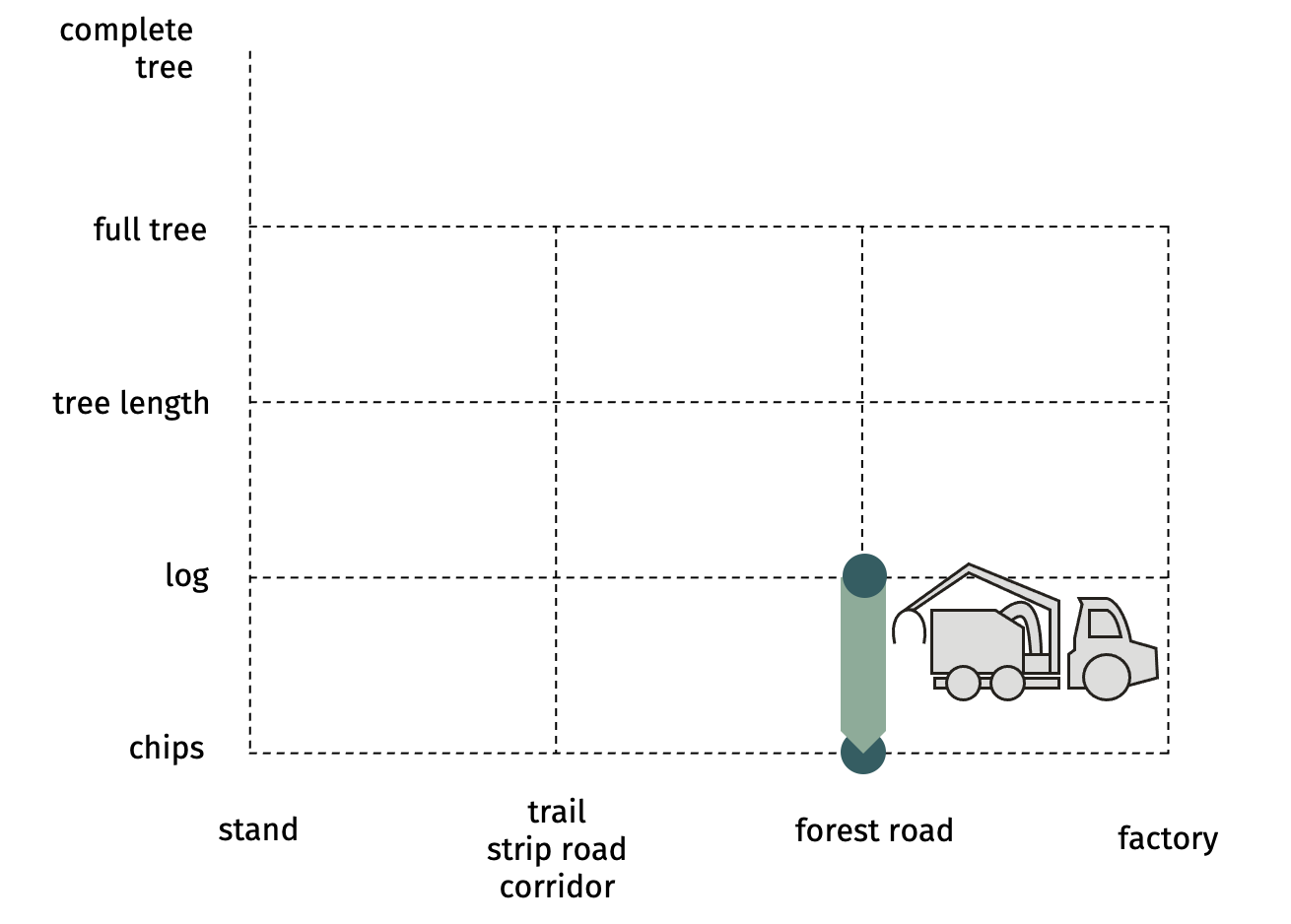

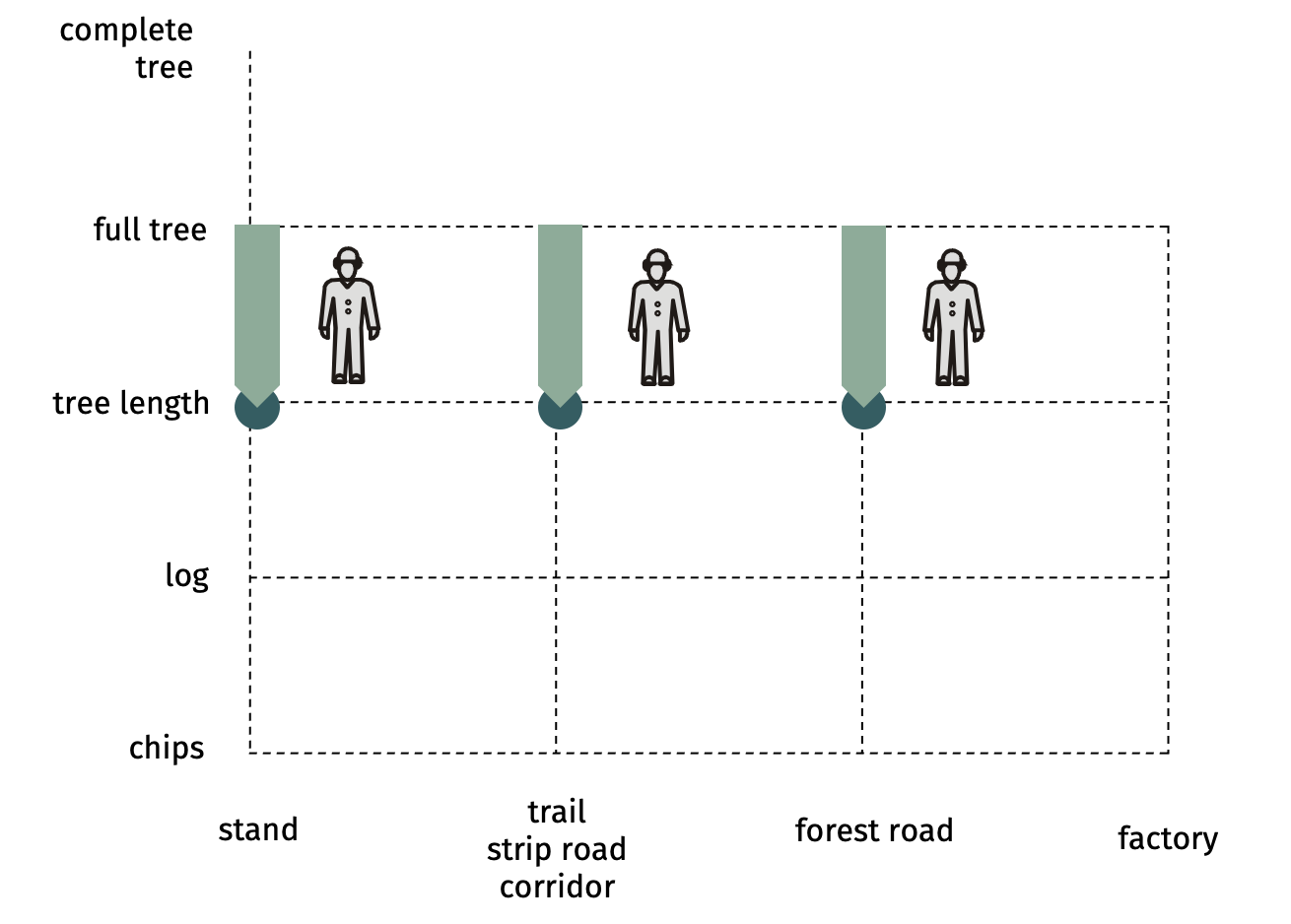

S-classesPublic recreation can get in conflict with harvesting operations. Based on SINUS-milieus, different user groups are found that have very different needs and expectations to the forest owner. But all forest visitors have one common need: they use the forest roads as their access to the forest and don’t want to be disturbed. If we keep the roads clear for people to move on them, this can help to improve the acceptance of forest techniques and operations. Thus, the forest roads take over the role as a key factor for the acceptance of techniques by the forest visitors. Based on the functiogram, we can define five S-classes for societal compatibility: S1 chipping of wood on the forest road of storing of chips there with noise, dust, and trash on the ground = arrow ending at 34; S2 processing round wood on the forest road with impact to the road = arrow down ending at 32 or 33; S3 unloading and loading of tree lengths or full trees along the forest road with skidding on the floor = arrow from 22 to 32 or 21 to 31; S4 unloading and loading of short wood along the forest road, only picking up of products = arrow from 23 to 33; S5 perfect, no contact with forest roads. (See more at TDiv PR1-E02)  | |

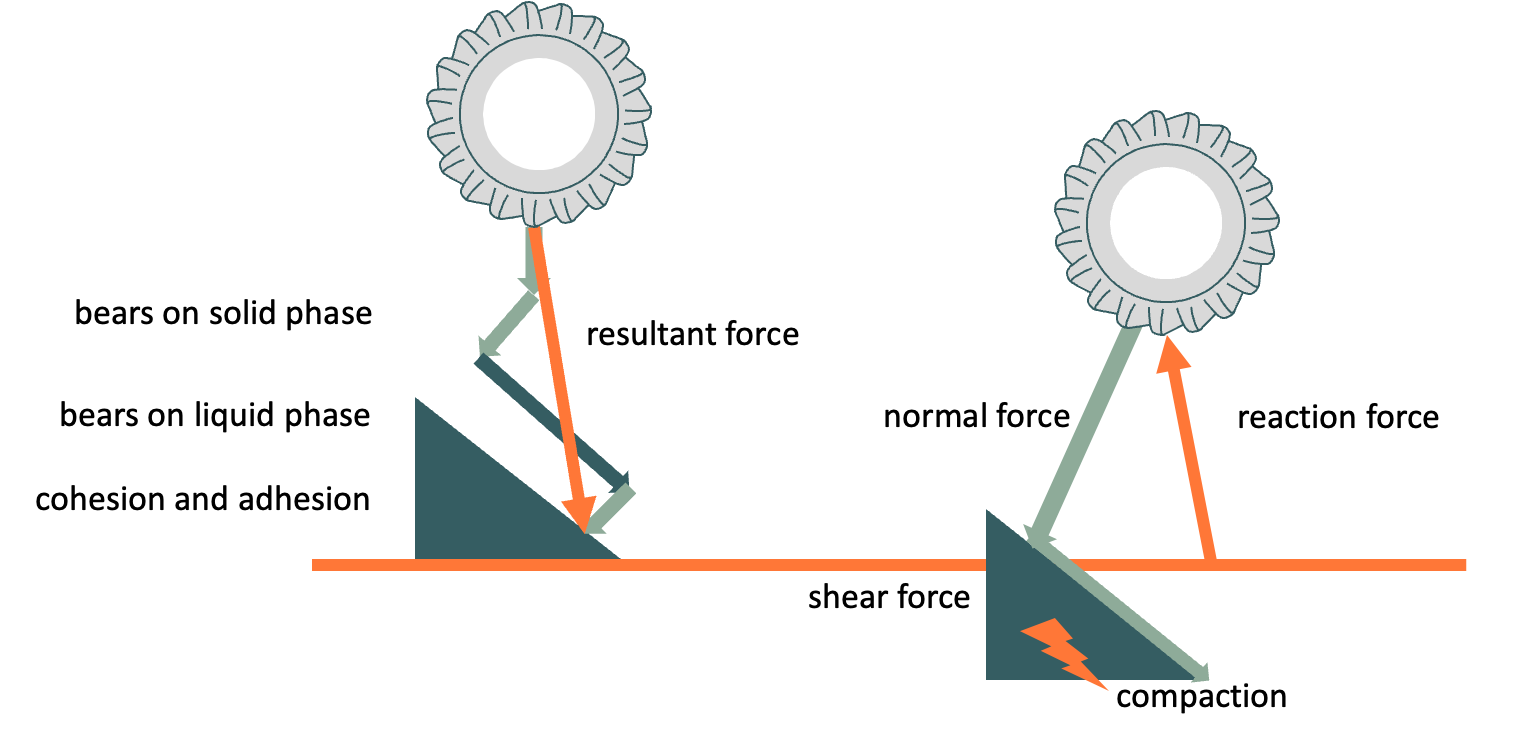

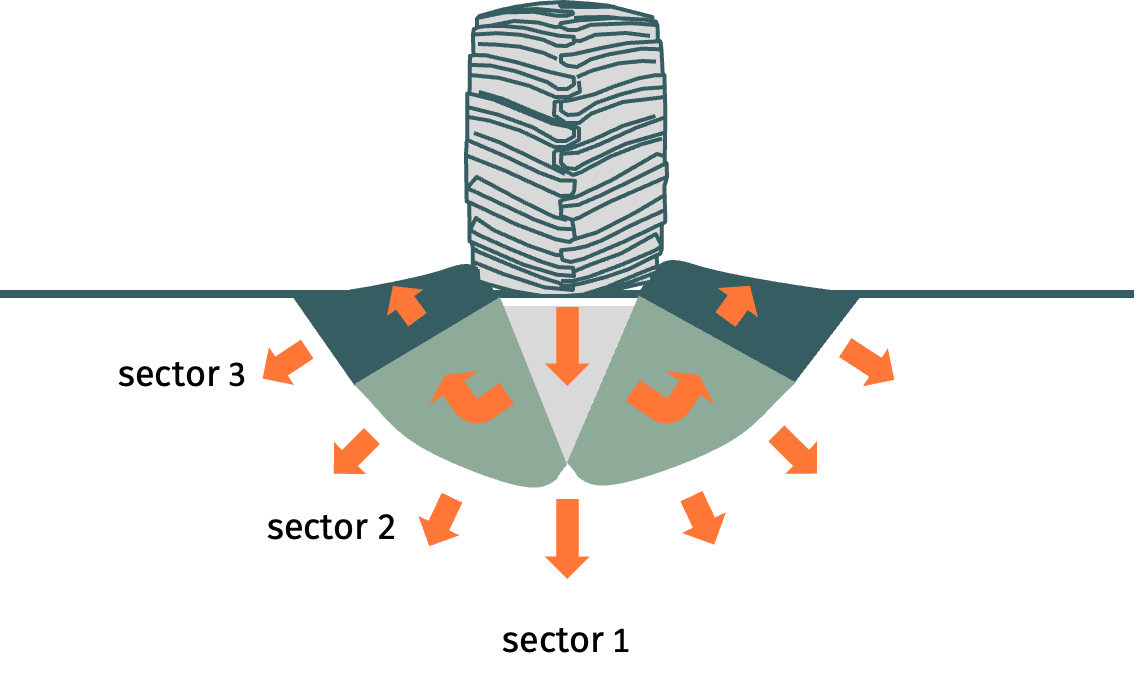

Sectors under wheelUnder a wheel, the load is covered by the soil. Inside the soil, zone of the same pressure (isobars) can be drawn like onion peels. Directly under the wheel the forces follow gravity and form a compaction. But to the left and right of the main vertical push, the soil can relax against the neighboring soil particles; the vectors turn around. The parts of the soil near the surface give way to the pressure and are lifted. Thus, ruts are not only the result of compaction, but also of lateral lifting of the soils beneath the ruts. (See more at PR1-D02)  | |

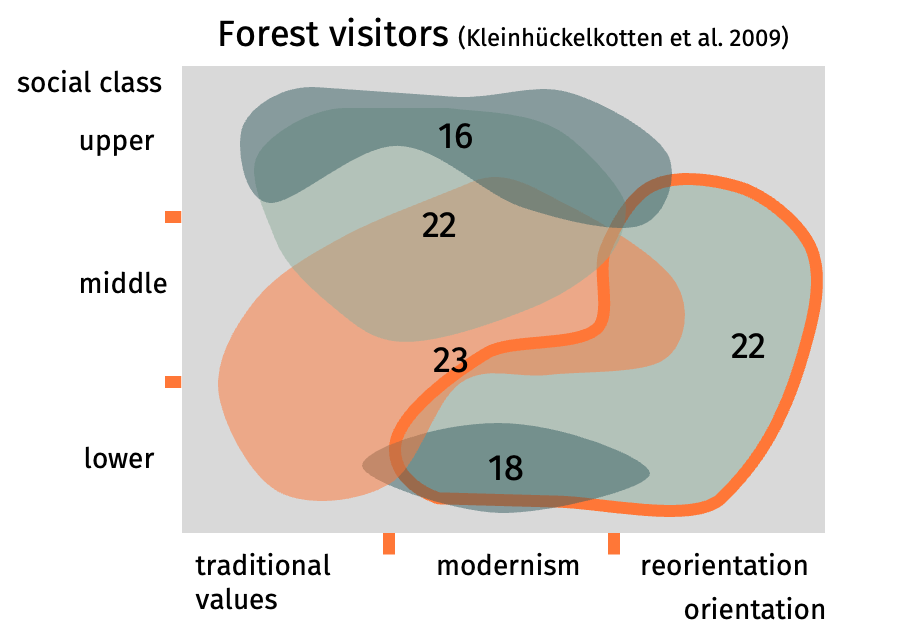

Self-centered forest usersIn a study from 2009, Kleinhückelkotten et al. have found five different groups of people who use the forests for recreation. One of them are the self-centered forest users, the others are holistic forest friends, ecological forest romantics, pragmatical distant persons, and indifferent persons. In the study, 22% have been characterized as self-centered forest users. For them, the forest is no more than a backdrop for their hedonistic activities, such as playing sports, picnicking etc. They regard any limitations as the unacceptable restriction of their freedom. As such, they are not amenable to restrictions caused by forest activities, regardless of harvesting methods and technology. (See more under TDiv PR1-E02)

| |

Side-effectsSee risks and side-effects | |

Simple mechanized workThe term mechanized work describes the level of mechanization of a technical operation. Other levels are manual work and motor-manual work. Mechanized work can further be divided into simple, advanced and automatic work. Simple mechanized work offers increased power and mobility, but all auxiliary functions are done by humans. Example: a cable skidder, which can move larger loads than a human can, and does that at a higher speed. But the attachment of the logs must be done manually by the operator. (See more at TDiv PR1-B04)

| |

Skiddingsee solutions for skidding | |

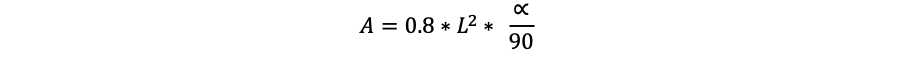

Skidding damageSkidding damage happens during the extraction. It can be caused by the machine or the skidded log. Animals seldom bump into trees, because they fear to be wounded. Machines have no sensors to protect from damage, only the driver should have. Therefore, in dense stands the moving pattern of the machine has an influence to the likelihood of a damage: Curves can be tricky, when the rear axle has a shorter turning radius than the front axle as it is common with Ackerman steering. Conventional machines like farm tractors and trucks have Ackerman steering. Dedicated forestry machines often have an articulated frame, where the two half-frames are connected by a central hinge. In that case, the rear wheels follow exactly the same track as the front wheels. The risk to damage trees is much lower. Another cause of damage is that the superstructure of a forest machine (like cabin, loading boom and basket) bumps against neighboring trees because of uneven floor. If the machine is fitted with bogies, the deflection of the chassis is only half as high then without bogies, so the danger of accident decreases. Damage to the stand can be caused by long logs, too. The area of the danger zone depends on the length of the log and the angle 𝛂 between log axis and strip road.  This formula says that the length has the most important influence on the danger zone. Thus, Systems that transport short logs make less damage to the forest stands. (See more at PR1-D01)

| |

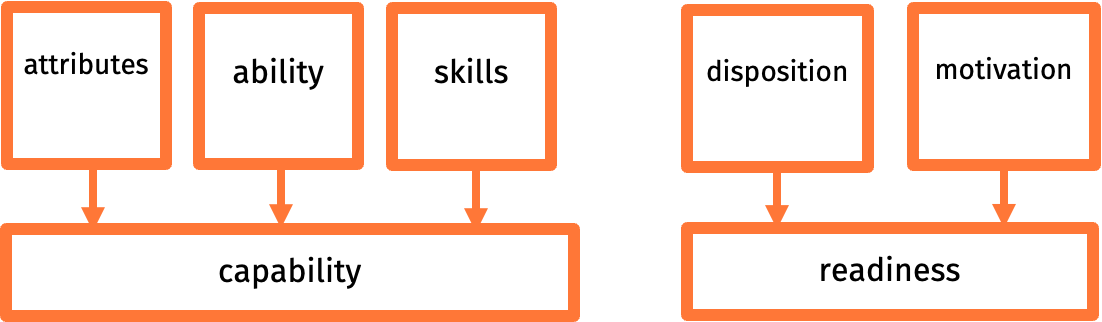

Skills of a workerErgonomics follows a very simple basic model that derives from physics: When you impact a body with a certain stress, the body will react with a corresponding strain. Since a standard method causes a stress that is typical for this standard method, the strain as a reaction to this typical stress situation should be typical, too. The intensity of the strain, however, is not the same. It depends on the worker: his personal attributes, his abilities and his skills (together they form the capability for work). And it varies due to the actual disposition and motivation (together called readiness for work), and his health. If the strain overruns the permanent work load, breaks are necessary for his personal recovery to avoid acute or chronic damage. Most jobs require a certain technique. Skilled persons can reach results that will never be possible for unskilled persons. (See more under TDiv PR1-E04)  | |

Social efficiencySocial efficiency see ergonomics | |

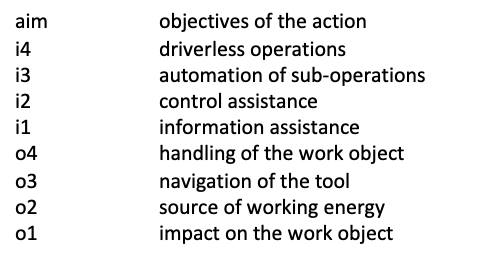

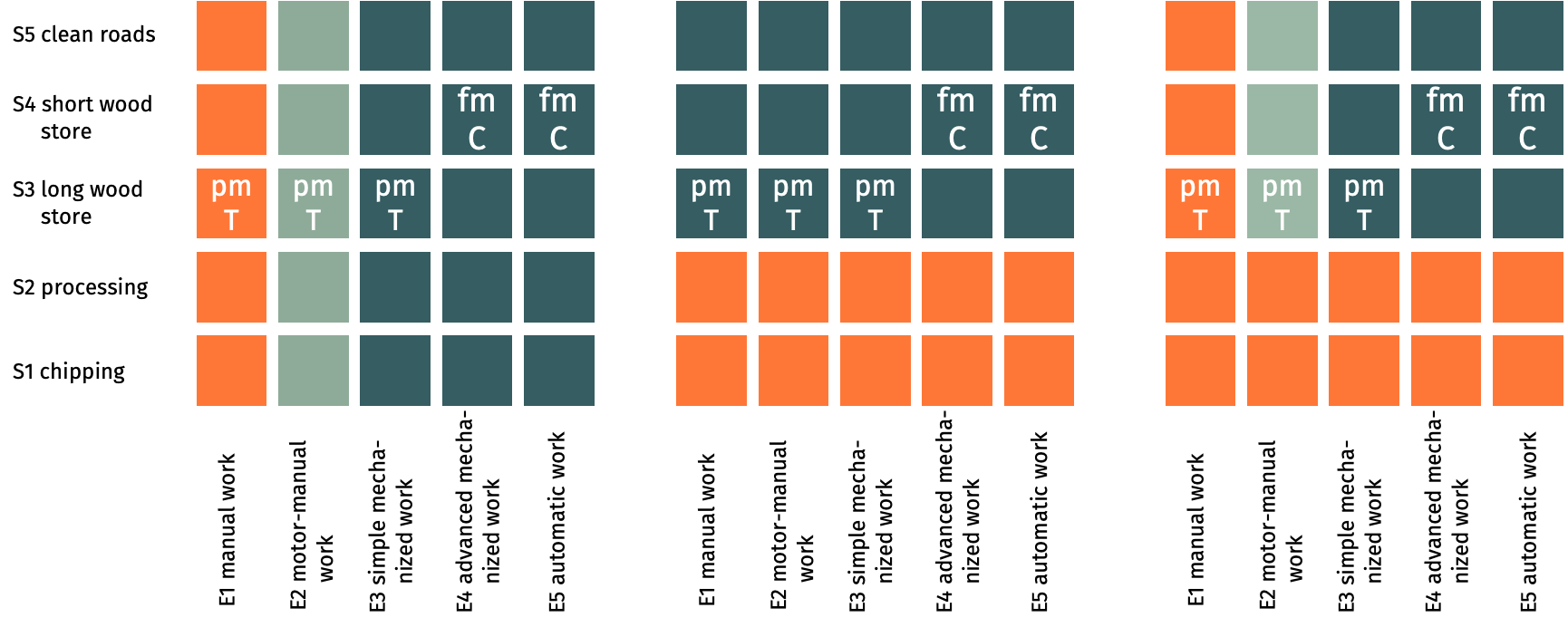

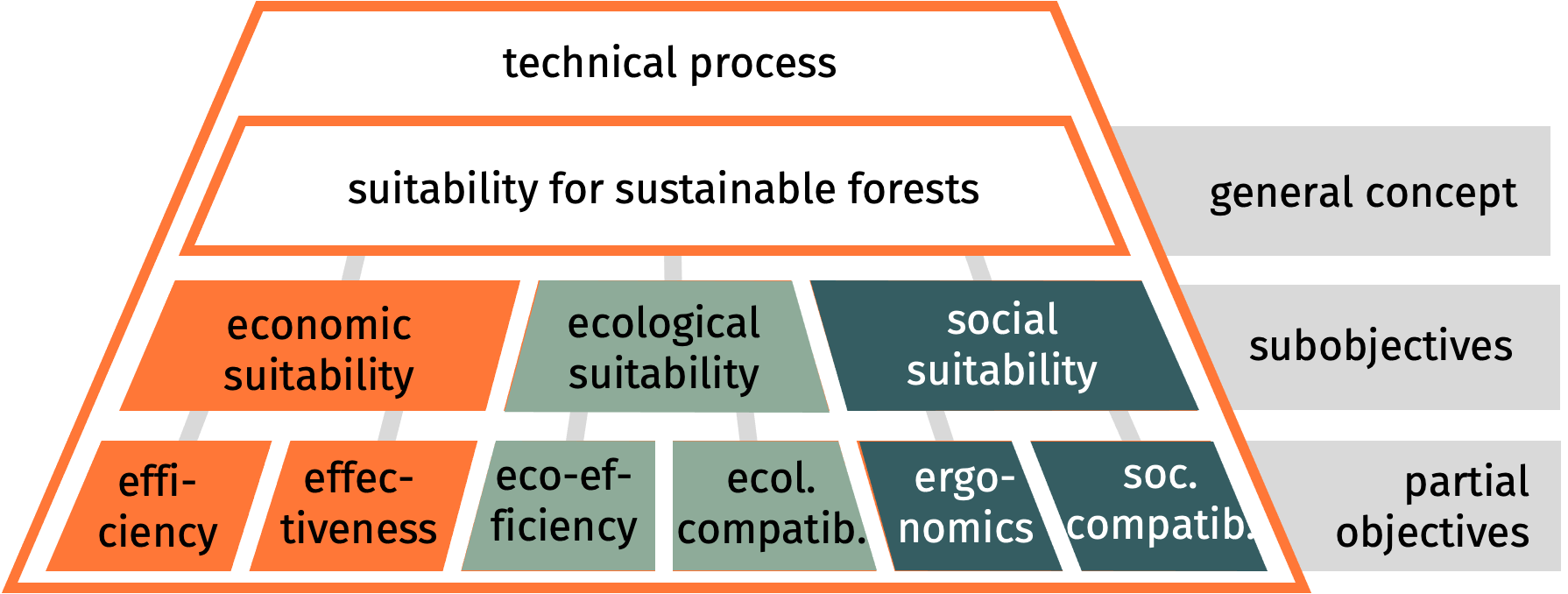

Social suitabilitySocial suitability is one sub-objective of the decision-making process. It corresponds with the social objective of the company in a means-end-relationship: The means should be developed in a way that it fulfills the end that is given by the objective of the company. The social suitability is subdivided into ergonomics and societal compatibility. On the same level are two competing sub-objectives: the economic and the ecological suitability. The relationships between them can be organized by the general concept for technical operations that is given by the company. The societal compatibility deals with the needs of the local society, within which the forest company operates. It is achieved by matching the different demands for recreation, heritage, employment etc. In Technodiversity, we have invented the S-class. Ergonomics, however, is focused on the wellbeing of the workers employed by the forest company, which is responsible for the working sites and methods. Employers must plan and conduct their operations in a way that minimizes the risk for the operators to suffer an accident or become ill. In Technodiversity, we have invented the E-class. Now we combine the assessments for ergonomics and societal compatibility in a 5x5-table, on x-axis the E-class and on y-axis the S-class. As an example, a fully mechanized CTL method with harvester and forwarder falls into the S-class S4 and E-classes E4 (forwarder) and E5 (harvester). Another option, a partly mechanized tree-length method with horse and tractor, falls in S-class 3 and E-classes E1 (horse), E2 (chainsaw), and E3 (tractor). Now the decision maker can mark his individual preferences. Here we chose traffic light colors to represent green (okay), yellow (limited), red (not acceptable). For example, one decision maker might feel uncomfortable with manual work due to safety concerns and prefer mechanized work, instead. Then he marks E1 with red, E2 with yellow, and the other columns with green (left table). Concerning compatibility with recreational needs (in the middle), our decision-maker may want to avoid processing on the forest road. Loading operations, however, could be accepted without constrains. Consequently, S1 and S2 are not acceptable, but all other S-classes are okay for this decision maker. When we combine those assessments (right table), at each intersection the less desirable color is dominant (comparable with the bottle-neck-rule). In our example we see, that the fully mechanized cut-to-length method with harvester and forwarder (fC) fits well to the societal assessment of this company. The partly mechanized method fails, due to the critical assessment of manual and motor-manual work. (See more

under TDiv PR1-A03, -E01, -E04, and E05)  | |

Societal compatibilitySocietal compatibility is a partial objective for decision-making. It wants to avoid disturbances that can occur in conflict with the needs and demands of the public. In forestry people enter the forests to recreate and enjoy their life and feel disturbed by forest operations. Cultural needs of the local population can be disturbed by technical activities, too. A third criterion may be the wish of local people to be employed by the forest company in order to earn money. As criteria in Technodiversity, we use the S-classes for societal needs. Together with its twin ergonomics we can assess the social suitability that is one sub-objective to find the optimal option. Parallel to the social suitability we also should look at the economic and the ecological suitability. For more information about systematics of decision-making, look at objectives and three-step model of optimization. (See more under TDiv PR1-A03, PR1-E02, and -E04)  | |

Societal demand for recreationSee recreation | |

Soil damageThe model of soil damage of Technodiversity acts on the assumption of tree soil states: A) Untouched forest soil: biologically healthy and productive B) Trafficable trail: compacted by former traffic and strong enough for future traffic C) Destroyed trail: impacted by former traffic in a way that is no longer usable. By traffic, a soil moves from untouched soil (A) to trafficable trail (B). After traffic, maybe it has a chance to find back to state (A) by biological (worms, roots…) and physical (frost) influences. As long as this happens in a reasonable time, we call it elastic deformation. But very often the traffic with our heavy machines causes a plastic deformation, which means that no natural regeneration will happen in a reasonable time period. This must not be regarded as damage as long as the technical function of the trail has priority for the owner. Because the compacted trail can be used for future harvesting operations, too, as long as it keeps its technical functionality. This has the advantage that next time the rate of compacted soil will not increase. To reach this, we demand for permanent trails as a central idea of eco-efficiency. For the question, how much of the soil is allowed to be fixed for technical purposes, no absolute answer can be found. This depends on the decision of the owner. Consequently, any further degradation of the soil towards destroyed trail (state C) must be avoided. There are two tactics: To stop the operation immediately when critical signs occur or to shape the harvesting system in a way that the likelihood of any damage is minimized. But sometimes the trail will be destroyed in a way that no more traffic can happen on it. Then it should be repaired by technical means (road construction) to recover the technical functionality. (See more at PR1-D02) | |

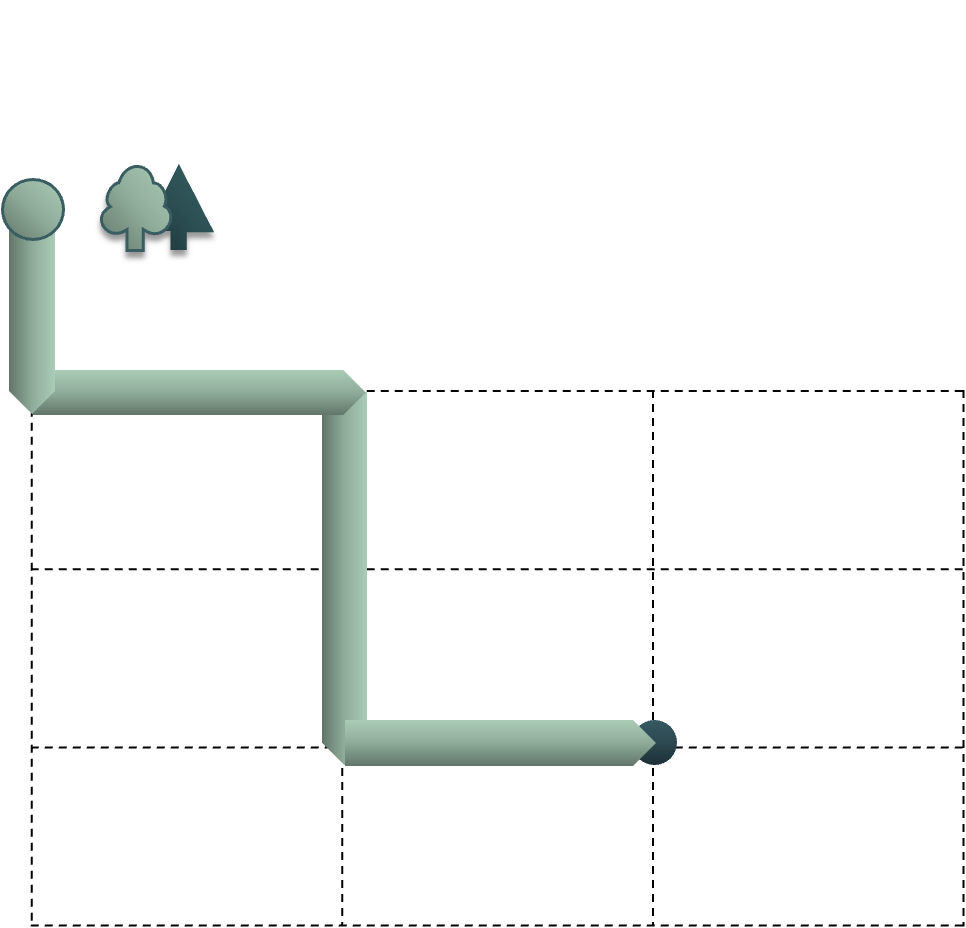

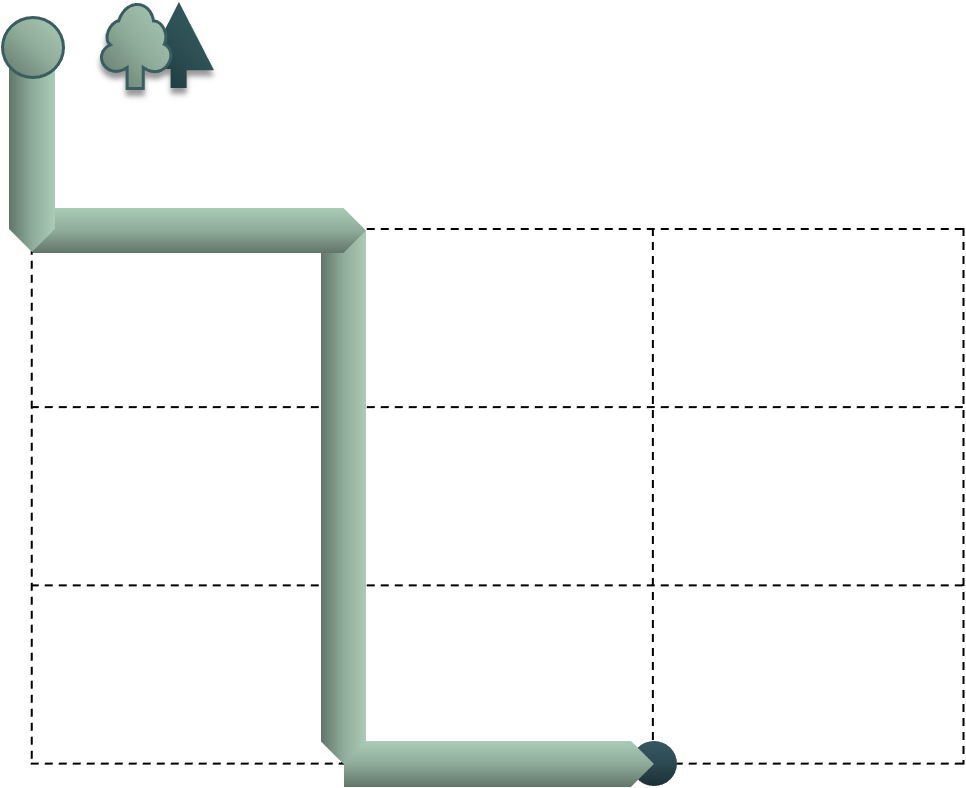

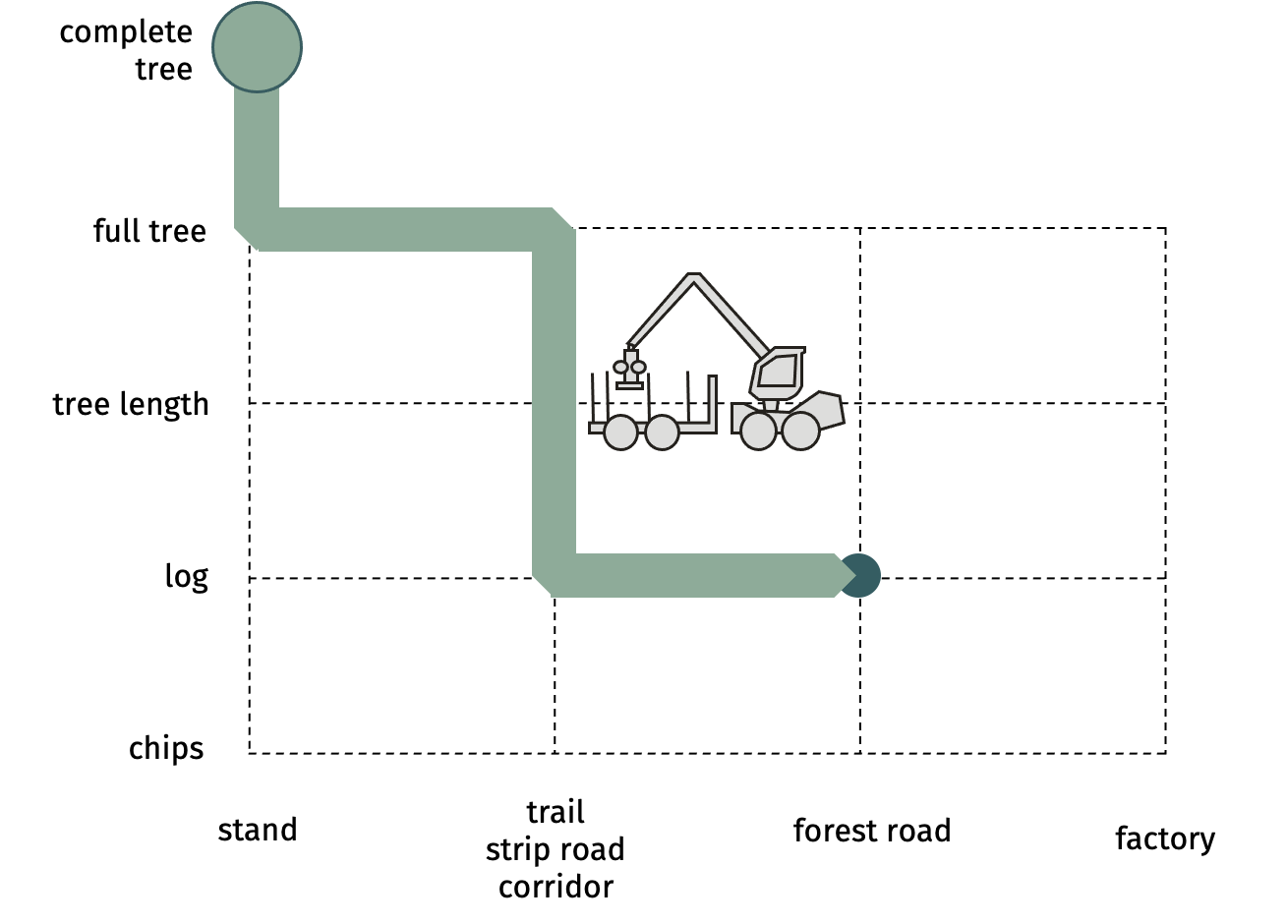

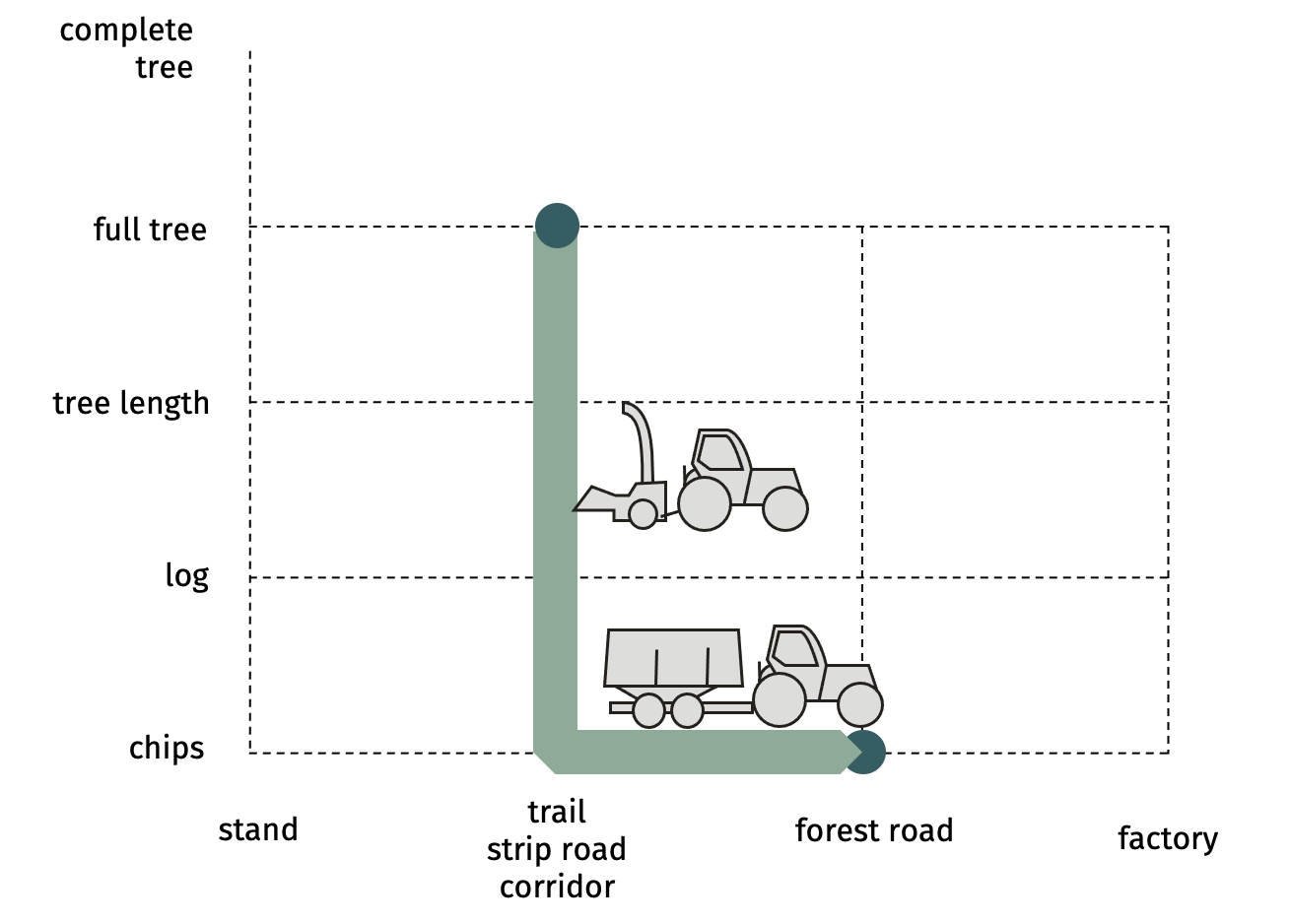

Solutions for „harwarding“ of short logsOne option which can only be executed by a special machine is the “harwarding” of short logs. In this case a special machine, the harwarder, fells the tree, delimbs it, cross-cuts it into logs and skids the logs to the forest road (buffer 10 to 33). All these sub-processes are done in one step without a buffer to interrupt. Since all the sub-processes are done by the harwarder, it is assigned to the mechanized work.

| |

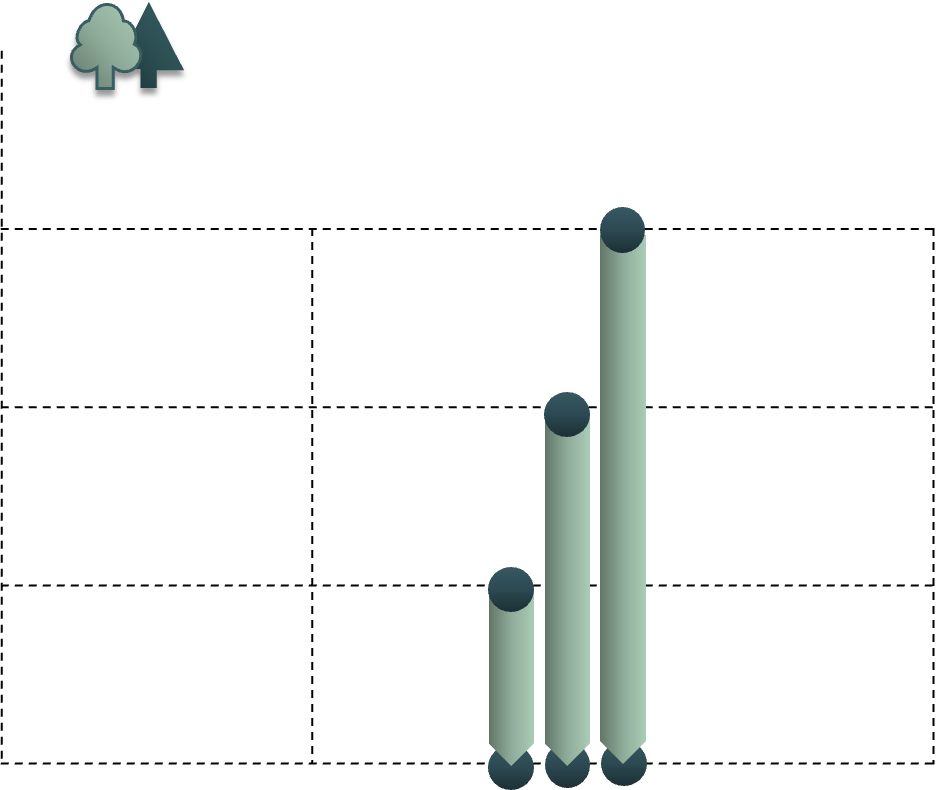

Solutions for chipping at the forest roadTo produce chips (= chipping) at the forest road, full trees (buffer 31 to 34), tree lengths (buffer 32 to 34) or short logs (buffer 33 to 34) can be used. The chipping is a mechanized work and can be executed by a chipper.   | |

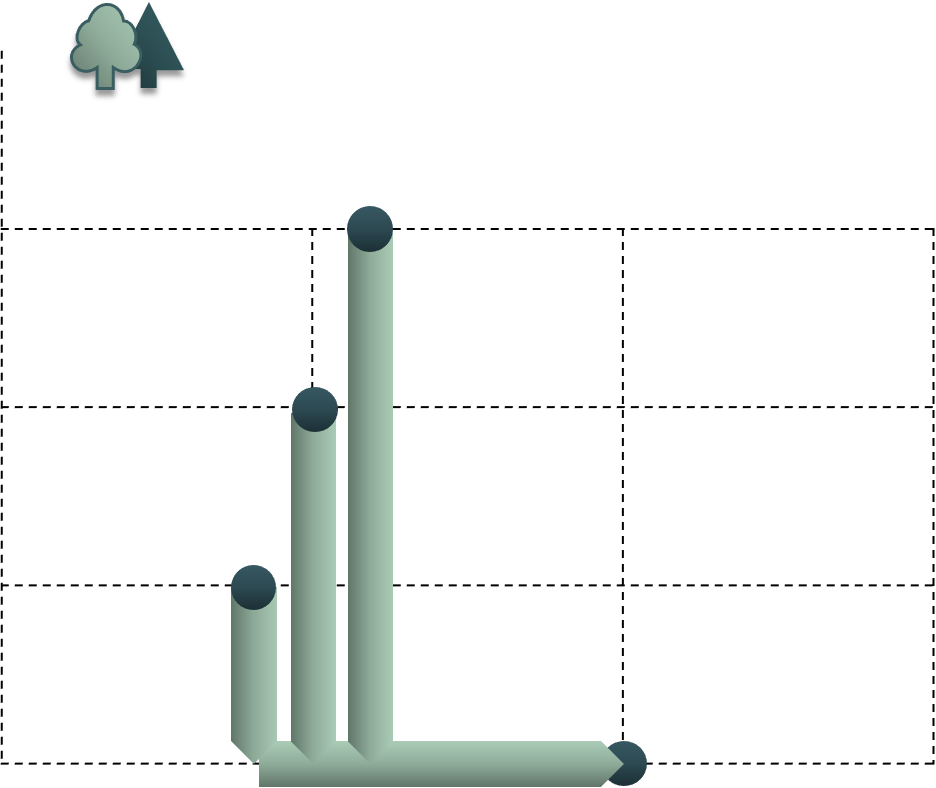

Solutions for chipping on the trailTo produce chips (= chipping) on the trail, full trees (buffer 21 to 24), tree lengths (buffer 22 to 24) or residues (buffer 23 to 24) can be used. The chipping is a mechanized work and can be executed by a chipper.   A specialized option is a biomass-harvester. This machine fells the tree and directly forms chips out of it (buffer 10 to 24).

| |

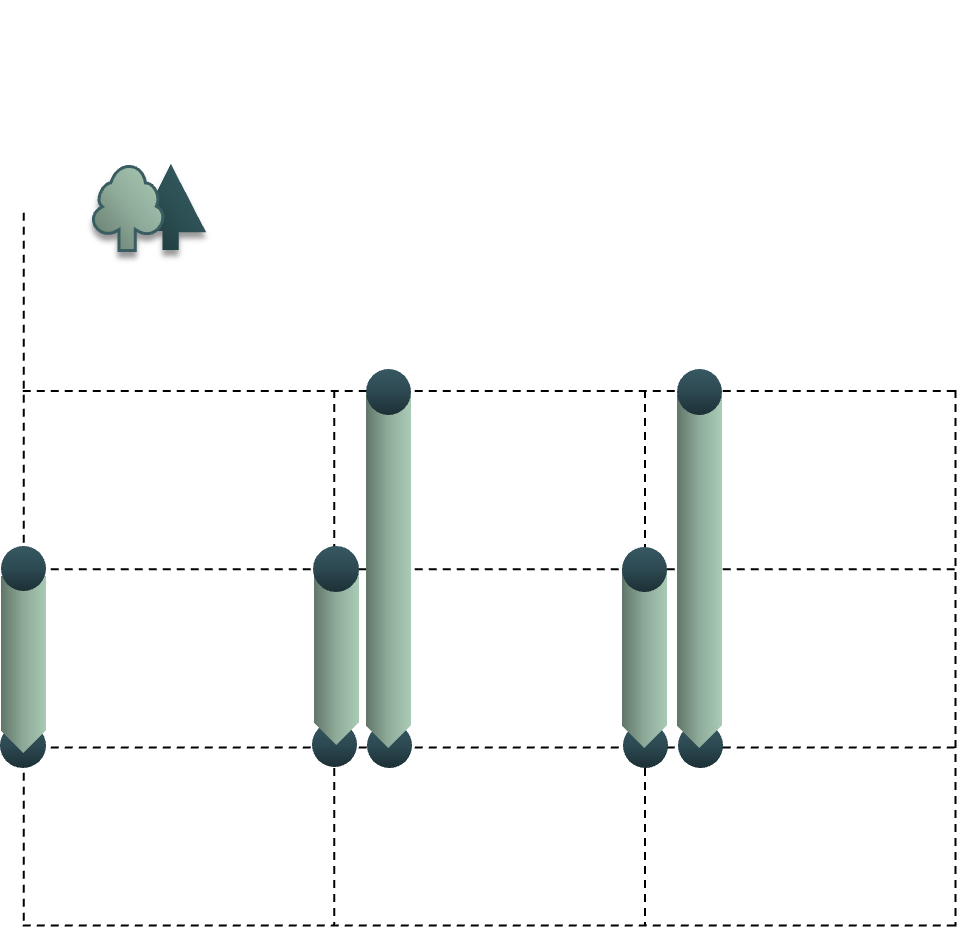

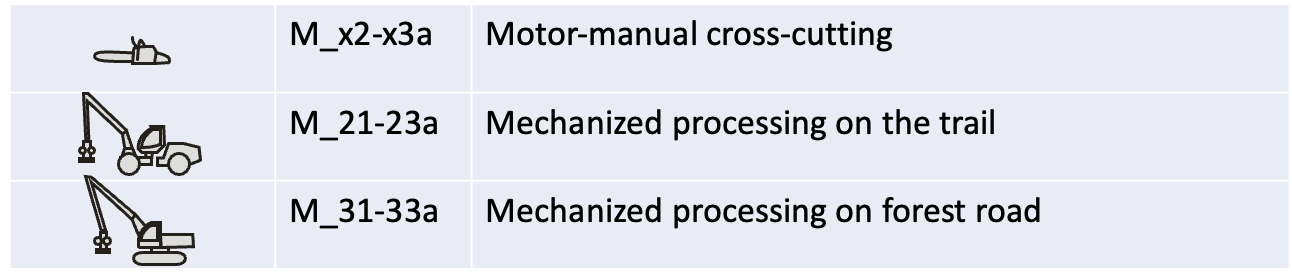

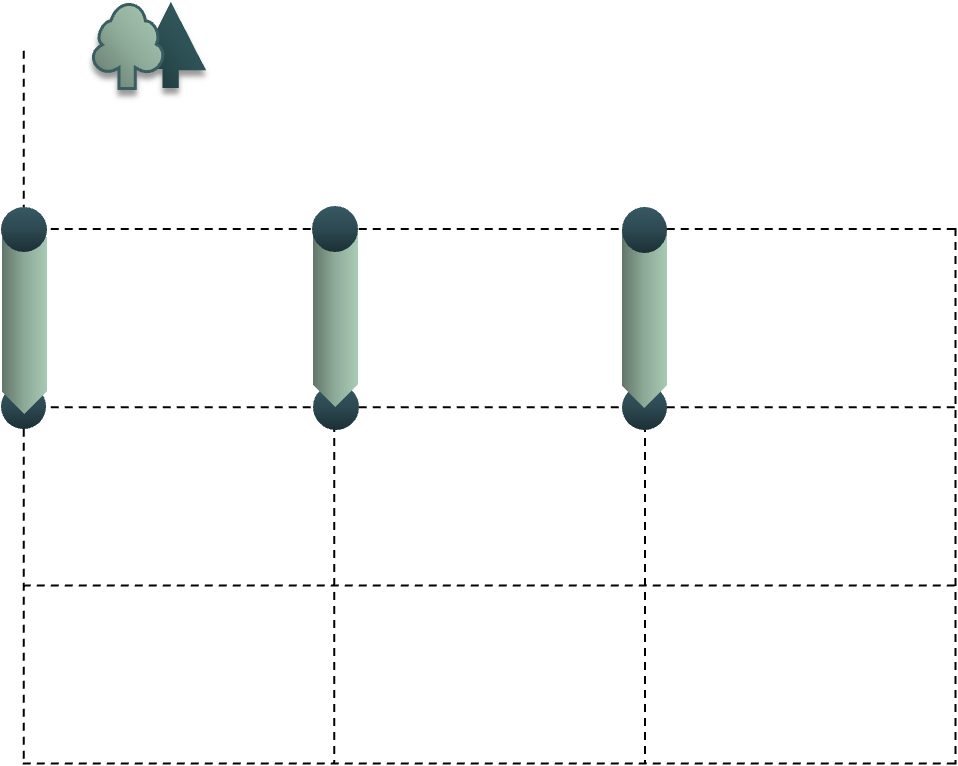

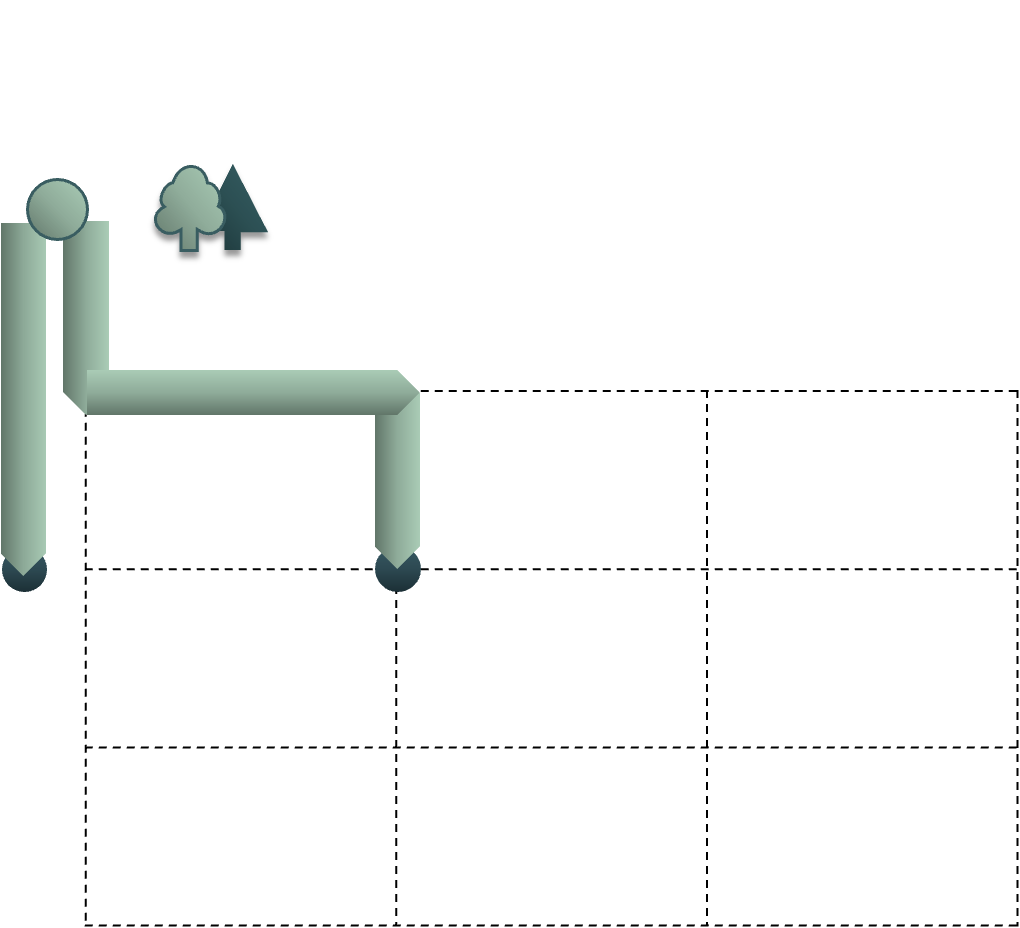

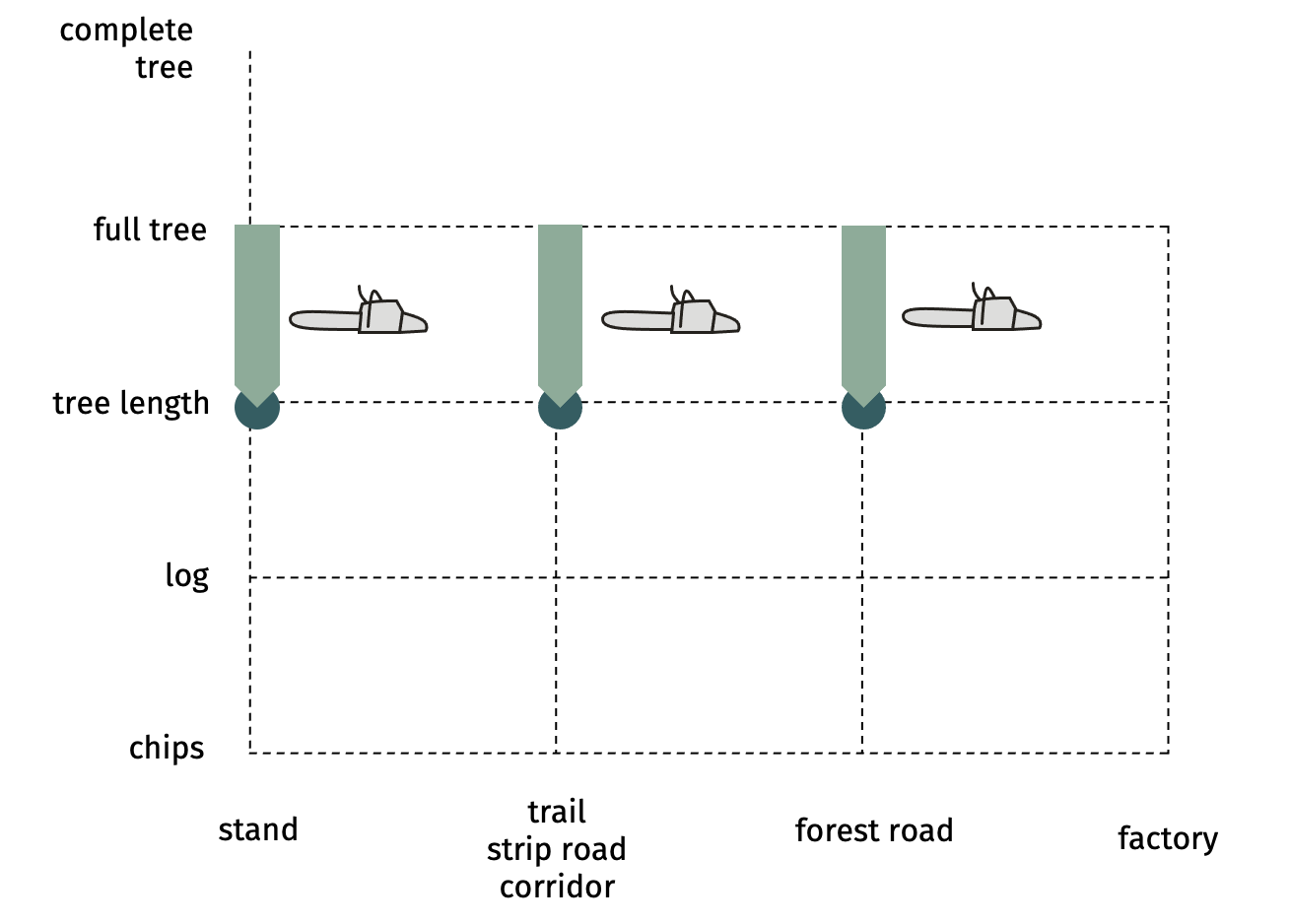

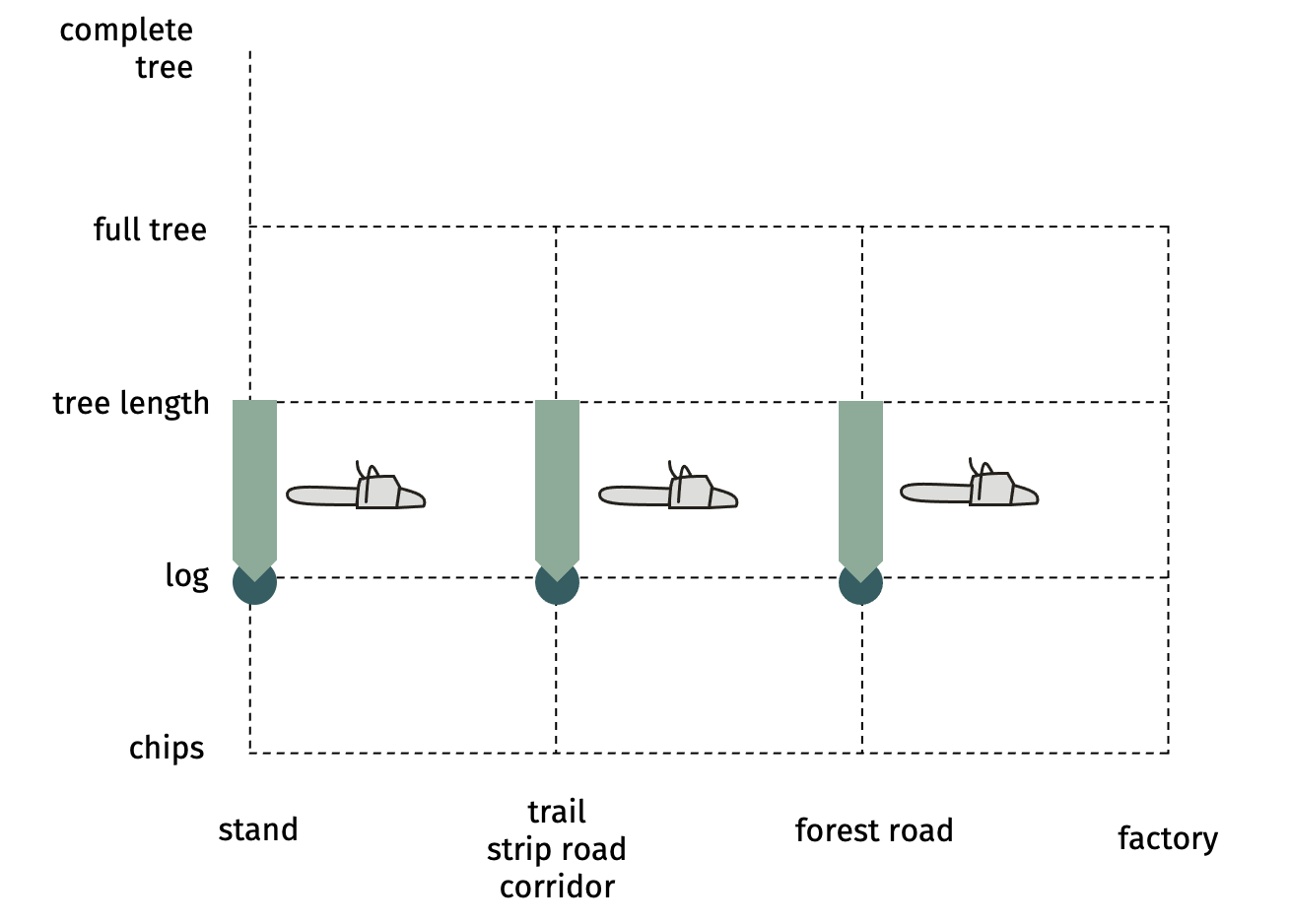

Solutions for cross-cuttingThe sub-process of cross-cutting describes the transformation from tree lengths or a full tree into short logs. It can be carried out either in combination with the delimbing of the tree or detached from the delimbing as a single function. If the tree is delimbed and cross-cut in one step, this is usually done on the trail (buffer 21 to 23) or the forest road (buffer 31 to 33). The combination of delimbing and cross-cutting is executed mechanically with a processor ( can also be executed with a harvester) on the trail or the forest road. If the tree length is cross-cut as a single function, it can be done either in the stand (buffer 12 to 13) or on the trail (buffer 22 to 23) or the forest road (buffer 32 to 33). Usually it is done motor-manually with a chainsaw.   | |

Solutions for delimbingDuring the sub-process of delimbing, a full tree is converted into a tree length by cutting of the top of the tree and the branches. If the tree is only delimbed, this is usually done motor-manually with the chainsaw. Depending on where the full tree is located, delimbing can be performed either in the stand (buffer 11 to 12), on the trail (buffer 21 to 22) or the forest road (buffer 31 to 32).

The sub-process of delimbing can also be carried out in combination with the felling of the tree. This combined option of felling and delimbing can be executed mechanically by a harvester or motor-manually with a chainsaw. While the tree that is felled and delimbed motor-manually remains in the stand (buffer 10 to 12) after the process, the tree that is felled and delimbed mechanically is lifted onto the trail during the process (buffer 10 to 22).   | |

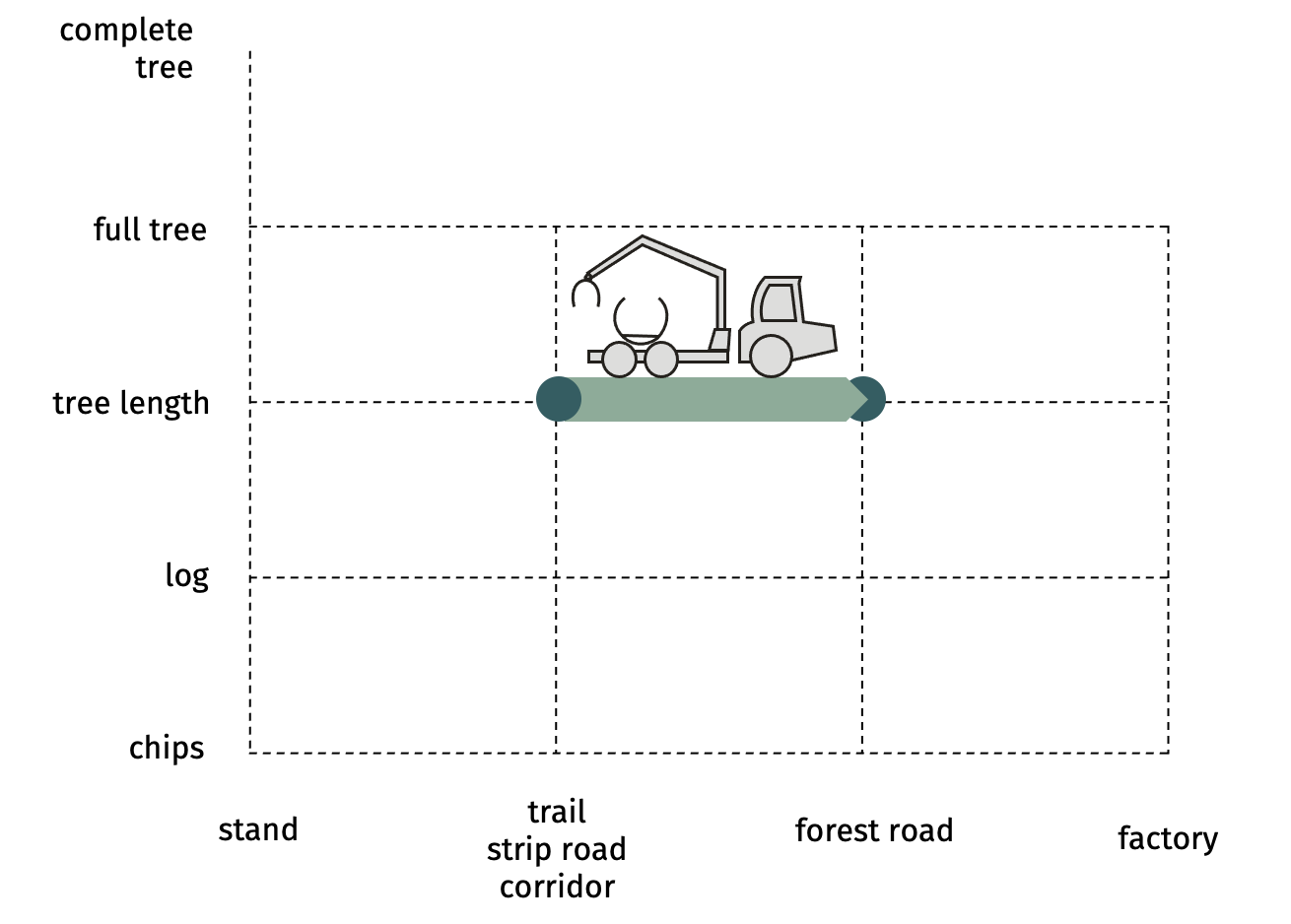

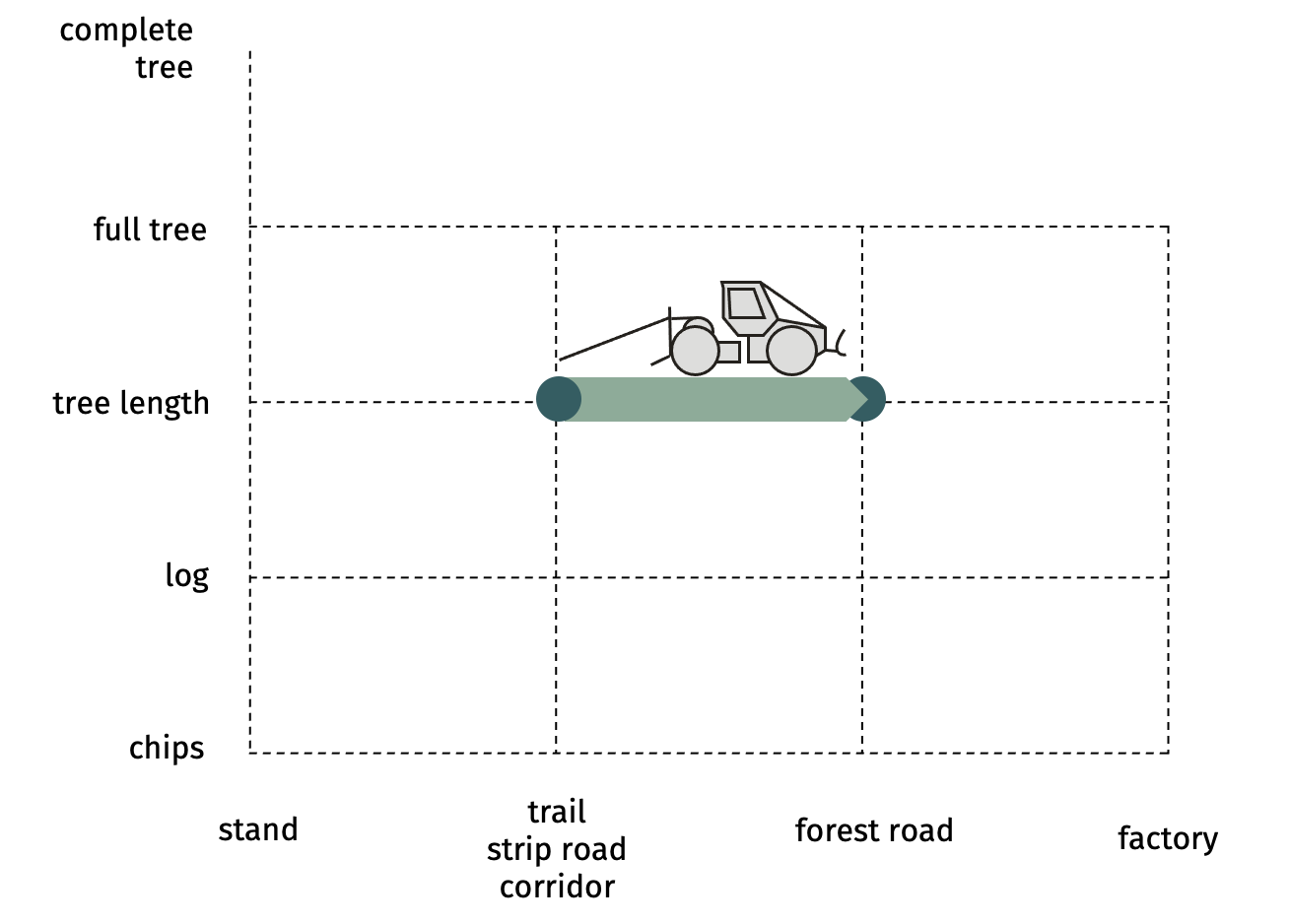

Solutions for extracting (skidding) tree lengthsDuring the sub-process of extracting/ skidding, the tree lengths are moved from the trail (buffer 22) to the forest road (buffer 32). Usually, the extracting is executed mechanically. Often used machines are the cable skidder and clam-bunk skidder. In both cases, the transport of the tree lengths is carried out in a dragging movement. The cable skidder can also be used not only for the skidding of tree lengths but also for the combined sub-processes of pre-skidding and skidding (see “Solutions for pre-skidding and skidding of tree lengths”).   | |

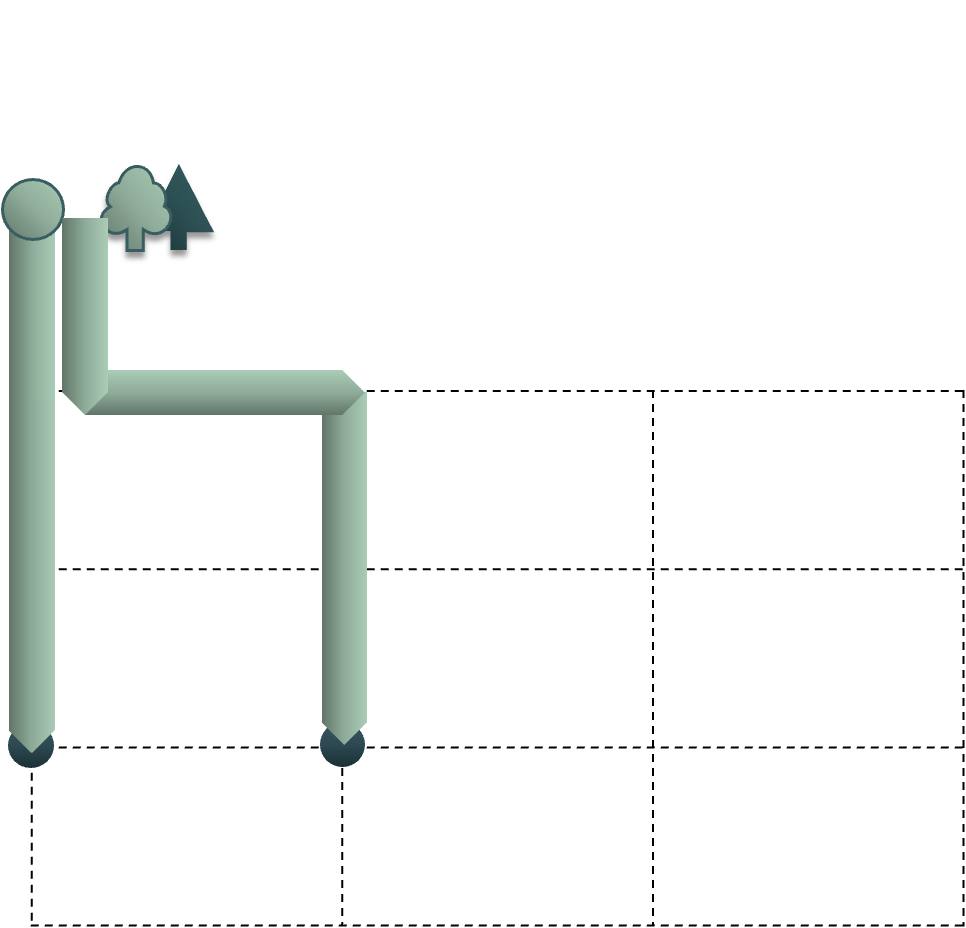

Solutions for extraction of short logsThe extraction of short logs describes the transportation of the logs from the trail to the forest road (buffer 23 to 33). It is a mechanized work, usually done by a forwarder or a tractor with a trailer.   | |

Solutions for fellingFor the subprocess of felling there are two options common. The complete tree can be either just felled or felled and then directly hauled. If the tree is only felled, the subprocess normally is performed motor-manually with a chainsaw. After felling, the full tree remains in the stand (buffer 10 to 11). | |

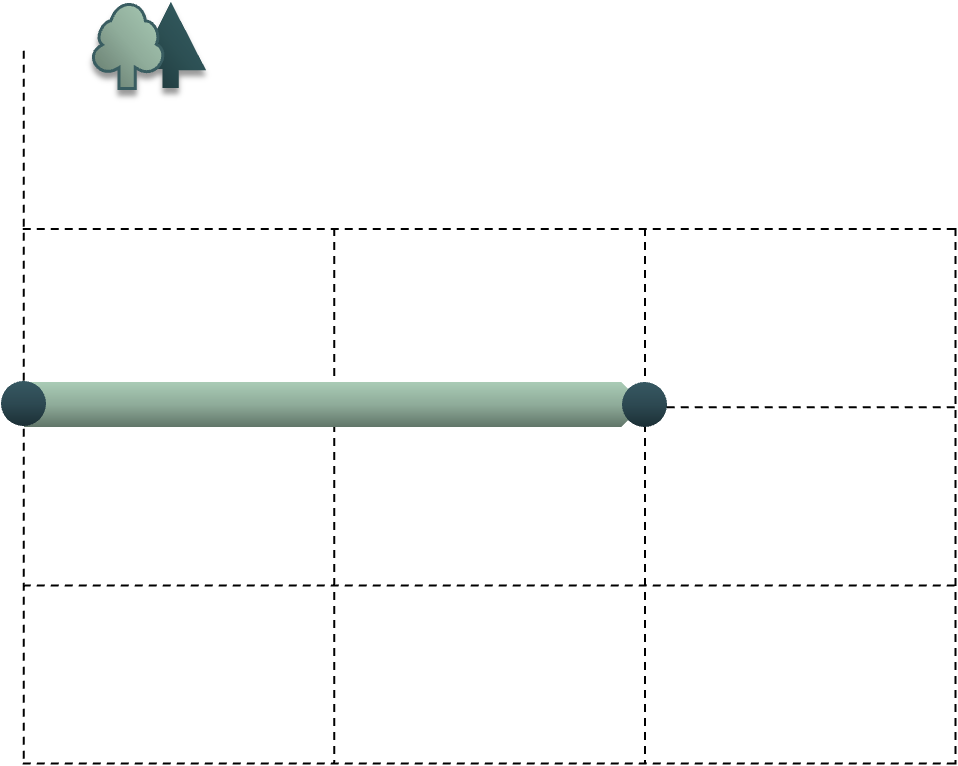

Solutions for felling and processing short logsThe felling and processing (= harvesting) of short logs can also be executed in one step. Without a buffer to interrupt the process, the complete tree is felled, branches are removed, and the tree is topped and cross-cut. This process can be done motor-manually with a chainsaw or mechanically with a harvester. If the harvesting takes place motor-manually, the logs remain in the stand near the stump (buffer 10 to 13). If the harvesting is done mechanically, the stem is lifted onto the trail during the process (buffer 10 to 23).   | |

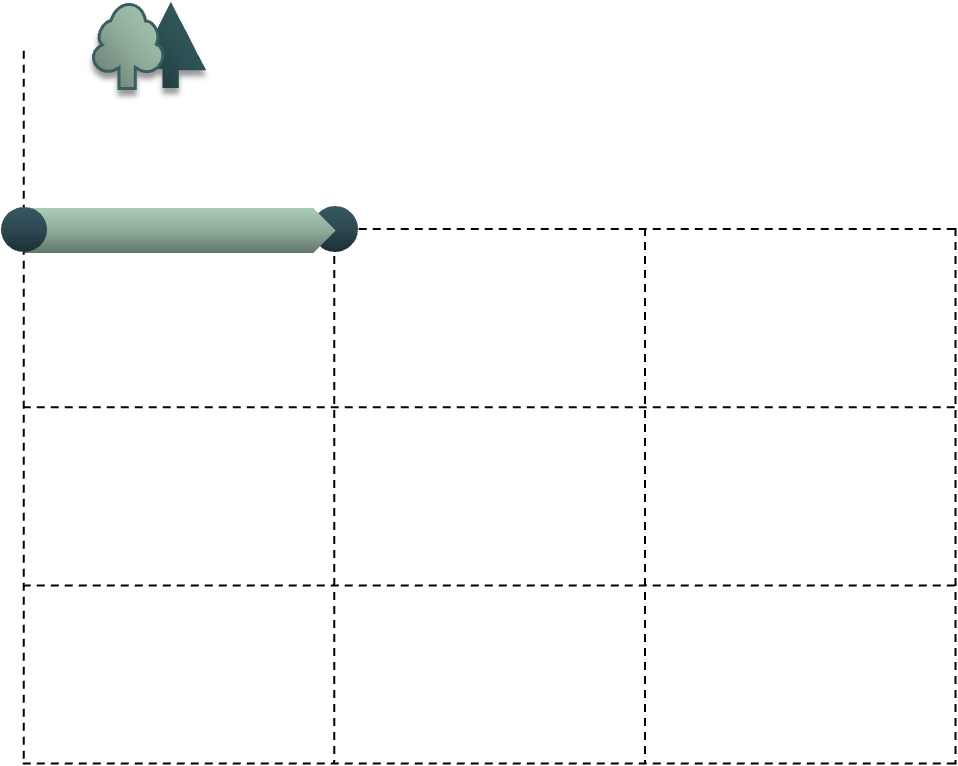

Solutions for pre-skidding and skidding of tree lengthsIn some cases, the sub-process of pre-skidding is not necessary and can be skipped. Then, the tree lengths are skidded directly from the stand (buffer 12) to the forest road (buffer 32). This may be the case, if there are no regulations for the machines to stay on a permanent trail or if the technology of the machines makes the sub-process of pre-skidding unnecessary. Machines which can skid tree lengths directly are for example the cable yarder or the cable skidder. While the cable yarder skids the tree lengths in a carrying movement to the forest road, the cable skidder needs to drag the tree lengths.   | |

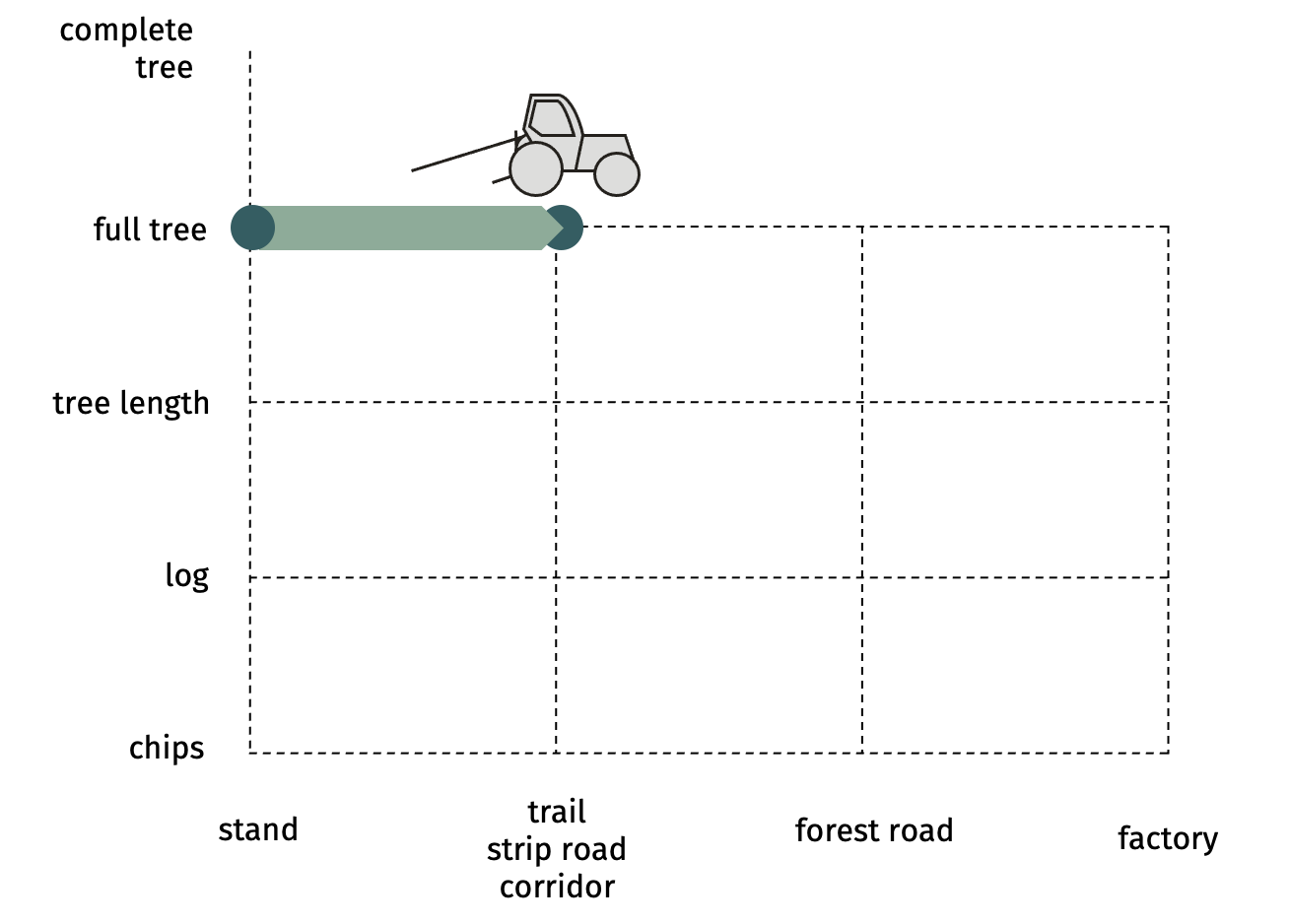

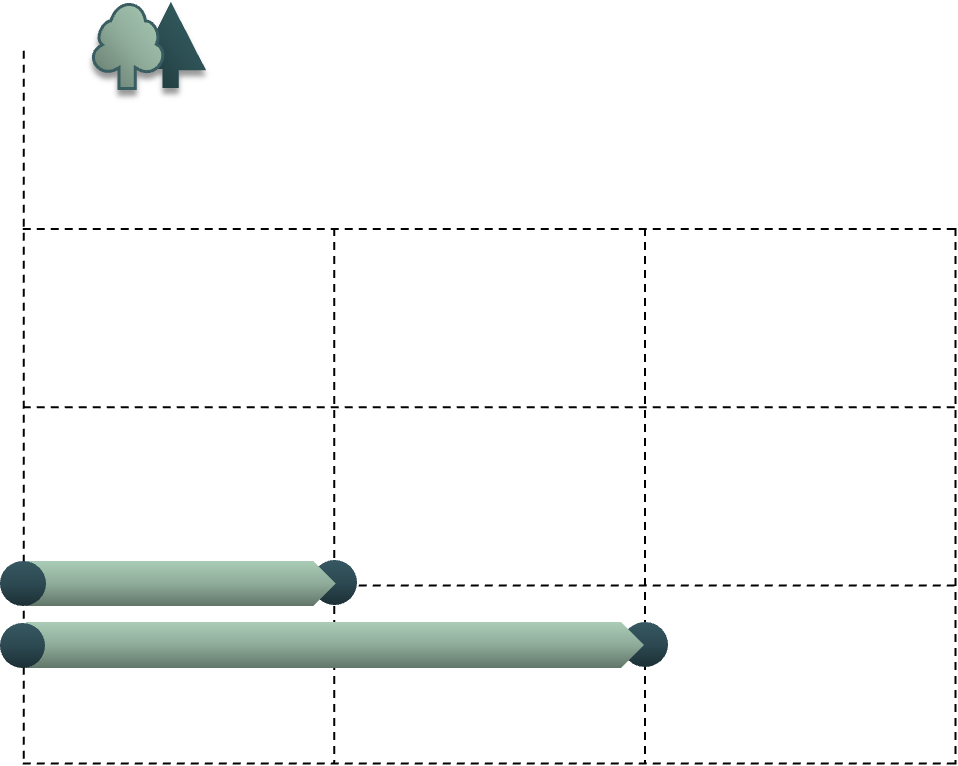

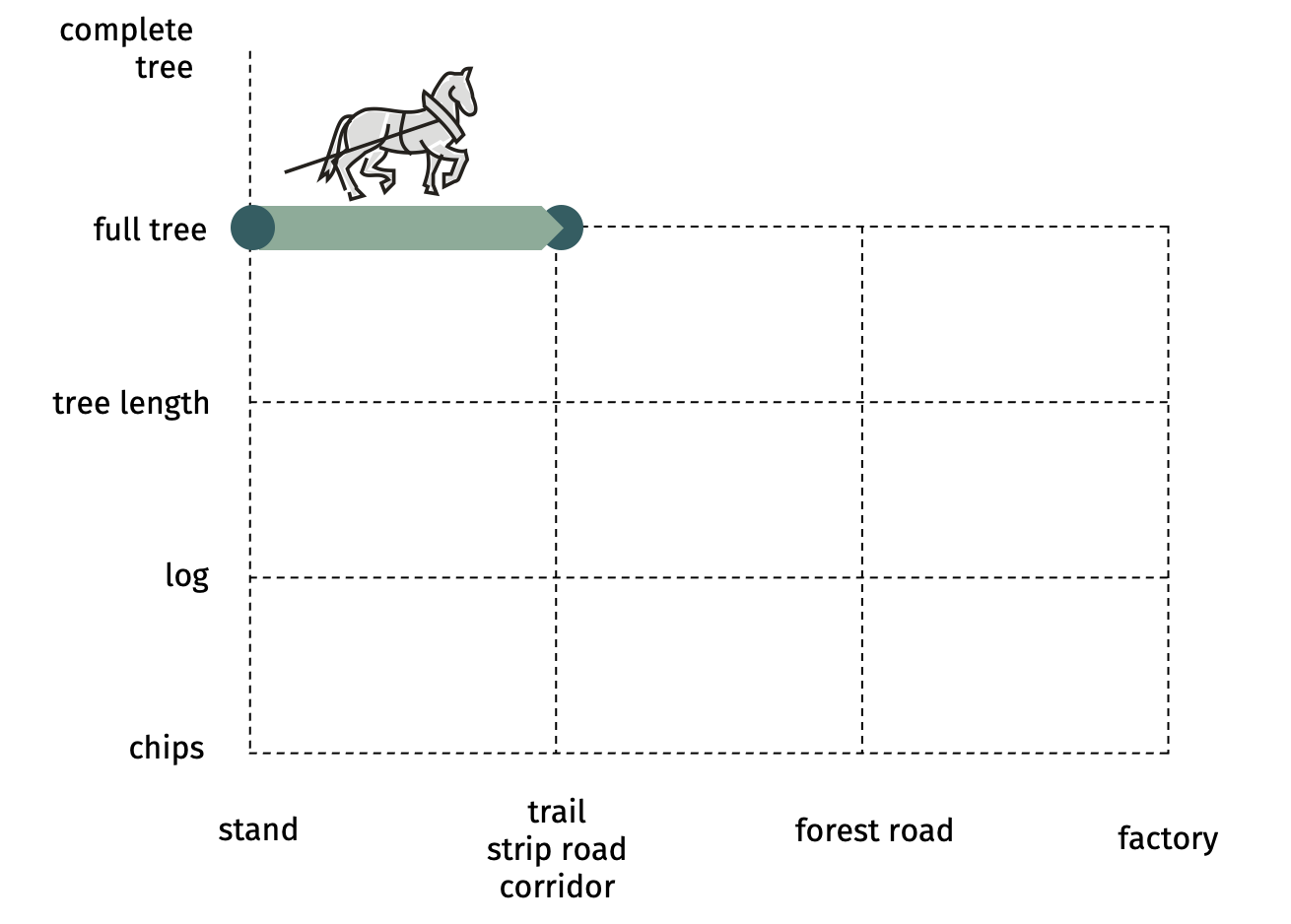

Solutions for pre-skidding full treesThe pre-skidding of full trees can be performed either by animals (horse) or as mechanized work by machines. As machines usually a tractor winch or a cable yarder are taken for the subprocess of pre-skidding. While the tractor winch and horse can only drag the full tree from the stand (buffer 11) to the trail (buffer 21), the cable yarder is able to carry the full tree to the trail.   | |

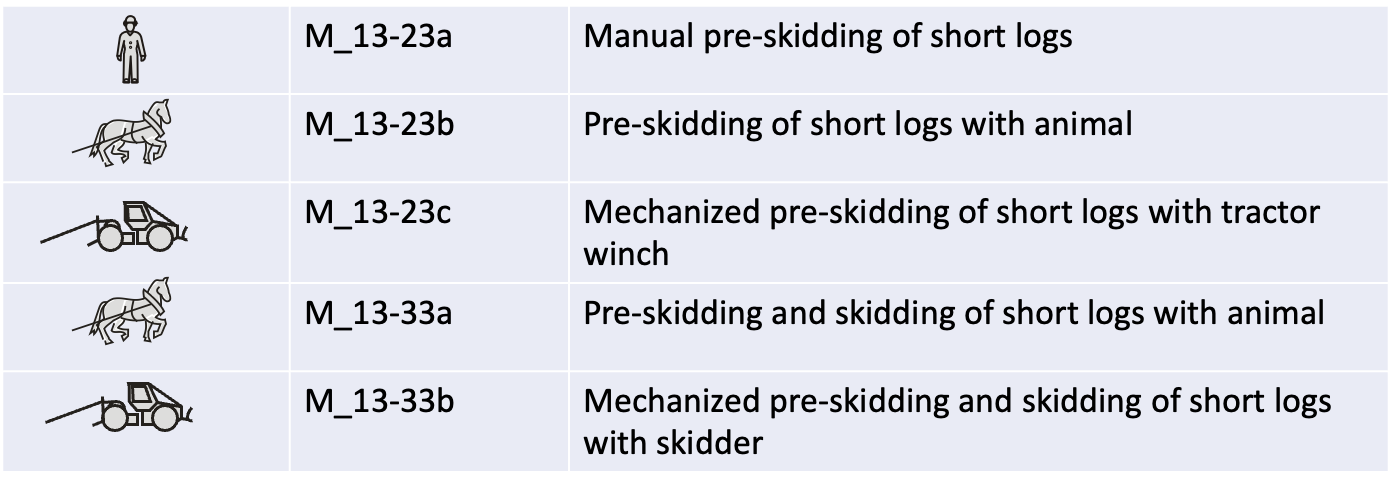

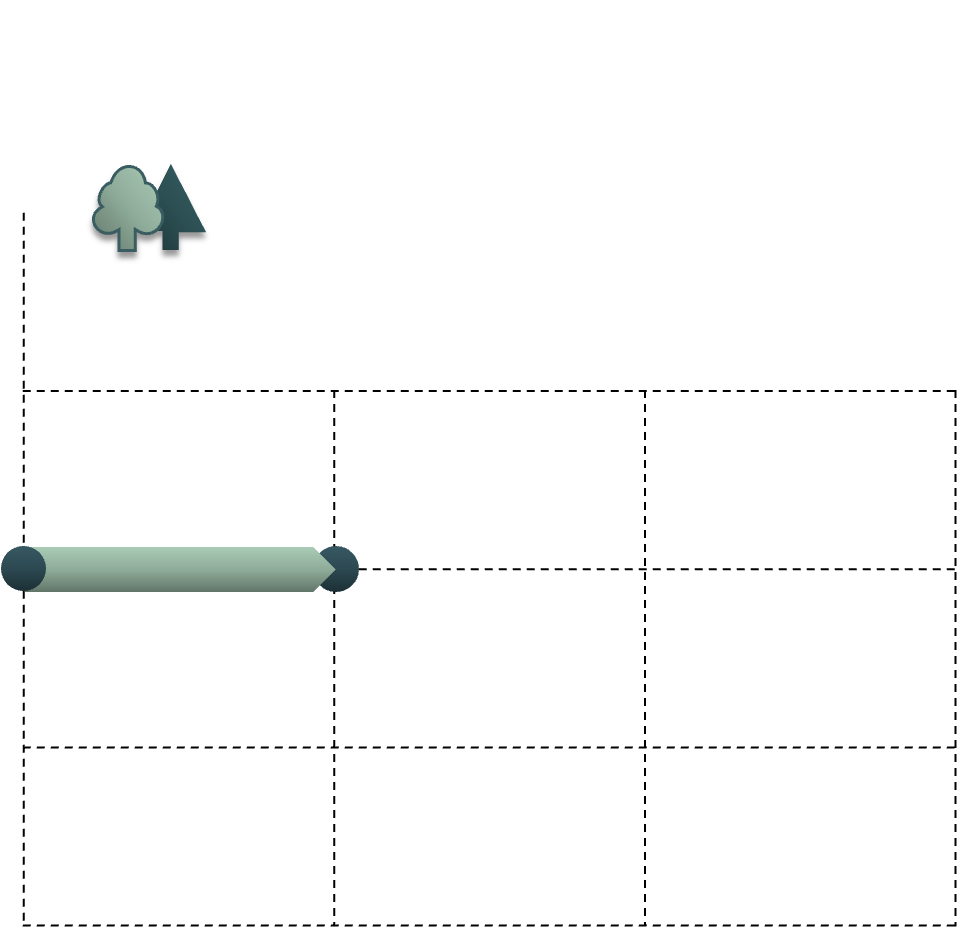

Solutions for pre-skidding short logsDuring the pre-skidding of short logs, the short logs are moved from the stand onto the trail (buffer 13 to 23). In special cases, the short logs can also be skidded directly from the stand to the forest road (buffer 13 to 33). Due to the “light” weight of the short logs, there are a lot of options possible for pre-skidding them. They can either be carried manual by a person or a mule or dragged by a horse. Another option is to pre-skid the logs mechanically with a cable skidder. The cable skidder and horse can also be used for the direct skidding of logs from the stand to the forest road.   | |

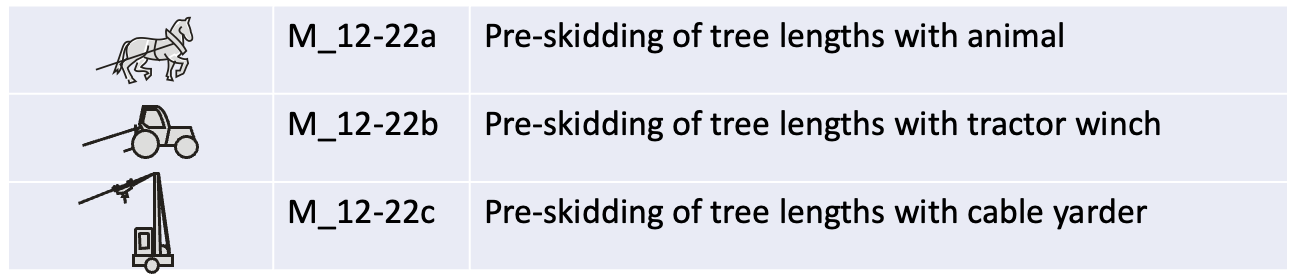

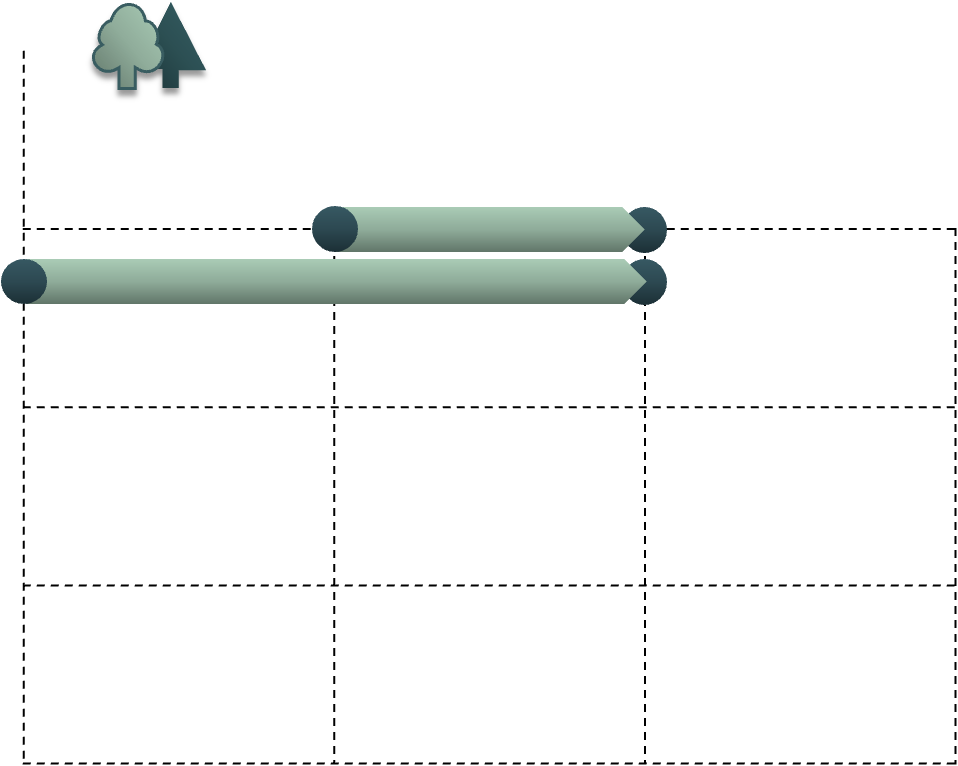

Solutions for pre-skidding tree lengthsThe pre-skidding of tree lengths (stem without branches and crown) can be performed either manual by animals (horse) or as mechanized work by machines. The most common options for the pre-skidding of tree lengths are the use of a horse, tractor winch or cable yarder. While the tractor winch and horse can only drag the tree length from the stand (buffer 12) to the trail (buffer 22), the cable yarder is able to carry the tree length to the trail (buffer 22).   | |

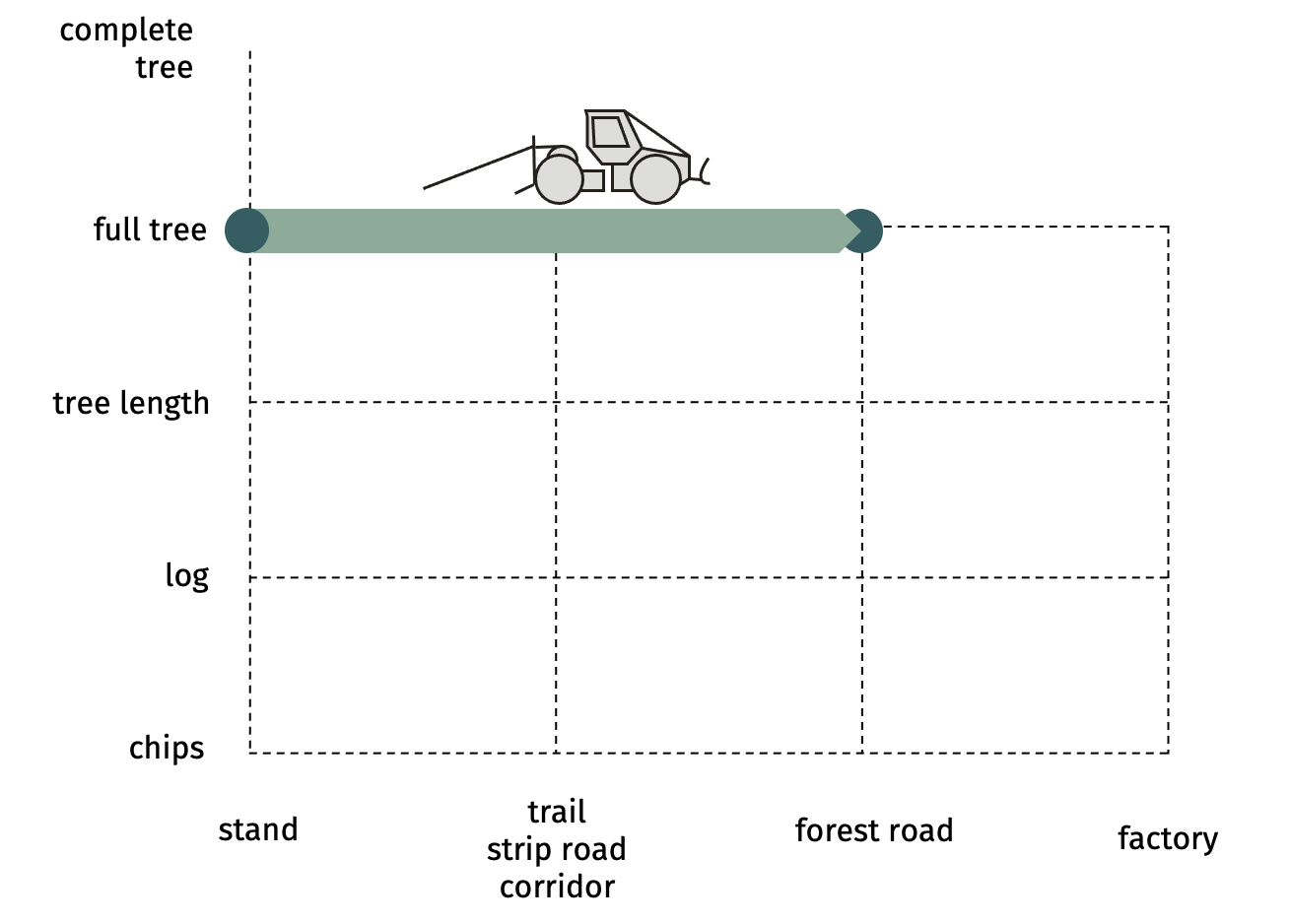

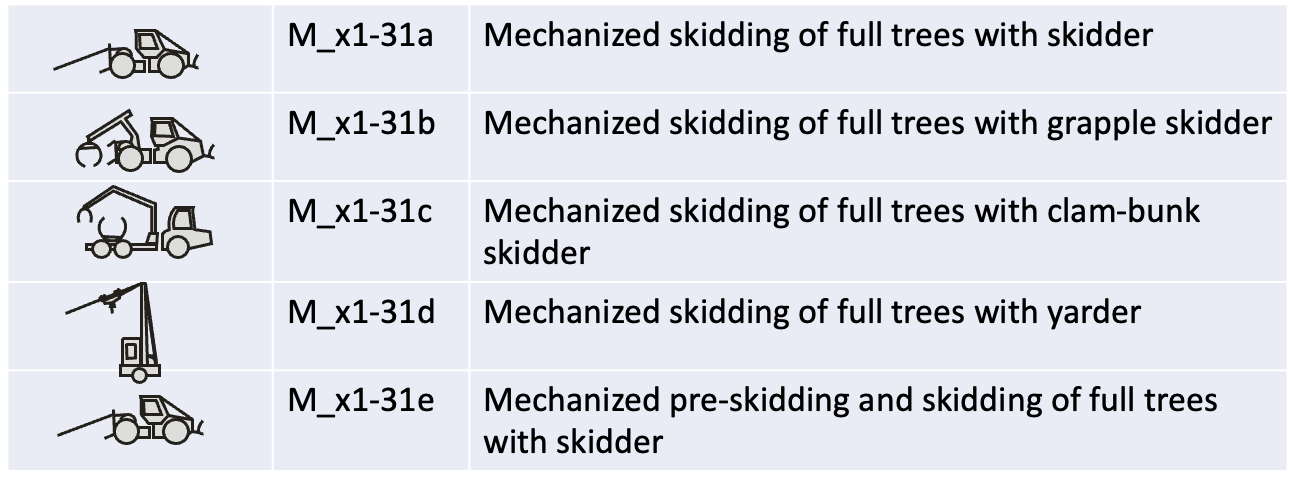

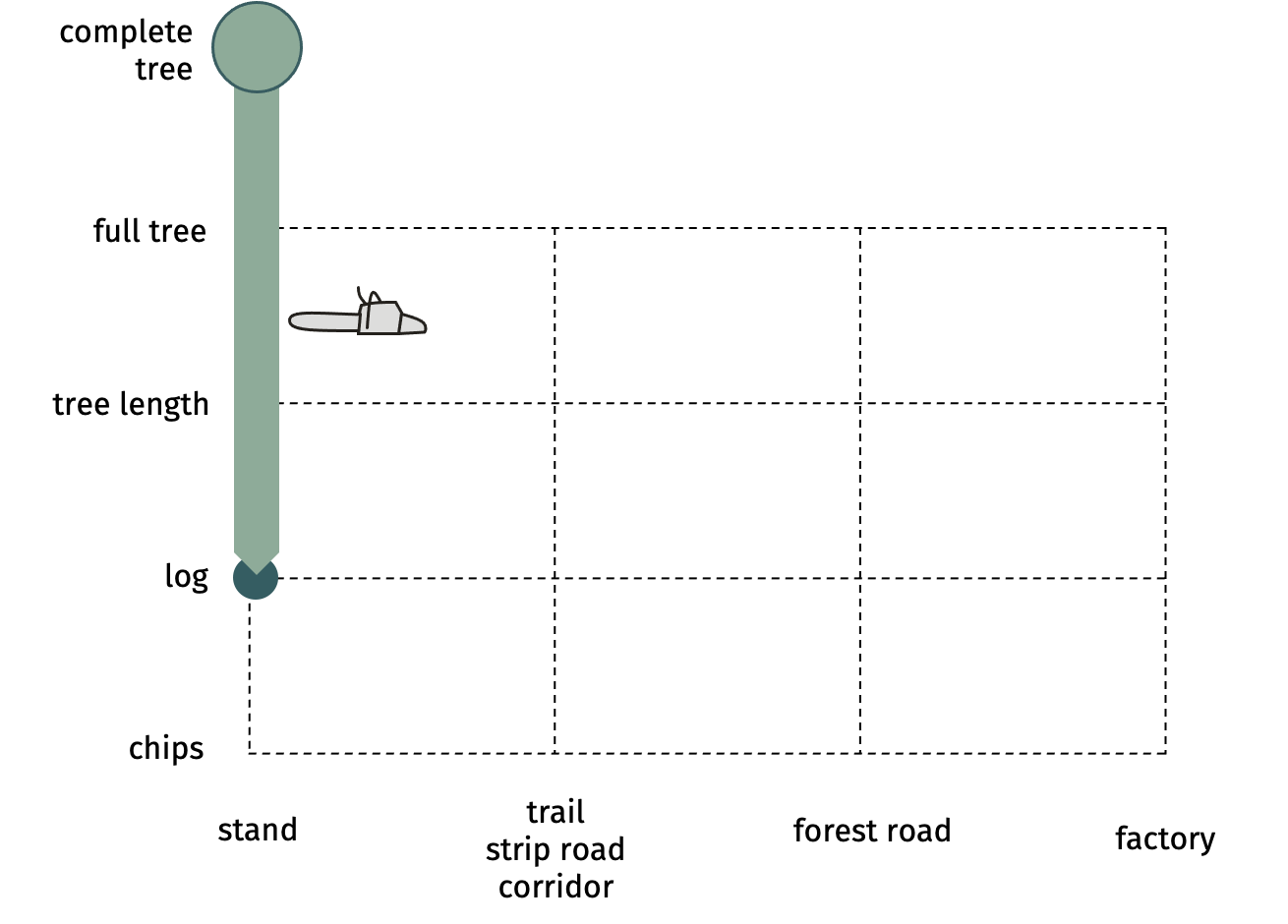

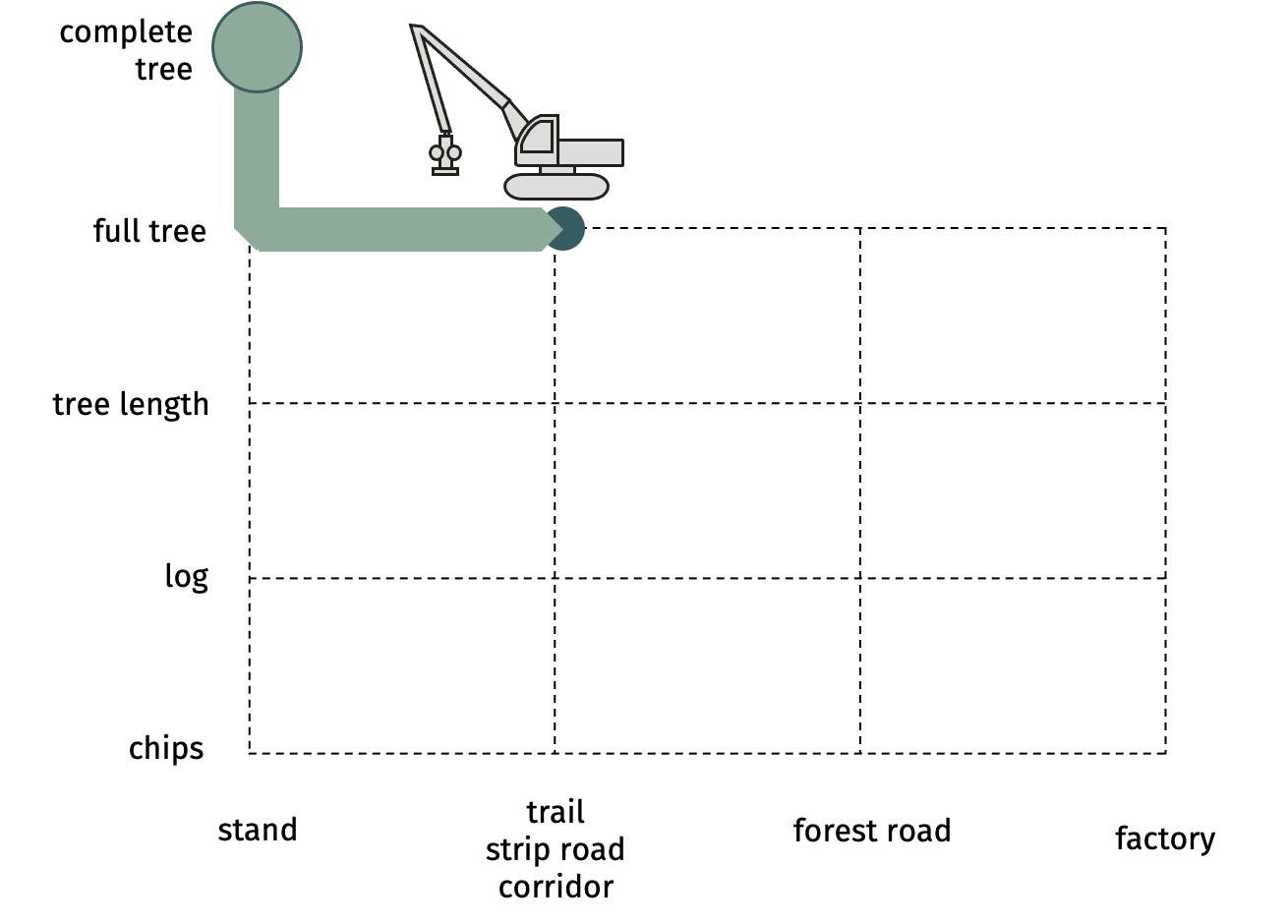

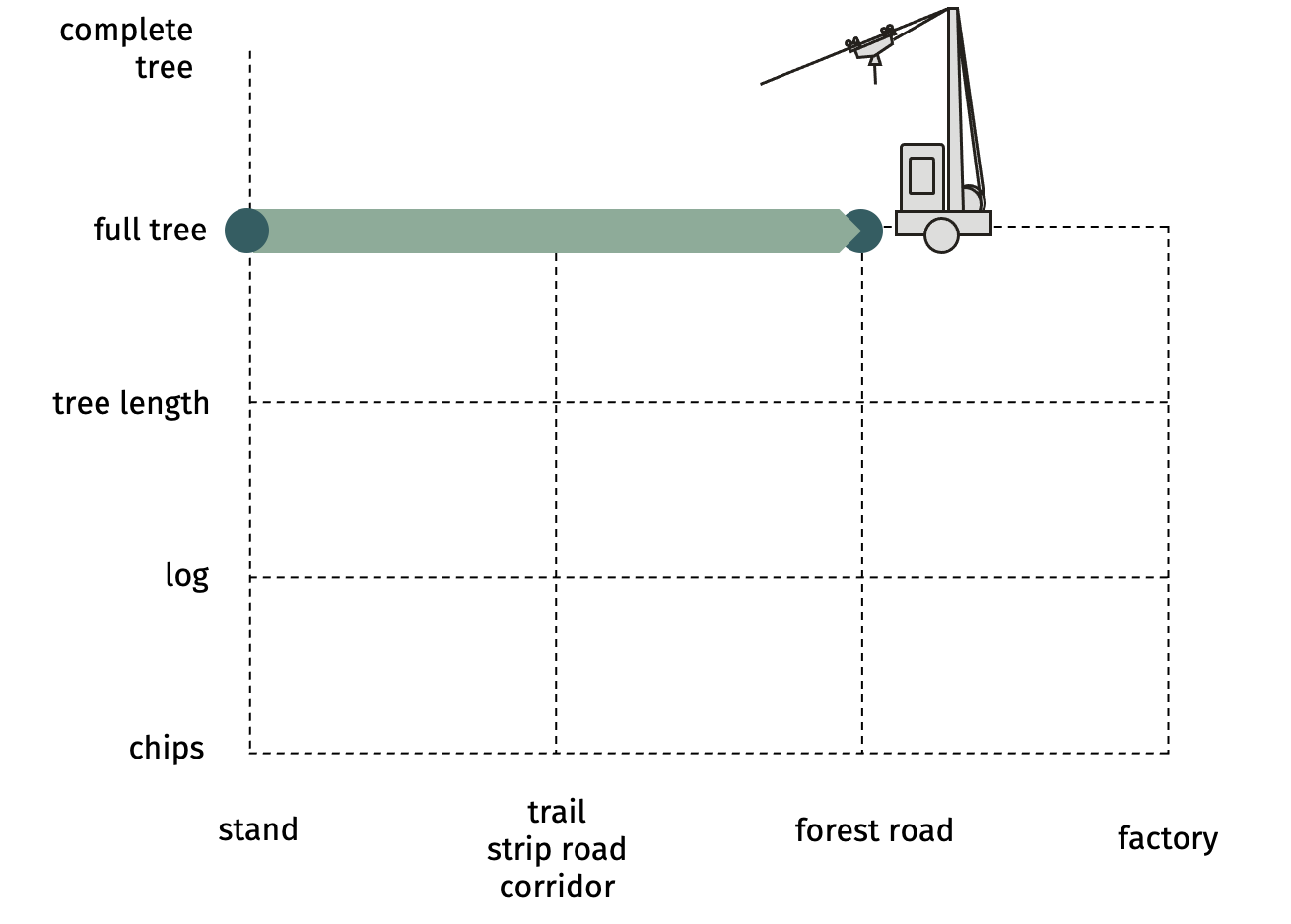

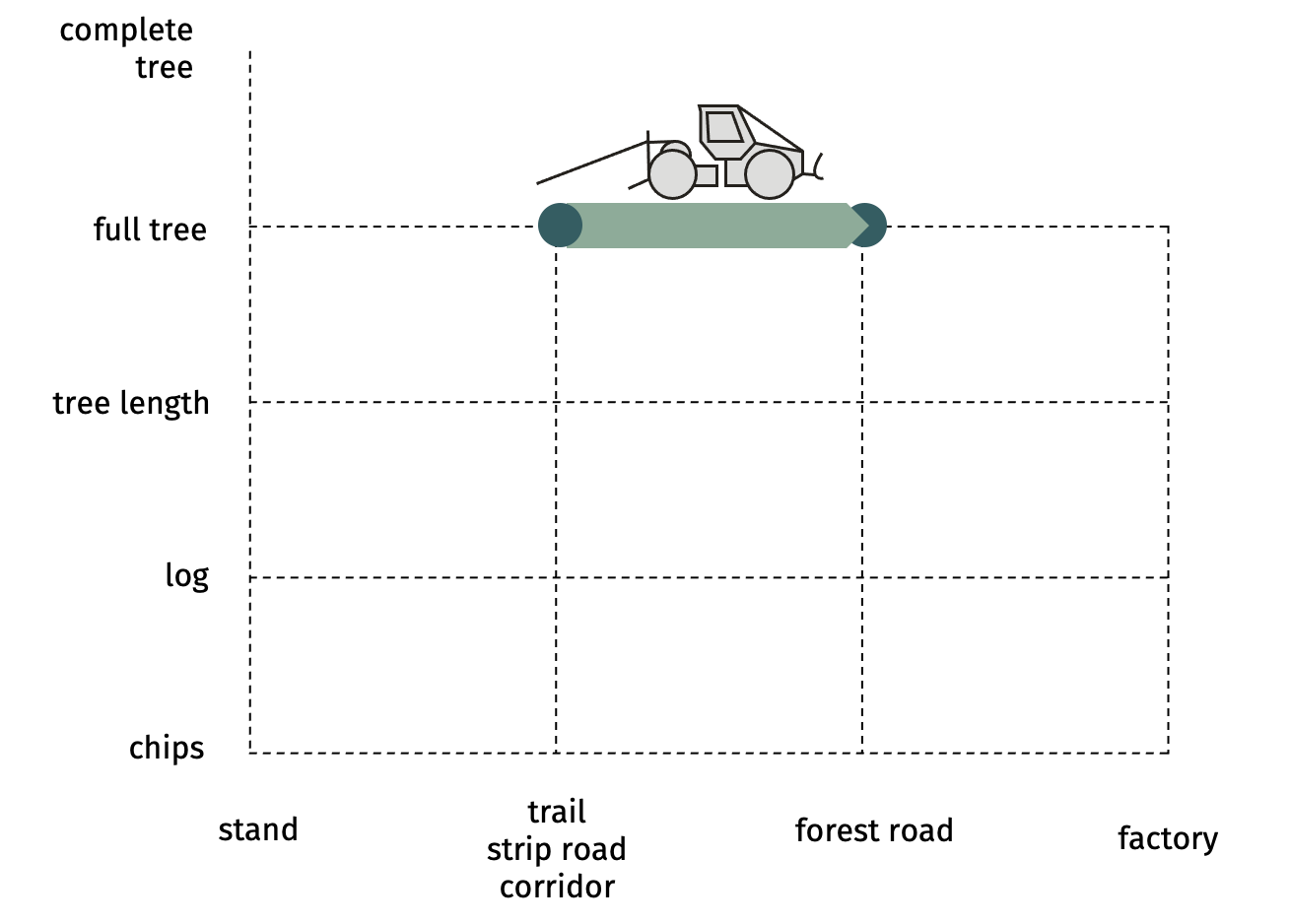

Solutions for skidding full treesThe skidding of full trees is commonly a mechanized sub-process. For the extraction of full trees several options are available. The clam-bunk skidder and grapple skidder are normally used only for the skidding from the trail (buffer 21) to the forest road (buffer 31). Whereas the cable yarder and the cable skidder can be taken not only for the skidding but also for the pre-skidding of full trees (buffer 11 to 31). The transportation of the full tree by cable skidder, grapple skidder or clam-bunk skidder is executed in a dragging movement, the transportation with the cable yarder in a carrying movement.  options described in this glossary are  | |

SP-10-11 motor-manual felling with chainsawCutting tree at the base with chainsaw and fell it in a predefined pattern. | |

SP-10-12 motor-manual harvesting of tree lengthFelling,

directly followed by delimbing and topping at the predefined diameter. Important:

felling direction in order to minimize the damage in stand at the pre-skidding

and extraction operations Functiogram:

Advantages

Example

Social suitability:

| |

SP-10-13 motor-manual harvesting of short logsFelling, delimbing and bucking to standard industrial logs or differentiated assortments directly in the stand  Advantages

Example:

Social suitability:

| |

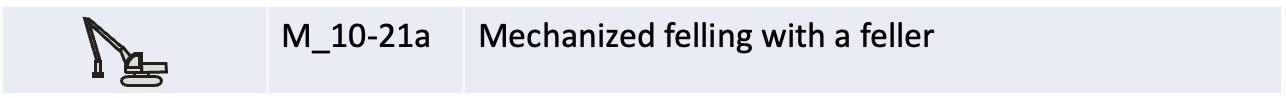

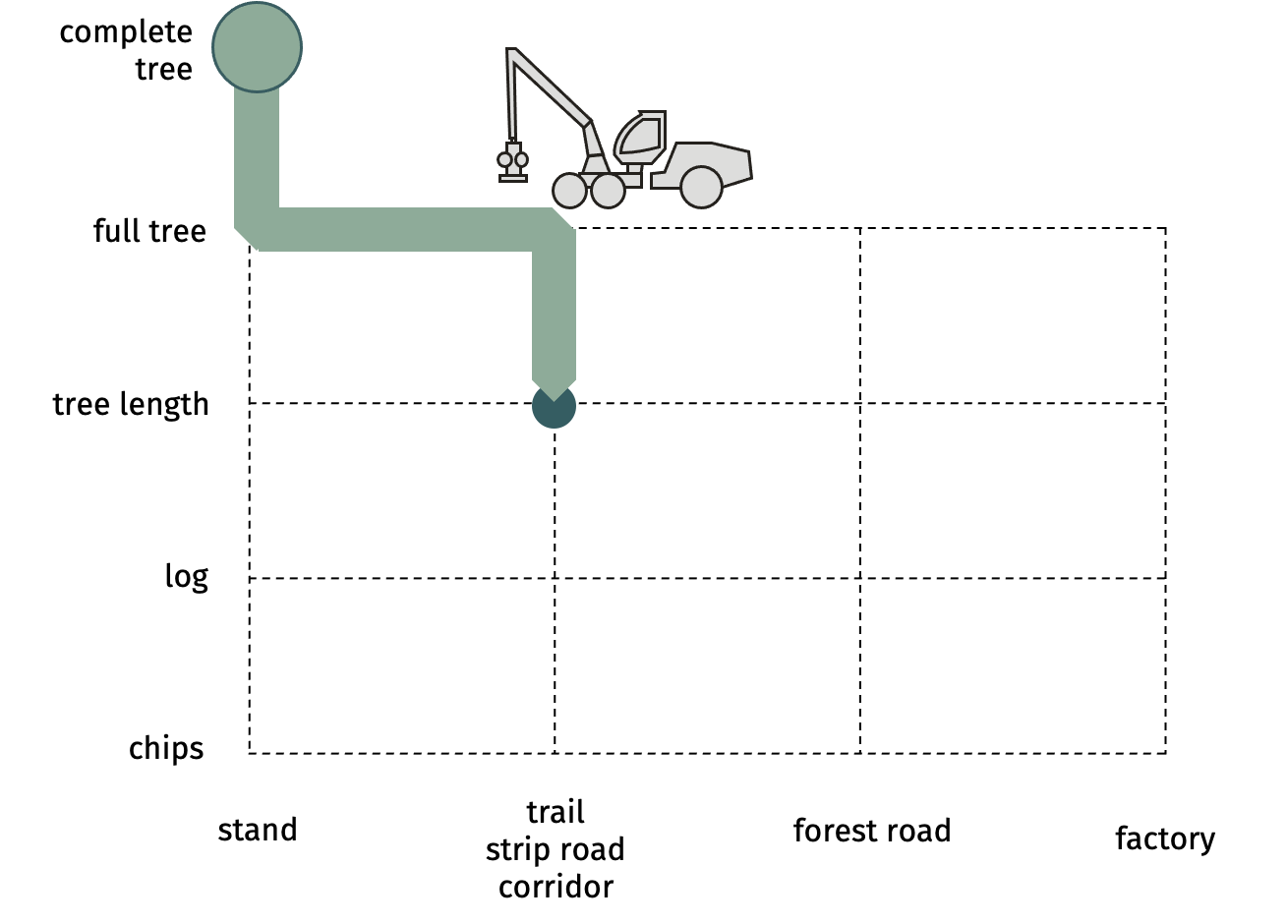

SP-10-21 mechanized felling with a fellerOnly felling as a preparation for processing on accessible ground or safer ground, or before grapple skidding. If this is the only function, the machine is called feller. But a harvester can do the job as well. Functiogram: Advantages

Example

Ecograms  Social suitability:

Literature: Schweier, J., Spinelli, R., Magagnotti, N., Becker, G. (2015) Mechanized coppice harvesting with new small-scale feller-bunchers: Results from harvesting trials with newly manufactured felling heads in Italy. Biomass and Bioenergy, 72, pp. 85-94. Spinelli, R., Cuchet, E., Roux, P. (2007) A new feller-buncher for harvesting energy wood: Results from a European test programme. Biomass and Bioenergy, 31 (4), pp. 205-210. Spinelli R., Hartsough B., Owende P., Ward S. (2002) Productivity and cost of mechanized whole-tree harvesting of fast-growing eucalypt stands. International Journal of Forest Engineering 13, p. 49-60. Cacot E. Chantier de St. Vitte sur Briance (87)- Abattage mecanisé des peuplements feuillus par une tête a guillotine. Paris: AFOCEL Flash Chantier CO68; 2004. Hiesl P, Benjamin J. 2013. A multi-stem feller-buncher cycle-time model for partial harvest of small-diameter wood stands. IFJE 2013;24(2):101-108. Visser R., Stampfer K. 2003 Tree lenght system evaluation of second thinning in a loblolly pine plantation. Southern Journal of Applied Forestry 27: 77-82 | |

SP-10-22 mechanized harvesting of tree lengthTrees are felled and delimbed with a harvester, but trees are not crosscut (generally with the intention of postponing bucking at a better facility in order to maximize value recovery)  Advantages

example:

Ecograms

Social suitability:

| |

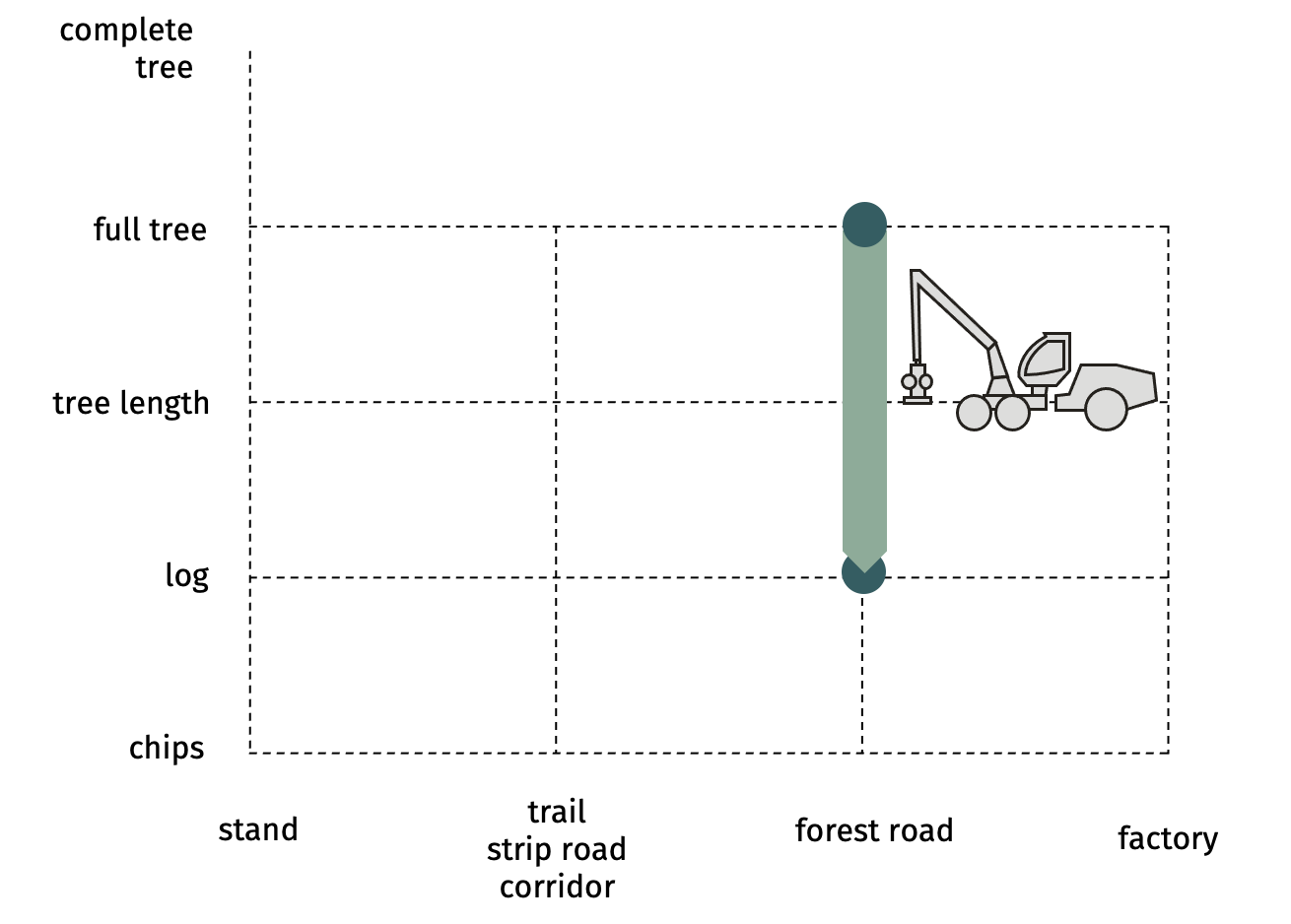

SP-10-23 mechanized harvesting of short logs

Advantages

Example:

Ecograms

Social suitability:

Literature: Brunberg T. 1997. Basic data for productivity norms for single-grip harvesters in thinning. The Forestry Research Institute of Sweden, Report 8/1997. 18 p. (In Swedish, English summary) Brunberg T. 1995. Basic data for productivity norms for heavy-duty single-grip harvesters in final felling. The Forestry Research Institute of Sweden, Report 7/1995. 22 p. (In Swedish, English summary) Emeyriat R., Picorit C., Reuling D., 1997. Perspectives of mechanised harvesting of maritime pine. Information Forèt, AFOCEL, Paris. Fiche 561, 6 p. (In French). Glöde D. 1999. Single- and double-grip harvesters: productive

measurements in final cutting of shelterwood. Journal of Forest Engineering 10

(2): 63-74. Hǻnell B., Nordfjell T., Eliasson L. 2000. Productivity and costs in shelterwood harvesting. Scandinavian Journal of Forest Research 15 (5): 561-569. Kärhä K., Rönkkö E., Gumse S. 2004. Productivity and cutting costs of thinning harvesters. International Journal of Forest Engineering 15 (2): 43-56. Nakagawa M., Hamatsu J., Saitou T., Ishida H. 2007. Effects of tree size on productivity and time required for work elements in selective thinning by a harvester. International Journal of Forest Engineering 18 (2): 24-28. Nurminen T., Korpunen H., Uusitalo J. 2006. Time consumption analysis of mechanized cut-to-length harvesting systems. Silva Fennica 40 (2): 335-363. Purfürst F. 2007. Human influences on harvest operations. Proceedings of Austro 2007/FORMEC’07 “Meeting the Needs of Tomorrows’ Forests – New Development in Forest Engineering” October 7-11 2007, Vienna and Heiligenkreuz, Austria. 9 p. Sirén M., Aaltio. 2003. Productivity and costs of thinning harvesters and harvester-forwarders. International Journal of Forest Engineering 14 (1): 39-48. Spinelli R., Magagnotti N., Nati C. 2009 Options for the mechanised processing of hardwood trees in Mediterranean forests. International Journal of Forest Engineering 20 (1): 39-44 Spinelli R., Owende P., Ward S. 2002. Productivity and cost of CTL harvesting of Eucalyptus globulus stands using excavator-based harvesters. Forest Products Journal 52 (1): 67-77. Spinelli, R., Hartsough, B., Magagnotti, N. (2010) Productivity standards for harvesters and processors in Italy. Forest Products Journal 60 (3), pp. 226-235. | |

SP-10-33 mechanized harvesting and forwarding with harwarder

Advantages

Example:

Ecograms

Social suitability:

| |

SP-10-34 mechanized felling and chipping with biomass harvesterOne single machine cuts and chips whole trees in one single passage. This system is applied to SRC plantations and the most popular units are based on powerful (≥300 Kw) foragers

Example:

Ecograms

Social suitability:

Literature: Spinelli et al. 2009, 2011 and many others | |

SP-11-12 delimbingsee SP-x1-x2 delimbing | |

SP-11-21 pre-skidding of full trees with animalsAfter felling, trees are pre-skidded to a strip road using animals, and most commonly draught horses. Different breeds are available in different regions, but the most popular are heavy breeds like French Percherons, Belgian Ardennes, or Italian TPR.  Advantages

Main use

Example:

Ecogram

Social suitability:

Literature: Baigent C. 1984. Clydesdale logging. LIRO Technical Release 6, 4 pp. De Paul M., Bailly M. 2005. À propos de la pression exercée par les pneus, chenilles et sabots. Forêt Wallonne 78: 21-33. De Paul M., Lombaerde F., Jourez B. 2006. Approche économique du cheval en forêt. Forêt Wallonne 81: 15-25. Harstela P., Tervo L. 1981 Bunching of timber by winches and horse. Folia Forestalia 466, 20 pp. In Finnish. Hedman L. 1987. Tools and equipment for horse logging. Small Scale For 1: 10-17. Hedman L. 1988. Skidding with horse to strip road. Small Scale For 2: 15-19. Leinert S. 1979 Einsatz veraltungseingener pferde beim vorrücken von schwachholz. Forsttechnische Informationen 1: 4-6. Magagnotti N., Spinelli R. 2011 Integrating animal and mechanical operations in protected areas. Croatian Journal of Forest Engineering 32: 489-499. Magagnotti N., Spinelli R. 2011 Financial and energy cost of low-impact wood extraction in environmentally sensitive areas. Ecological Engineering 37: 601-606. McNamara D, Kaufman J. 1985. Can horses compete with tractors? State of California, For. Dept., Sacramento, CA. For. Note 95, 7 p. Pynn L. 1991. Logging with horse power. Can Geogr 3: 31-35. Shresta S, Rummer R, Dubois M. 2005 Utilization and cost of log production from animal logging operations. Int J For Eng 16: 167-180 Shresta S, Lanford B., Rummer R, Dubois M. 2008 Soil disturbances from horse/mule logging operations coupled with machines in the Southern United States. Int J For Eng 19: 17-23 Schroll E. (Editor) 2008 Holzrücken mit pferden – Handbuch für die waldarbeit mit pferden. Starke Pferde Verlag, Lemgo, Germany. In German. Snoeck B. 2000. Ces chevaux « qui traînent au bois ». Forêt Wallonne 46: 12-23. Thérer Y. 2006. Situation du débardage au cheval en Région Wallonne, enquête auprès de débardeurs. Forêt Wallonne 82: 18-27. Toms C., Dubois M., Bliss J., Wilhoit J., Rummer B. 2001 A survey of animal-powered logging in Alabama. South J Appl For 25: 17-24 | |

SP-11-21 pre-skidding of full trees with tractor winchPre-skidding of full trees from the felling site to the strip road with a winch that is mounted or attached to a tractor. Advantages

Limitations, threshold

Main use

Winching performance depends on many factors, but mostly on extraction distance and tree size. However, extraction distance and tree size have the strongest effect on cycle time, productivity and pre-skidding cost.

Since winch pre-skidding is extremely sensitive to distance, it should be used on very short distances, only. If tree volume is large enough, then one can obtain acceptable results also on medium distances, up to 50 m. Ecograms

Social suitability

Literature: Dekking J. 1984 Goliat, a small tractor with tracks. IEA/FE/CPC7 Report, 17 pp. Dunnigan J. 1993 Braided KevlarTM Cable: Trials in Skidding Wood With an ATV. Field Note FN-022. FERIC. Pointe Claire, Quebec, Canada. Ewing R. 2001 Use of a portable capstan winch and associated hand tools in manual thinning. FERIC Advantage Reports, 28: 4 p. Ewing R. 2003 Harvesting riparian zones using cable skidders equipped with Spectra synthetic-fibre mainlines. FERIC Advantage Reports, 20: 6 p. Harstela P., Tervo L. 1981 Bunching of timber by winches and horse. Folia Forestalia 466, 20 pp. In Finnish. Hill S. 1991 D4H tractor and towed arch in radiate clearfell. LIRA Report 16, 8. 4 p. Horvat D, Spinelli R, Šušnjar M. 2005 Resistance coefficients on ground-based winching of timber. Croatian Journal of Forest Engineering 30: 3-11 Leek N. 1976 Bunching with Radiotir 740 in thinnings. Nederlands Bosbouw Tijdschrift 48: 151-157. Magagnotti N., Spinelli R. 2012 Replacing steel cable with synthetic rope to reduce operator workload during log winching operations. Small Scale Forestry 11: 223-236. Picchio R., Magagnotti N., Sirna A., Spinelli R. 2012 Improved winching technique to reduce logging damage. Ecological Engineering 47: 83-86. Prebble R. 1986. Evaluation of the Logquip smart arch. LIRA Report 11, 5. 4 p. Pritchard N. 1986. The Logquip smart arch for small crawler tractors. LIRA Report 8. 4 p. Ryans M. 1980 Evaluation of the Agri-Winch: a farm tractor-mounted logging winch. FERIC Tech. Rep. TR41. 18 p. Spinelli R, Magagnotti N 2012 Wood extraction with farm tractor and sulky: estimating productivity, cost and energy consumption. Small-scale Forestry 11: 73-85. TDB 2002 ATC timber sulky. Information Note ODW 9.04, Ae Village, UK. 5 p. Turner T., Huyler N. Bousquet D. 1988 Farm Tractor Skidding Costs in Relation to Profitability of a Fuelwood Harvesting System. Nort.h J Appli For 5: 207-210 Vaughan L. 1988 Thinning with small crawler tractors. LIRA Report 13, 26. 6 p. Zeĉić Z., Krpan A., Vukuŝić S. 2005 Productivity of Holder 870 tractor with double drum winch Igland 4002 in thinning beech stands. Croatian J For Eng 26: 49-56. | |

SP-11-31 pre-skidding and skidding of full trees with a tractorFelled trees are pulled to a trail by means of a tractor winch and collected; when some full trees are collected, the tractor extracts them to the forest road and unloads alongside the road. Functiogram

Advantages

Limitations. thresholds

Main use

Example:

Ecograms

Social suitability:

| |

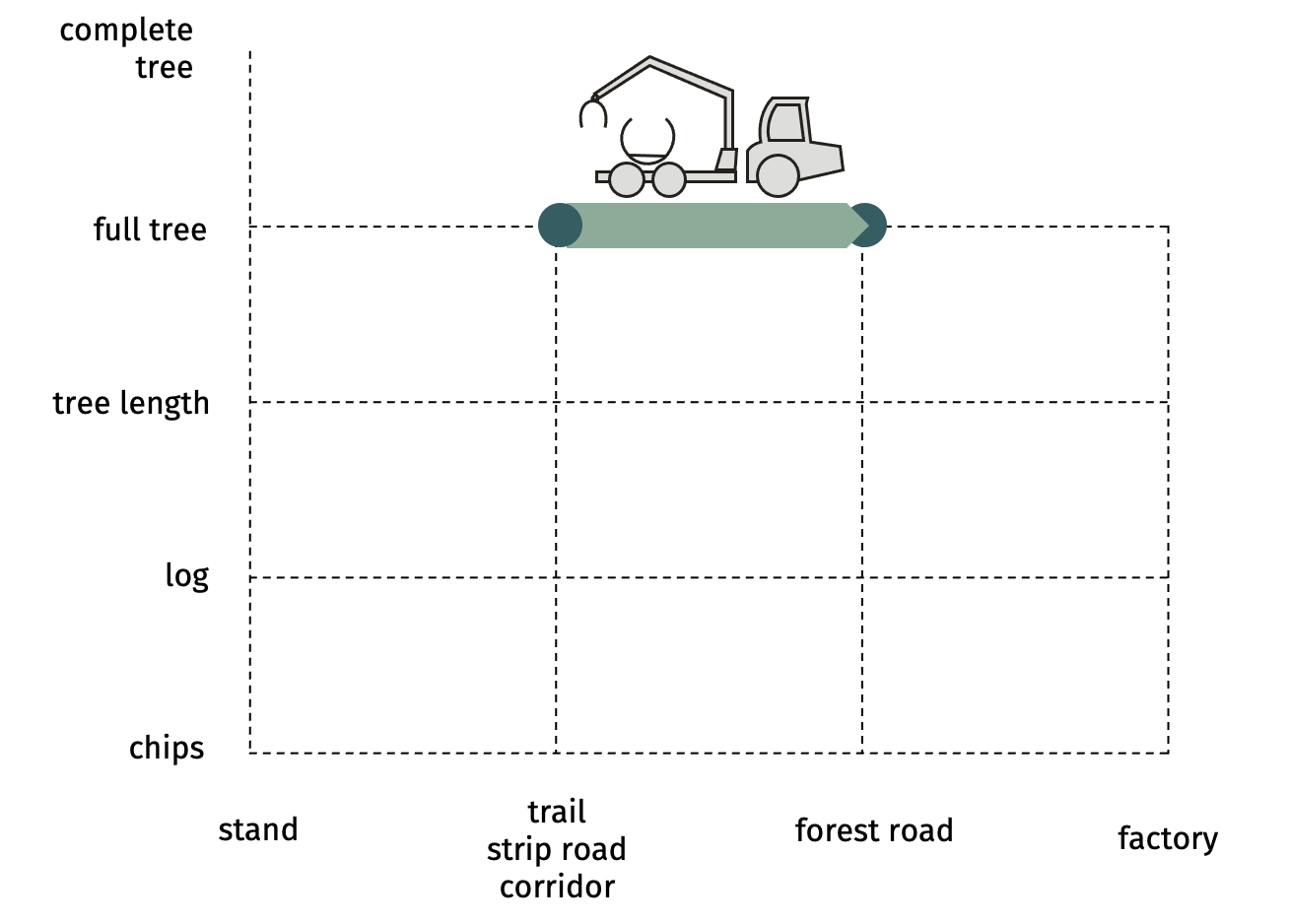

SP-11-31 pre-skidding and skidding of full trees with yarderFull trees are moved to a landing (roadside landing, landing pad etc.) suspended under a carriage that runs on a cable (skyline). In a limited corridor tress can be pre-skid to the skyline as well before they are extracted. Different types and configurations are available (live, standing, running skyline, self-propelled carriage, swing yarders - carriages with cable or grapple).  Advantages

Example:

Ecogram

Social suitability

Literature: Spinelli R., Marchi E., Visser R., Harrill H., Gallo R., Cambi M., Neri F., Lombardini C., Magagnotti N. (2017) The effect of carraige type on yarding productivity and cost. International Journal of Forest Engineering - Accepted paper. Spinelli R., Magagnotti N., Visser R. (2015) Productivity models for cable yarding in Alpine forests. European Journal of Forest Engineering 1, p. 9-14. Spinelli, R., Magagnotti, N. (2011) The effects of introducing modern technology on the financial, labour and energy performance of forest operations in the Italian Alps. Forest Policy and Economics, 13 (7), pp. 520-524. Huyler, N., LeDoux, C., 1997. Cycle-time equation for the Koller K300 cable yarder operating on steep slopes in the Northeast. Res. Pap. NE-705, USDA Forest Service, Northeastern Forest Experiment Station 4 p. Senturk, N., Ozturk, T., Demir, M., 2007. Productivity and costs in the course of timber transportation with the Koller K300 cable system in Turkey. Building and Environment 42: 2107-2113. Stampfer, K., Visser, R., Kanzian, C., 2006. Cable corridor installation times for European yarders. International Journal of Forest Engineering 17: 71-77. Zimbalatti, G., Proto, A., 2009. Cable logging opportunities for firewood in Calabrian forests. Biosystems Engineering 102: 63-68.

| |

SP-12-13 cross-cuttingsee SP-x2-x3 cross-cutting | |

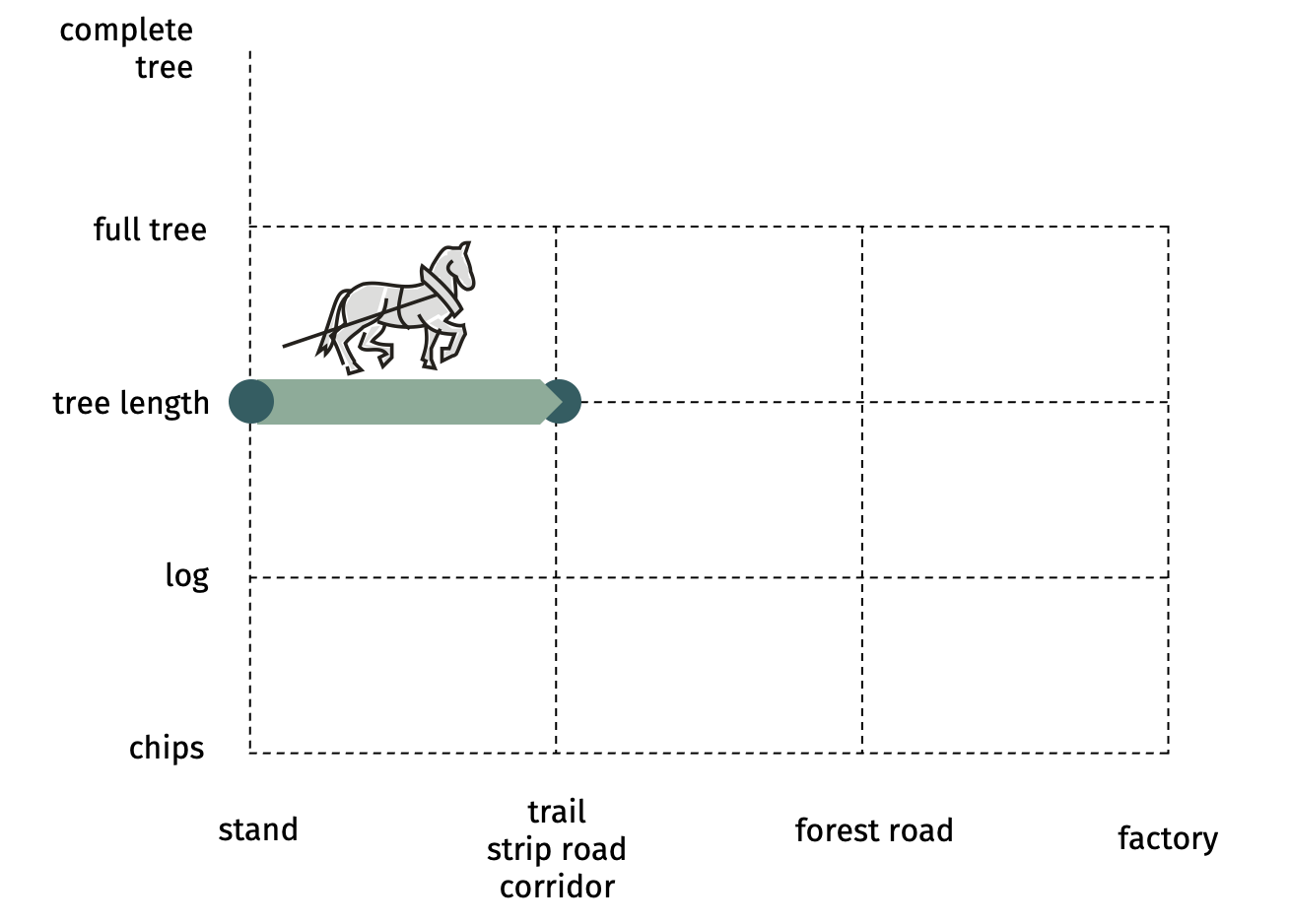

SP-12-22 pre-skidding of tree lengths with a horseAfter felling, delimbing, and topping, tree lengths are pre-skidded to a strip road using animals, and most commonly draught horses. Different breeds are available in different regions, but the most popular are heavy breeds like French Percherons, Belgian Ardennes, or Italian TPR.

Advantages

Limitations, thresholds:

Main use

Example:

Social suitability:

| |

SP-12-22 pre-skidding of tree lengths with tractor winchFelled and delimbed tree lengths are pulled to the trail with a cable winch that is mounted or attached to a tractor.  Advantages

Limitations, threshold

Main use

Example:

Ecograms  Social suitability

| |

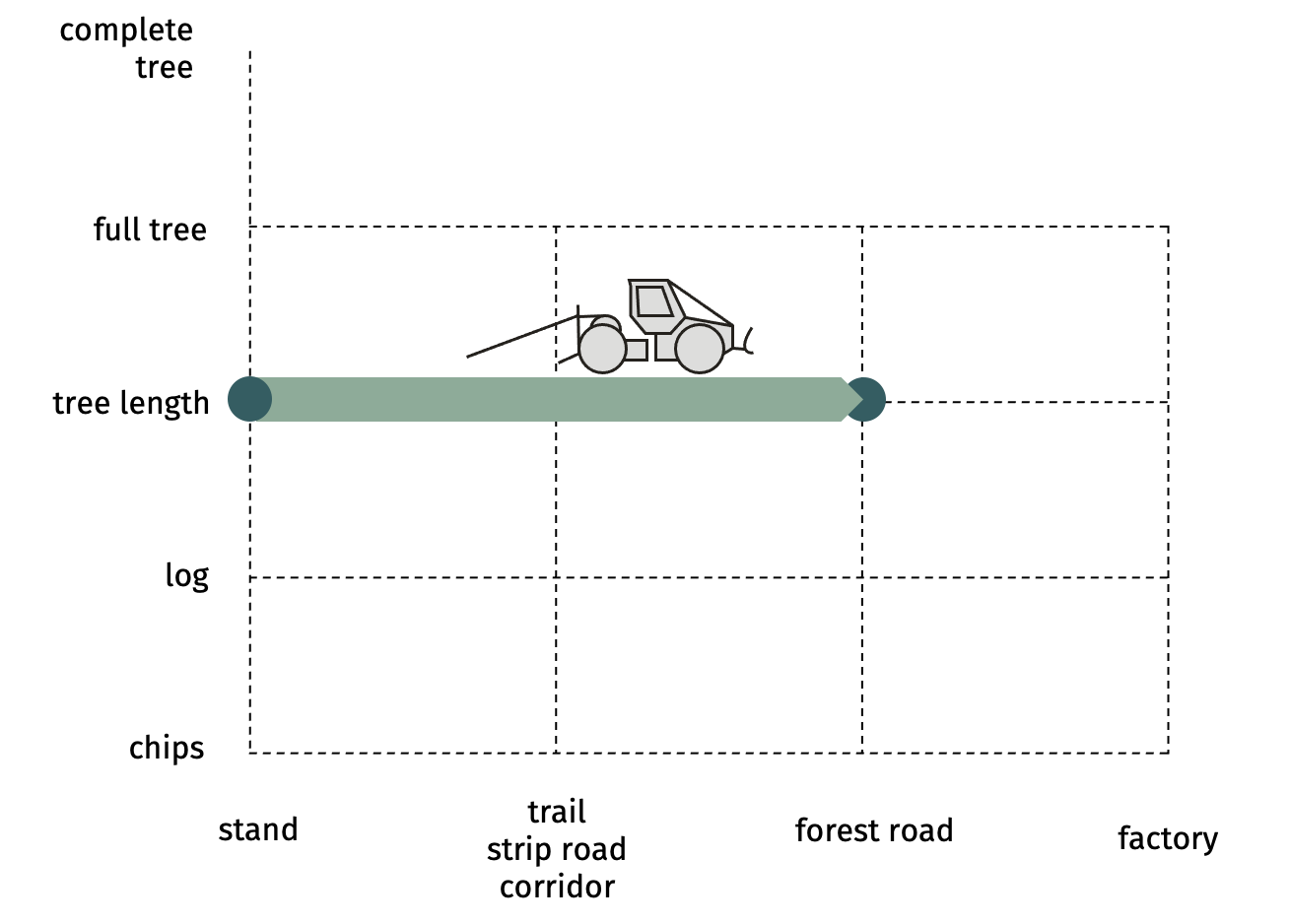

SP-12-32 mechanized pre-skidding and skidding of tree lengths with skidderTree-lengths are dragged to the landing by a tractor equipped with a single or double-drum winch. The winch is used for assembling the load and for pre-skidding the tree-lengths to the skid trail if necessary.  Advantages

Example:

Ecograms

Social suitability:

Literature: Logging arch study for farm tractors - Merlo study etc. | |

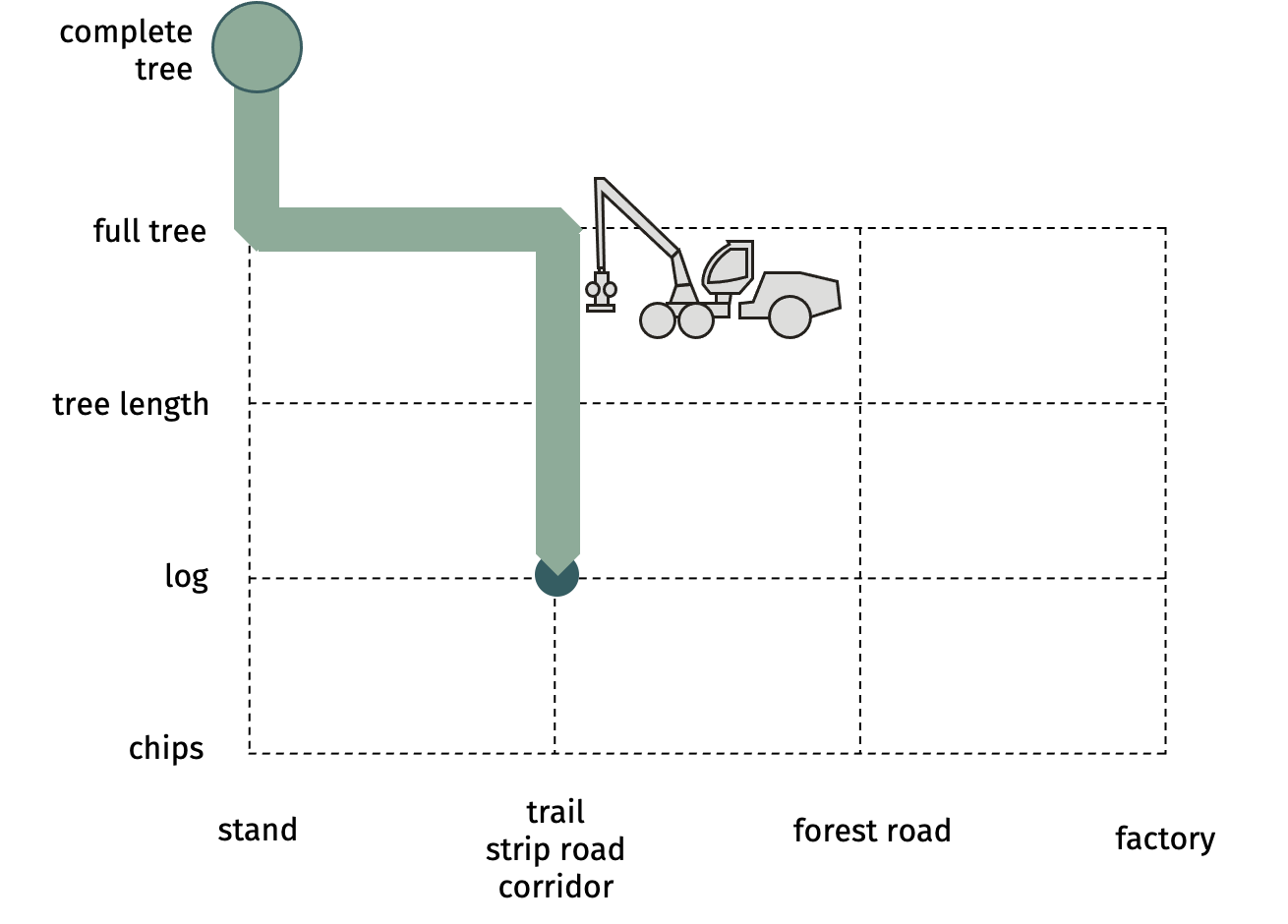

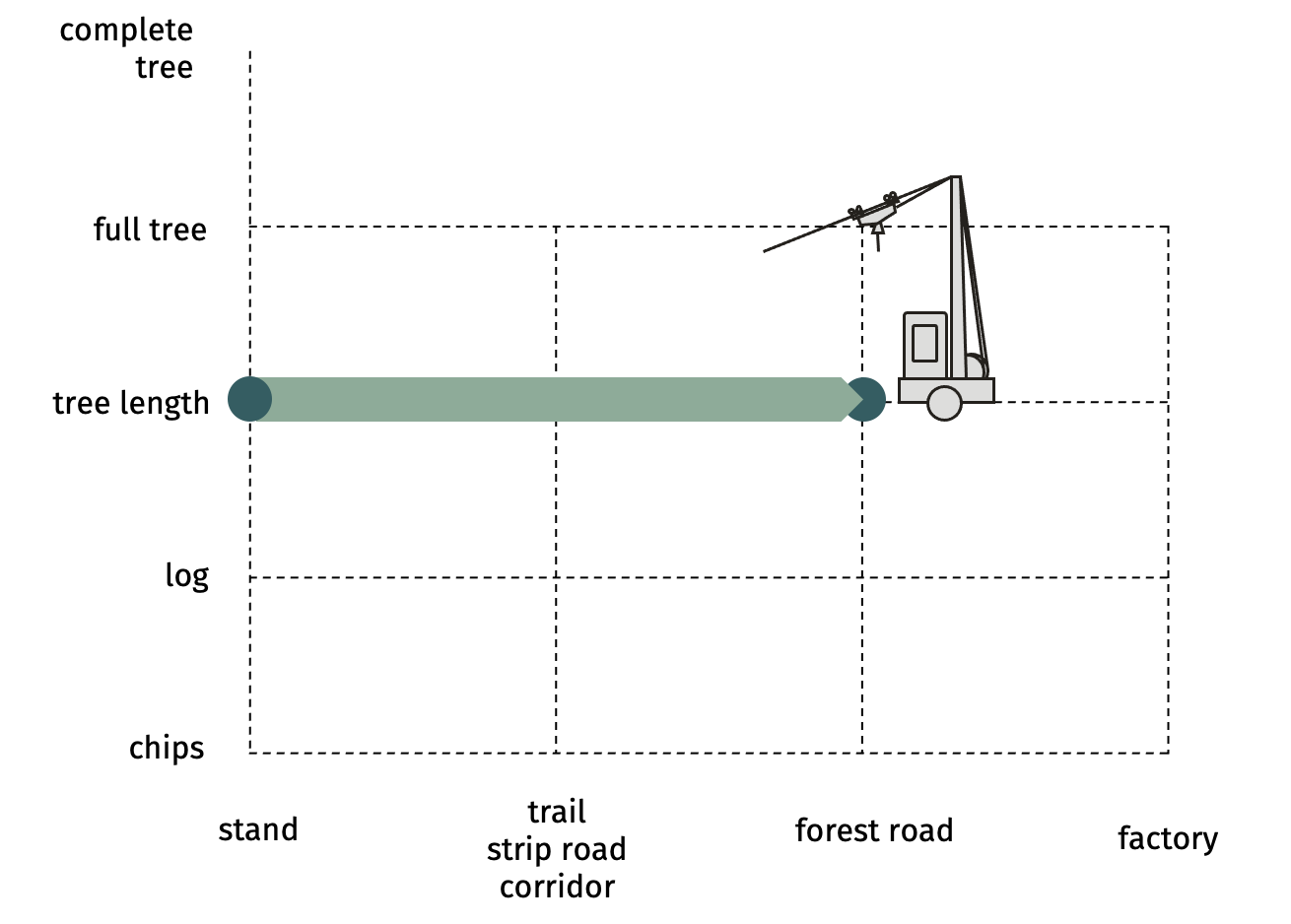

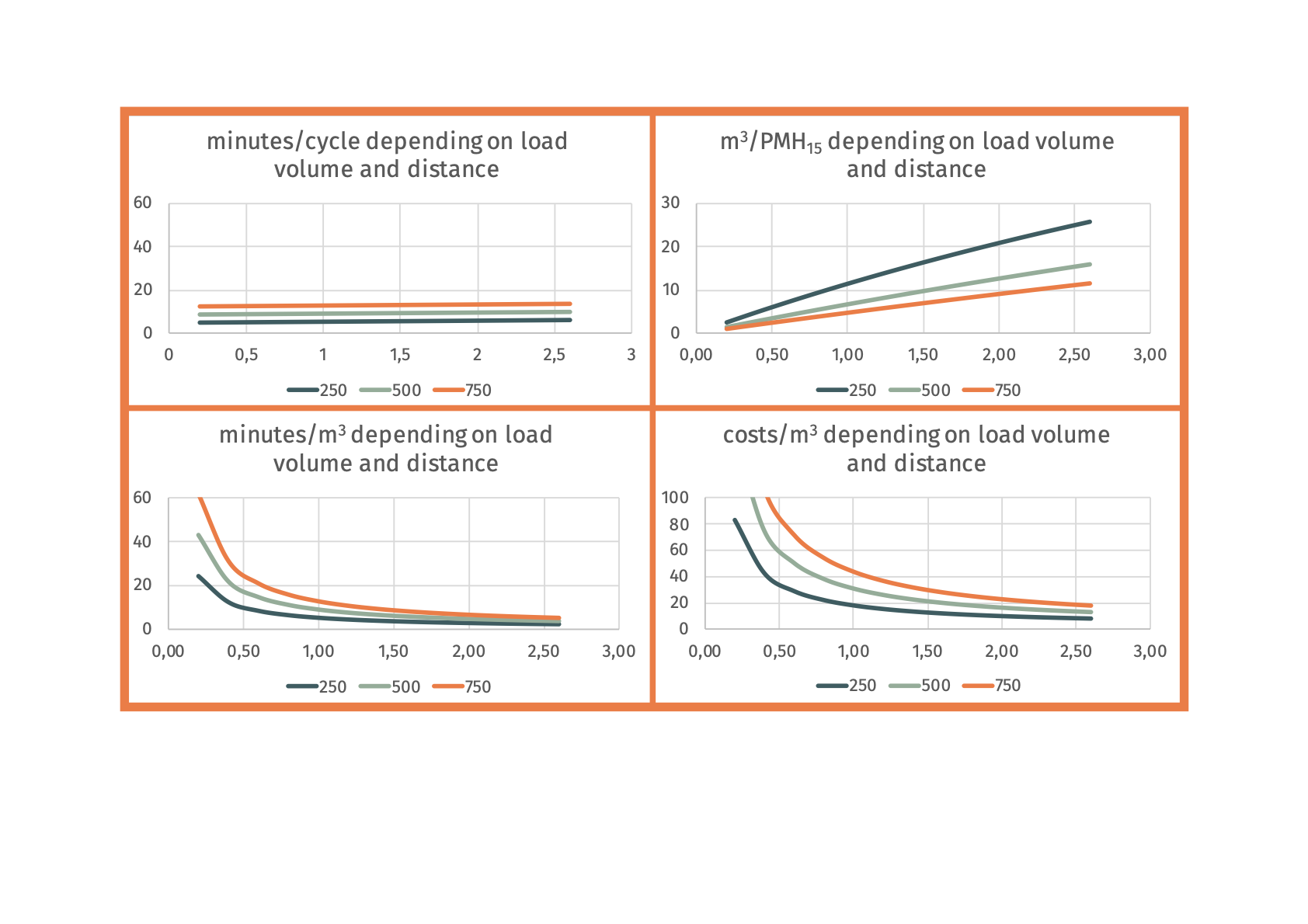

SP-12-32 mechanized pre-skidding and skidding of tree lengths with yarderFull trees are

moved to a landing (roadside landing, landing pad etc.) suspended under a

carriage that runs on a cable (skyline). Different types and configurations are

available (live, standing, running skyline, self-propelled carriage, swing

yarders - carriages with cable or grapple)  Advantages

Example:

Ecogram

Social suitability

Literature: | |

SP-13-23 manual pre-skidding of logs with animalShort logs can be pre-skidded (dragged) by draught horses or mules

Advantages

Example:

Ecogram

Social suitability:

Literature: mules – see coppice database, manual, chutes- see coppice database

| |

SP-13-23 manual pre-skidding of short logsShort logs

can be moved manually by workers by throwing them downhill, or sliding them with the use of sappies

or chutes.

Advantages

Example:

Ecogram

Social suitability:

Literature: | |

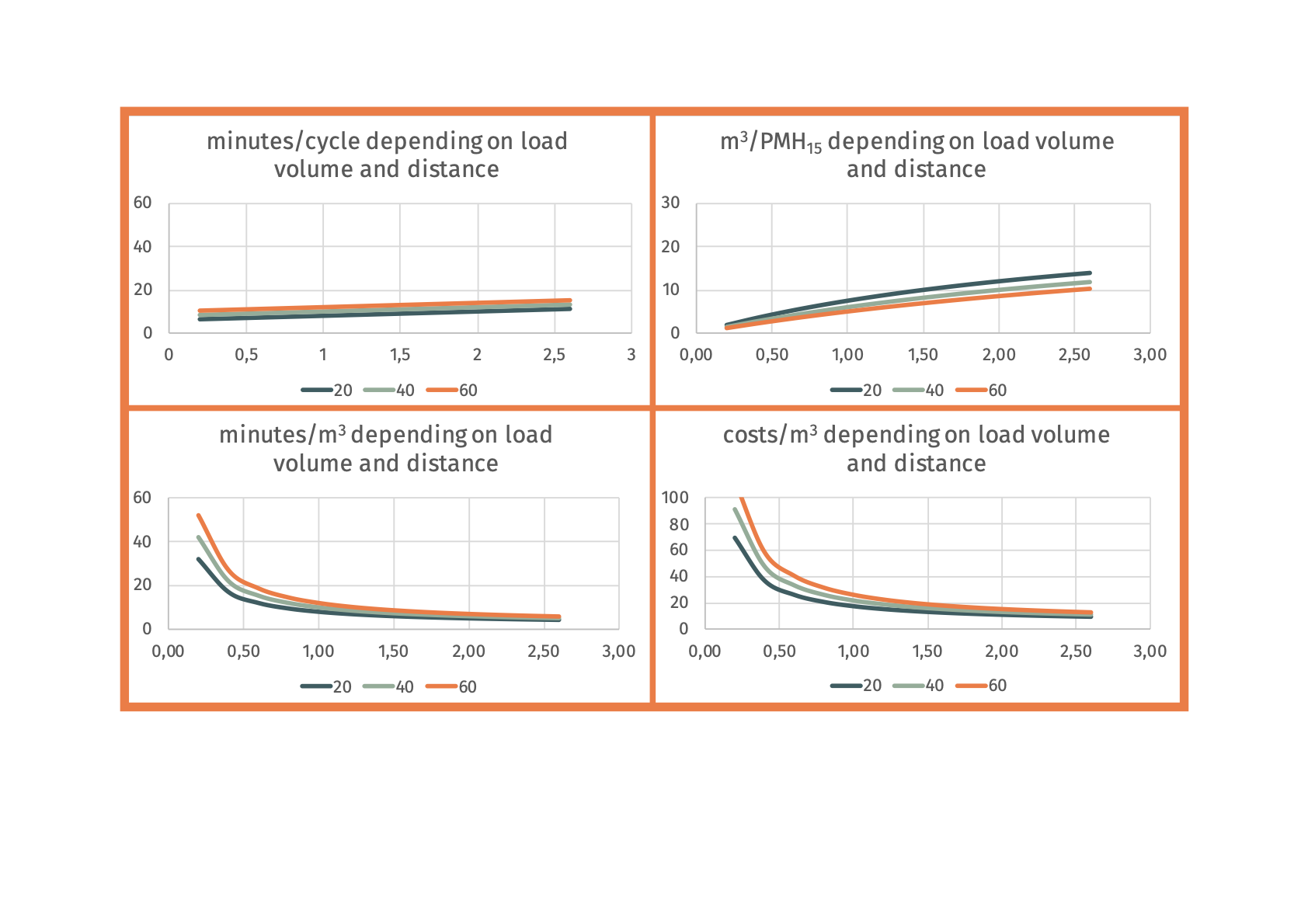

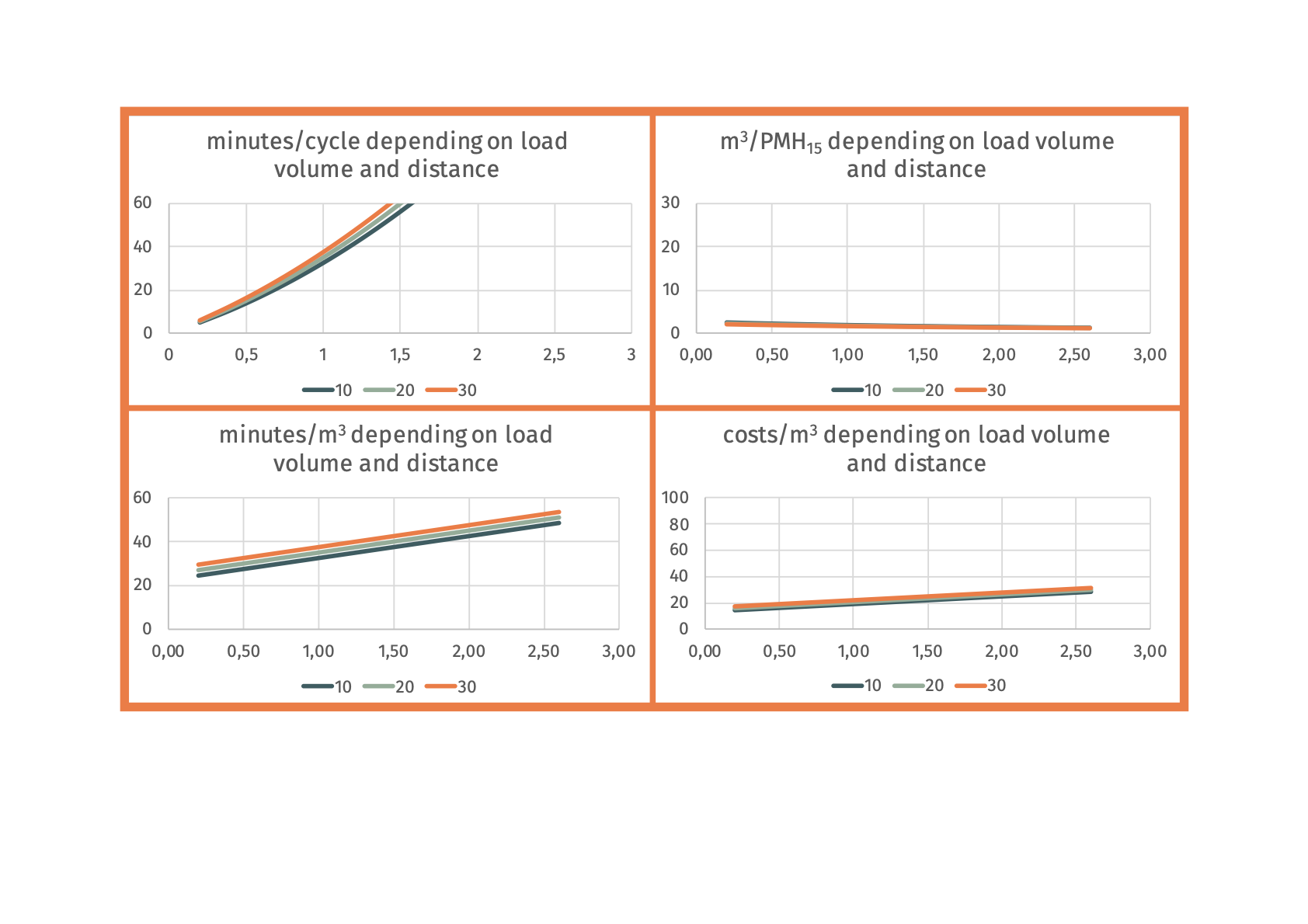

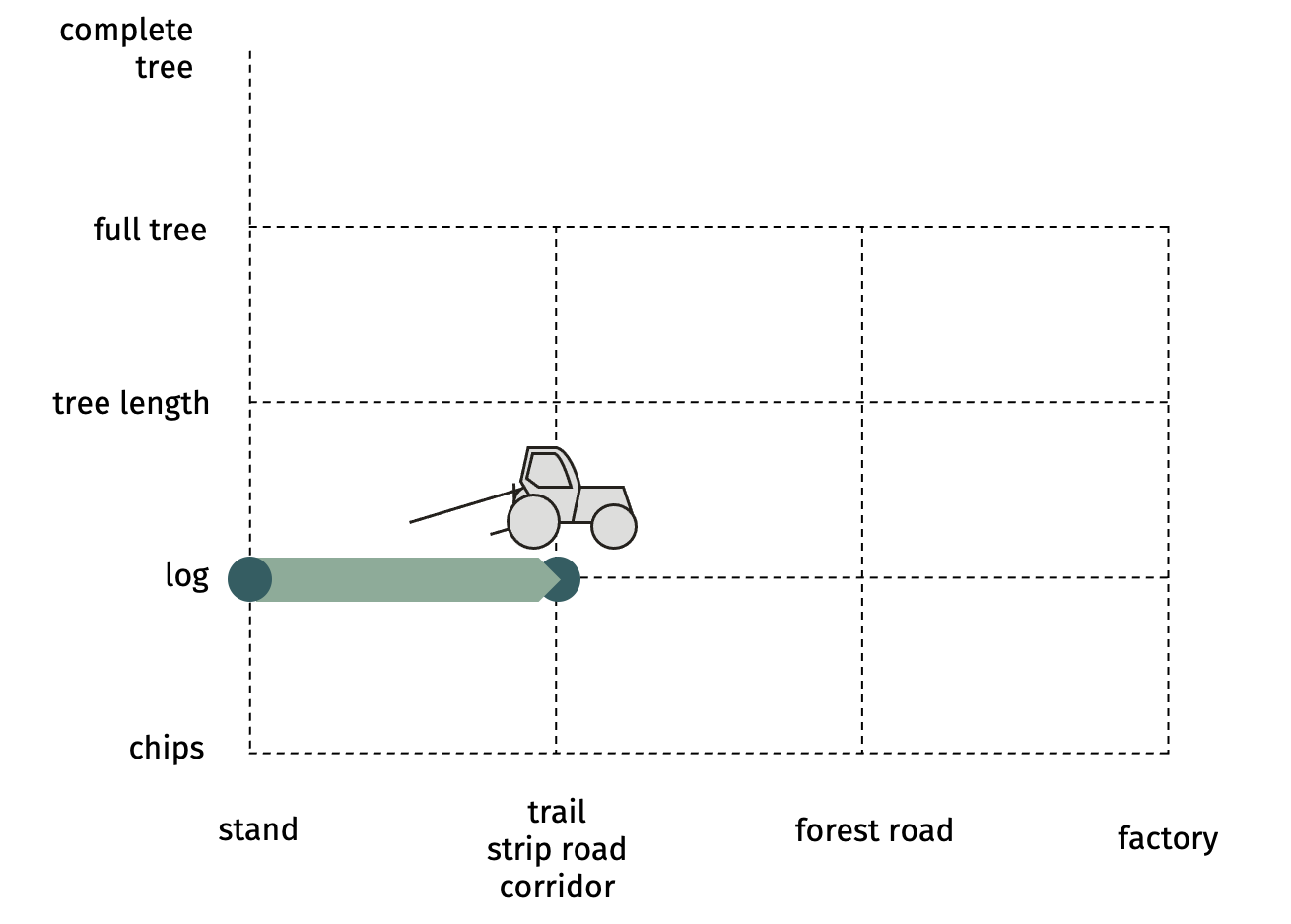

SP-13-23 mechanized pre-skidding of short logsWhen trees are cross-cut at the felling site, the logs must be pre-skidded to the trail separately. This is only rational when the weight of the tree length is too high. For example, the basic log can be separated from the rest of the stem before pre-skidding.  Advantages

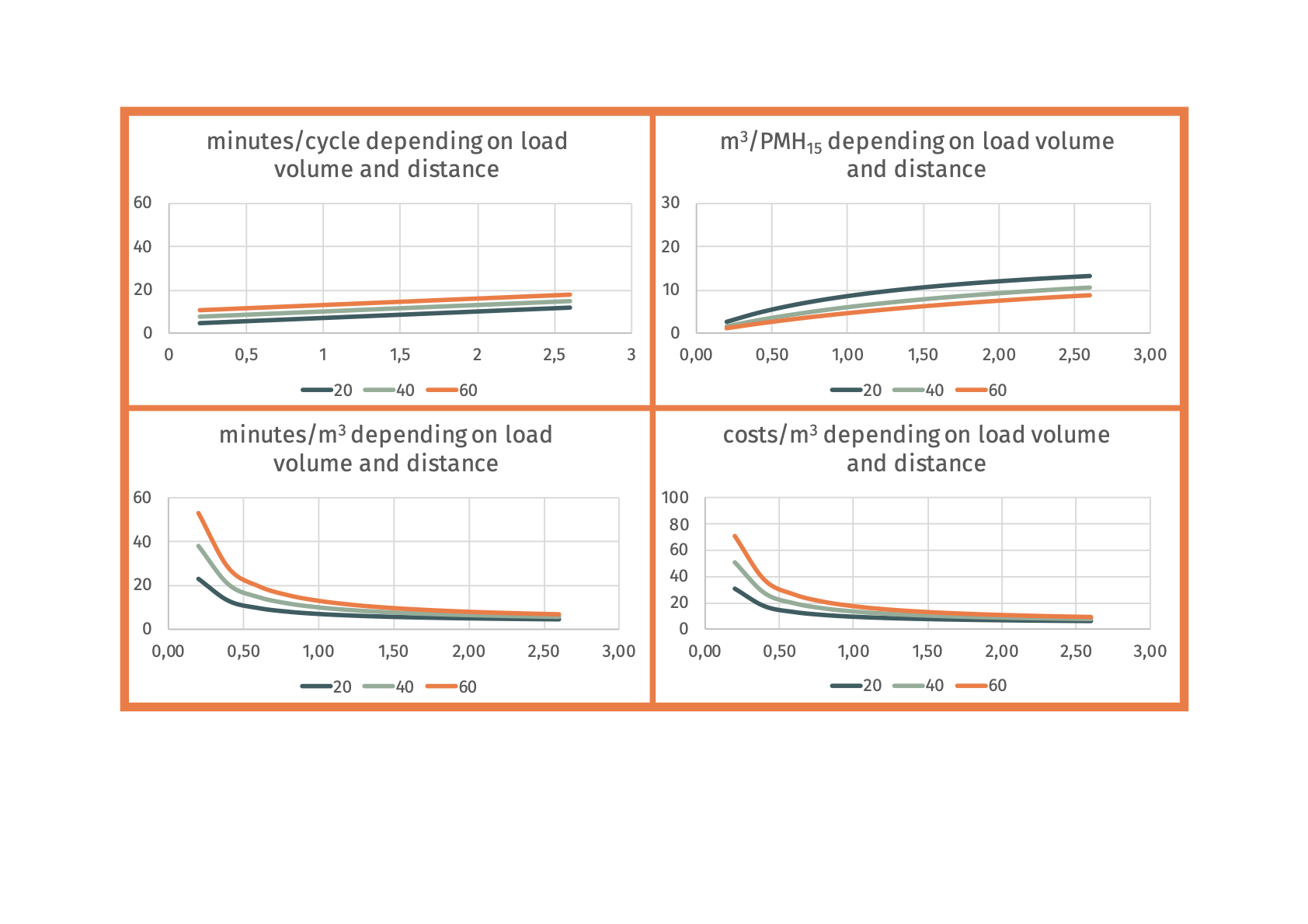

Minutes per cycle Example:

Ecograms

Social suitability:

| |

SP-21-22 delimbingsee SP-x1-x2 delimbing | |

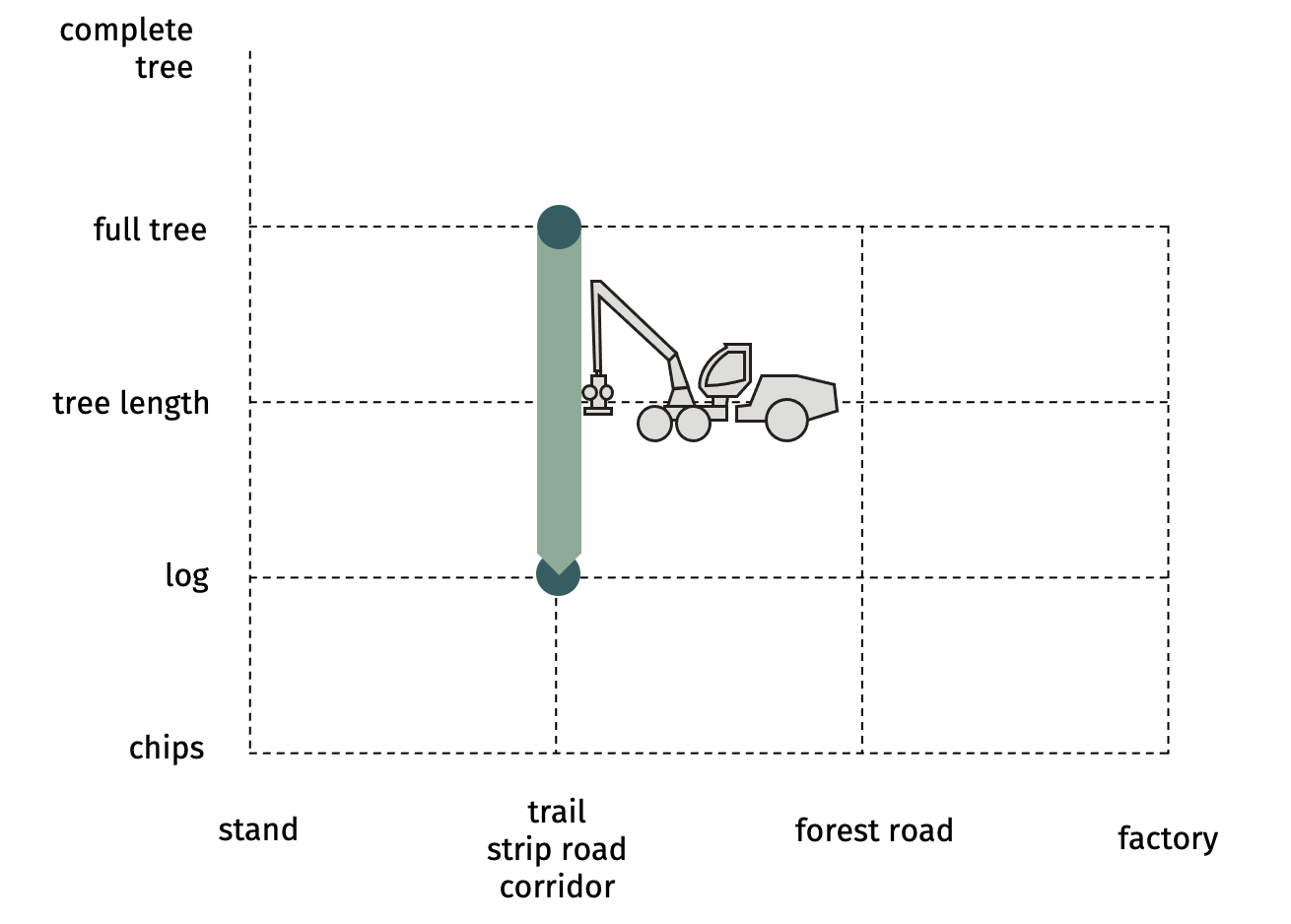

SP-21-23 mechanized processing on the trailProcessor (or harvester) standing on skid road processing the full tree that is laying down in reach of feeding device. The processing includes measuring, forecasting dimension, suggesting assortments, delimbing and cross-cutting.  Advantages

Example:

Ecograms

Social suitability

| |

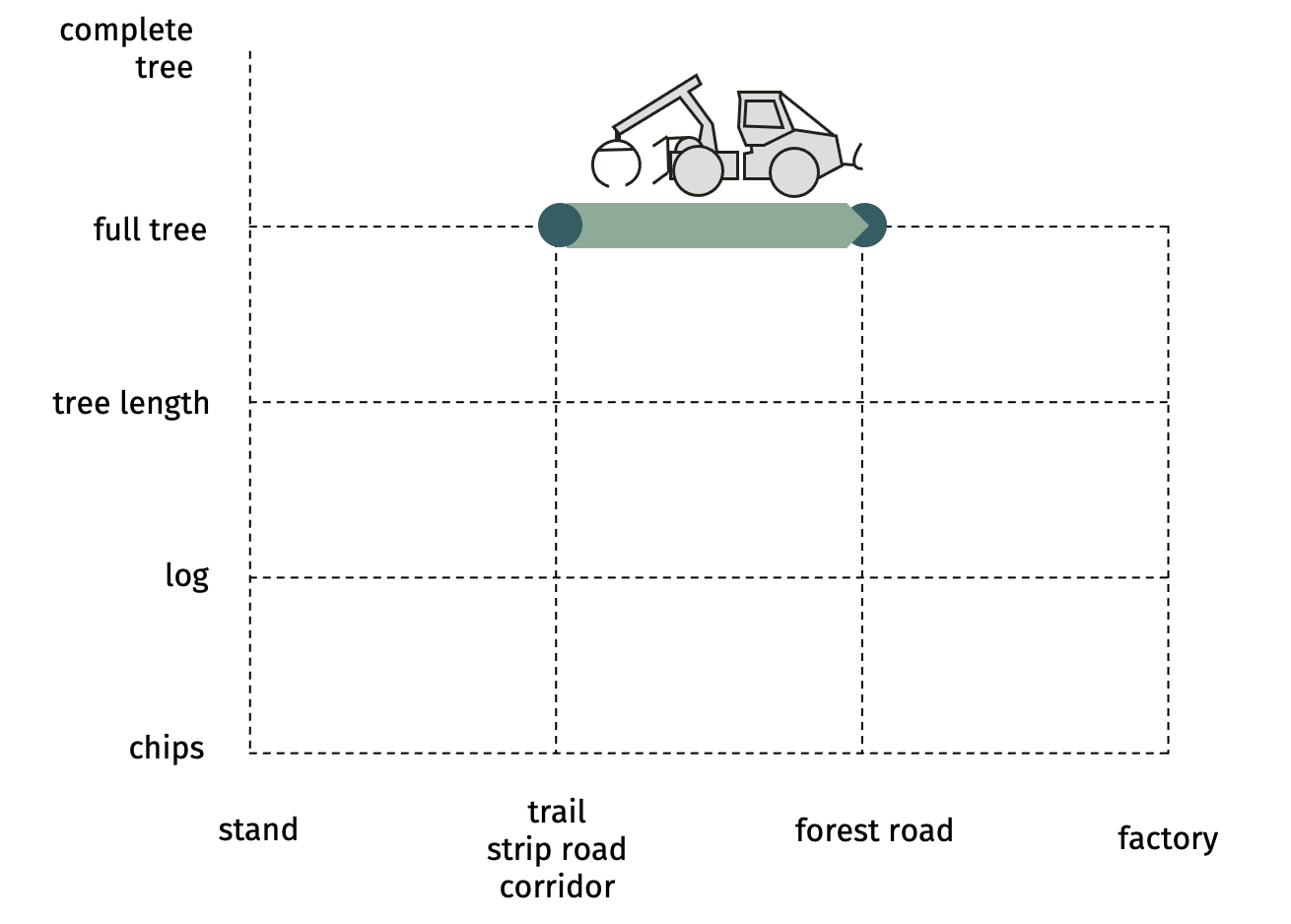

SP-21-31 mechanized skidding of full tree with grapple skidderFull trees are dragged to the roadside landing by a machine that uses a grapple to collect the trees.  Advantages

Example:

Ecograms

Social suitability:

| |

SP-21-31 mechanized skidding of full trees with skidderFull trees are

dragged to the roadside landing by a tractor (dedicated skidder, crawler,

forestry fitted farm tractor) using chains or cable.  Advantages

Example:

Ecograms

Social suitability:

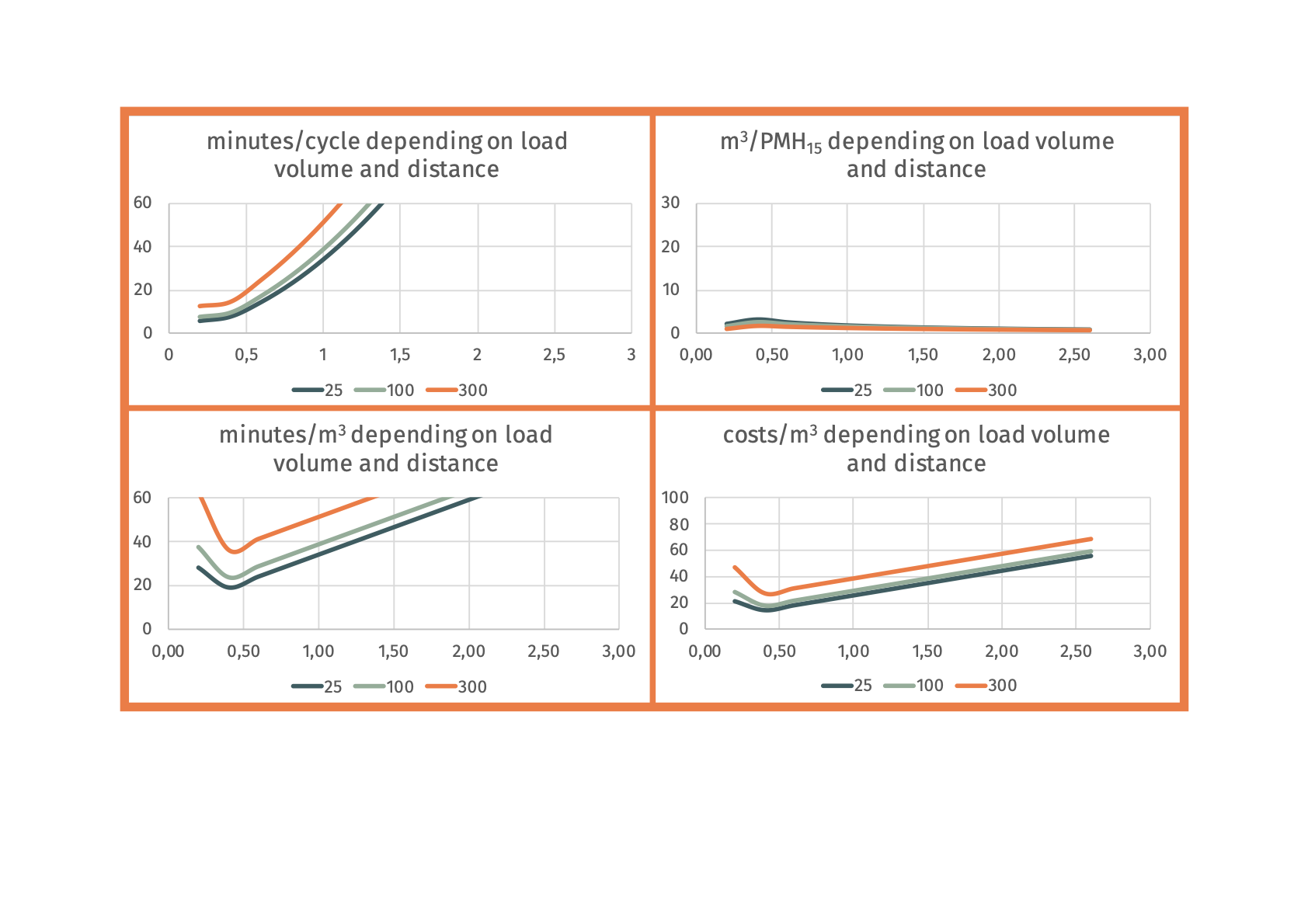

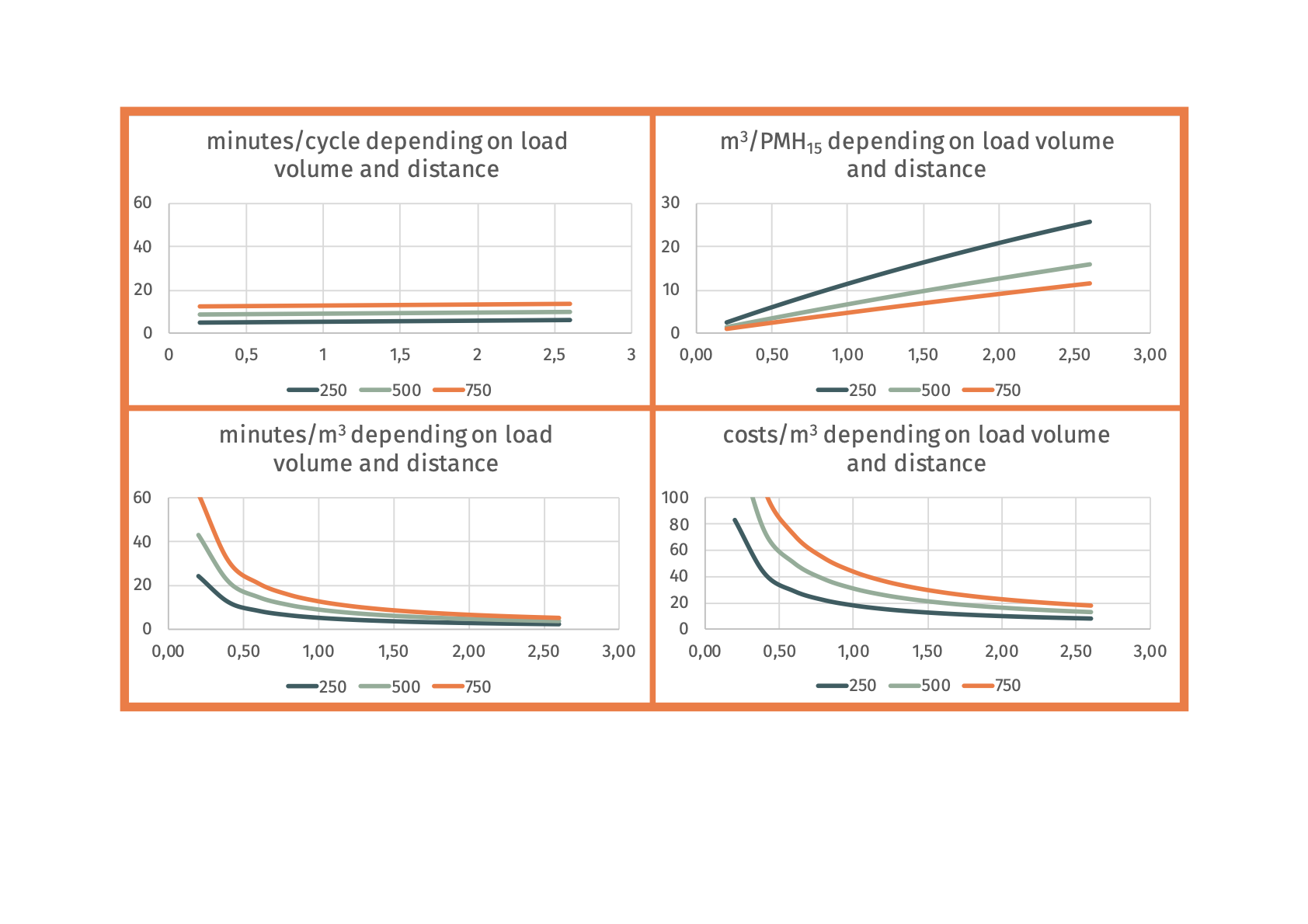

graph from Ecotrac study and Rien's lesson (re-conduce everything to tree size m3 on the x-axis, then different lines for different distances and maybe one graph for small skidder and one for large skidder) | |

SP-21-31 skidding of full tree with clam-bunk skidderFull trees are

skidded with their butts resting on the rear axle of the skidder, while tree

tops drag on the ground. The butts

are retained on top of the rear axle by an inverted grapple (clambunk) and

placed on that grapple using a hydraulic loader. Functiogram  Advantages

Example:

Ecograms

Social suitability:

| |

SP-21-34 mechanized chipping of full trees on the trailFull trees that are laid down alongside the trail are chipped by a self-propelled chipper or a tractor powered chipper with terrain capability. Chips are blown into an integral bin and then transferred to a chip shuttle (forwarder-based) or into a bin trailer, towed by the same tractor or by an accompanying tractor.  Advantages

Example:

Ecograms

Literature: Check Waterford studies | |

SP-22-23 cross-cuttingsee SP-x2-x3 cross-cutting | |

SP-22-32 mechanized skidding of tree lengths with clam-bunk skidderTree lengths that are pre-skidded to the trail are skidded to the forest road using a clam-bunk skidder. This includes: loading the trees with the crane into the clam-bunk, skidding them to forest road, storing them alongside road or a landing.  Advantages

Example:

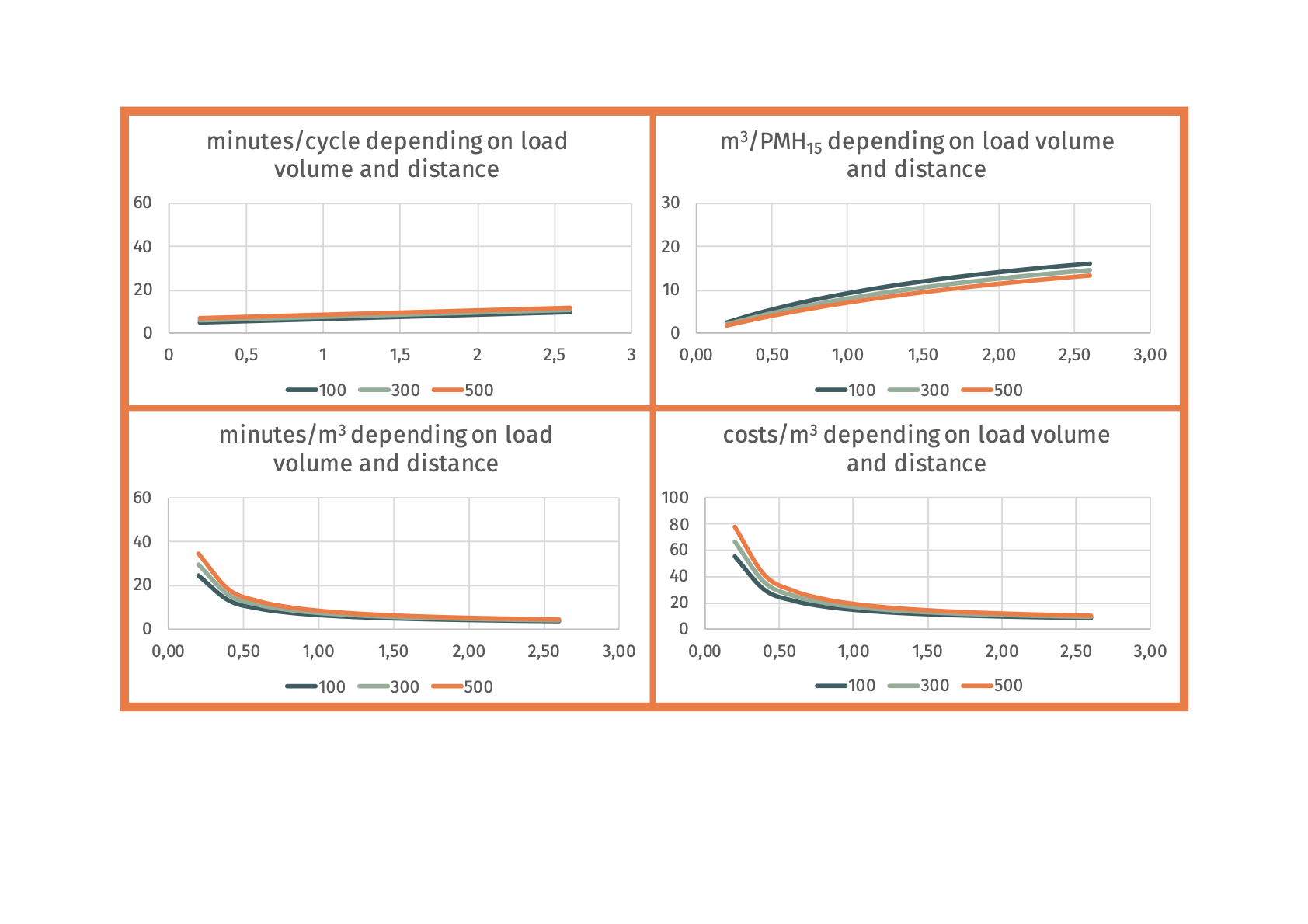

Ecograms

Social suitability

Logging arch study for farm tractors - Merlo study etc. | |

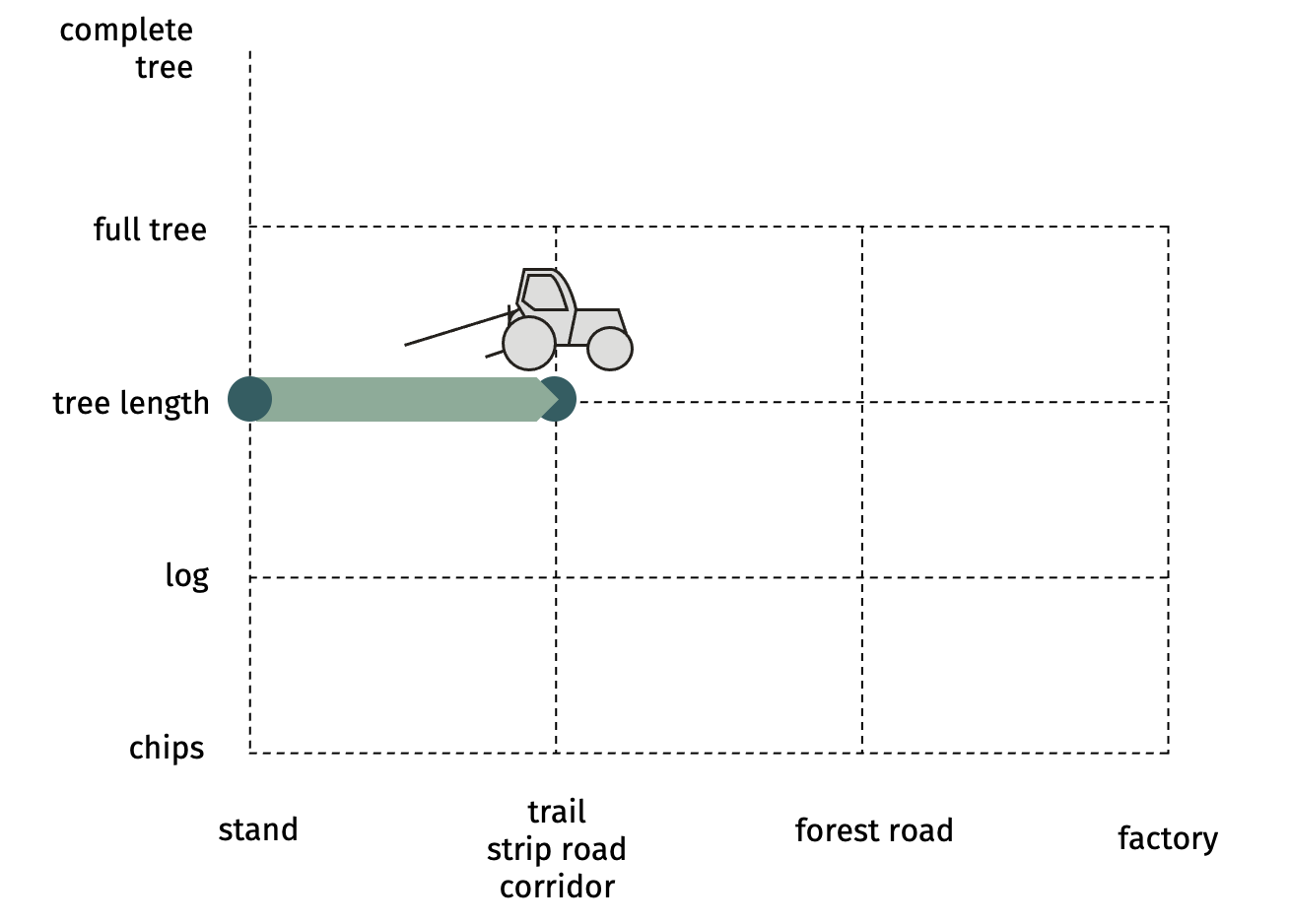

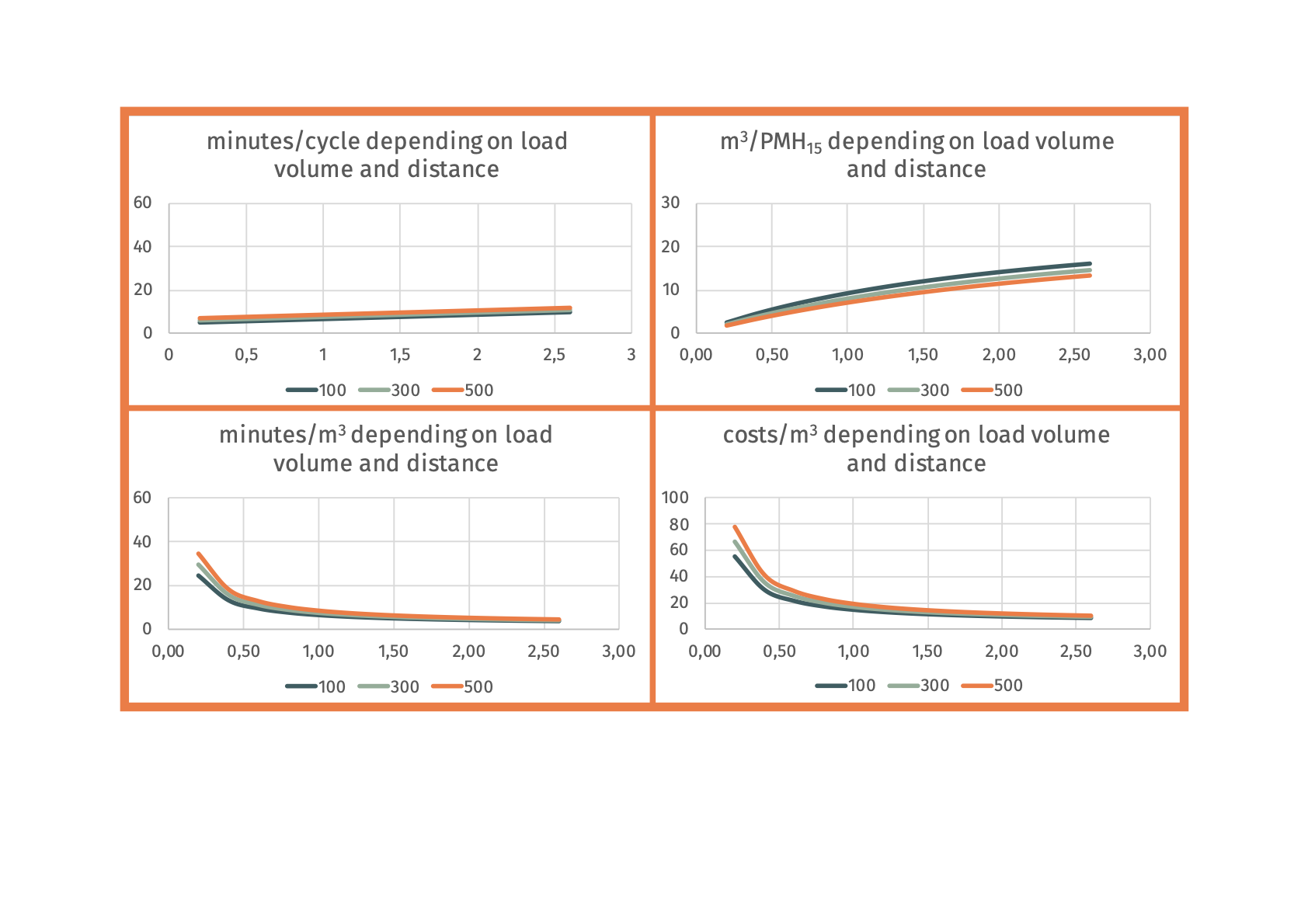

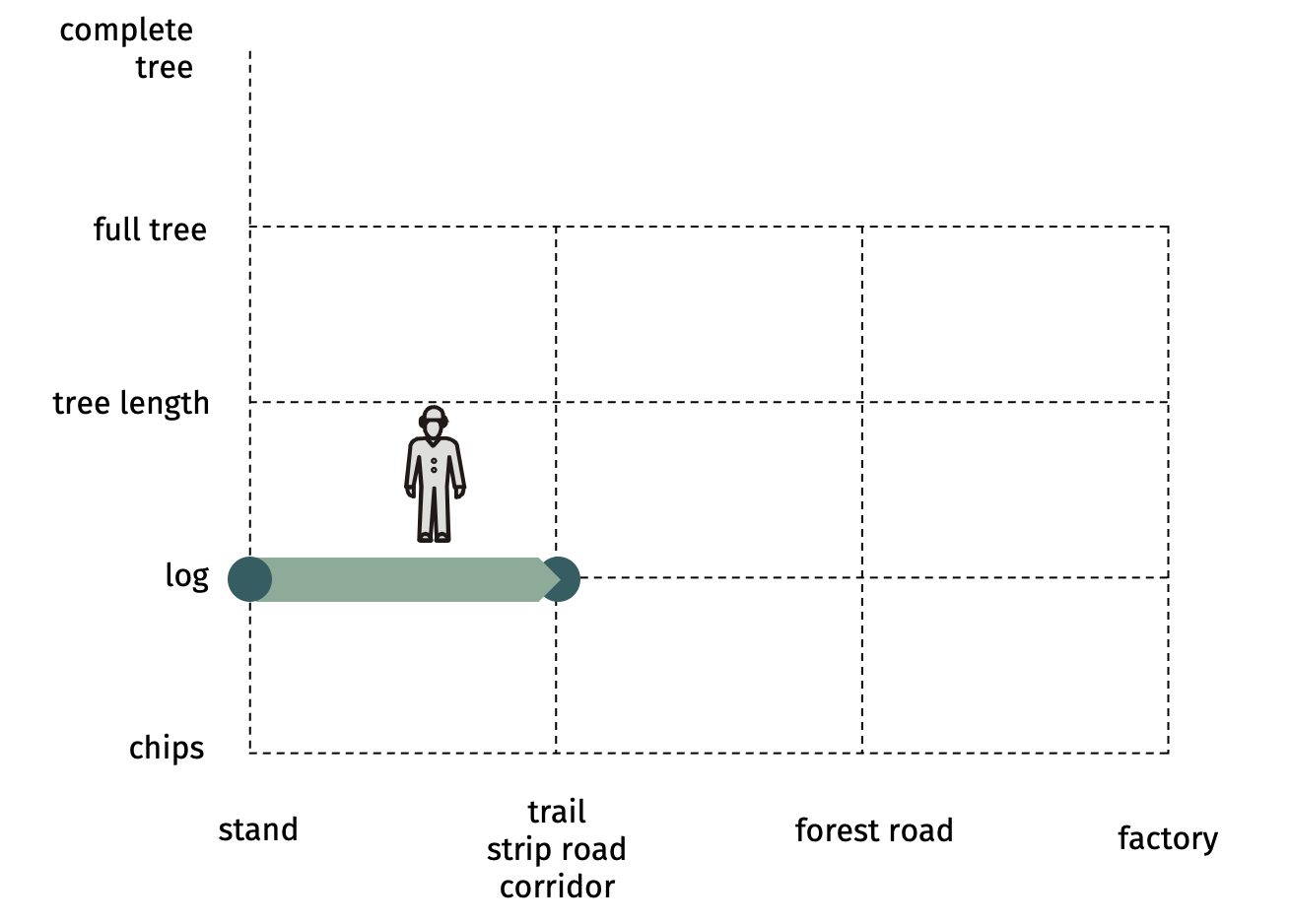

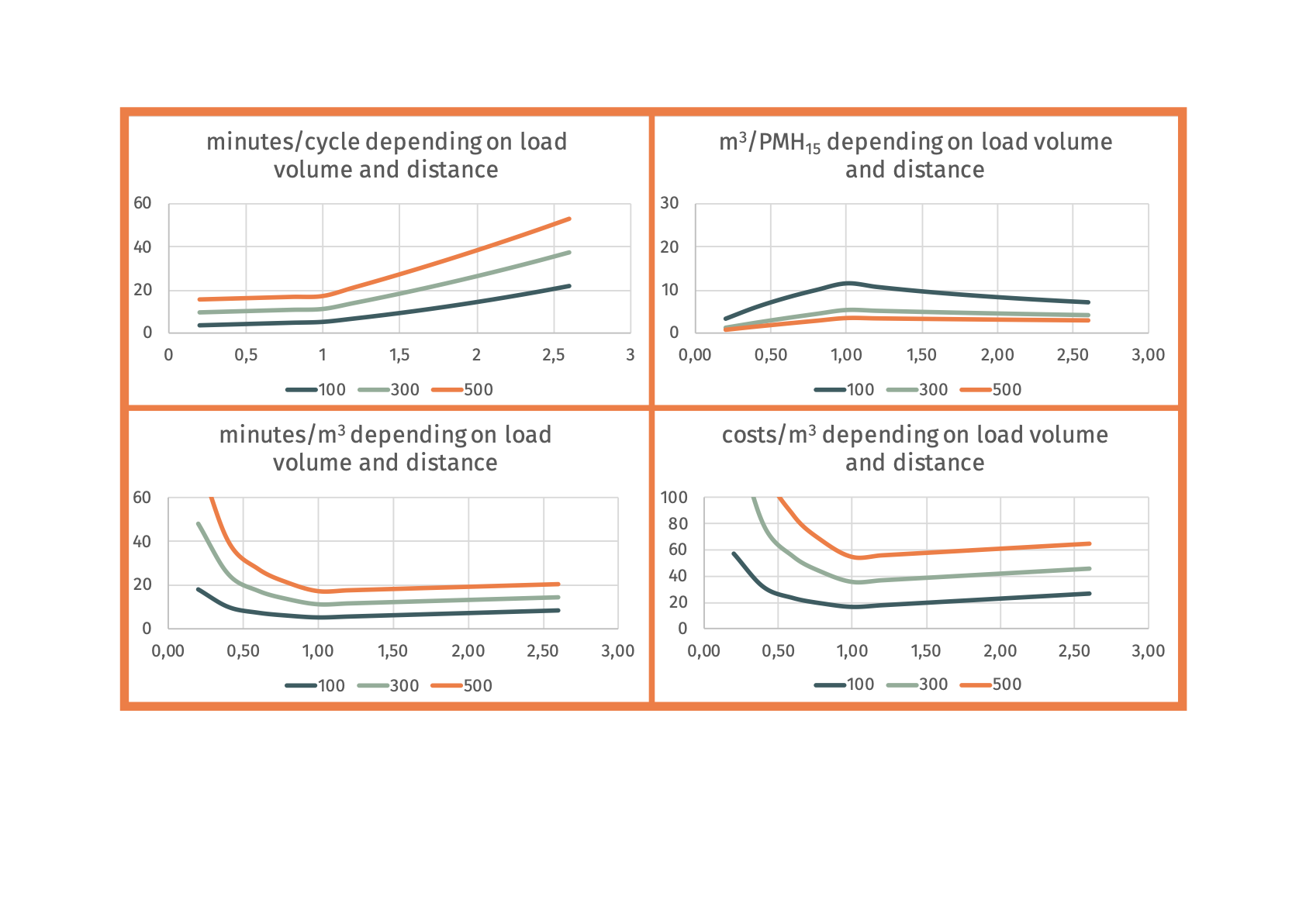

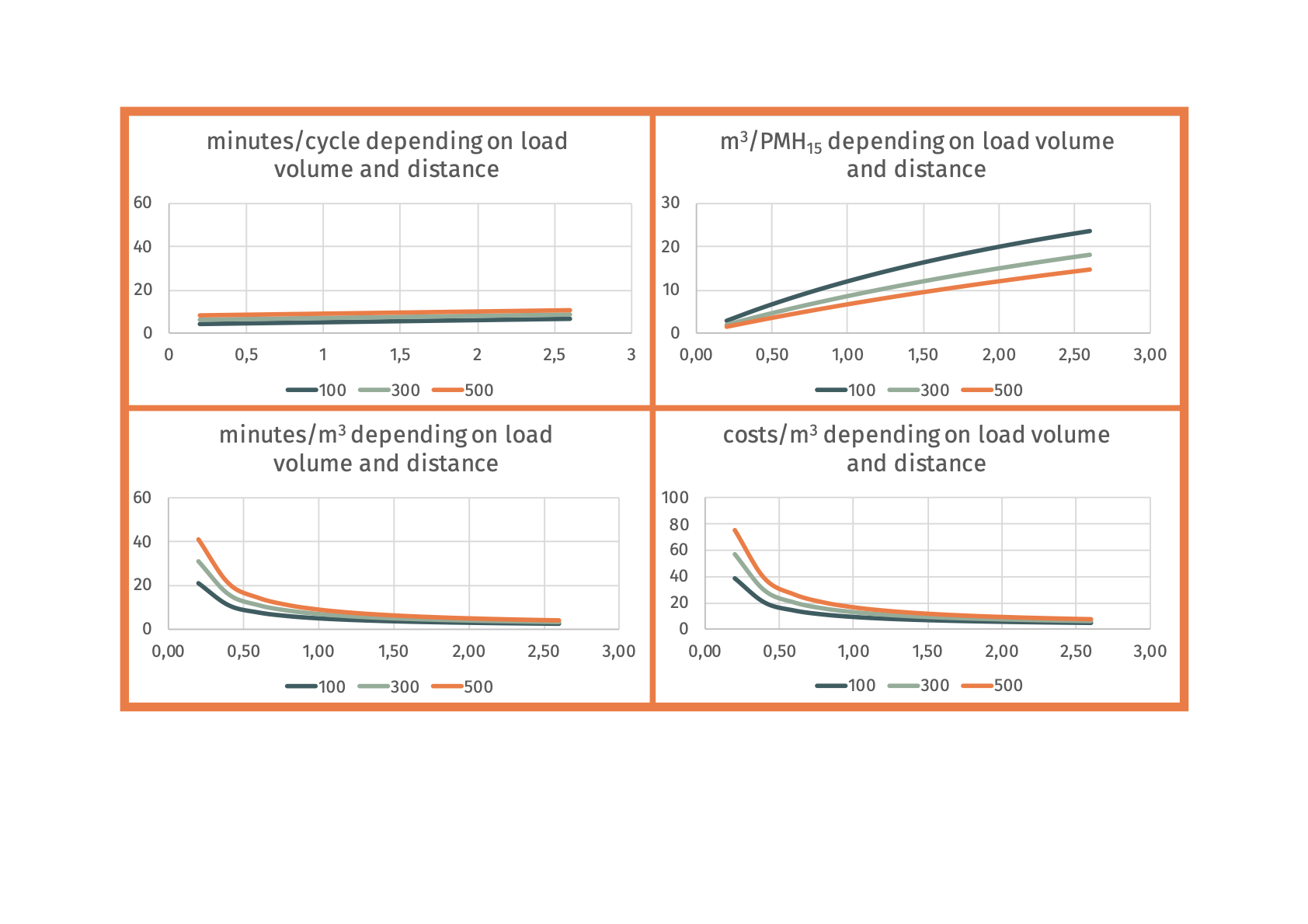

SP-22-32 mechanized skidding of tree lengths with skidderTree lengths that are pre-skidded to the trail are skidded to the forest road. This includes: setting chokers on several tree-lengths to optimize the load, skidding them to forest road, storing them alongside road or a landing.  Advantages

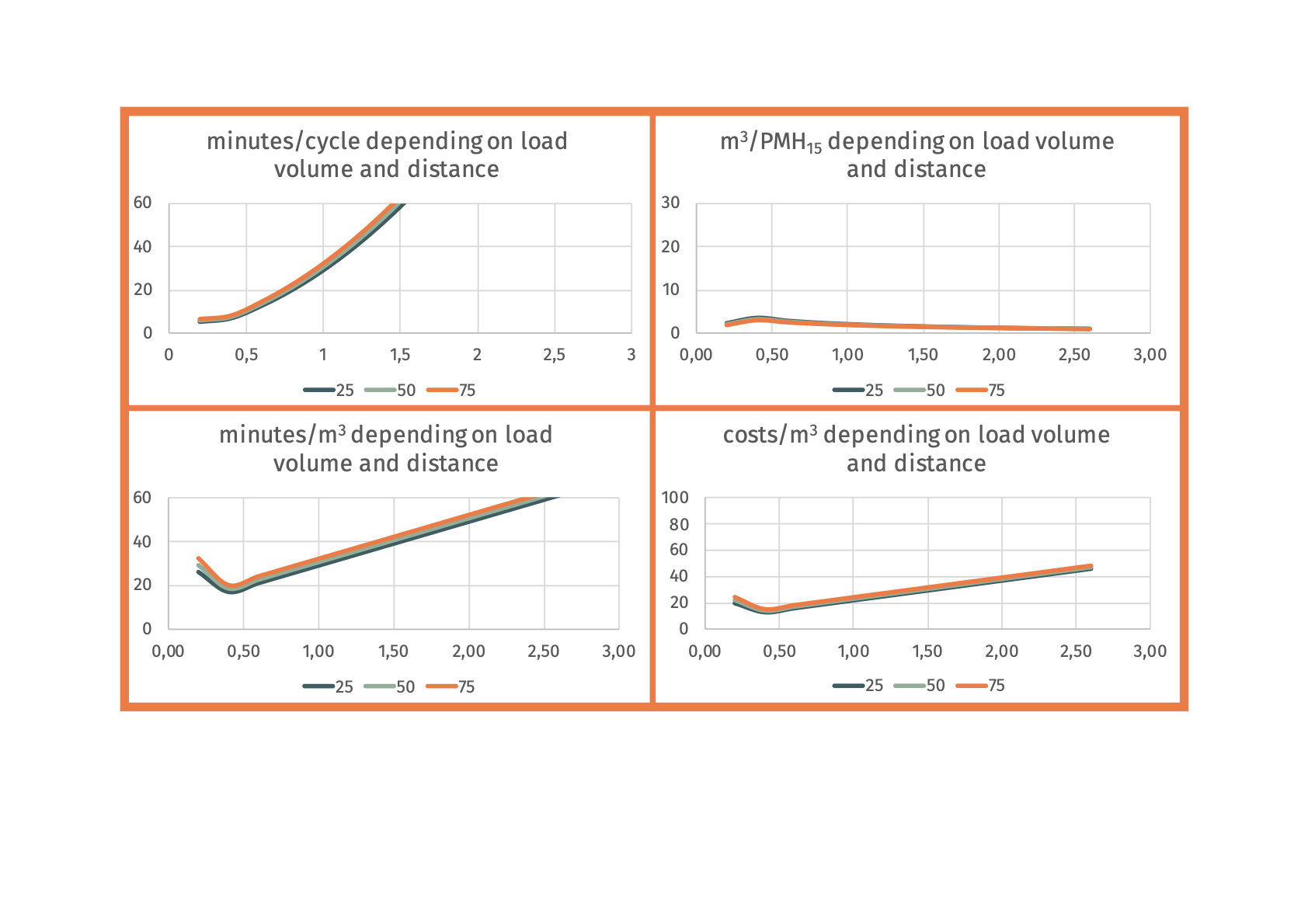

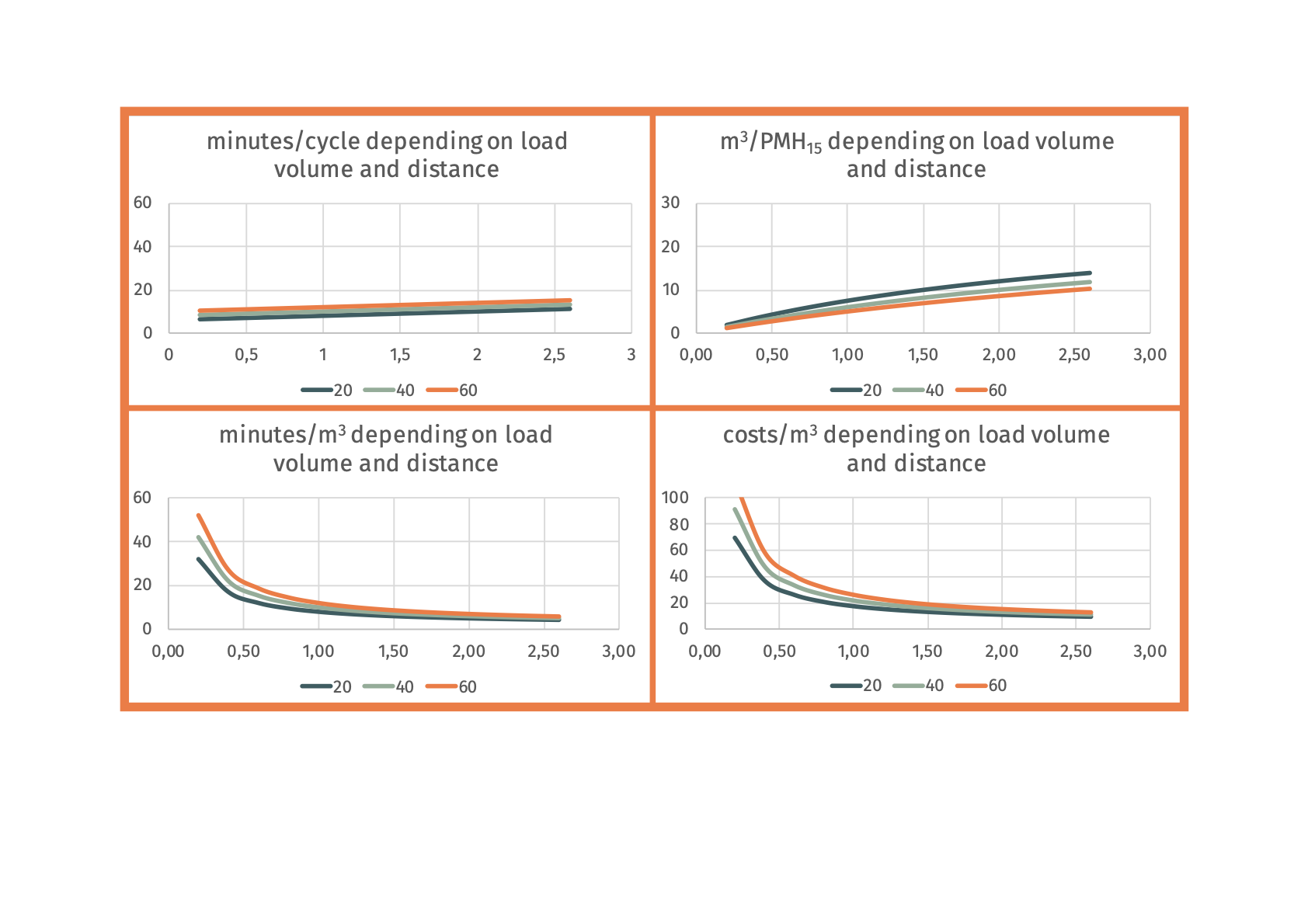

Minutes per cycle Example:

Ecograms

Social suitability

| |

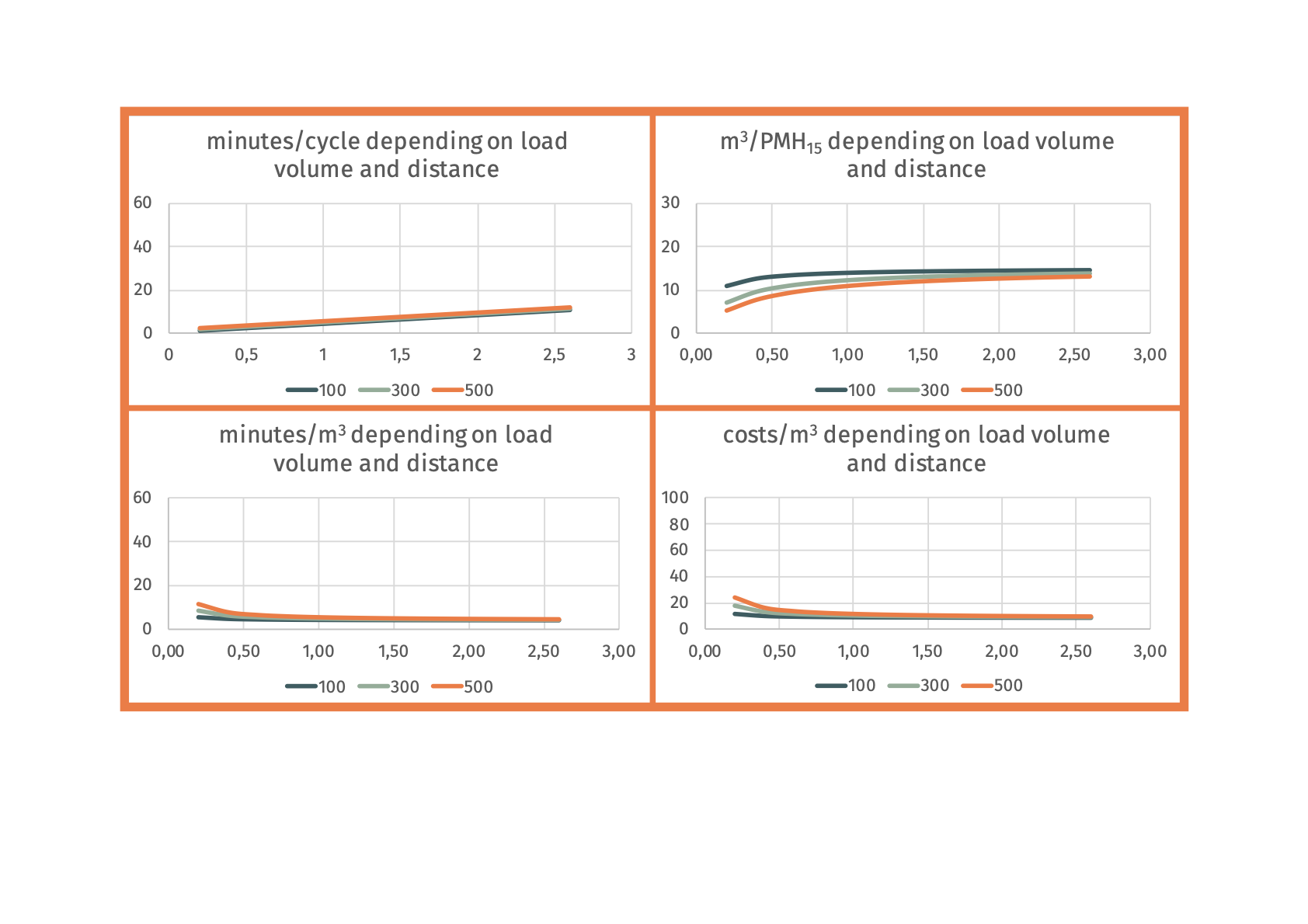

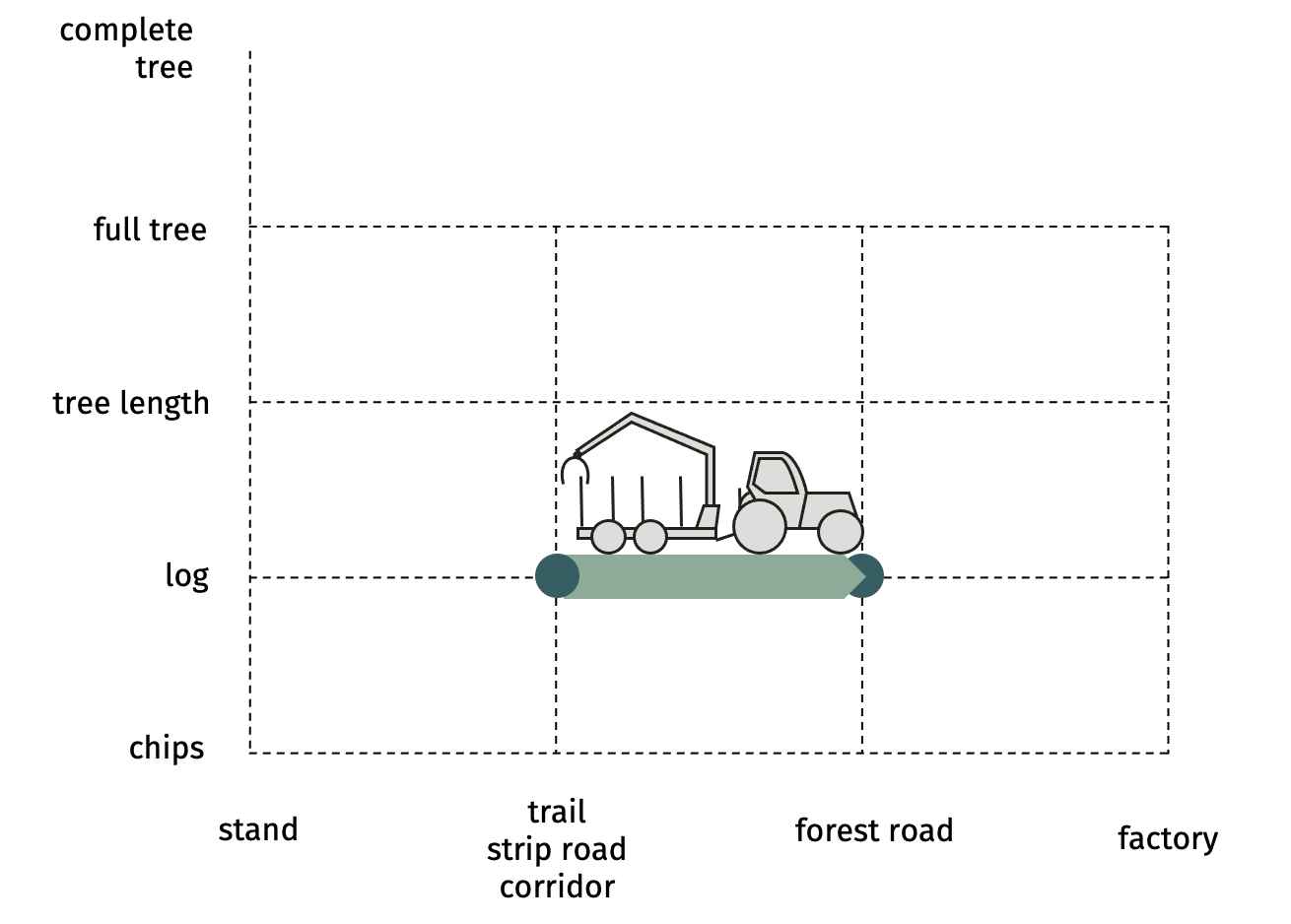

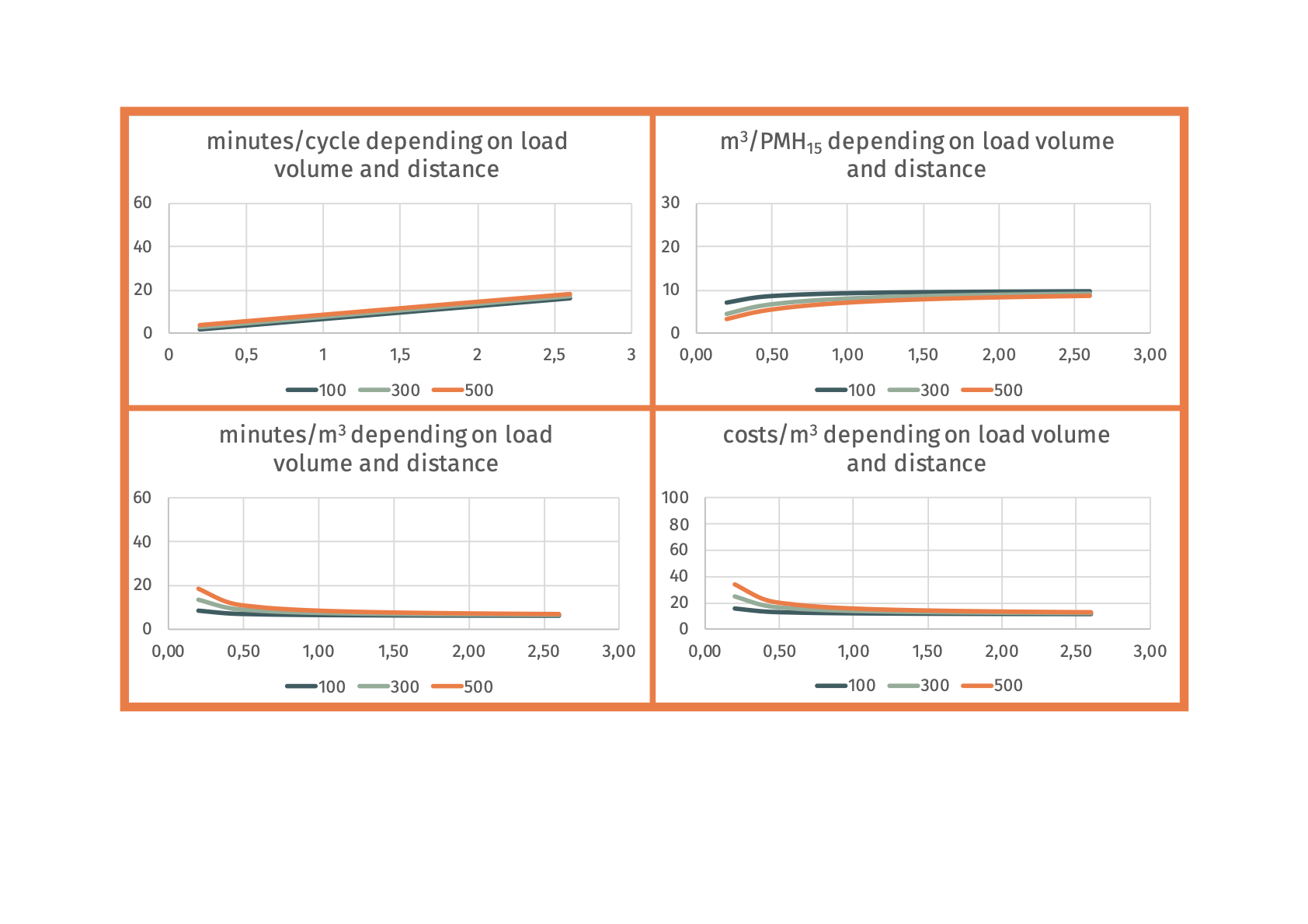

SP-23-33 mechanized forwarding of short logs with forwarderPicking up logs that are stored alongside skid road, normally separating different assortments, forwarding them to forest road, unloading.

Advantages

Example:

Ecograms

Social suitability:

| |

SP-23-33 mechanized forwarding of short logs with tractor and trailerPicking up

logs that are stored alongside skid road, normally

separating different assortments, only forwarding together in order to utilize

the trailer, transporting to forest road, unloading.

Advantages

Example:

Ecograms

Social suitability:

| |

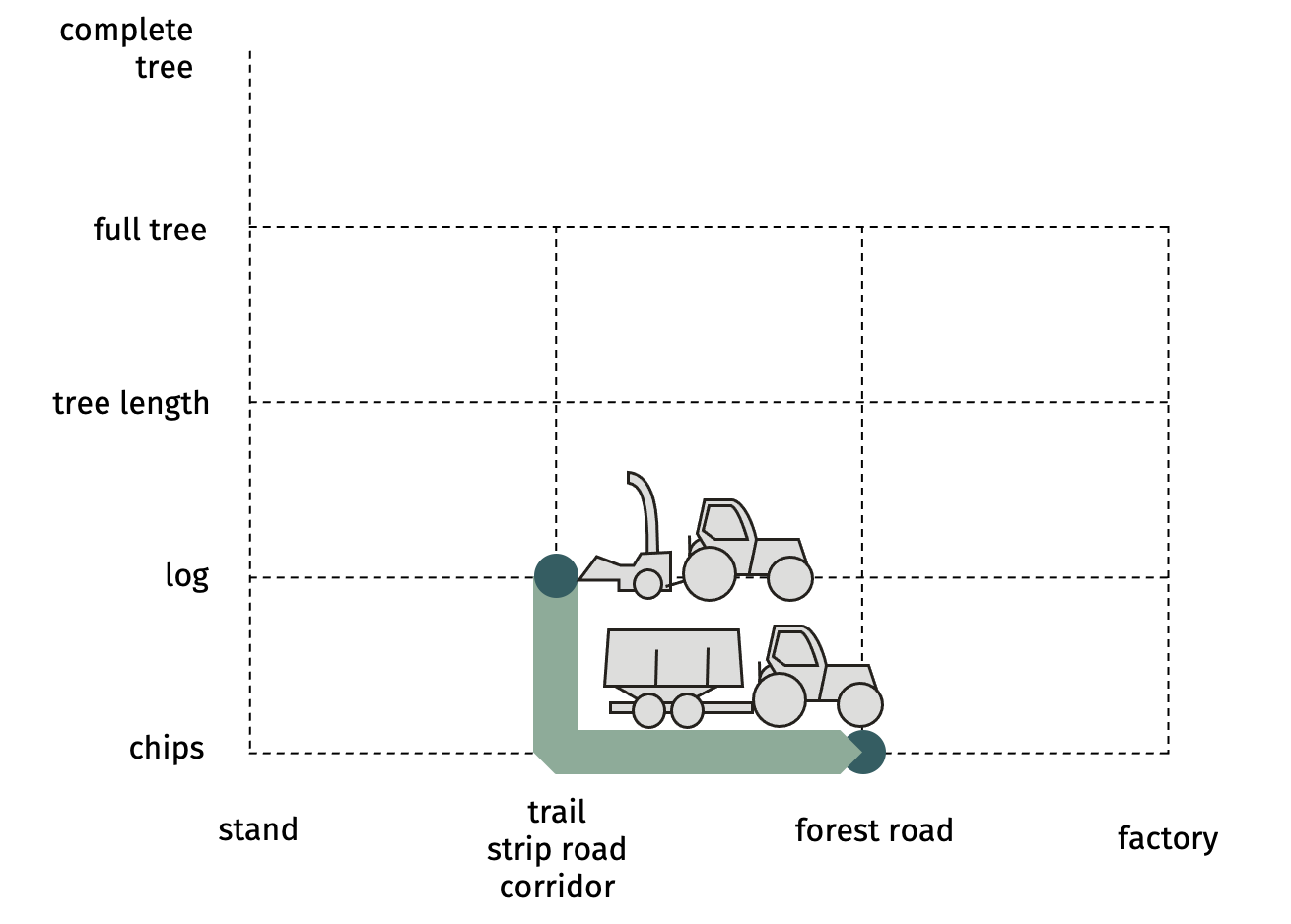

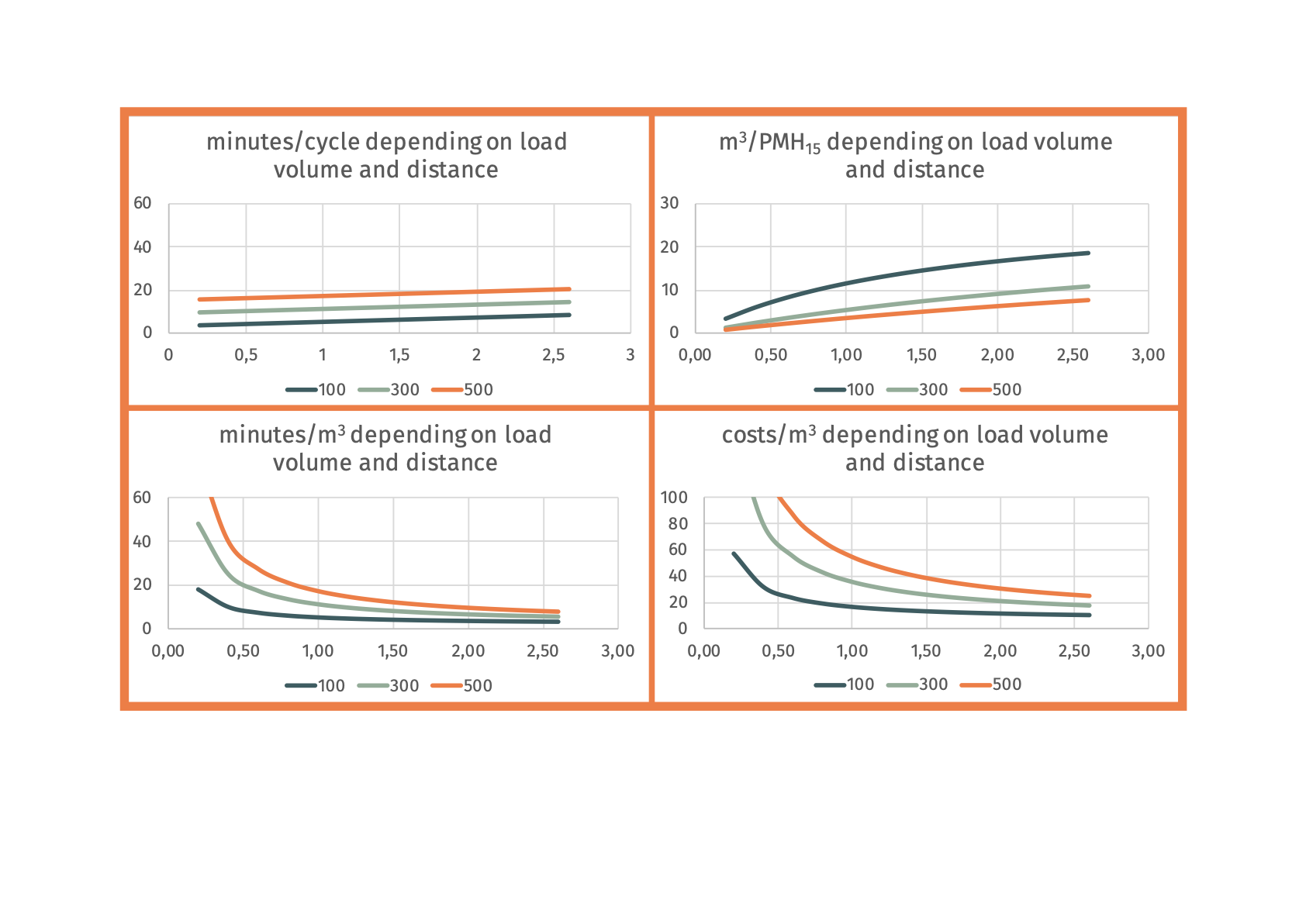

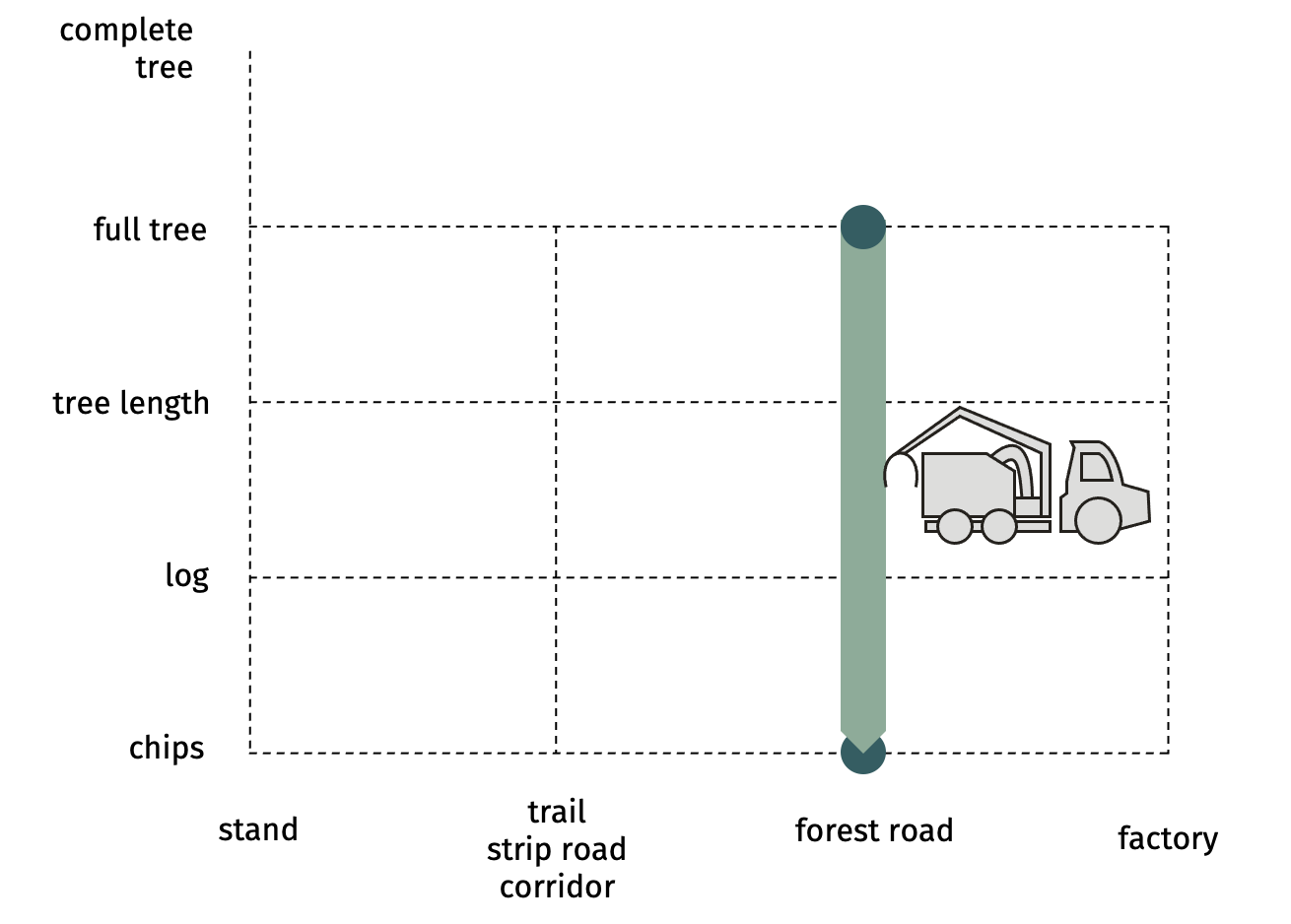

SP-23-34 mechanized chipping of residues on the trailLogs are

chipped by a self-propelled chipper or a tractor-powered chipper, fed by a

loader. Chips are blown into an integral bin, a bin trailer, towed by the same

tractor or by an accompanying machine. The most effective team is that composed by a

self-propelled chipper with integral loader and bin and a chip-shuttle

(forwarder-based eg. Silvatec)  Advantages

Example:

Ecograms

Literature: Spinelli & Hartsough 2001, Spinelli & Magagnotti 2010, and many more | |

SP-31-32 delimbingsee SP-x1-x2 delimbing | |

SP-31-33 mechanized processing on the forest roadProcessor

(or harvester) standing on forest road and processing

the skidded full trees, which are stored.  Advantages

Example:

Ecogram

Social suitability:

| |

SP-31-34 mechanized chipping of full trees at forest roadFull trees are chipped at a roadside landing  Advantages

Economic suitability Example:

Ecogram

Social suitability

Literature: Eliasson, L., Von Hofsten, H., Johannesson, T., Spinelli, R., Tierfelder, T., 2015: Effects of sieve size on chipper productivity, fuel consumption and chip size distribution for open drum chippers. Croatian Journal of Forest Engineering 36: 11-17. | |

SP-32-33 cross-cuttingsee SP-x2-x3 cross-cutting | |

SP-32-34 mechanized chipping of tree lengths at forest roadTree lengths that are stored at the forest road are chipped.

Advantages

Example:

Ecogram

Social suitability

| |

SP-33-34 mechanized chipping of short logs at forest roadLogs are chipped from stacks piled at the roadside. The work can be done with any chipper, in any configurations. Chips can be discharged directly onto trucks, onto tractor- trailers or on the ground. Surge bins can also be used  Advantages

Advantages

Example:

Ecogram

Social suitability:

| |

SP-x1-x2 manual delimbingLimbs are to be cut by axe or comparable knives: with one cut the branch should be separated - therefore more suitable for younger trees and conifer species  Advantages

Example:

Social suitability

| |

SP-x1-x2 motor-manual delimbingWhen the tree is felled (lays on ground) the limbs are cut from bottom to top. Three methods: 2 whorls at a time, whorl by whorl, and in the crown from top to the side. When finished turn the log and work the other side  Advantages

Example:

Ecogram

Social suitability

| |

SP-x2-x3 motor-manual cross-cuttingAfter

measuring and decision where the optimal cuts have to be set, the trunk is cut into

2 or more pieces, (nearly) each of them marketable assortment.  Advantages

Example:

Social suitability

| |

Standard methodIf a working method is recognized to be a good solution for a certain task, it can be upraised as standard. For a standard method, the tools, machines, working steps, inputs and outputs are described in detail as well as the operational method of the worker. So, by naming the standard all persons have a common view of the process that should be performed. This is also the basis for education: since everything is standardized, the standard method can be explained and trained very well. In former times we called it “best practice” – but this word puts into mind that it should never be modified. Standard, in contrast, has the implication that it defines the direction and the goal, but can be adapted to the acute situation if needed. (See more under TDiv PR1-E03) | |

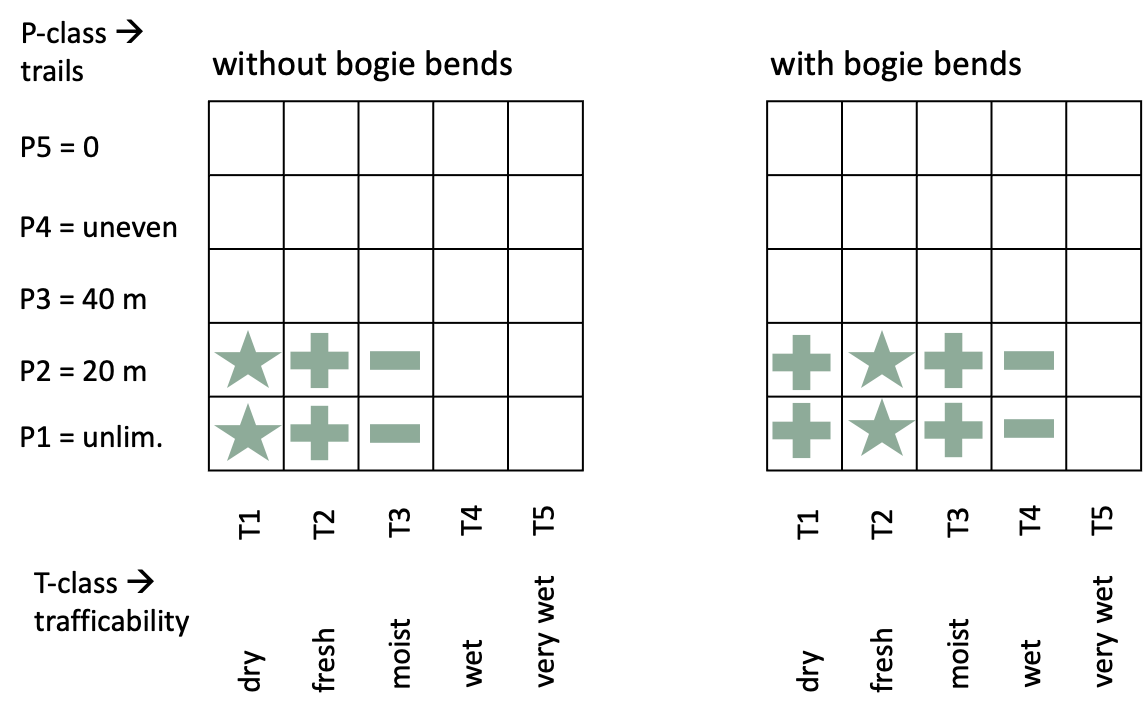

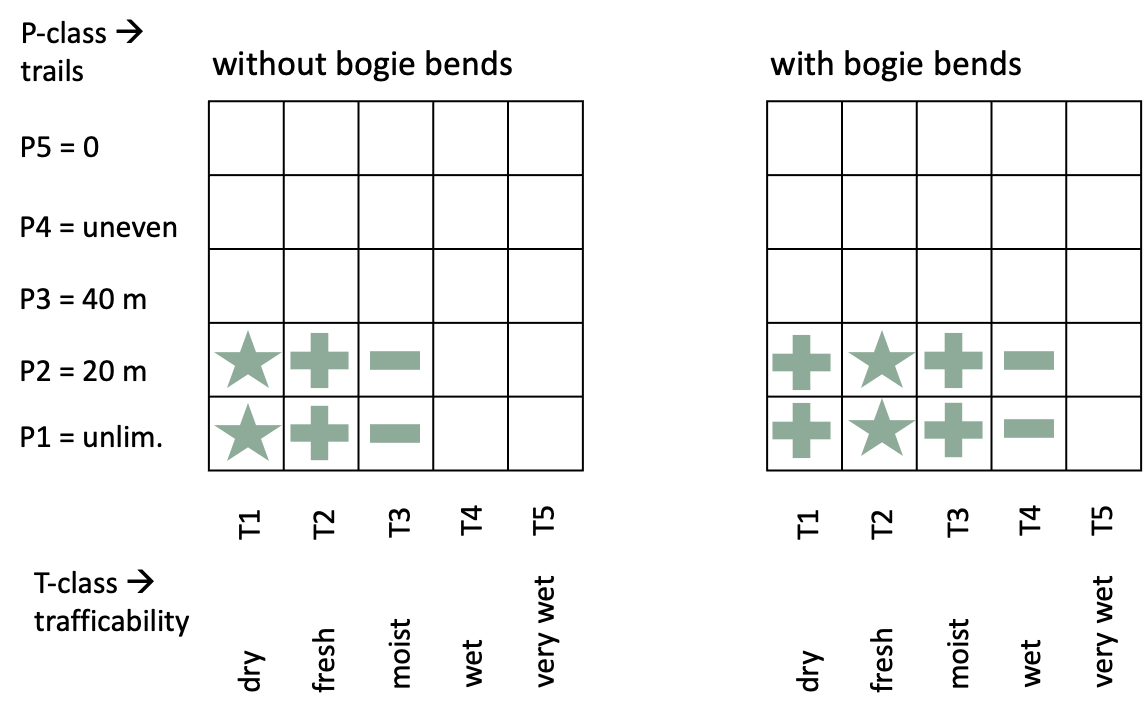

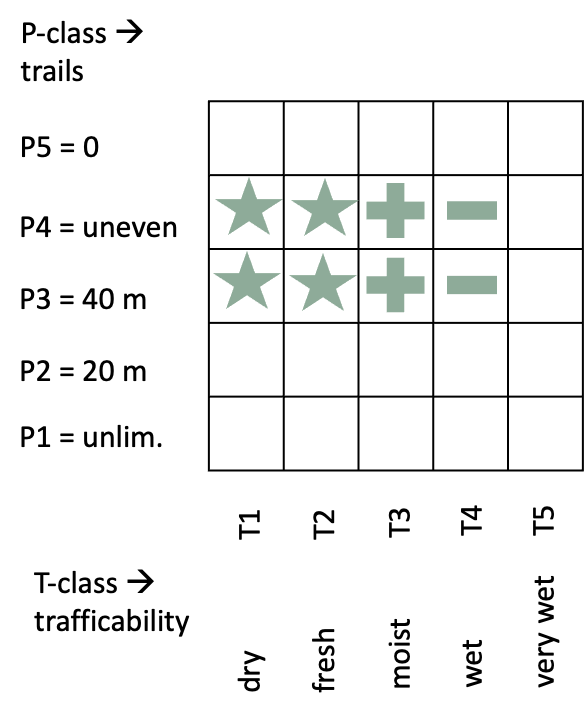

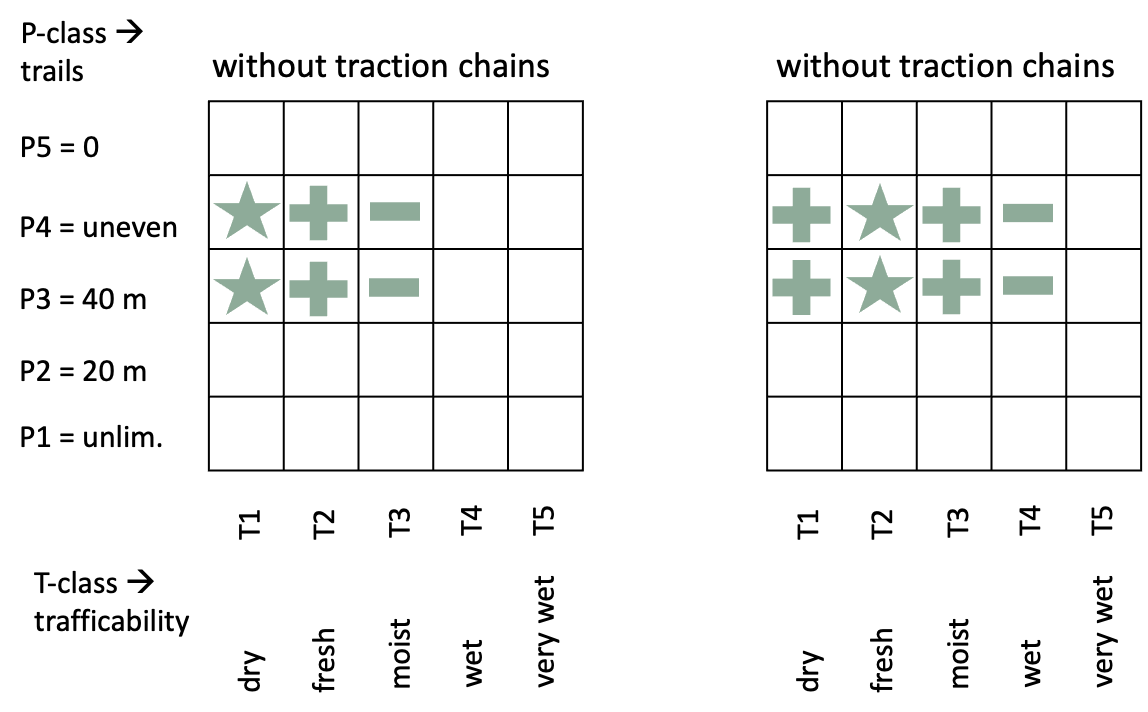

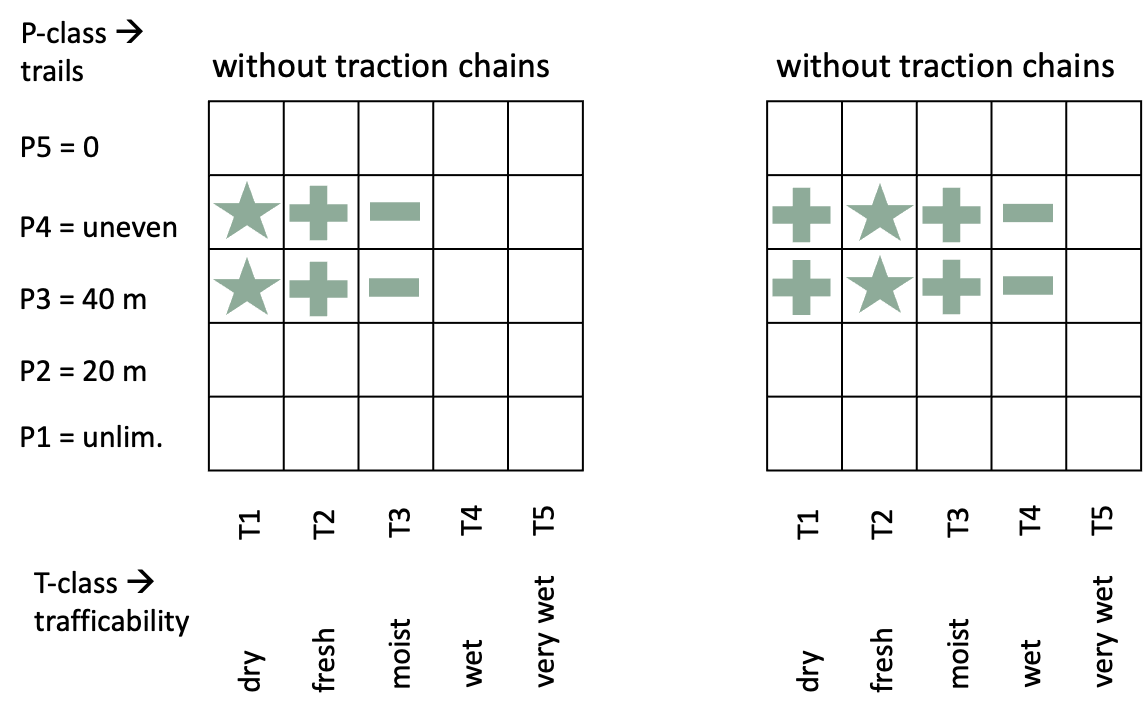

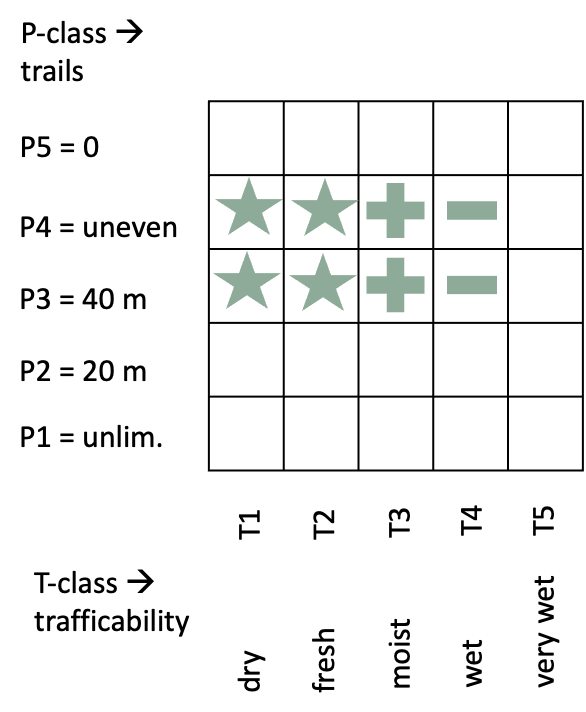

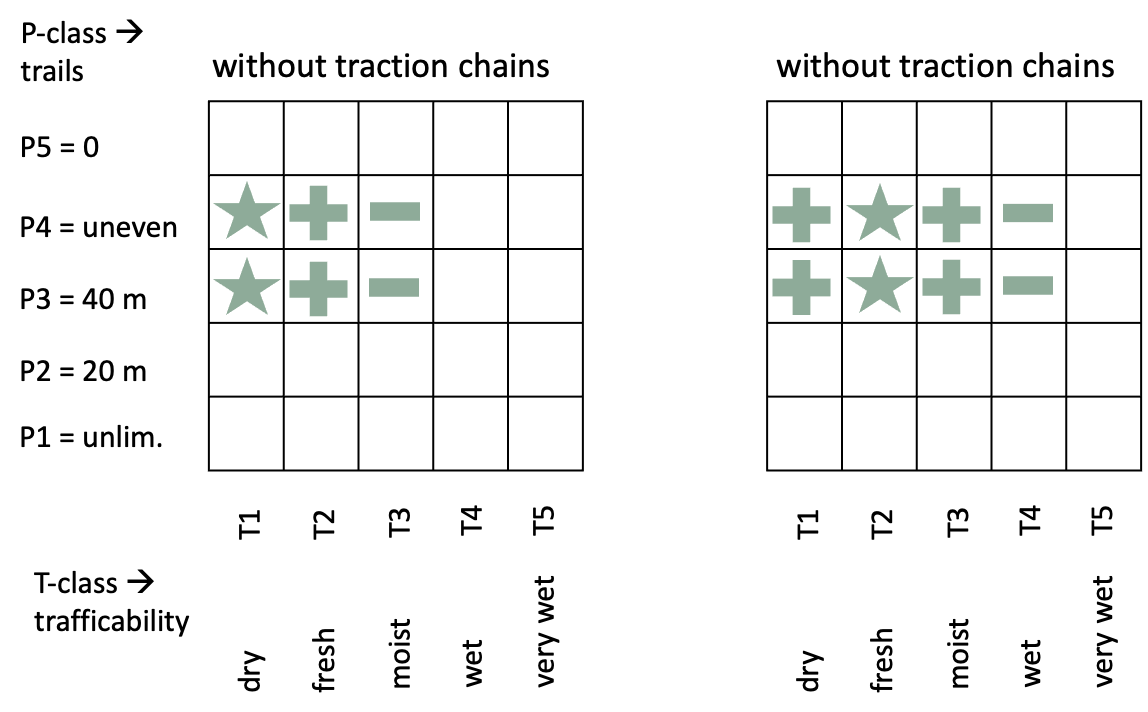

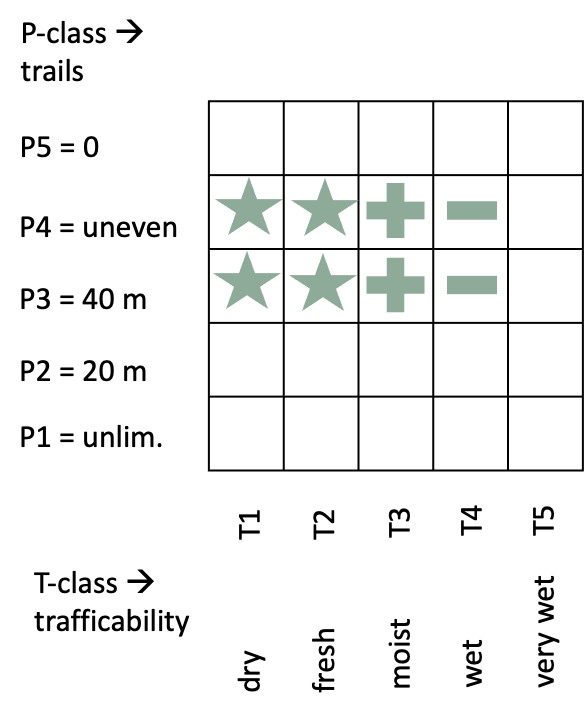

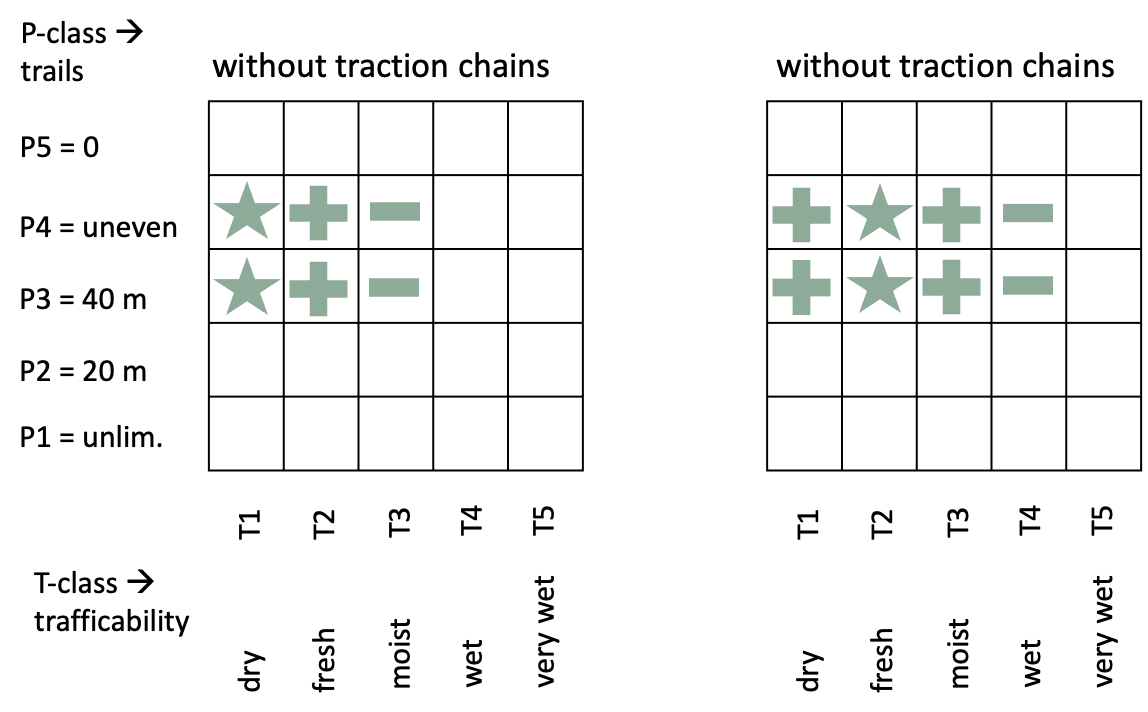

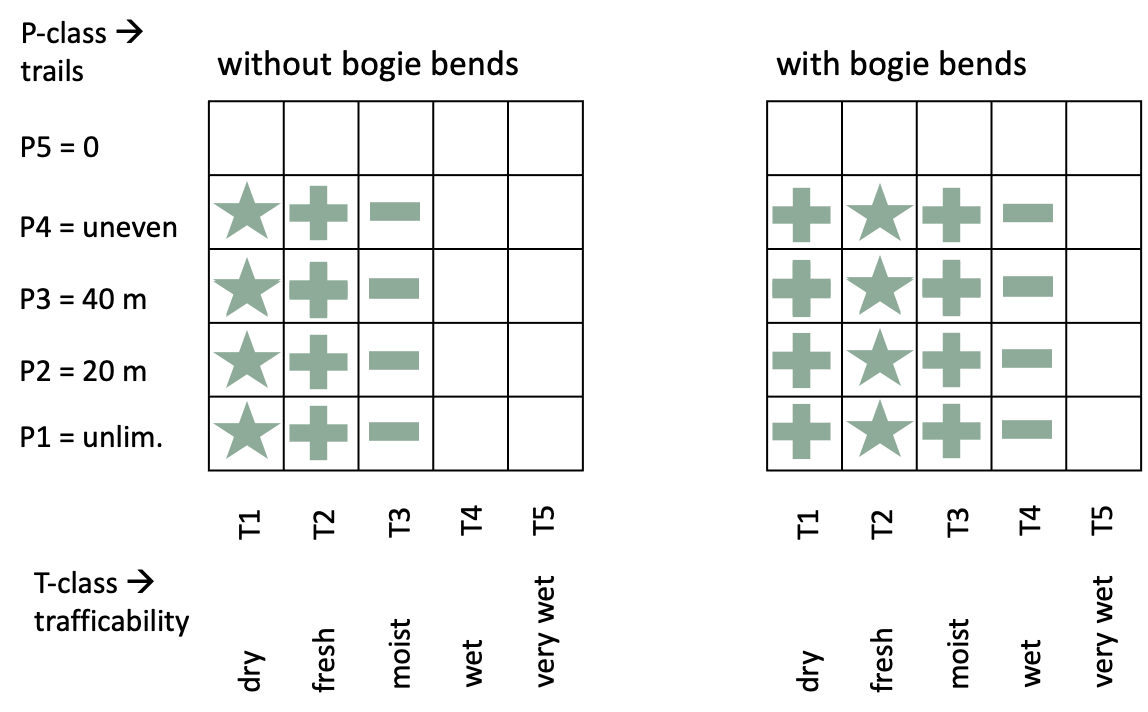

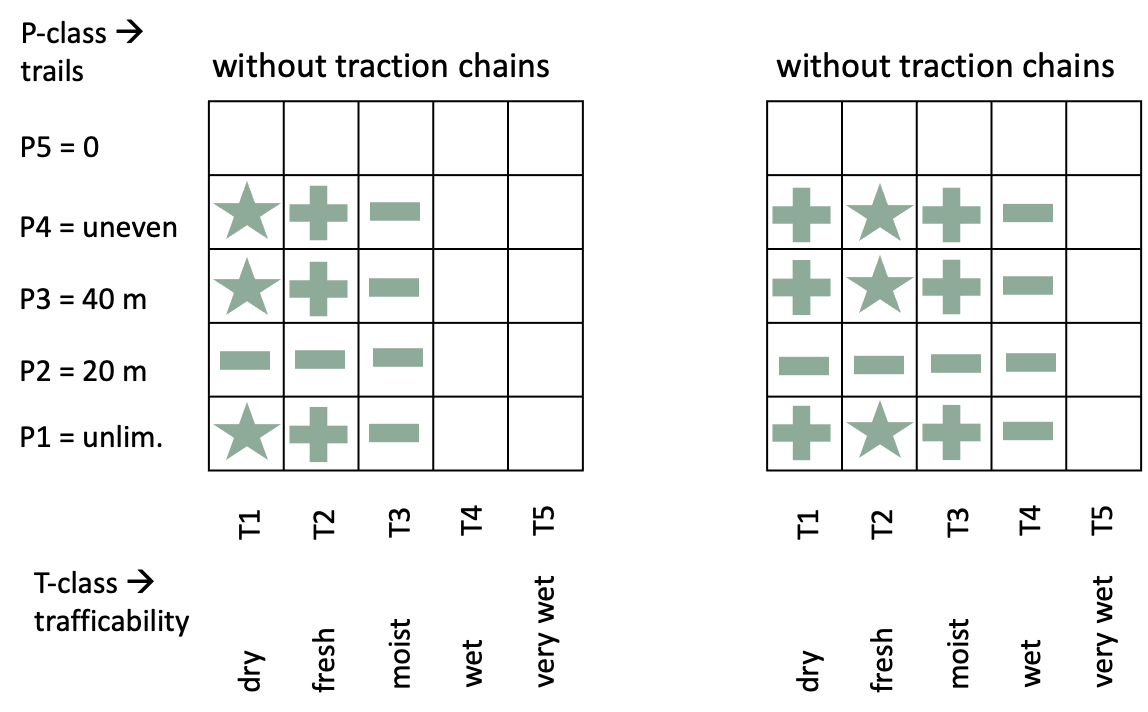

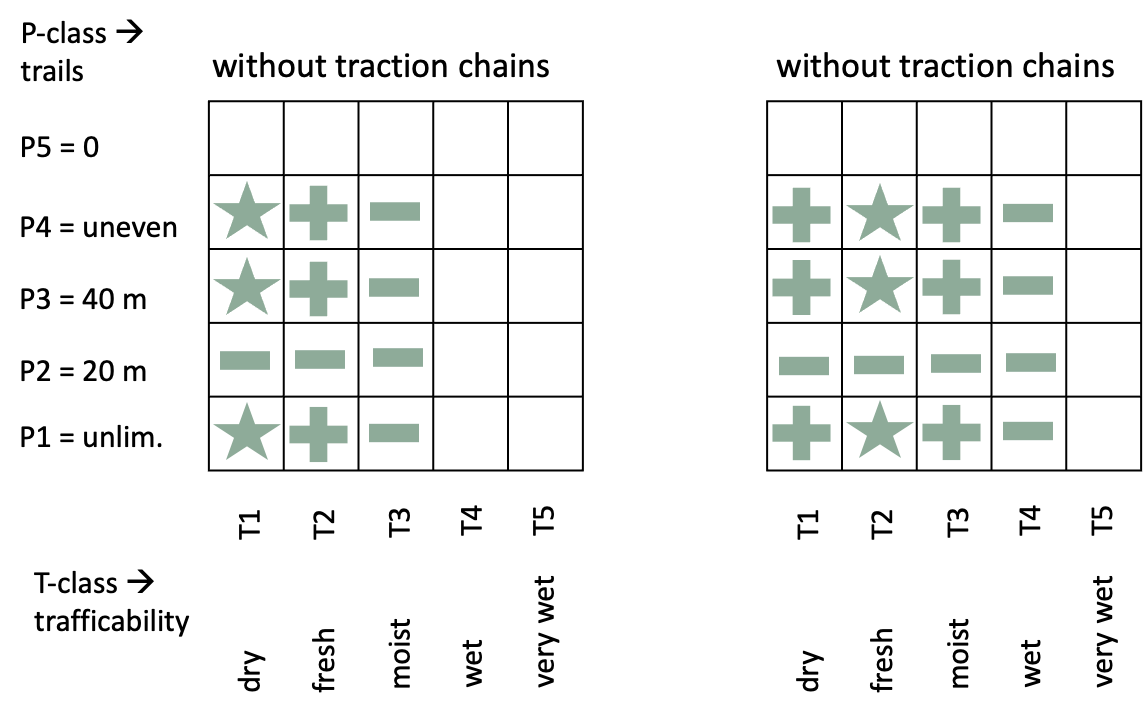

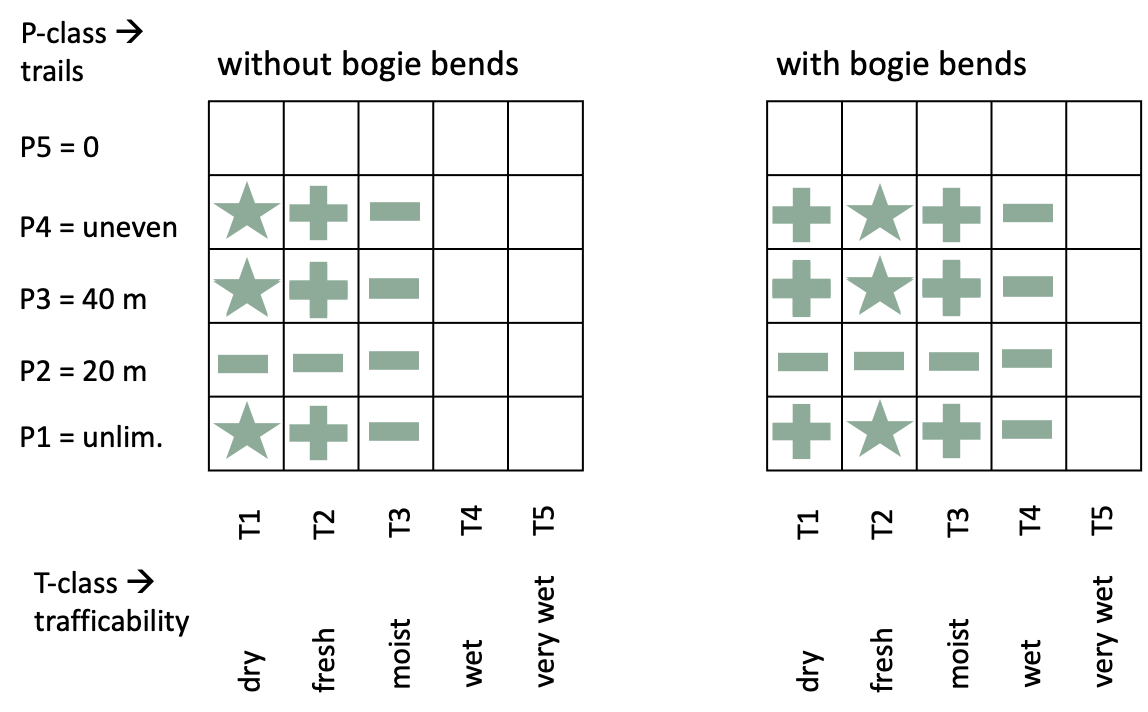

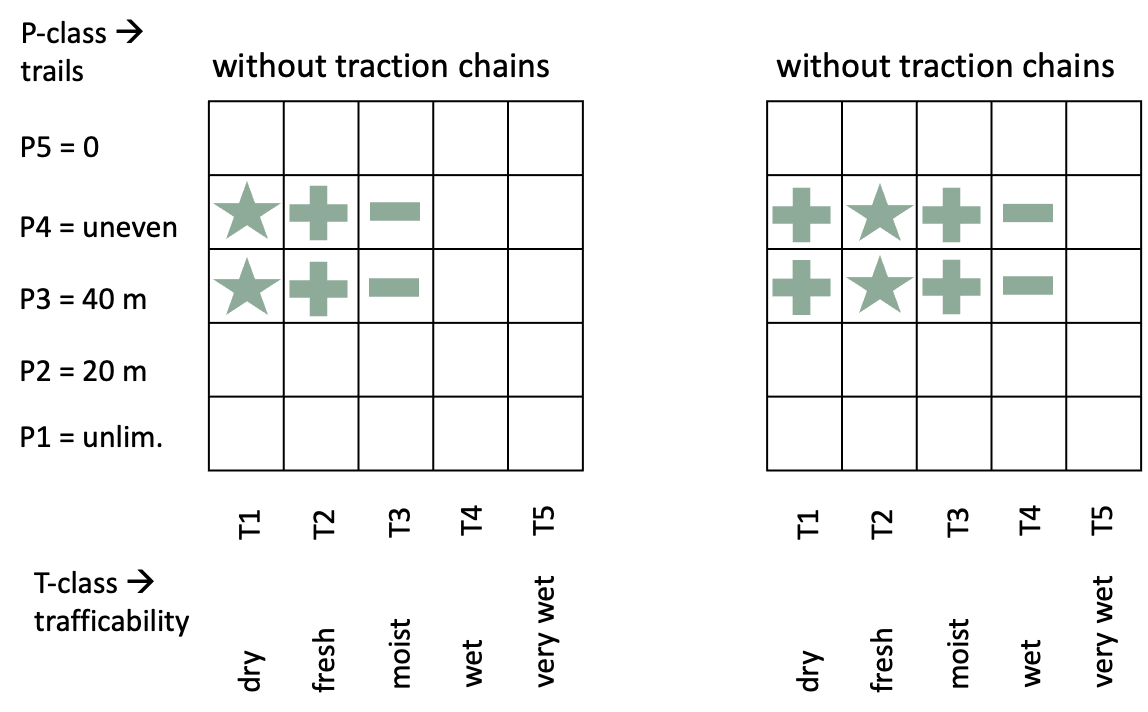

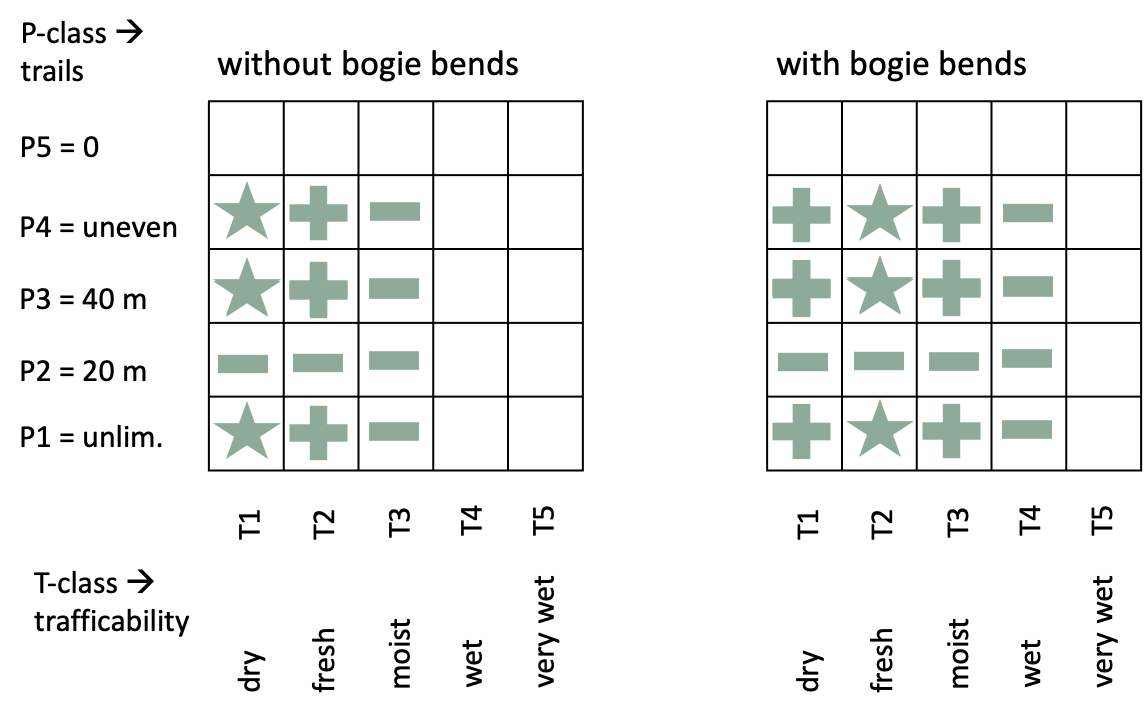

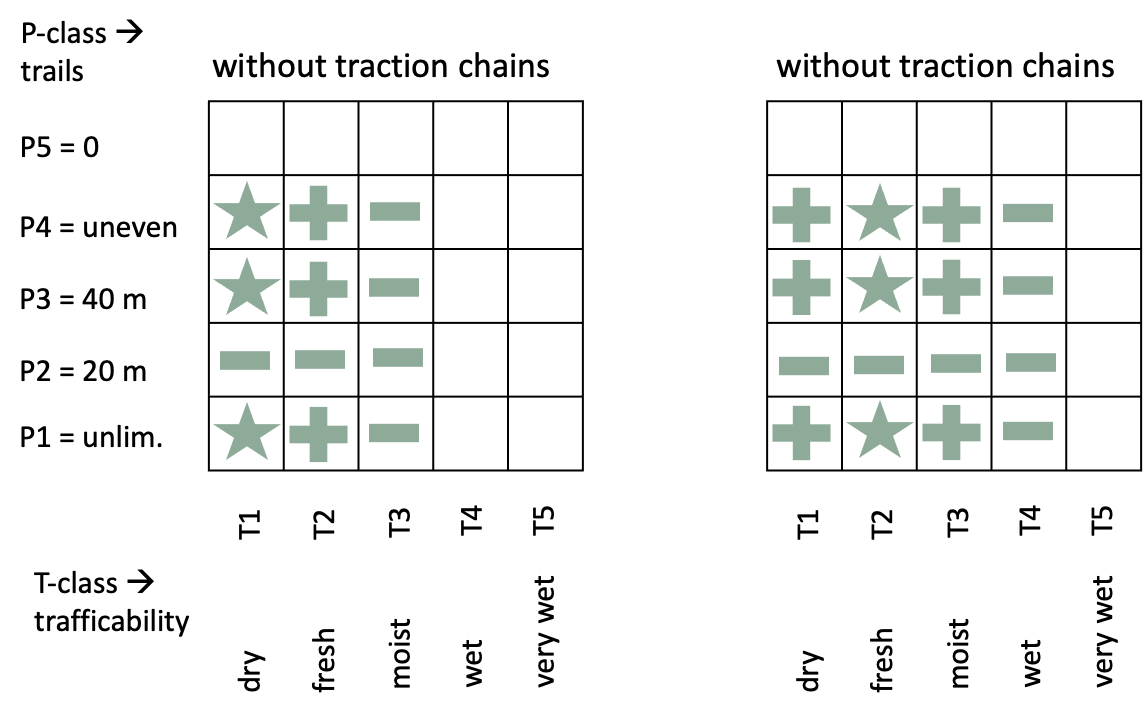

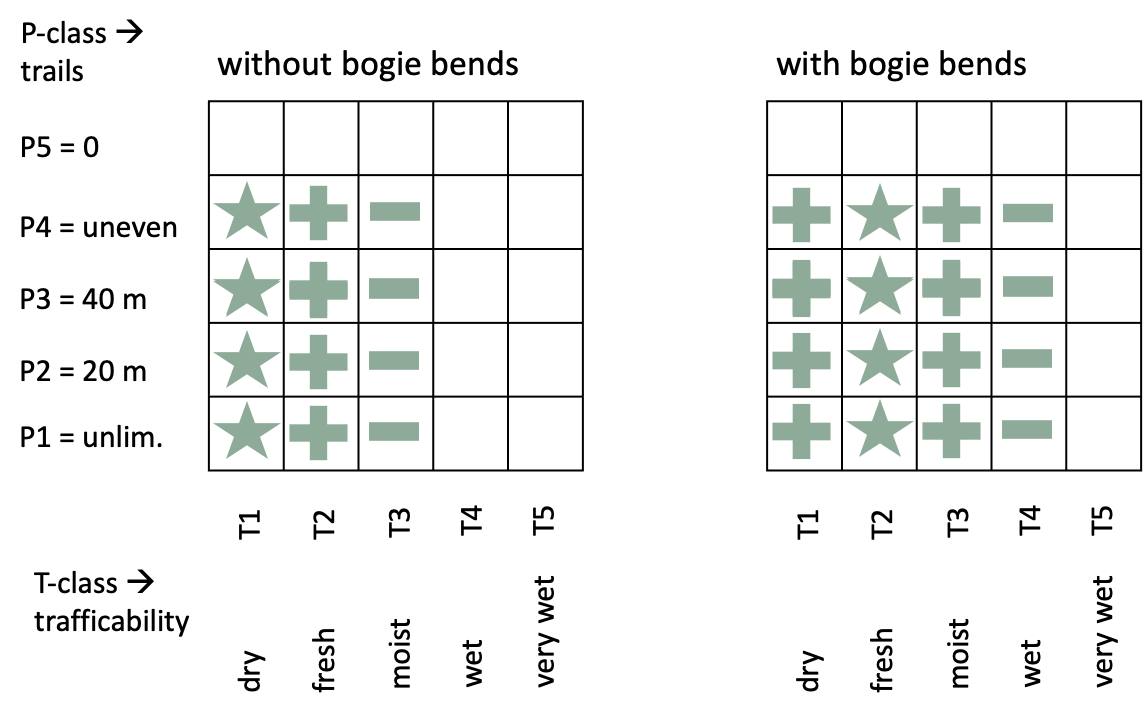

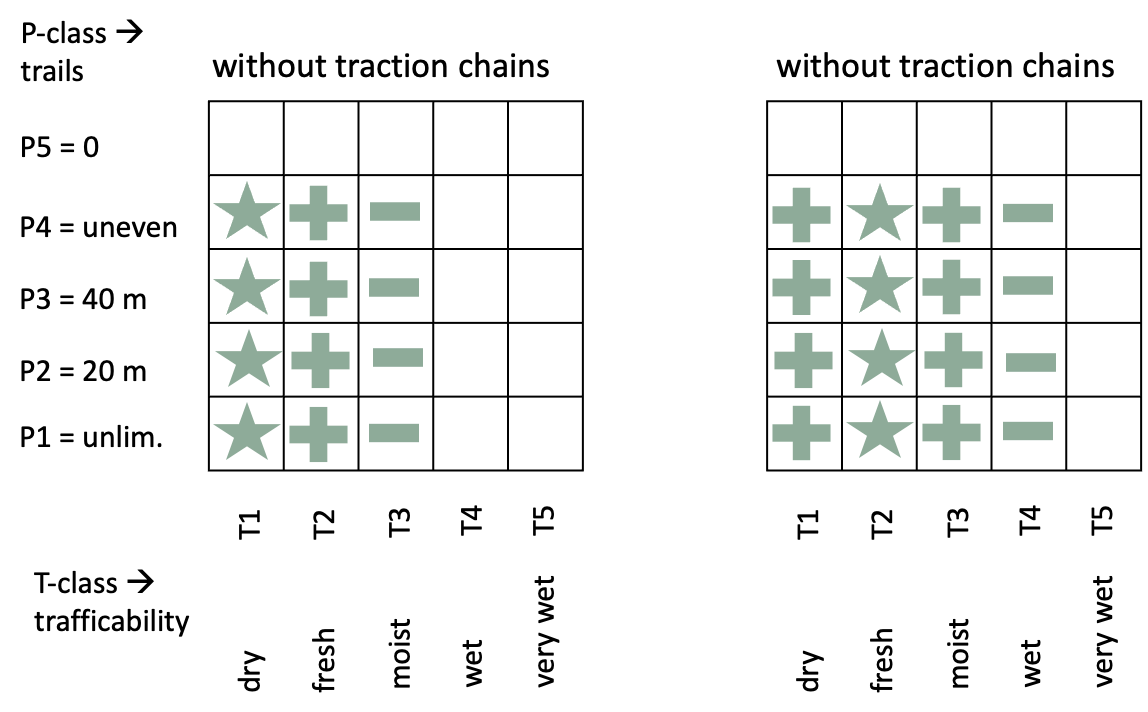

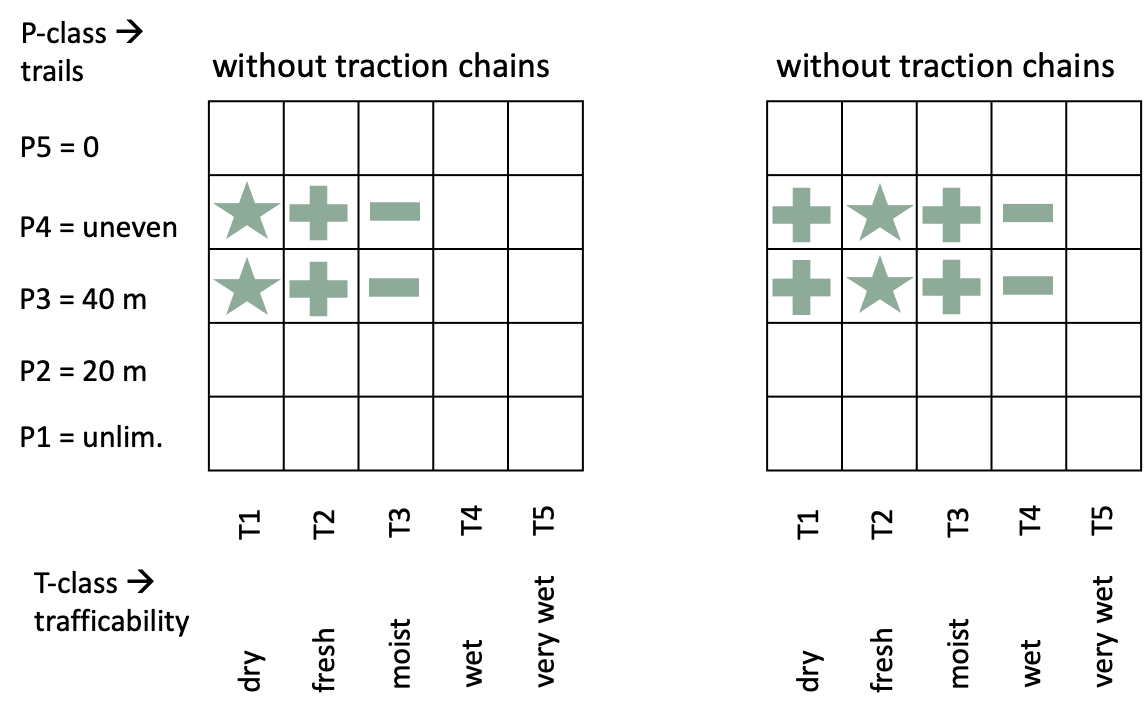

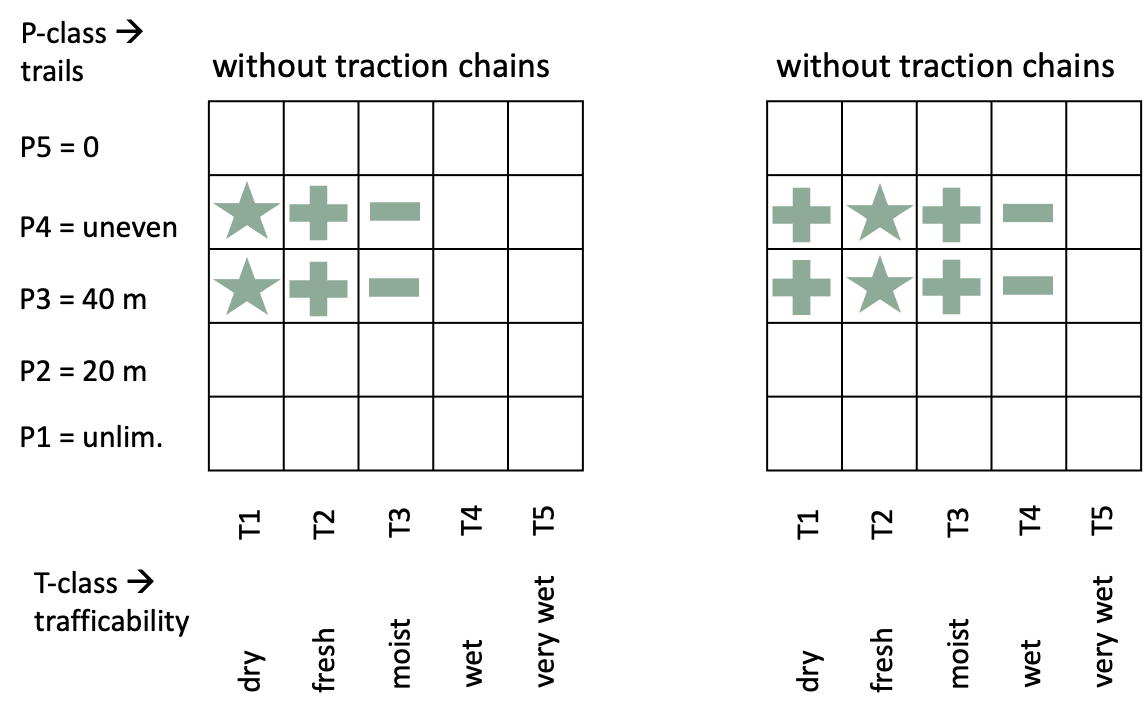

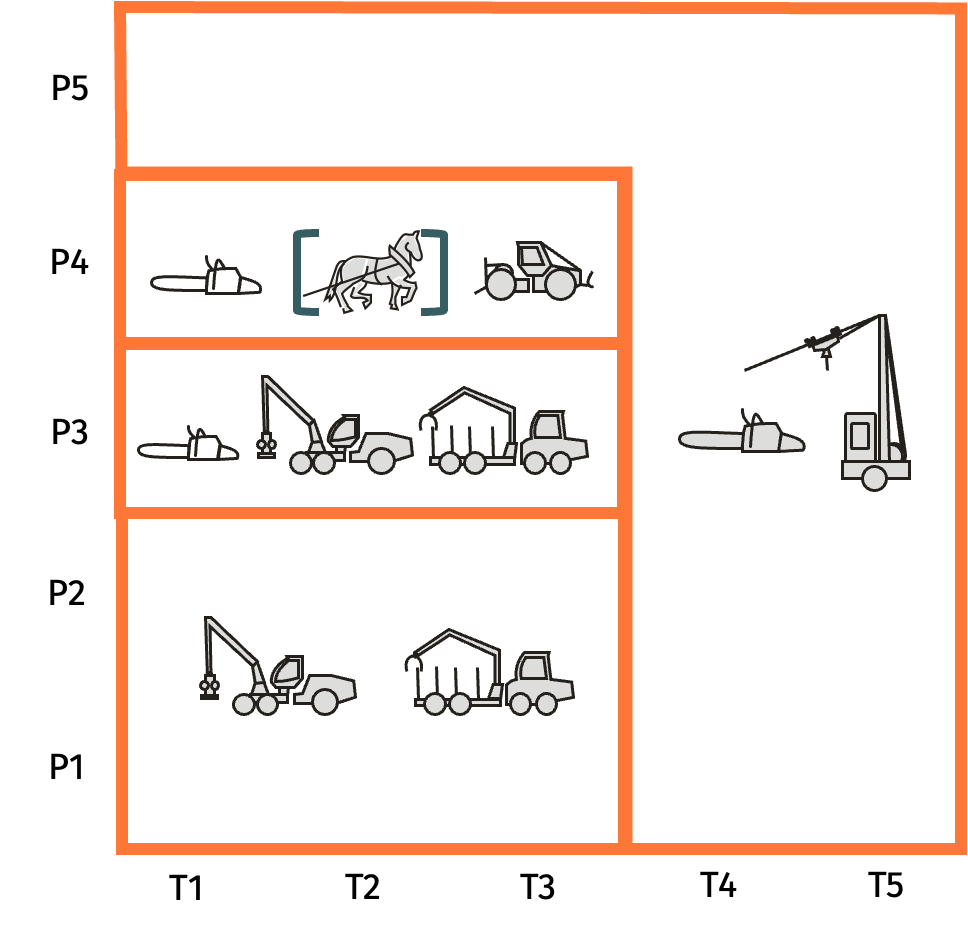

Standard methodsunder certain conditions. T-classes 1-3, P-classes 1 and 2: At stands with temporary trails or permanent trials with 20 m spacing, the fully mechanized ctl-method is best for coniferous trees and for young broadleaf trees, too. T-classes 1-3, P-class 3: Where the 40 m trail spacing is adopted, the almost fully mechanized ctl-method with auxiliary felling by chainsaw sets the standard. T-classes 1-3, P-class 4: At wider trail spacing, which happens mainly in valuable broadleaf stands, partly mechanized tree length methods are preferred. T-classes 4 and 5, all P-classes or all T-classes, but P-class 5: Outside trafficable areas, methods that use the yarder for extraction set the standard. (See more at TDiv PR1-D05)  | |

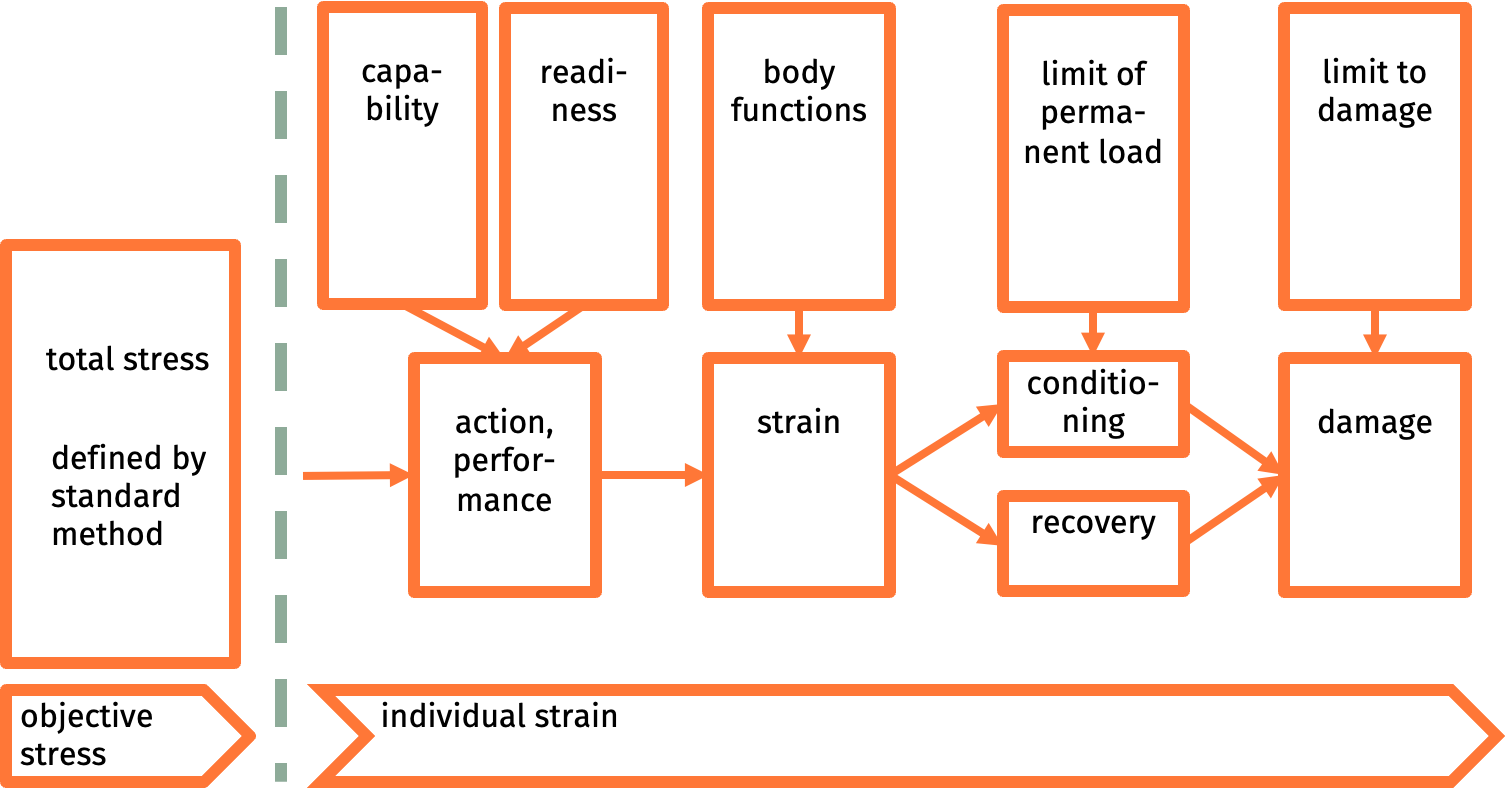

Strain at workErgonomics follows a very simple basic model that derives from physics: When you impact any body with a certain stress, the body will react with a corresponding strain. For example, when you push a wooden stick that is fixed at one end from the side (= stress), it will get bowed (= strain). When we release the stress, the stick will become straight again. This means that the strain will release, too. But if the stress exceeds a certain threshold, the strain can overcome the resistance of the stick, so that it will break. This limit to damage defines the maximum stress that the wooden stick can bear. When we transfer this simple model to working conditions, it must be modified in a couple of points. On the stress side, standard methods have a typical stress. But on the strain side, people are individuals: They have different attributes like gender, age, height, weight, power… In practical life, these attributes are regarded to be invariable. Everybody has his individual abilities and strengths. The same job that is easy for somebody can be difficult for another person; we say that the first person is more talented for this job than the other one. Most jobs require a certain technique. Skilled persons can reach results that will never be possible for unskilled persons. These three factors together – attributes, abilities and skills -form the capability of the person. If their capability fits the demands of the standard method, the strain is low. If not, strain will keep accumulating… But due to organic reasons like health, conditioning, tiredness, hunger and time of the day, the strength can vary. We call that: disposition. On the other side, motivation also has an important influence on. Both together are called: readiness for work. While capability is the potential of any given person, readiness is the percentage of that potential actually activated. When the worker can manage his workload independently, he can find the right pace to keep strain at an acceptable level.But sometimes the strain exceeds that level. For example, when the worker is pushed to reach a certain performance that is beyond his long-term capacity or when he is so motivated that he does not realize that he is overreaching. Then the strain will accumulate. To remain with our simple model above, we look for a permanent work loadthat can be coped with on a day-by-day basis until the worker retires. If the actual strain momentarily exceeds this permanent load, it will not be a problem. In real life, this happens very often. It can even improve the training and exercise (conditioning). But at the end of the day there should be a balance between periods of excessive strain and periods of lower strain (recovery). Otherwise, overload will accumulate and result in damage. Based on this model, there are various possibilities to lower the strain. It is up to the manager to combine them in the best possible way, by: - providing enough time for breaks adequate to the type and quantity of strain (recovery); - encouraging physical and psychological fitness through proper exercise and diet (conditioning); - creating ideal working conditions to increase readiness - adapting work assignments to the physical and psychological capacity of each worker; - the ultimate measure is to assign tasks and to adjust the workloads according to each worker’s individual capacity. But when we have different technical options for performing a certain job, we should prefer the option that fits best the capacity of the available workers. (See more under TDiv PR1-E04)  | |

Strategical levelOriginally the term "strategy" has been used in military and means leading a large army. Today the term is adapted to civil needs and means decisions that create potential for action in the future. In our context of forest operations, the person, who is responsible for strategical decisions (a forest district officer, e.g.), decides about investments in tools, machines and workforce. His job is to develop the resources that are necessary to solve any future problems. (see more in TDiv PR1-A05)

| |

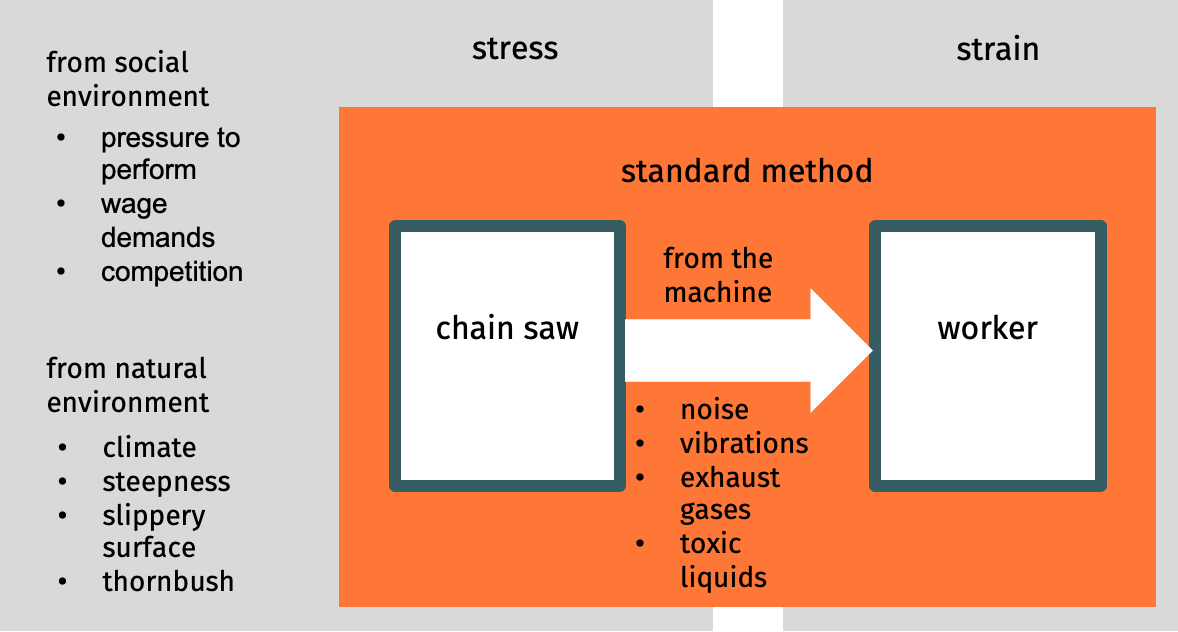

Stress and strainErgonomics follows a very simple basic model that derives from physics: When you impact any body with a certain stress, the body will react with a corresponding strain. For example, when you push a wooden stick that is fixed at one end from the side (= stress), it will get bowed (= strain). When we release the stress, the stick will become straight again. This means that the strain will release, too. But if the stress exceeds a certain threshold, the strain can overcome the resistance of the stick, so that it will break. This limit to damage defines the maximum stress that the wooden stick can bear. When we transfer this simple model to working conditions, it must be modified in a couple of points. On the stress side, the working method is connected with typical stresses. For example at motor-manual processing: The chainsaw produces noise and vibration, has toxic emissions and is very dangerous. The natural working site can be heavy and dangerous, and the social relations with colleagues and superiors may cause stress, too. This stress seems very complex. But social stress from group dynamics normally has nothing to do with the standard work method and pertains to social science, not ergonomics... And stress coming from the natural environment causes a percentual scaling of the stress that is connected with the working method as such. So, the composition of stress is very typical for this specific working method. Thus: Without knowing how the stressing factors are combined and how they work together, the complex stress is typical for this standard method and can be assessed by expert opinion. The simple model that we had above feigns that the stress of a standard method will permanently cause the same strain for the worker. But here the reality is much more complex, too, because all workers are different concerning attributes, health, conditions etc. (See more under TDiv PR1-E03)  | |

Suitability, ecologicalSuitability, ecological see ecological suitability | |

Suitability, economicSuitability, economic see economic suitability

| |

Suitability, socialSuitability, social see social suitability | |

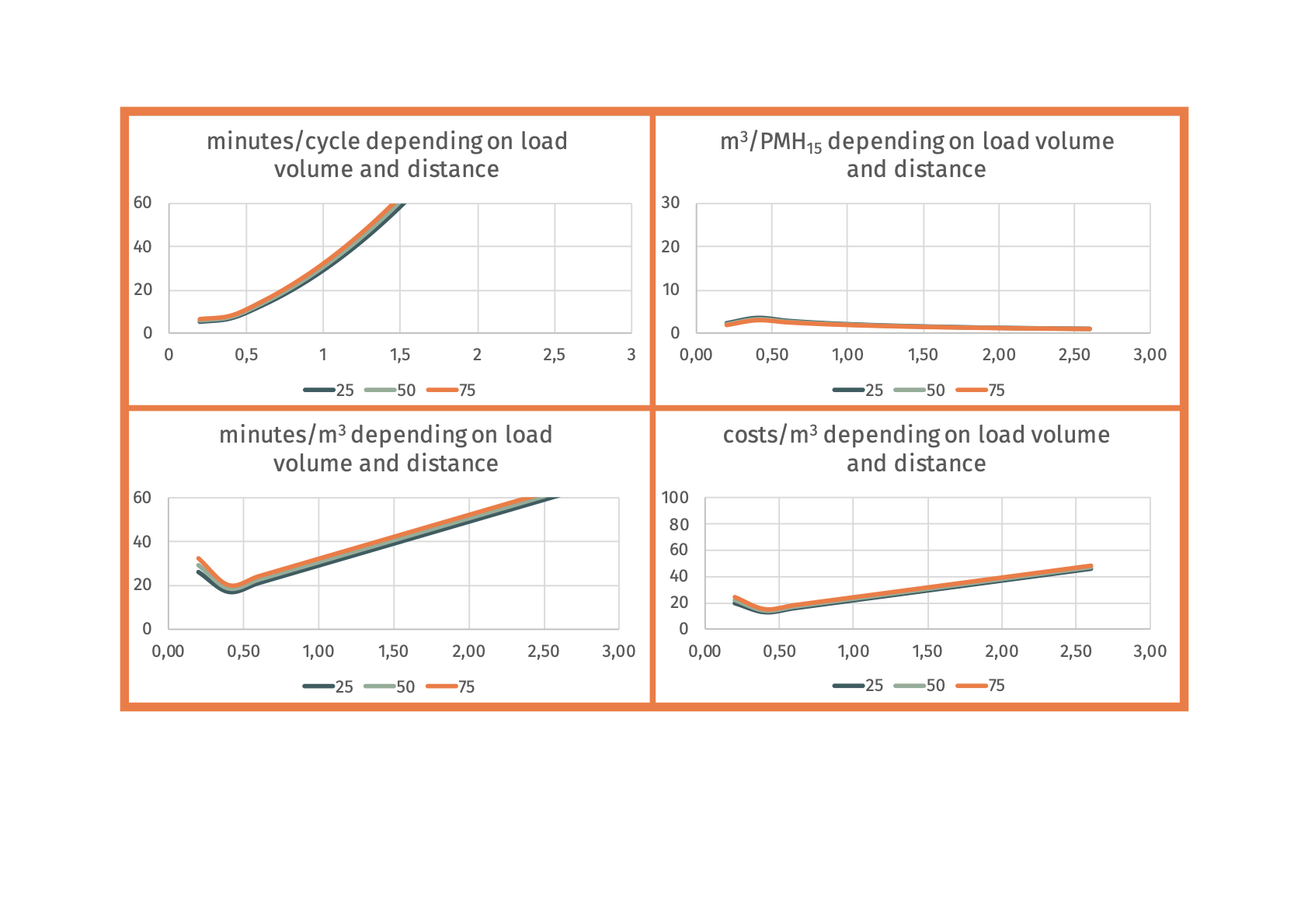

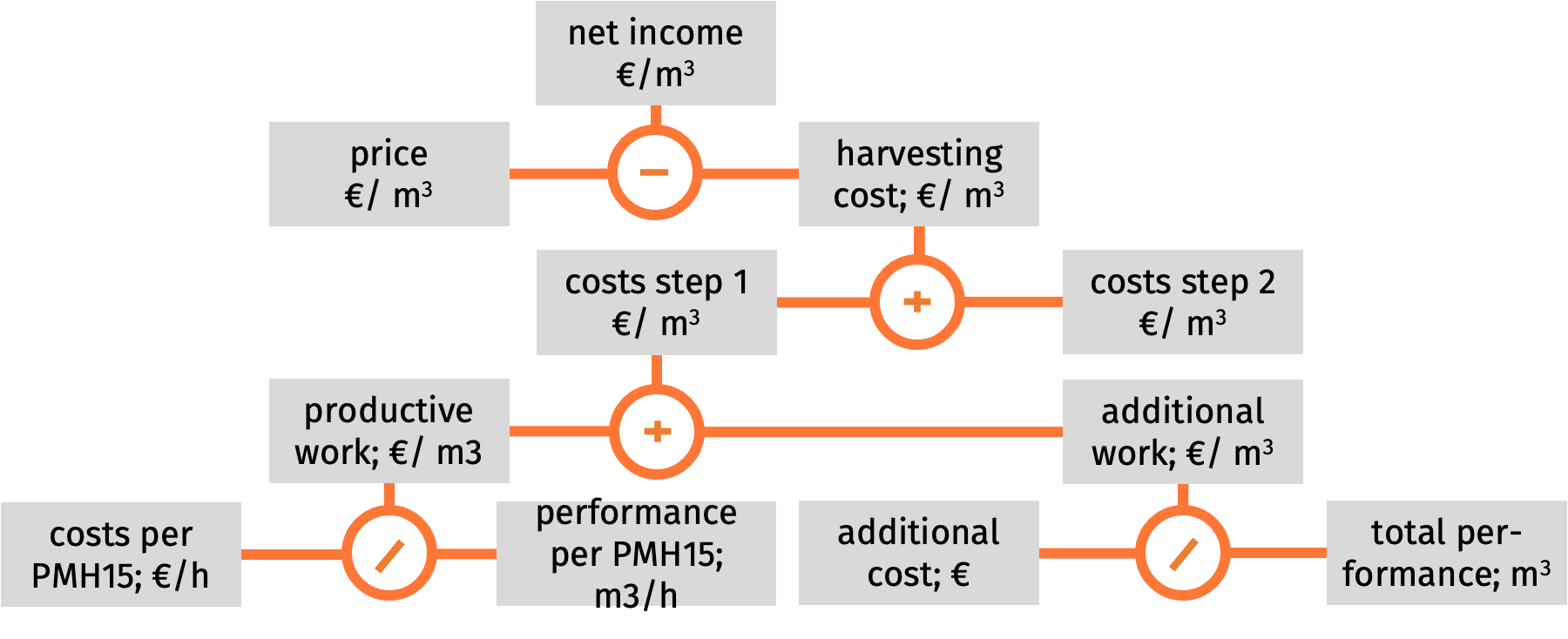

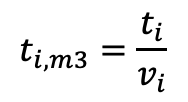

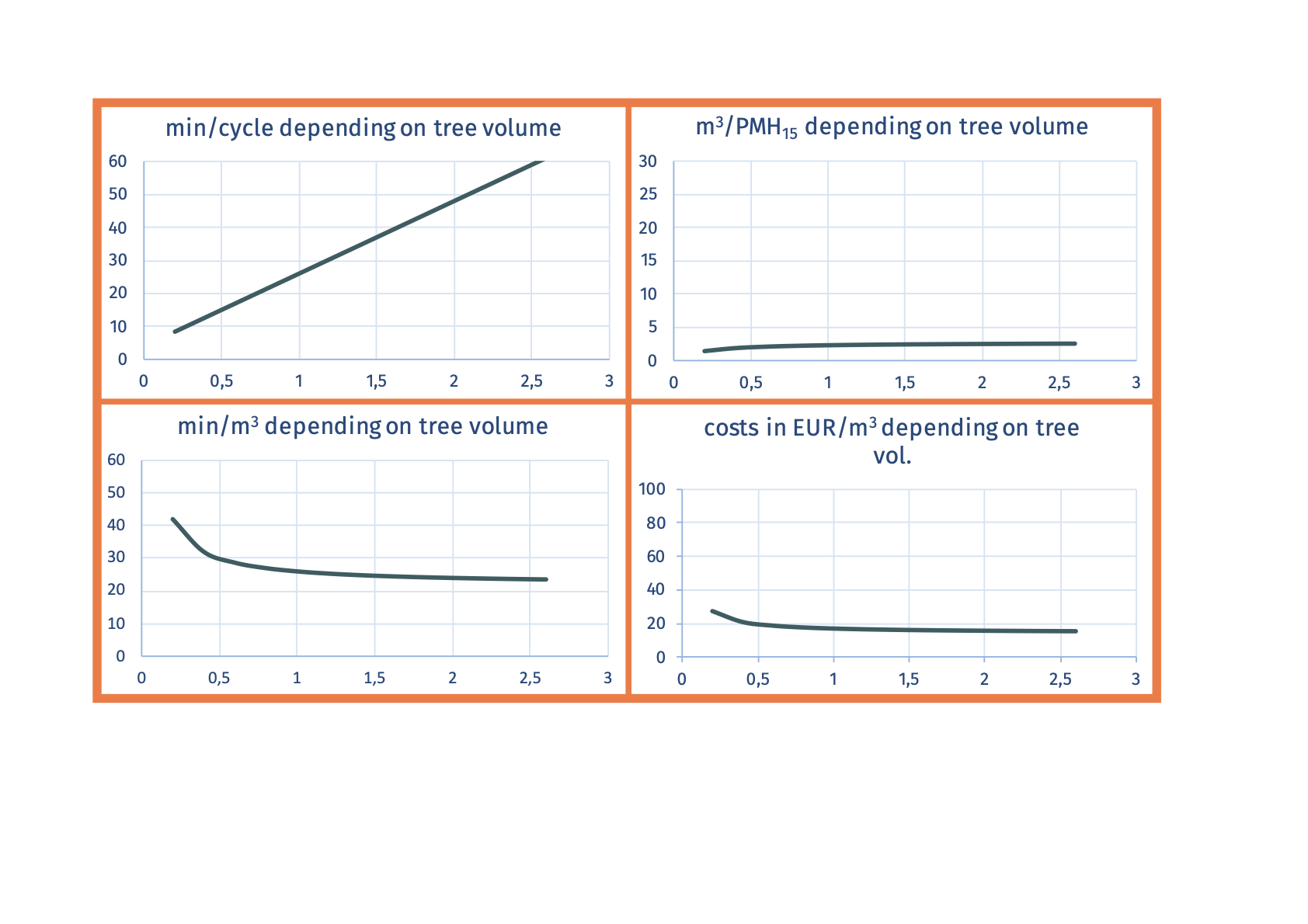

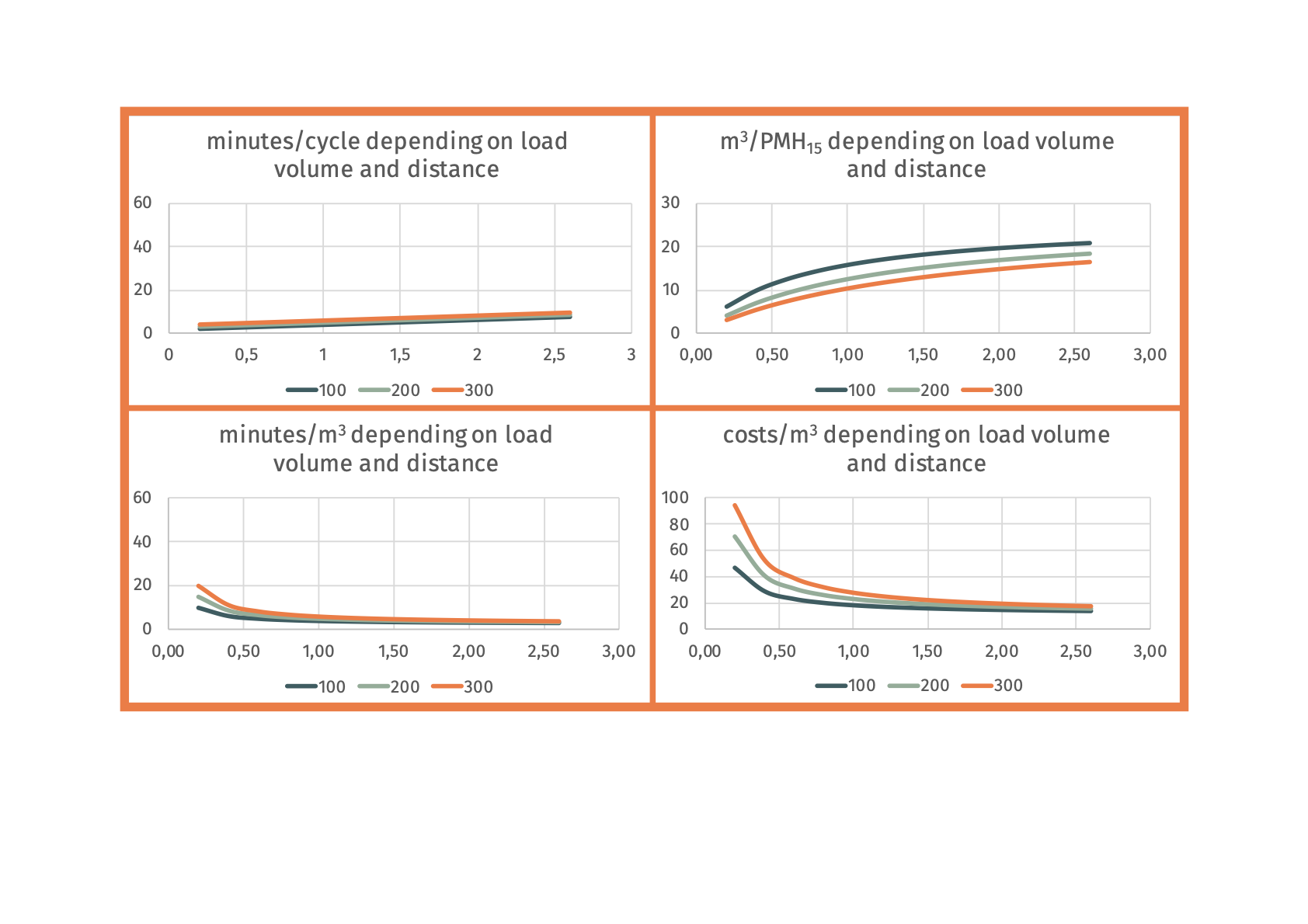

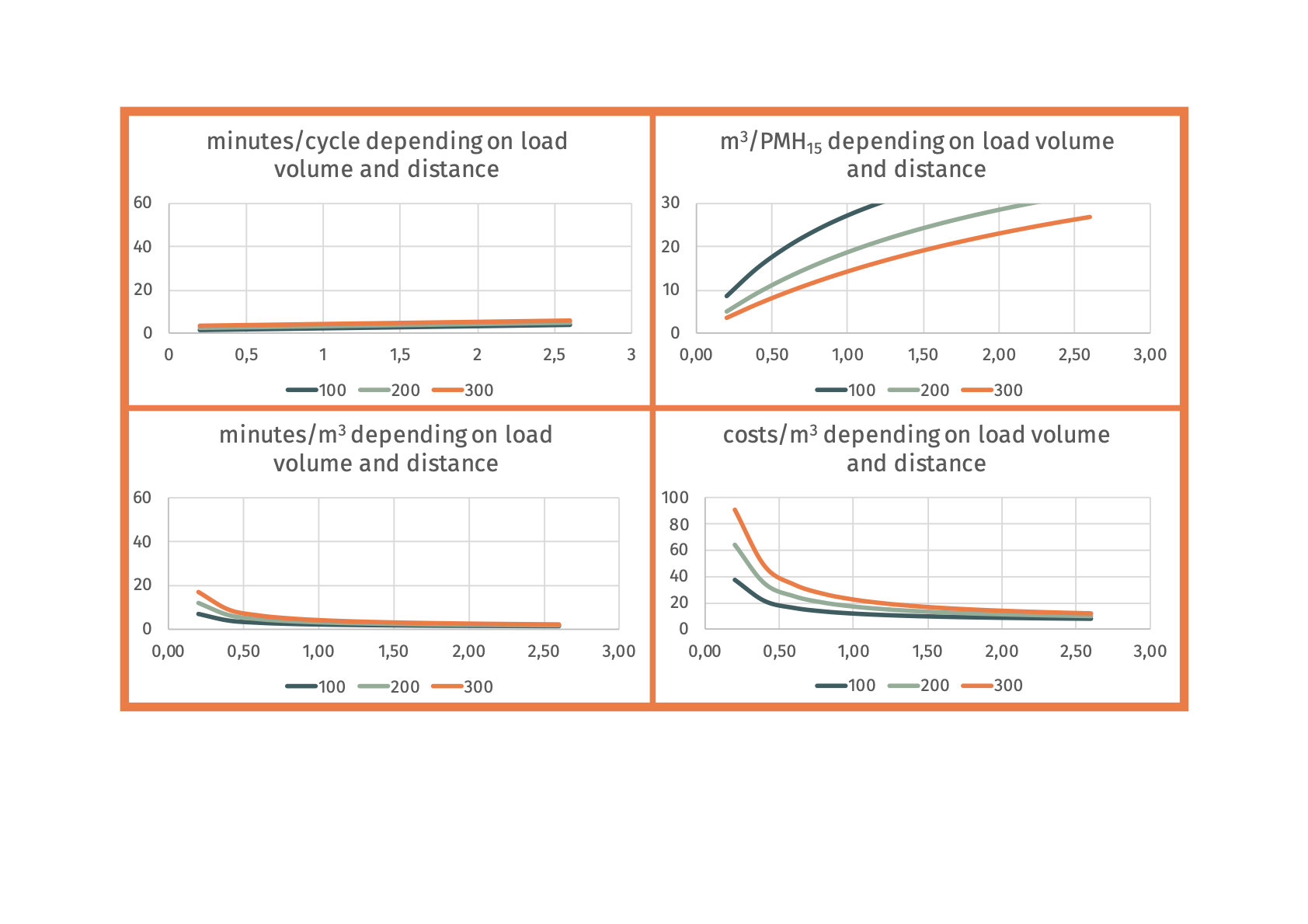

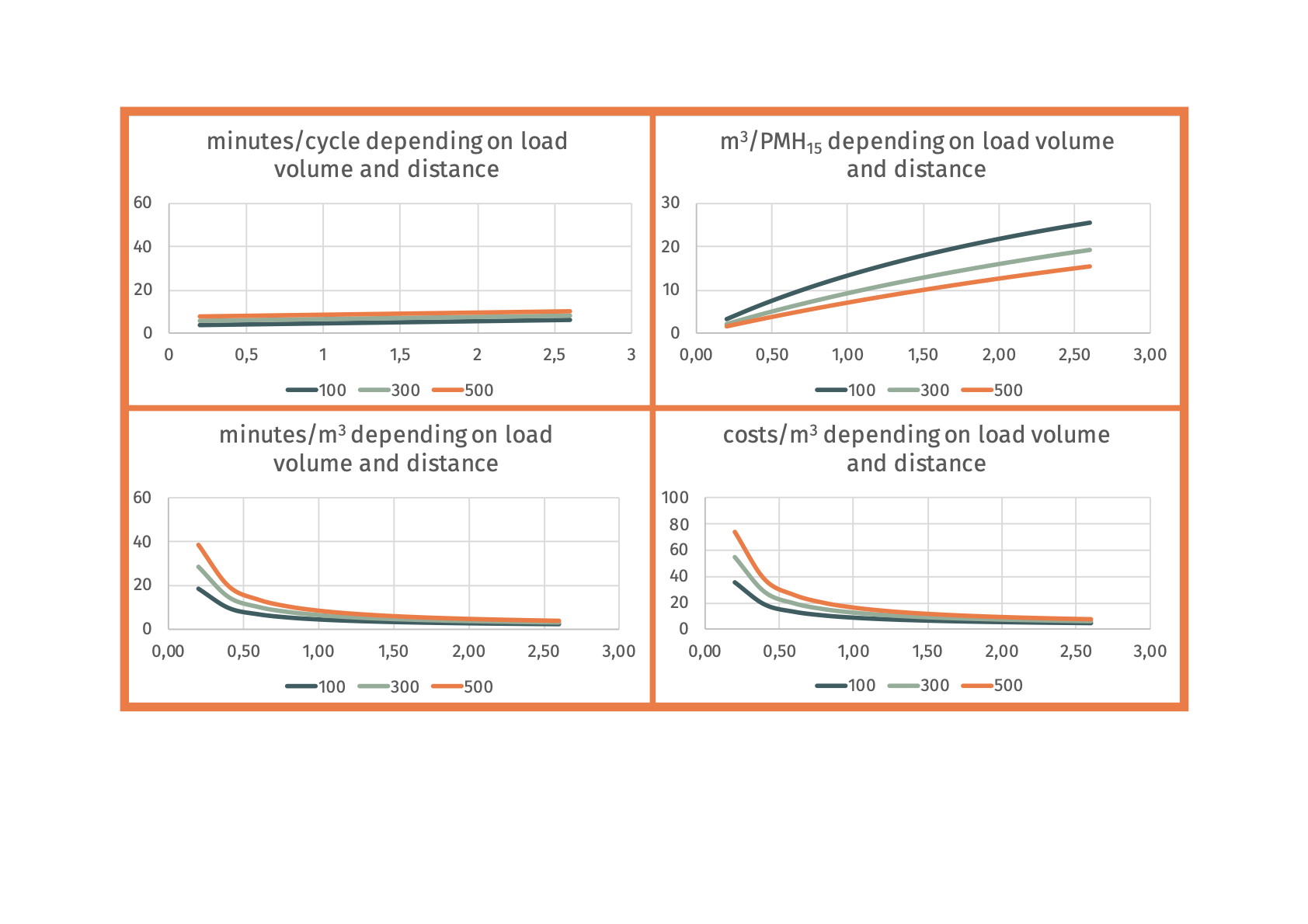

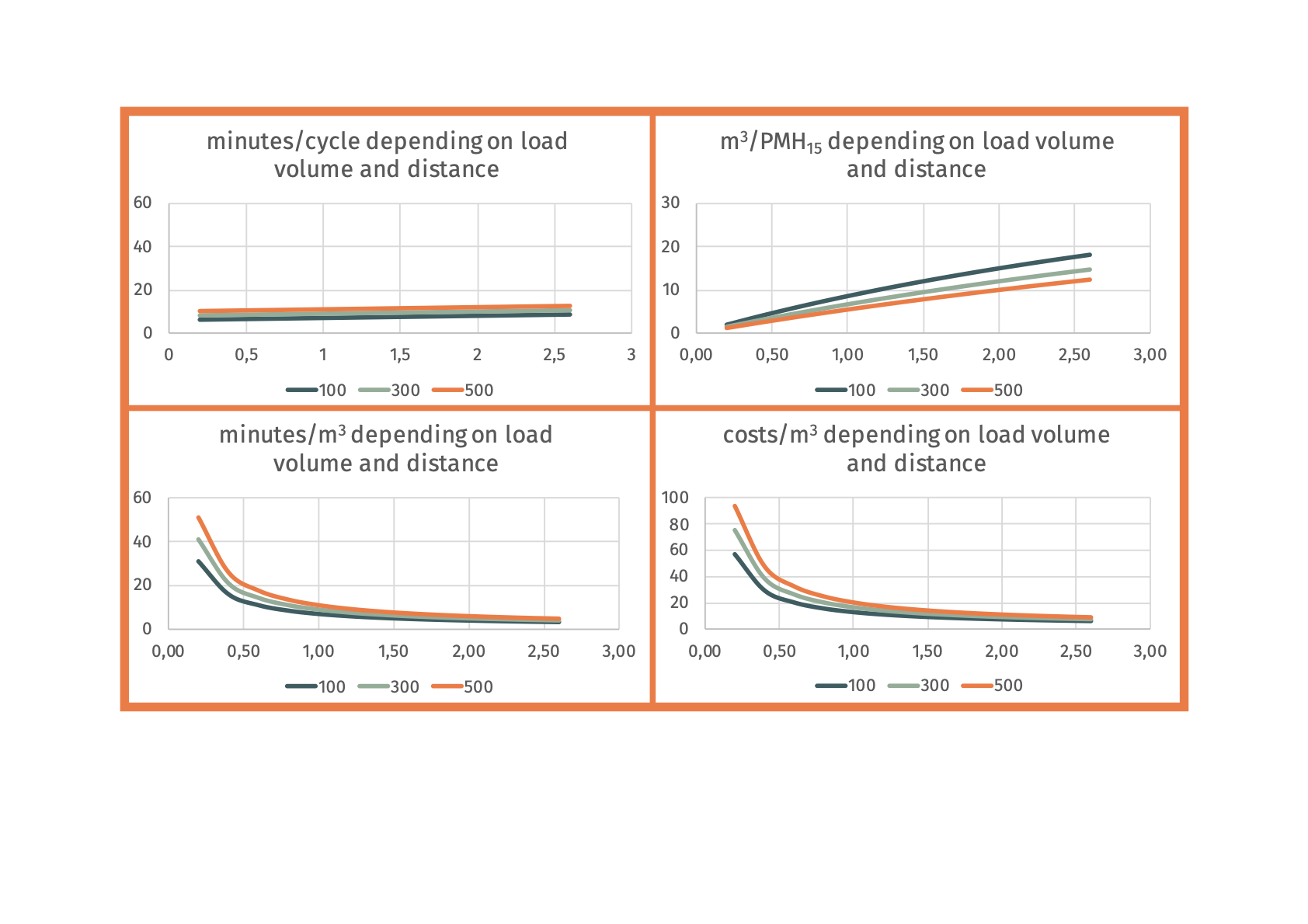

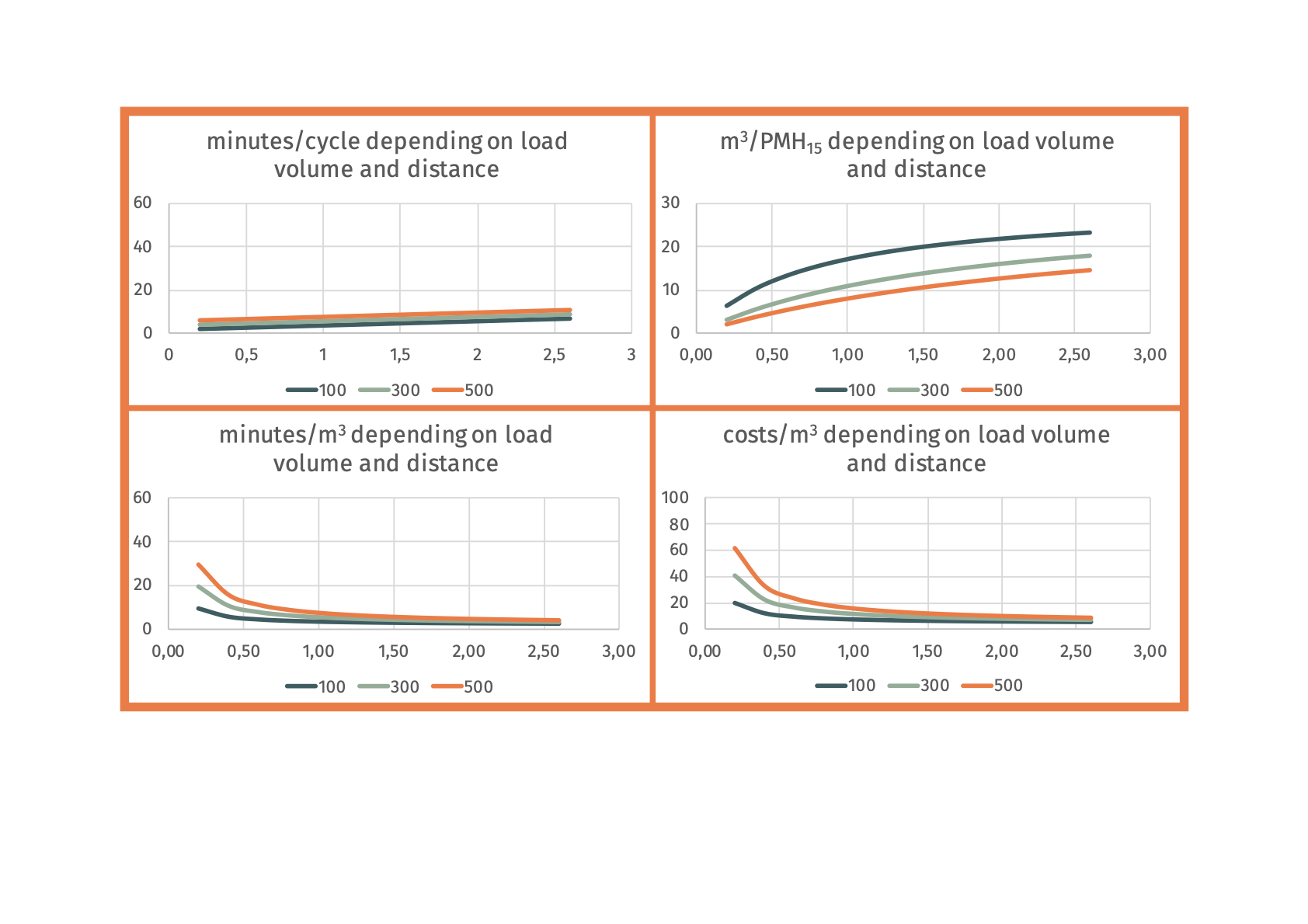

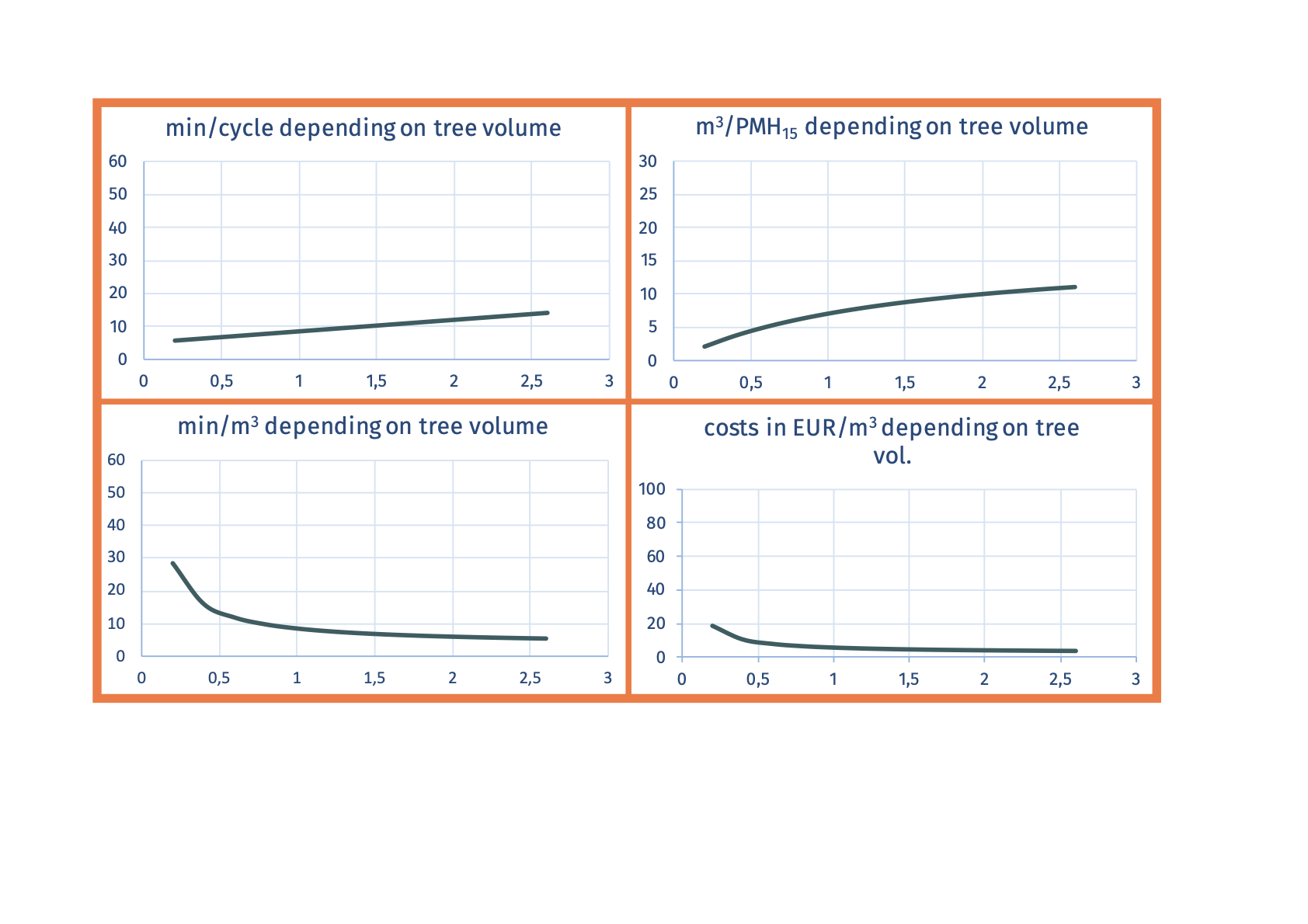

System costsWhen we sell timber on the market, we receive the price of the logs. But we also invest some money to harvest the trees and transport the logs. So only the difference between price and costs, the net income, is available for the company's profit. Let us assume here, that the price only depends on the qualitative and quantitative attributes of the harvest. Thus, the income mostly is influenced by the system costs. To maximize the income, we need to minimize the total system costs. Since most harvesting processes are composed by two or more sub-processes, the costs of a total process are given by the sum of the costs of its constituent sub-processes. But the machines and the operators are charged at an hourly rate. Given this information, we must first calculate the costs per hour. In science, we call this hour PMH15 that means productive machine hour including short interruptions of the work up to 15 minutes. To do this, we use the engineering formula. In that working hour, the system will process a certain number of products. The ratio between products and time is called system performance. When we know the performance, we can match the costs per hour to the production in order to get the costs per unit of a product. For timber harvesting, we need to divide the costs per hour by the productivity, that is: m3 per hour.

Machines and employees cost money, whether they work or not. This means that the system will generate a cost even when it is not producing anything. Those additional unproductive times (i.e. more than 15 minutes per hour) and costs that are necessary to production (maintenance, preparation etc.) must also be accounted for. To do this, we add all additional costs and divide them by the total sum of m3 on that specific working site. Finally the costs of the sub-systems must be added to find the total system costs. (See more at TDiv PR1-C01)

| |

System costs per hour | |

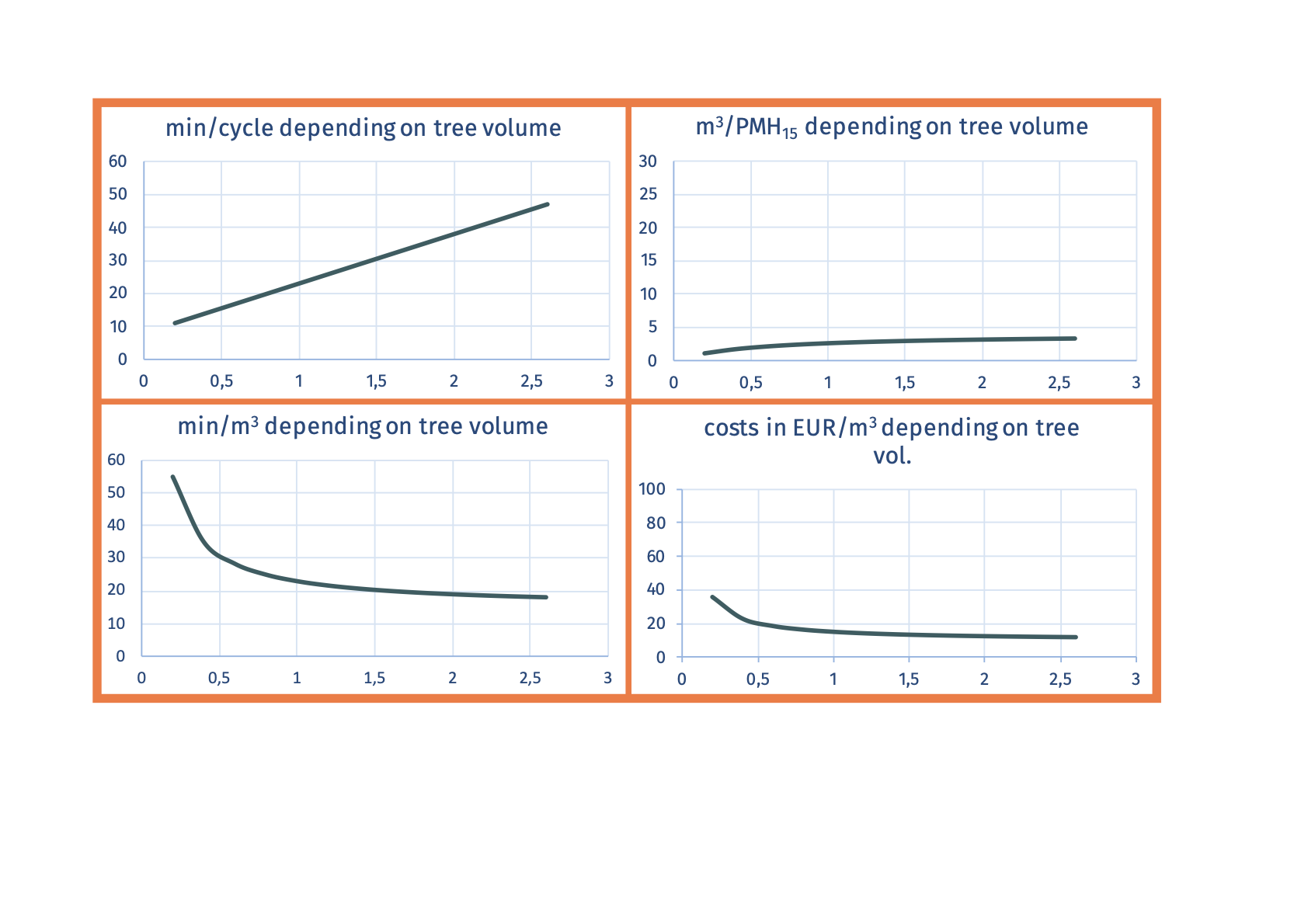

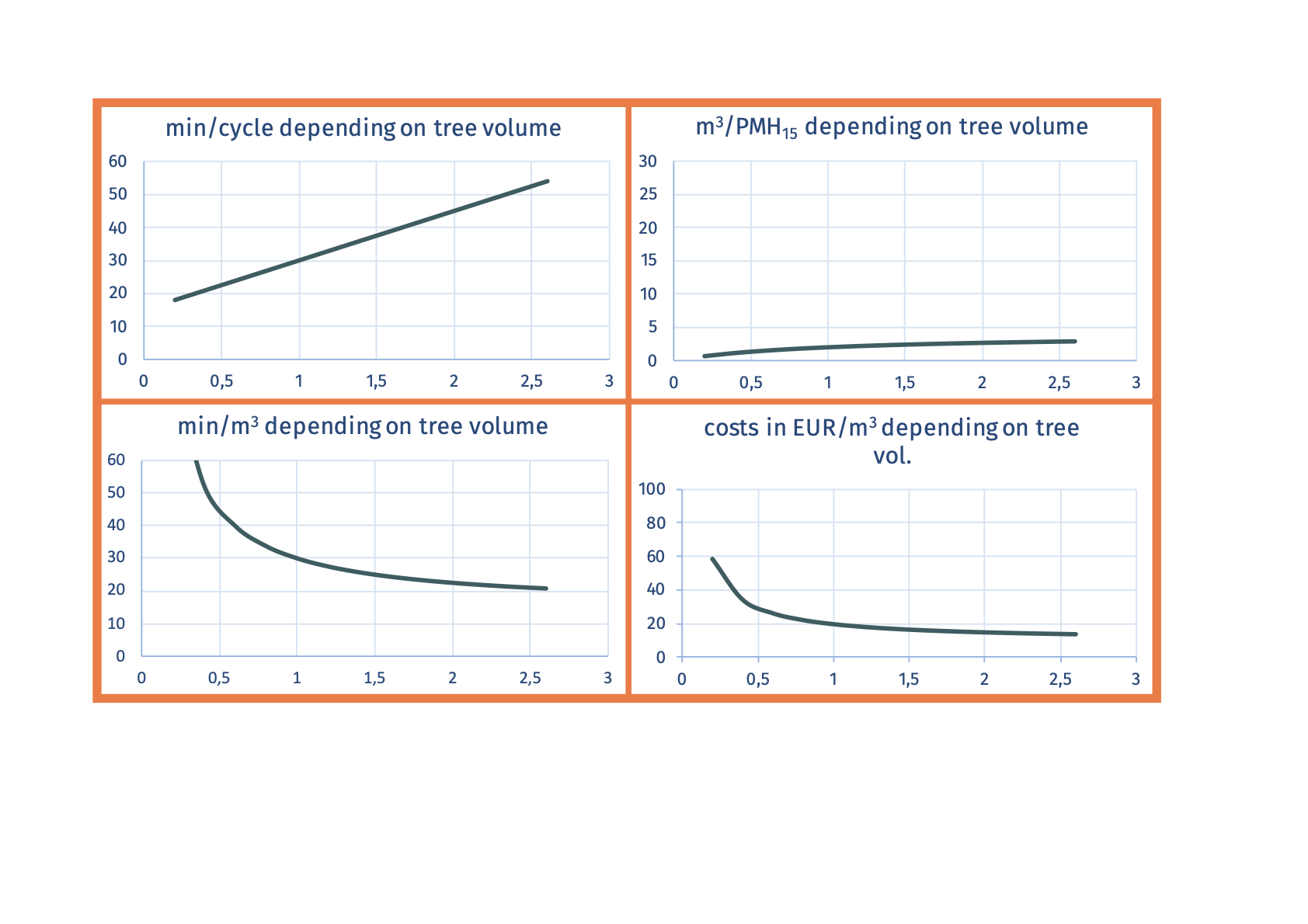

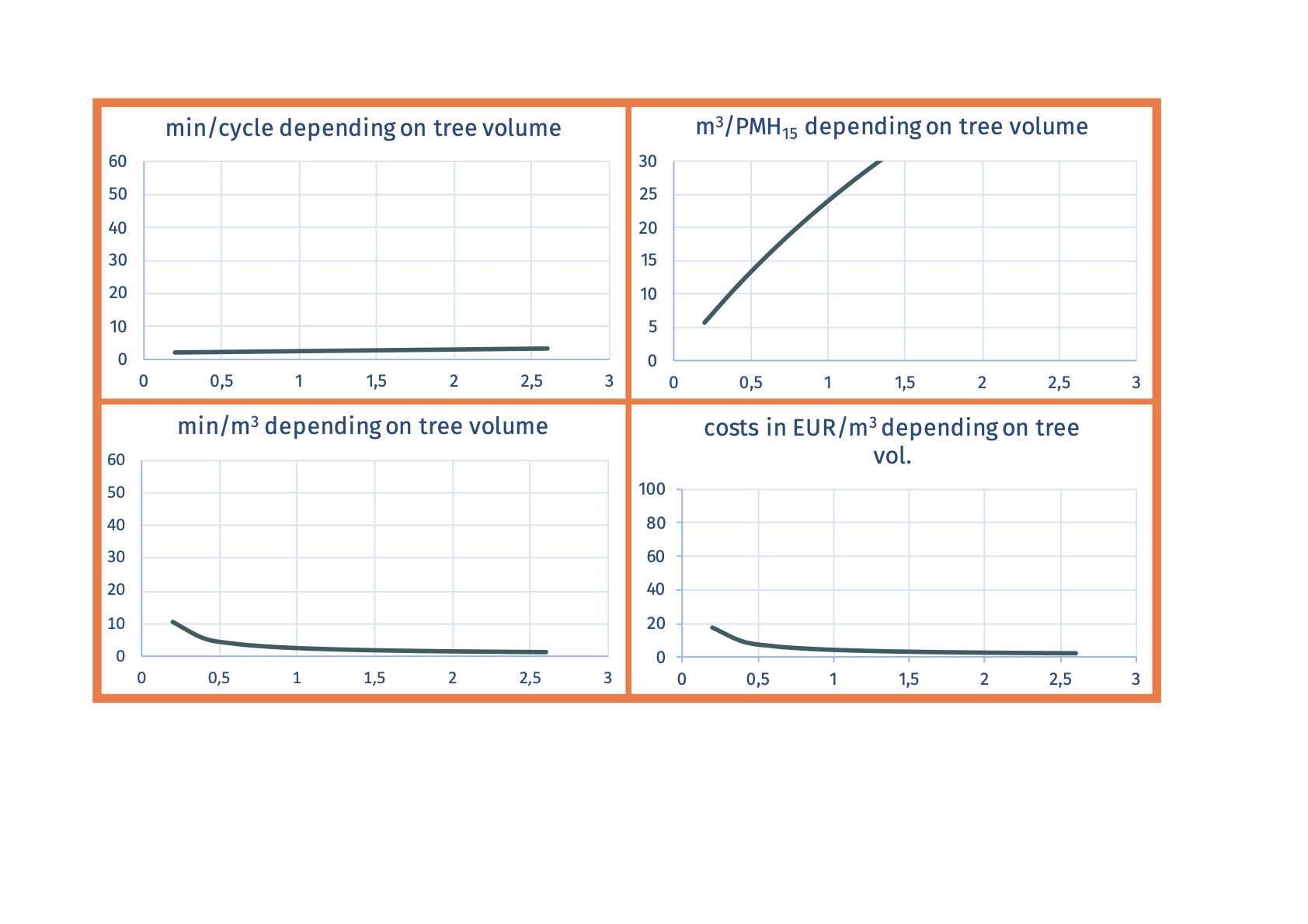

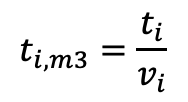

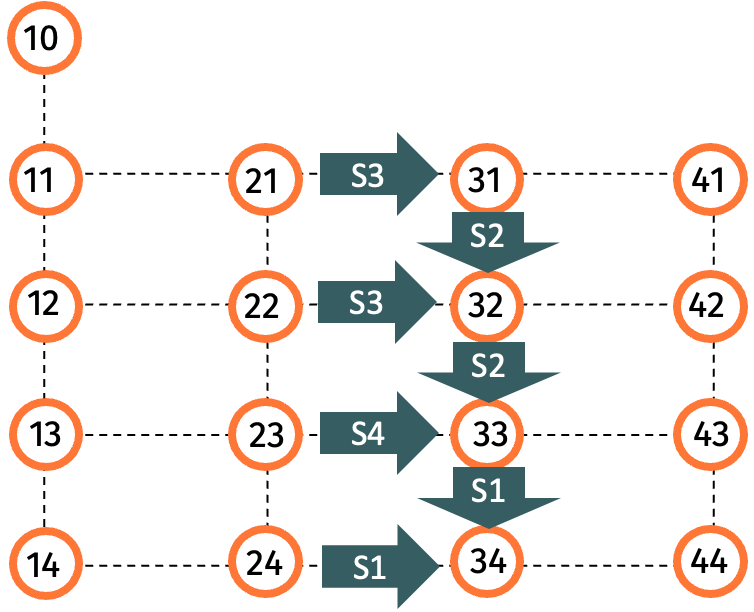

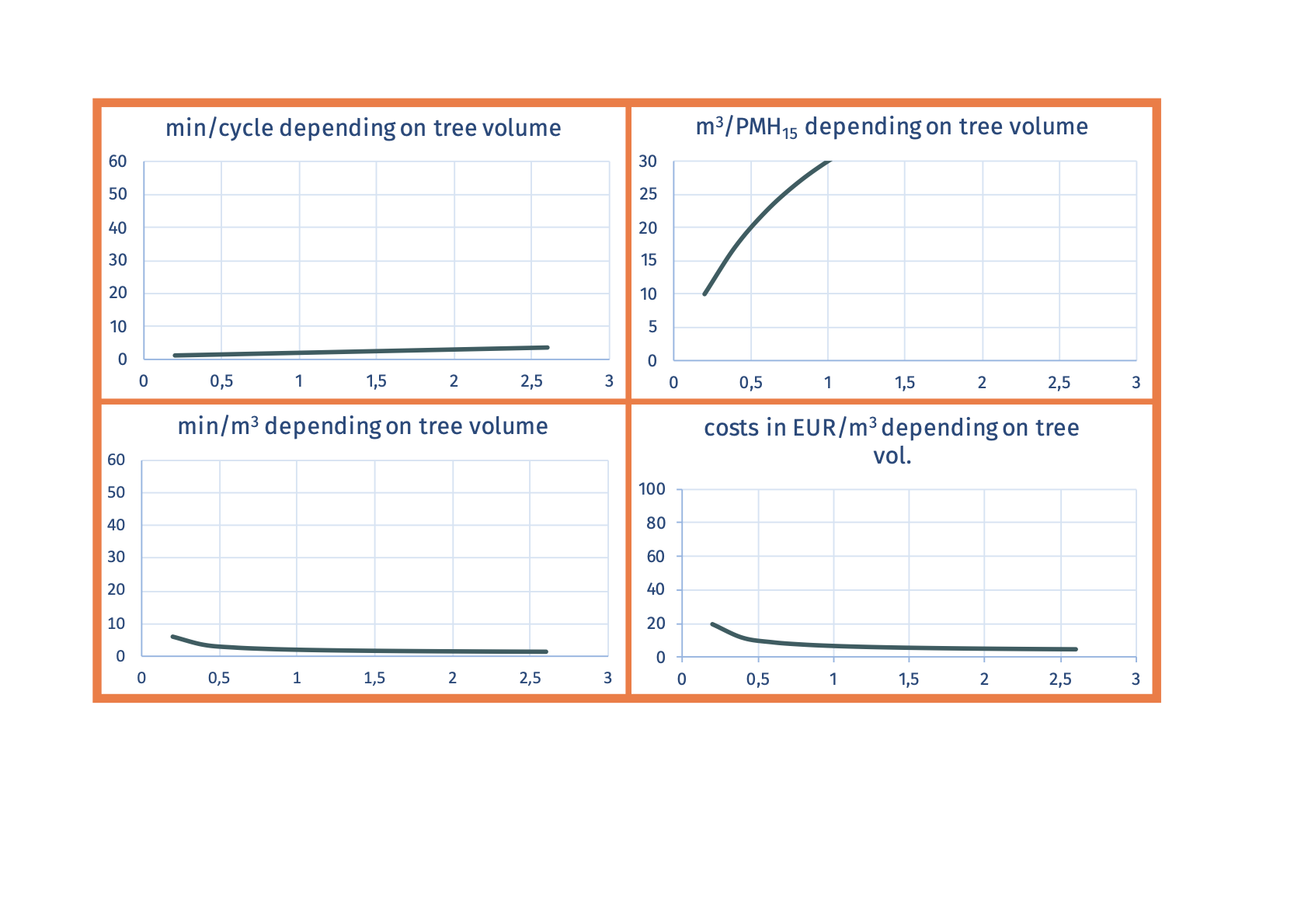

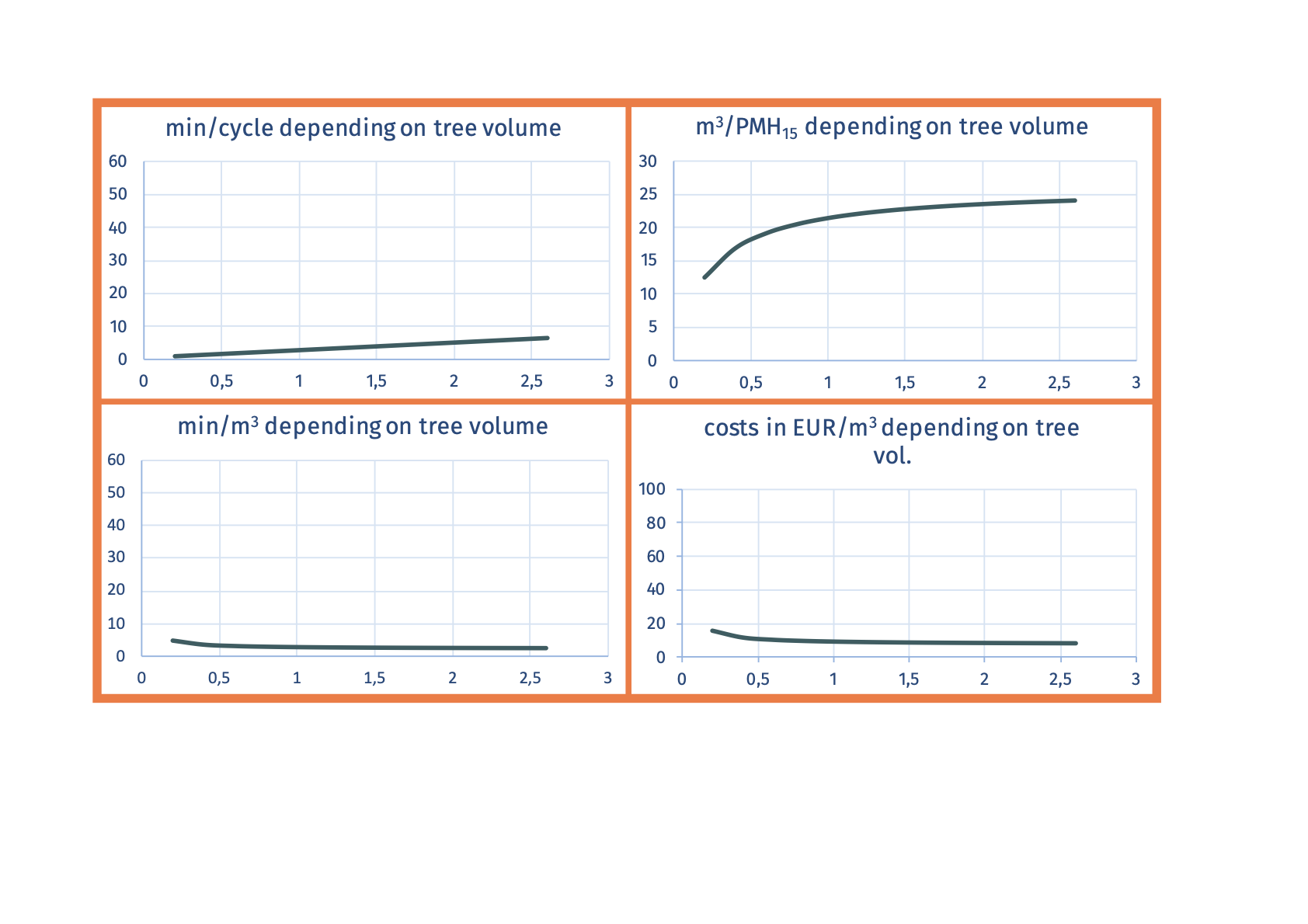

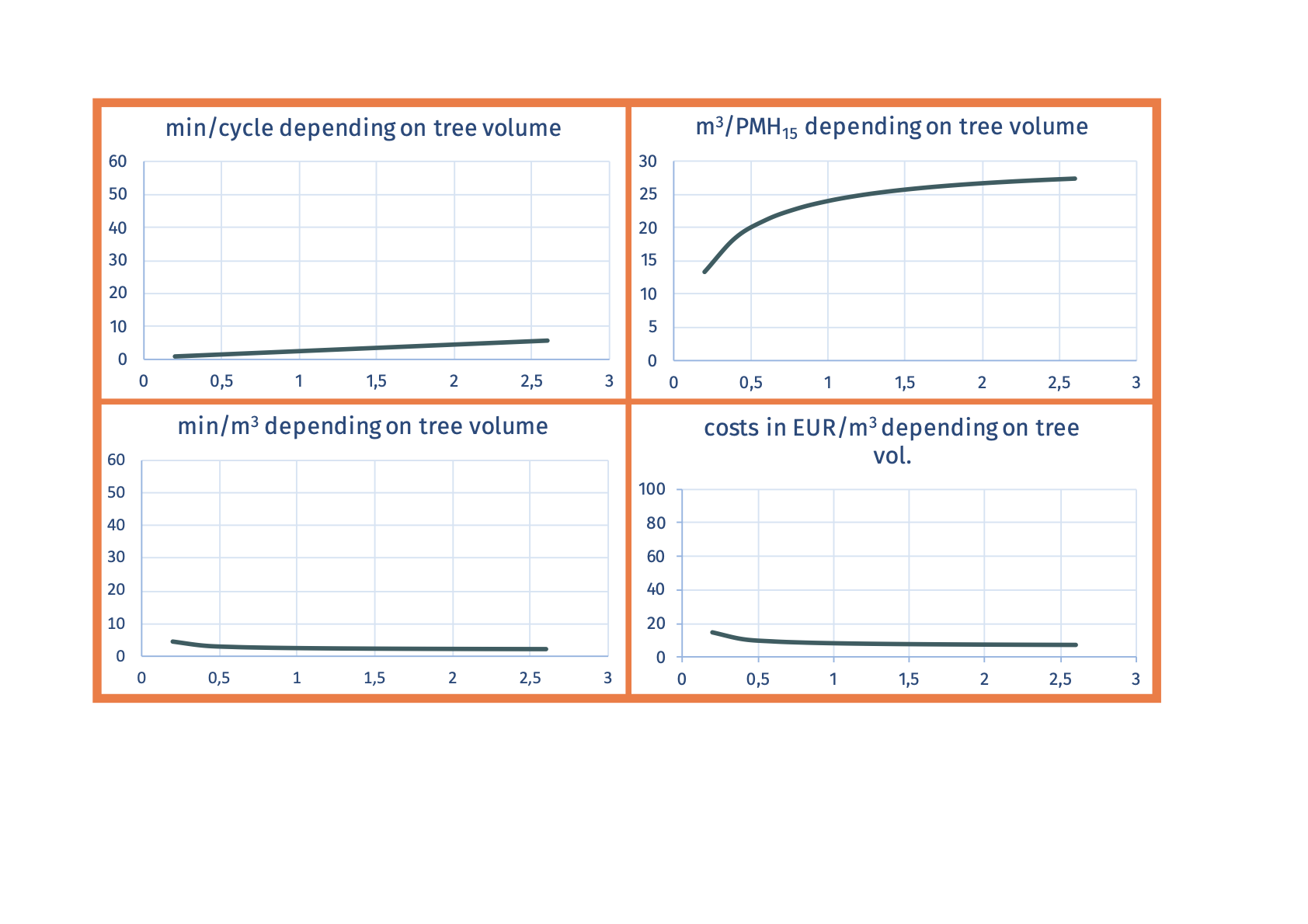

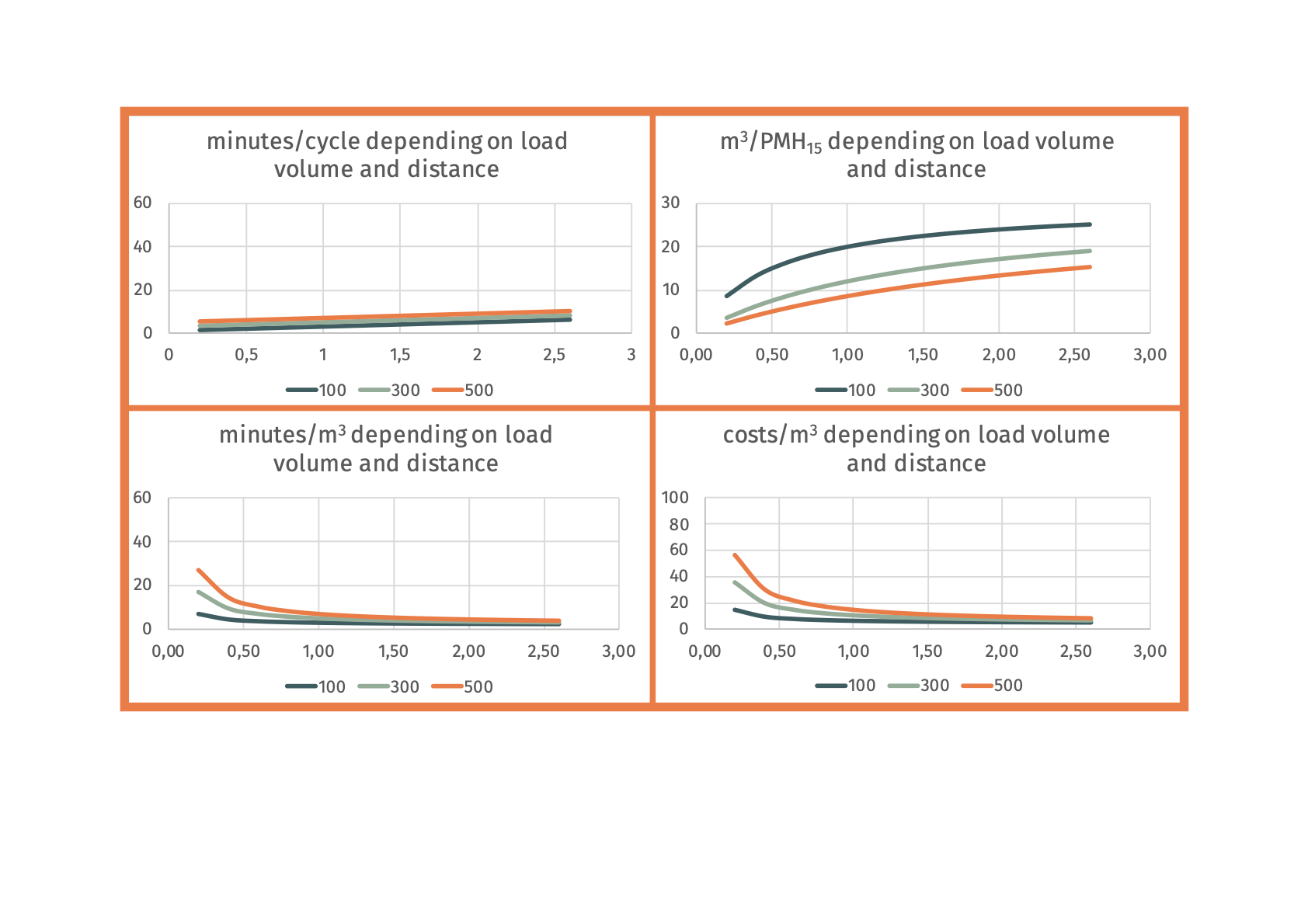

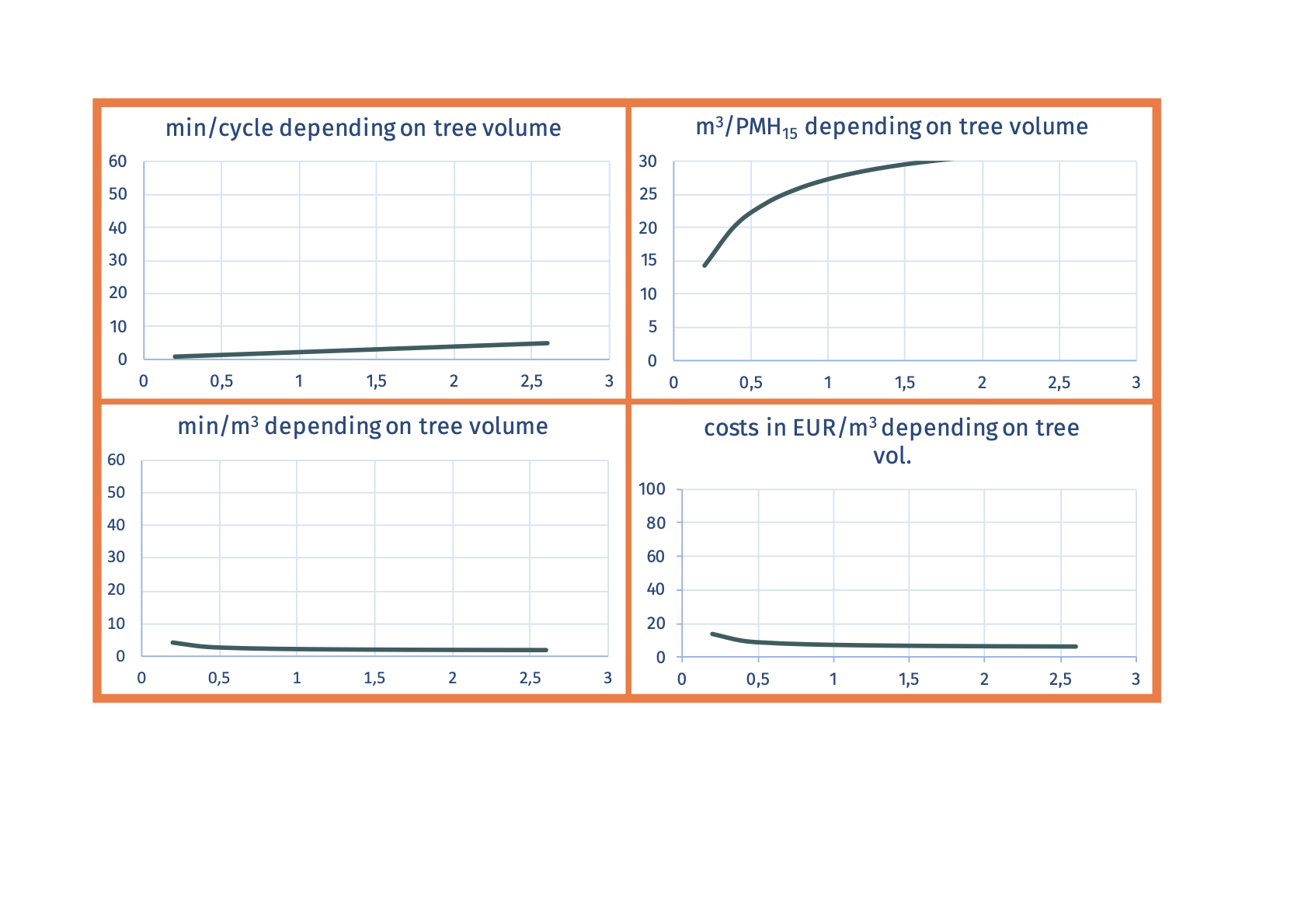

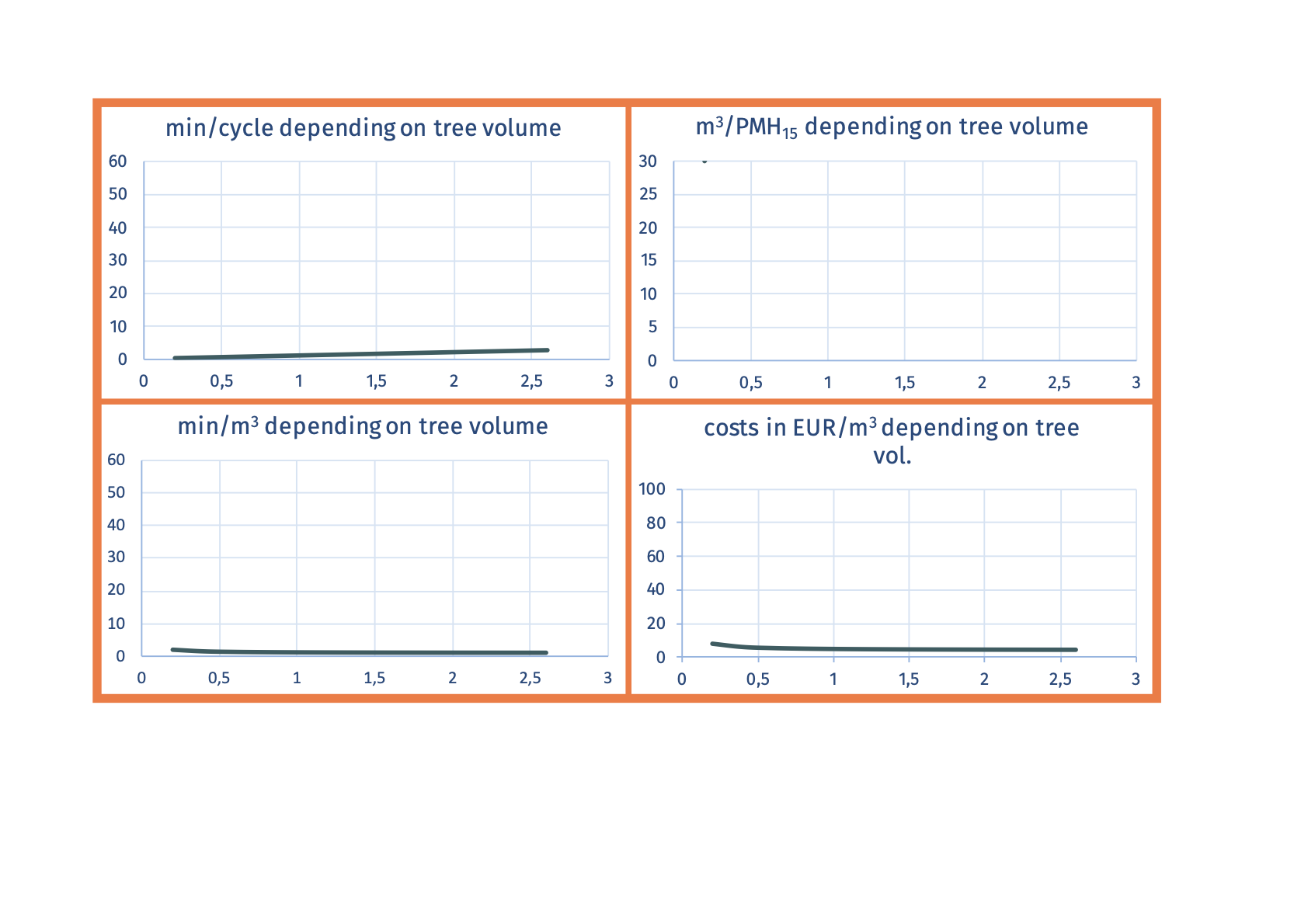

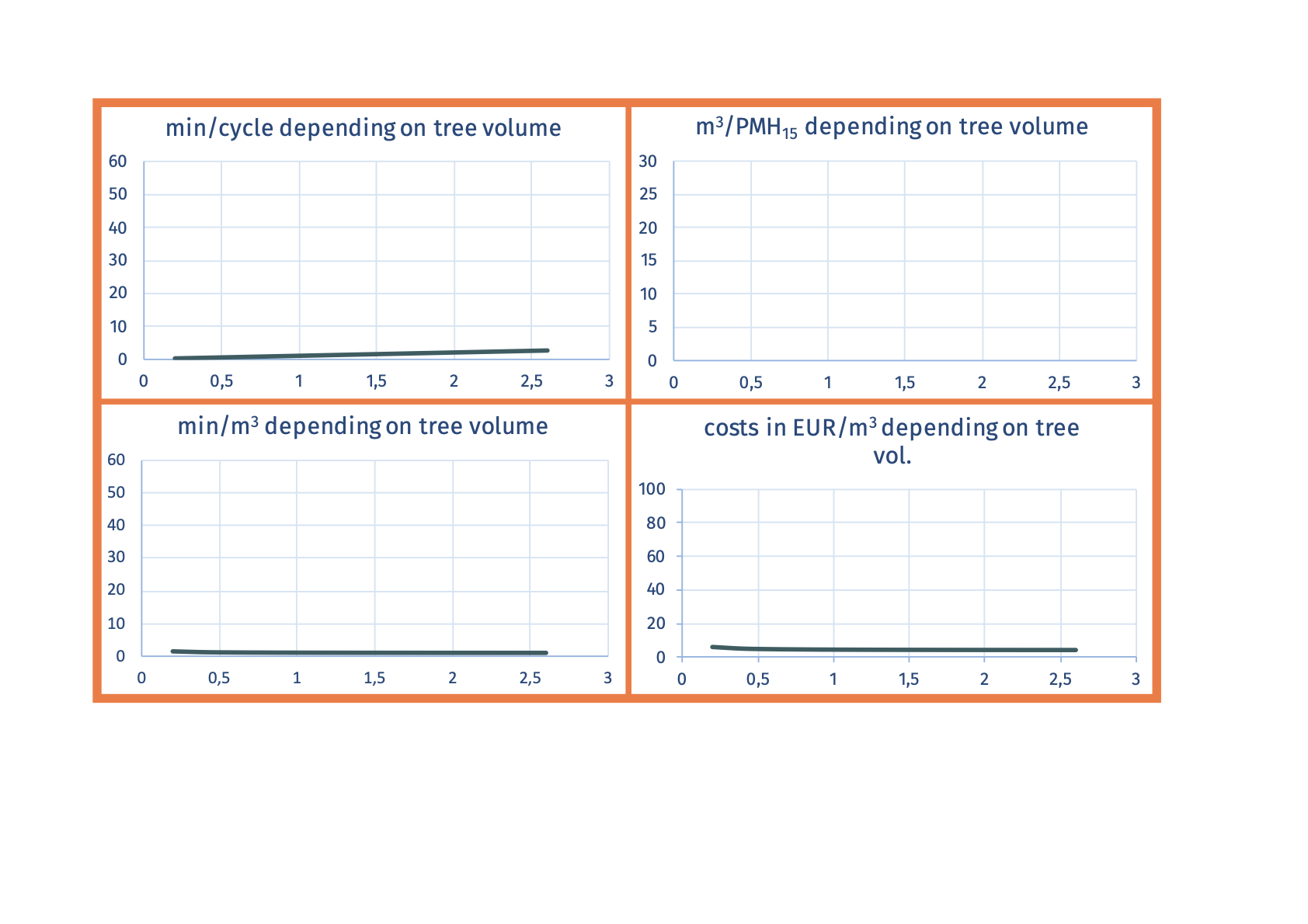

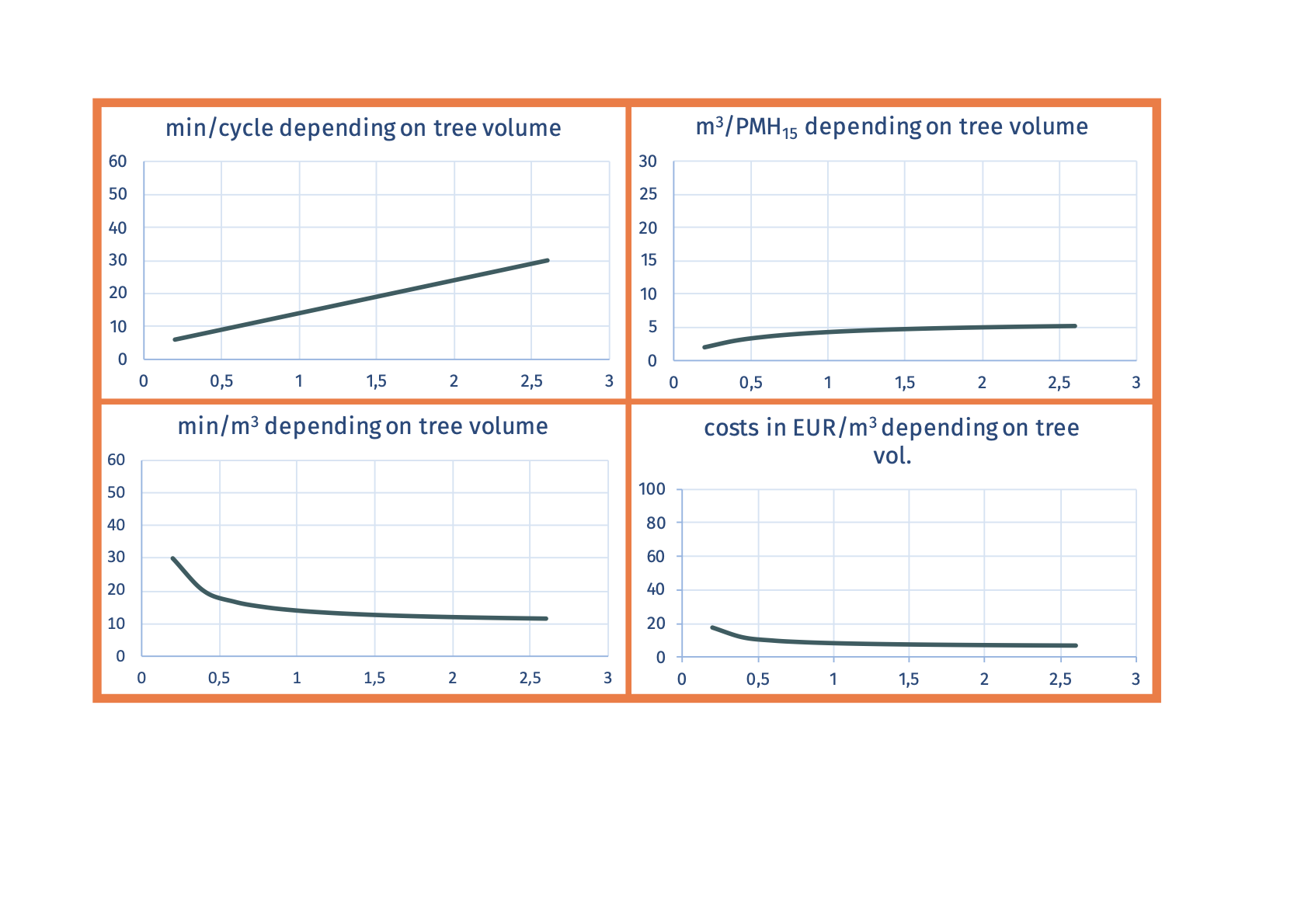

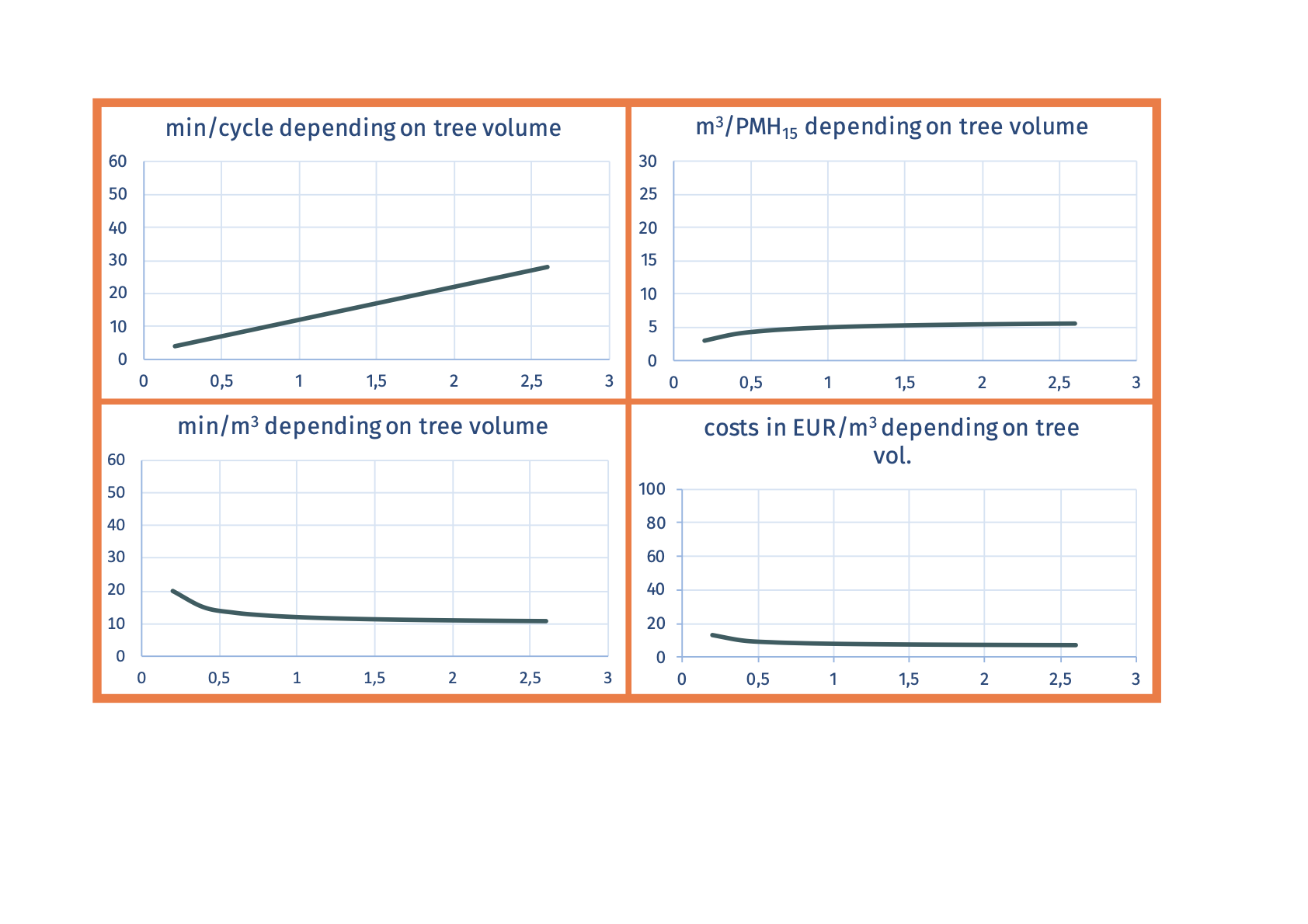

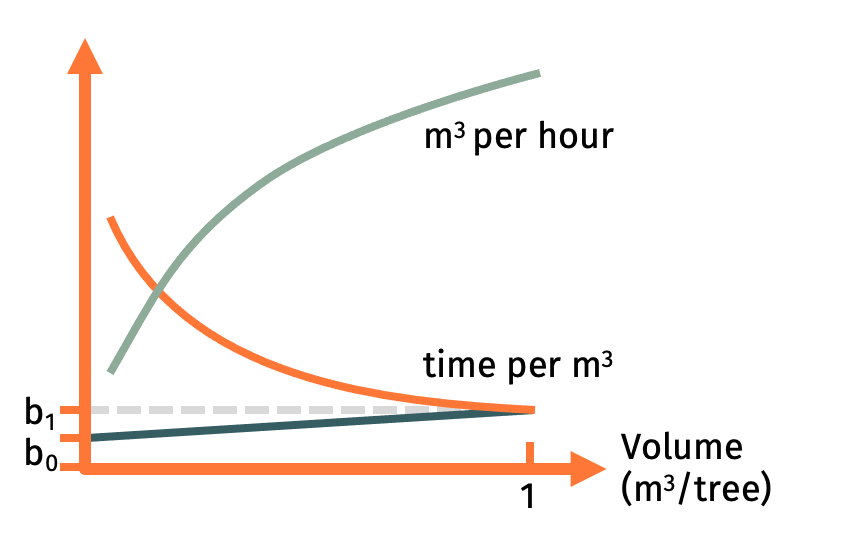

System performanceSystem performance is the productivity of a working system in products per hour. In forest harvesting, normally the products are not indicated by the trees, but by the cubic meters (m3) that are harvested per hour. The performance of a working system depends very much on the attributes of the working object. Besides the tree species, the dimension of the harvested trees has a high influence to the productivity. In scientific publications about working systems, performance is normally represented by a typical curve (green line): • It is low for smaller work objects (in our case: trees) • It increases with the work object size according to a non-linear degressive trend. Some graphs also report time consumption in minutes per cubic meter (red curve). Again, we recognize a typical curve: • Time per cubic meter is higher for small trees compared with big ones • The trend is degressive. This system behavior is known as the principle of tree volume. The time to process a given work object increases, but not as much as the volume of the object increases. The problem is that we know this overall trend, but we don’t have the exact parameters case-by-case. This makes prediction difficult and laborious. In Technodiversity, we suggest a simple solution: Scientific experience has shown that the time consumption per tree depends on its volume according to a typical relationship: • The bigger the tree, the longer the time needed • The data cloud can be well represented by a linear regression • The regression line crosses the y-axis above the origin. Of course, in scientific case studies different curve types will offer a better fit, but the linear function is fairly good, too, and gives us the chance to get an overall estimation of the performance. This general assumption makes it possible to forecast the system performance even with very few data points. Provided that we can accept the linear approximation, we can describe the relationship between time per tree and tree size with the equation just below:

The time ti is composed by two summands: b0 is the fixed time required for processing one single tree. It does not depend on the size of the tree. It is typically the time to walk to the tree, clean the area around it etc. b1 is the time required for processing a single tree. It depends on its size, so we say it is variable. b1 indicates the time consumption at one tree that has exactly the volume of 1 cubic meter. Is the tree smaller, let’s say only 0.5 m3, than the product of b1 times its volume vi is also 0.5 compared with 1 m3. Given this basic line, the time per m3 is

with

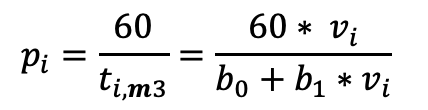

This curve ti,m3 includes our two independent variables b0 and b1 with the consequence that it looks different for each working system. Now, dividing 60 min/h by the time consumption ti,m3 we get the performance in m3/h

with

and It shows the typical degressively increasing curve of performance (green): • the bigger the average tree the higher the performance per hour • but the increment gets less and less. • Why do we need to complicate our lives by tracing the process all the way back to the time consumption per tree? • Because that way we get to the original source of time consumption. • We know that the relationship between time consumption per tree and tree size can be represented by a linear regression with two parameters b0 and b1. Those two parameters contain all the information that we need. • To find those parameters, very few time measurements are enough. • We can also modify the two parameters of the regression formula for rough forecast purposes: • When we see, that in our case the preparation time b0 per tree is higher than normal (because of thornbushes, slippery ground etc.), we can “correct” this parameter with a best estimate. • When we know that our operator is quicker than an average operator, we may adapt the parameter b1 to his performance level. (See more at TDiv PR1-C03)

| |

System productivitySee system performance | |