Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

S |

|---|

SP-10-13 motor-manual harvesting of short logsFelling, delimbing and bucking to standard industrial logs or differentiated assortments directly in the stand  Advantages

Example:

Social suitability:

| |

SP-10-21 mechanized felling with a fellerOnly felling as a preparation for processing on accessible ground or safer ground, or before grapple skidding. If this is the only function, the machine is called feller. But a harvester can do the job as well. Functiogram: Advantages

Example

Ecograms  Social suitability:

Literature: Schweier, J., Spinelli, R., Magagnotti, N., Becker, G. (2015) Mechanized coppice harvesting with new small-scale feller-bunchers: Results from harvesting trials with newly manufactured felling heads in Italy. Biomass and Bioenergy, 72, pp. 85-94. Spinelli, R., Cuchet, E., Roux, P. (2007) A new feller-buncher for harvesting energy wood: Results from a European test programme. Biomass and Bioenergy, 31 (4), pp. 205-210. Spinelli R., Hartsough B., Owende P., Ward S. (2002) Productivity and cost of mechanized whole-tree harvesting of fast-growing eucalypt stands. International Journal of Forest Engineering 13, p. 49-60. Cacot E. Chantier de St. Vitte sur Briance (87)- Abattage mecanisé des peuplements feuillus par une tête a guillotine. Paris: AFOCEL Flash Chantier CO68; 2004. Hiesl P, Benjamin J. 2013. A multi-stem feller-buncher cycle-time model for partial harvest of small-diameter wood stands. IFJE 2013;24(2):101-108. Visser R., Stampfer K. 2003 Tree lenght system evaluation of second thinning in a loblolly pine plantation. Southern Journal of Applied Forestry 27: 77-82 | |

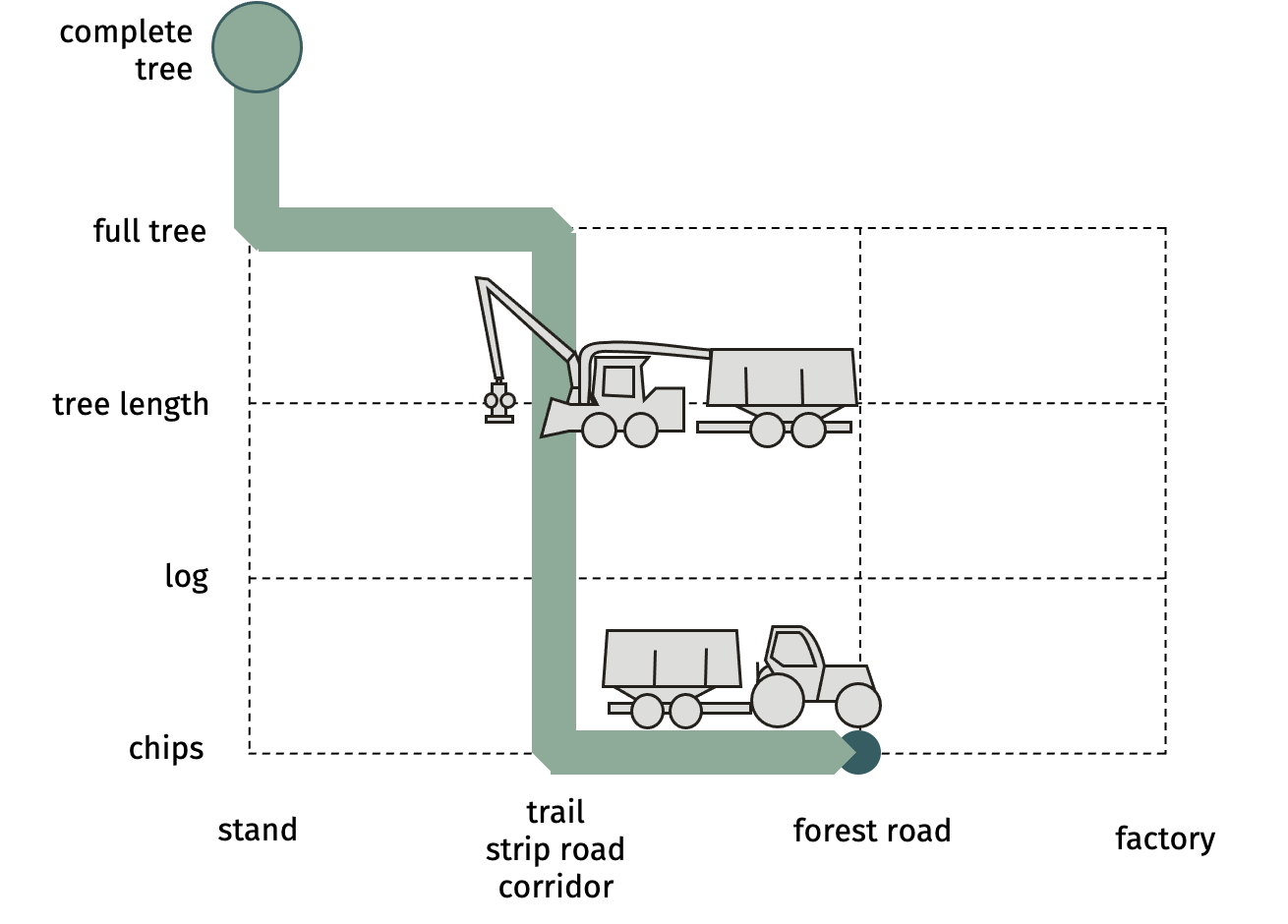

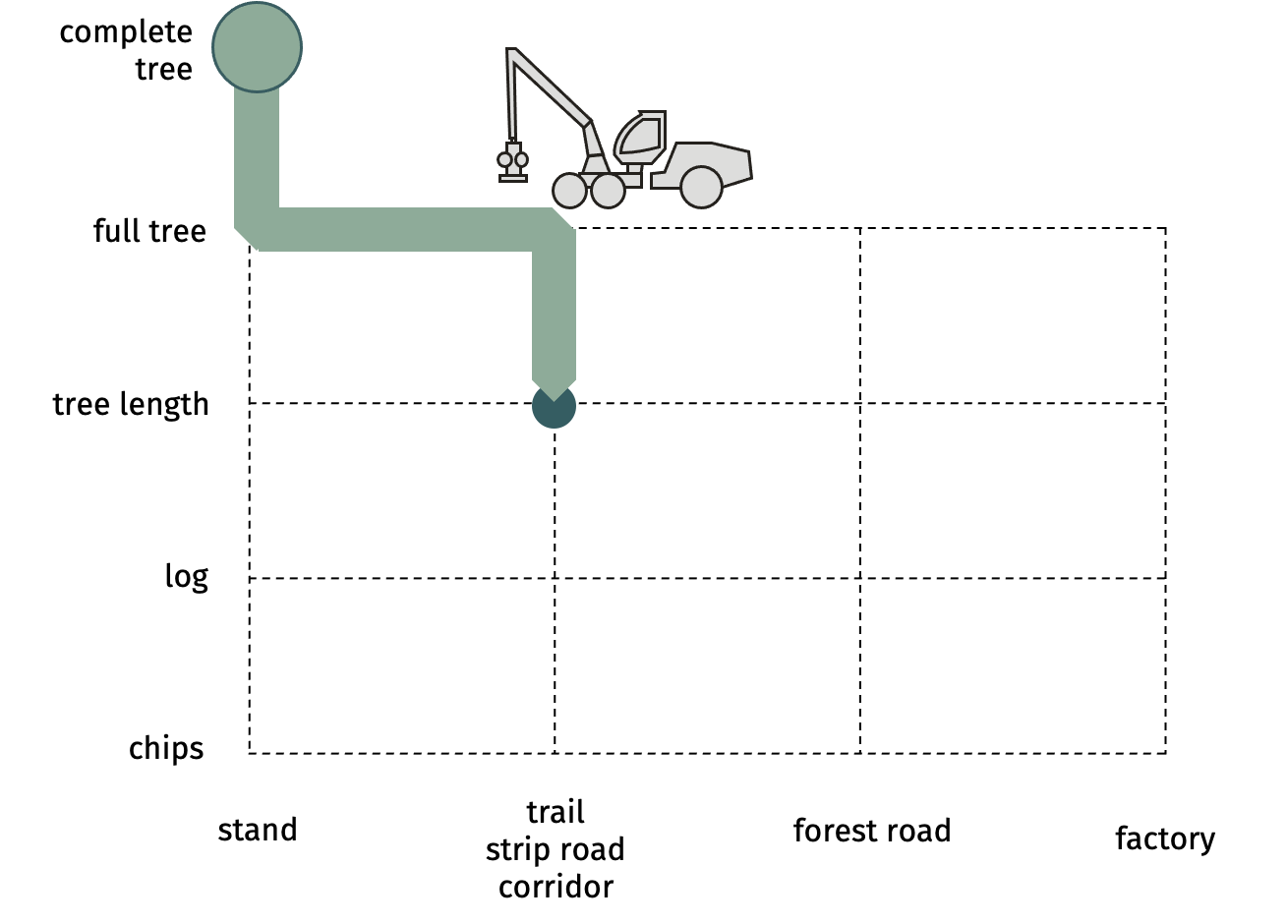

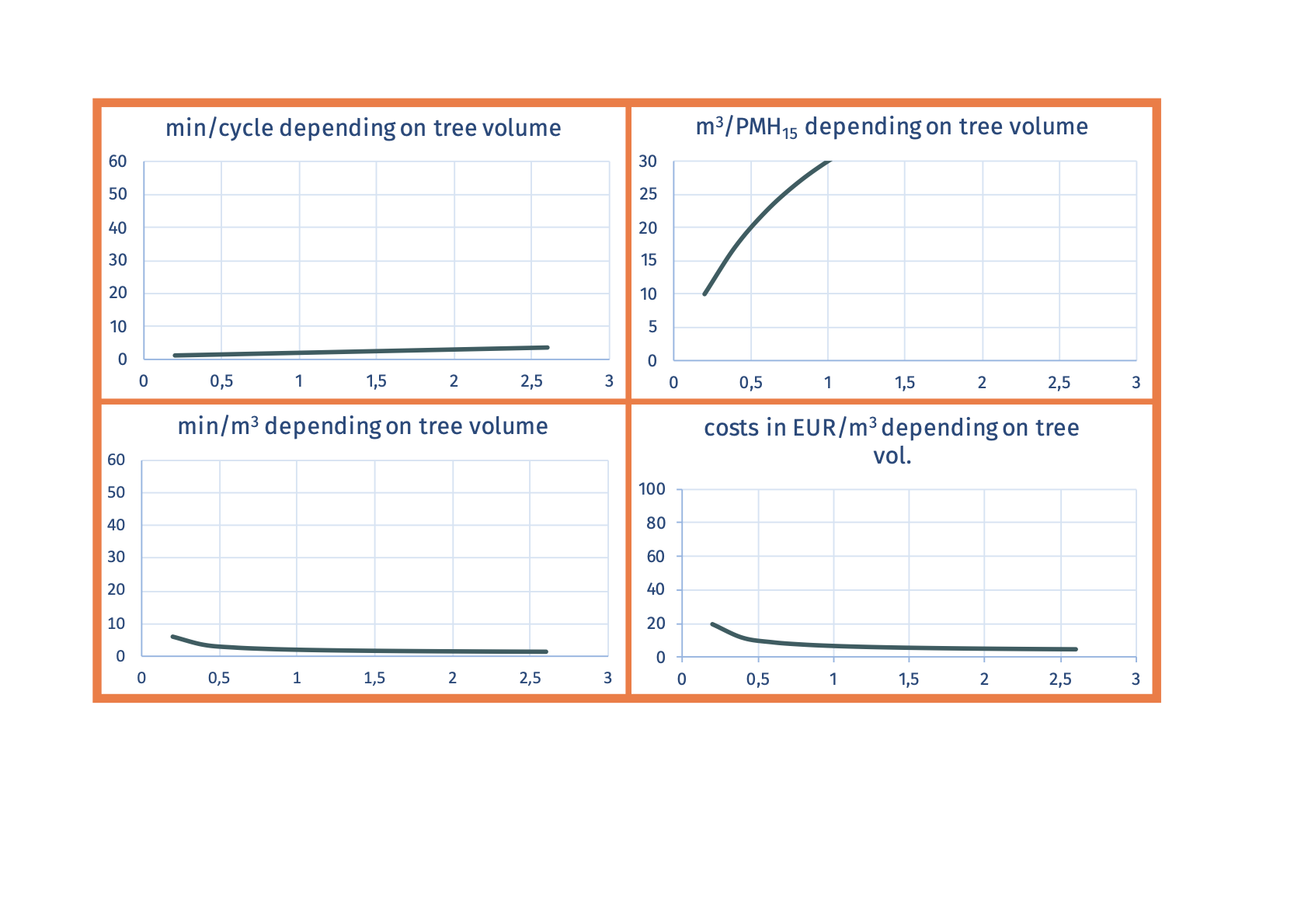

SP-10-22 mechanized harvesting of tree lengthTrees are felled and delimbed with a harvester, but trees are not crosscut (generally with the intention of postponing bucking at a better facility in order to maximize value recovery)  Advantages

example:

Ecograms

Social suitability:

| |

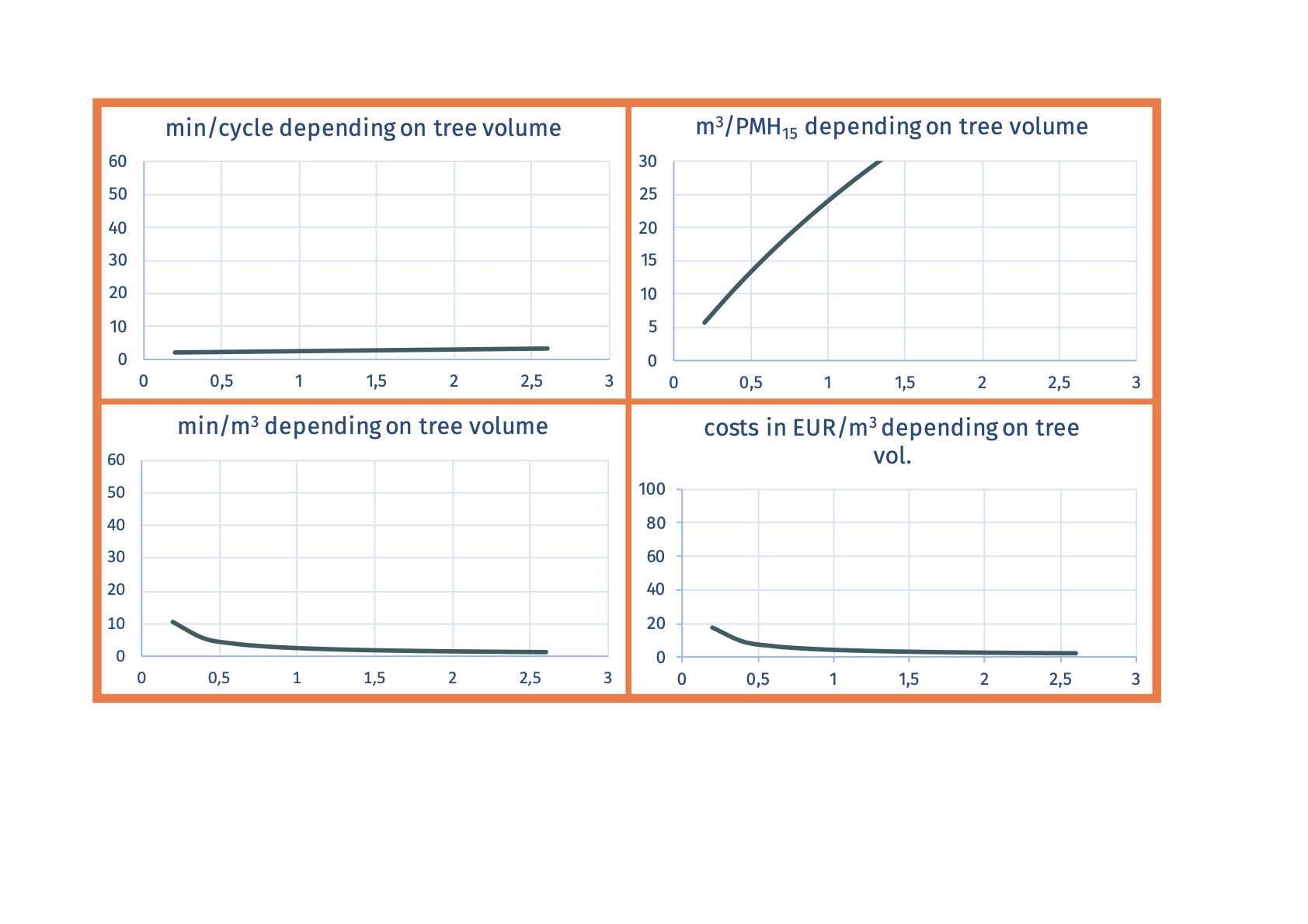

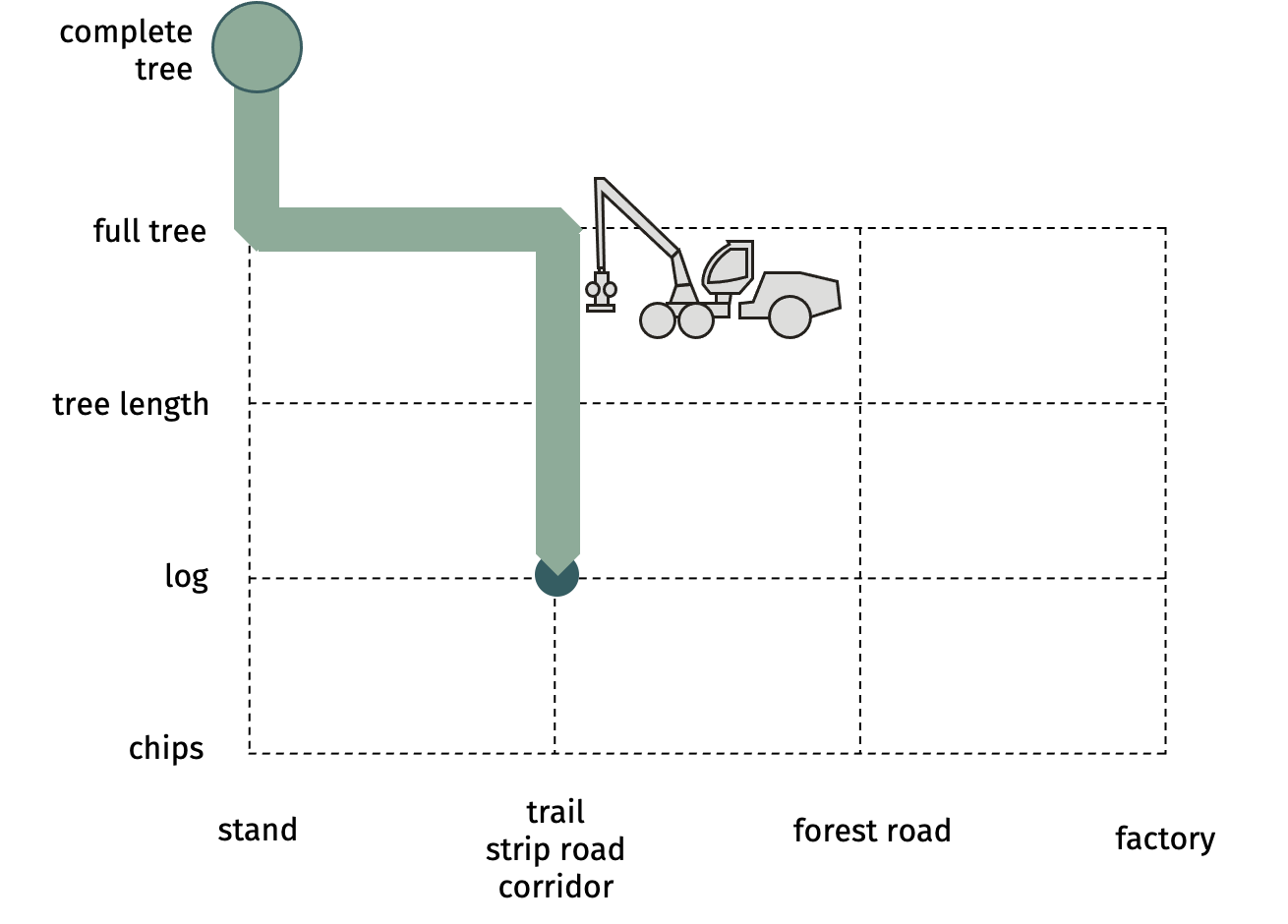

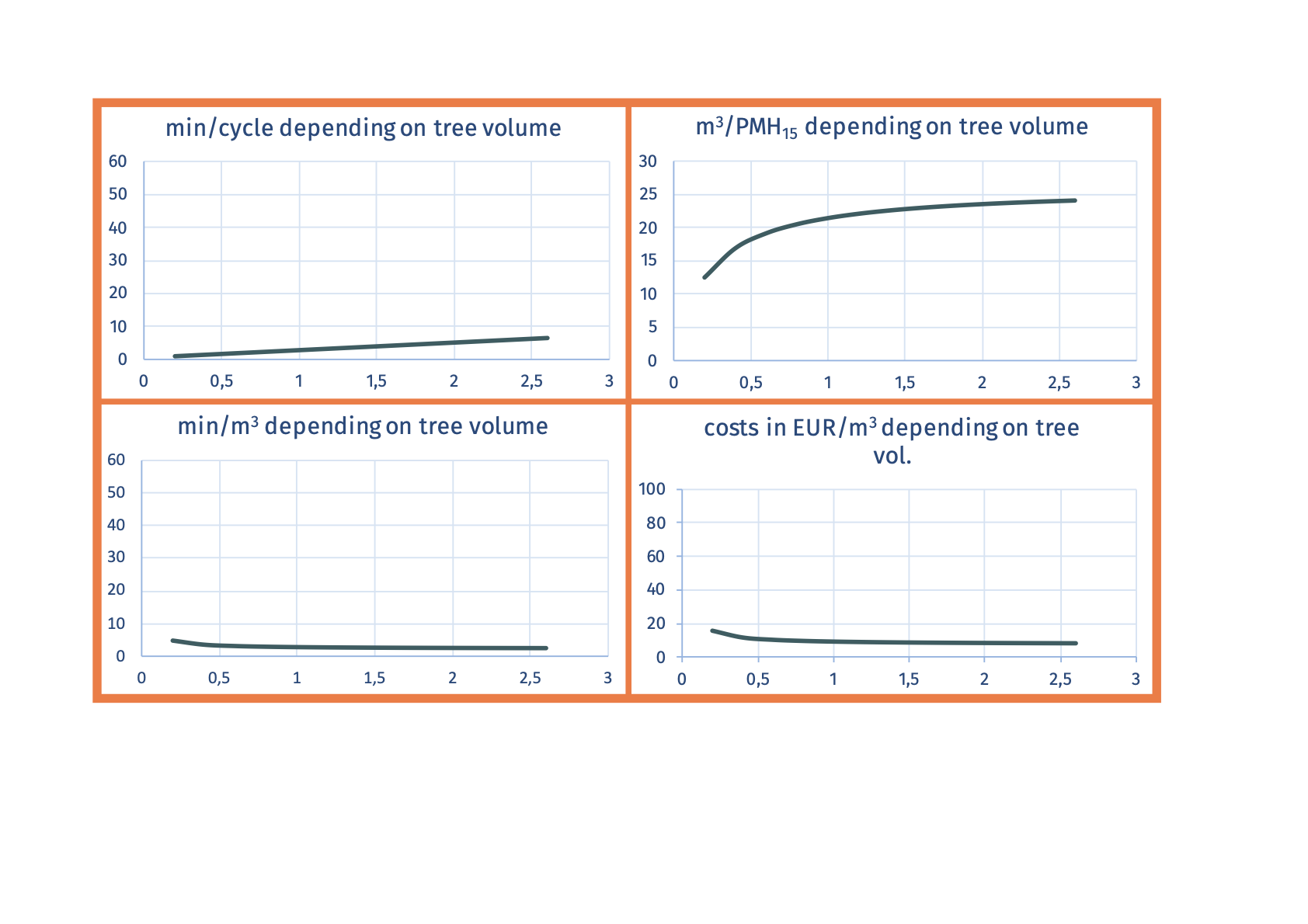

SP-10-23 mechanized harvesting of short logs

Advantages

Example:

Ecograms

Social suitability:

Literature: Brunberg T. 1997. Basic data for productivity norms for single-grip harvesters in thinning. The Forestry Research Institute of Sweden, Report 8/1997. 18 p. (In Swedish, English summary) Brunberg T. 1995. Basic data for productivity norms for heavy-duty single-grip harvesters in final felling. The Forestry Research Institute of Sweden, Report 7/1995. 22 p. (In Swedish, English summary) Emeyriat R., Picorit C., Reuling D., 1997. Perspectives of mechanised harvesting of maritime pine. Information Forèt, AFOCEL, Paris. Fiche 561, 6 p. (In French). Glöde D. 1999. Single- and double-grip harvesters: productive

measurements in final cutting of shelterwood. Journal of Forest Engineering 10

(2): 63-74. Hǻnell B., Nordfjell T., Eliasson L. 2000. Productivity and costs in shelterwood harvesting. Scandinavian Journal of Forest Research 15 (5): 561-569. Kärhä K., Rönkkö E., Gumse S. 2004. Productivity and cutting costs of thinning harvesters. International Journal of Forest Engineering 15 (2): 43-56. Nakagawa M., Hamatsu J., Saitou T., Ishida H. 2007. Effects of tree size on productivity and time required for work elements in selective thinning by a harvester. International Journal of Forest Engineering 18 (2): 24-28. Nurminen T., Korpunen H., Uusitalo J. 2006. Time consumption analysis of mechanized cut-to-length harvesting systems. Silva Fennica 40 (2): 335-363. Purfürst F. 2007. Human influences on harvest operations. Proceedings of Austro 2007/FORMEC’07 “Meeting the Needs of Tomorrows’ Forests – New Development in Forest Engineering” October 7-11 2007, Vienna and Heiligenkreuz, Austria. 9 p. Sirén M., Aaltio. 2003. Productivity and costs of thinning harvesters and harvester-forwarders. International Journal of Forest Engineering 14 (1): 39-48. Spinelli R., Magagnotti N., Nati C. 2009 Options for the mechanised processing of hardwood trees in Mediterranean forests. International Journal of Forest Engineering 20 (1): 39-44 Spinelli R., Owende P., Ward S. 2002. Productivity and cost of CTL harvesting of Eucalyptus globulus stands using excavator-based harvesters. Forest Products Journal 52 (1): 67-77. Spinelli, R., Hartsough, B., Magagnotti, N. (2010) Productivity standards for harvesters and processors in Italy. Forest Products Journal 60 (3), pp. 226-235. | |

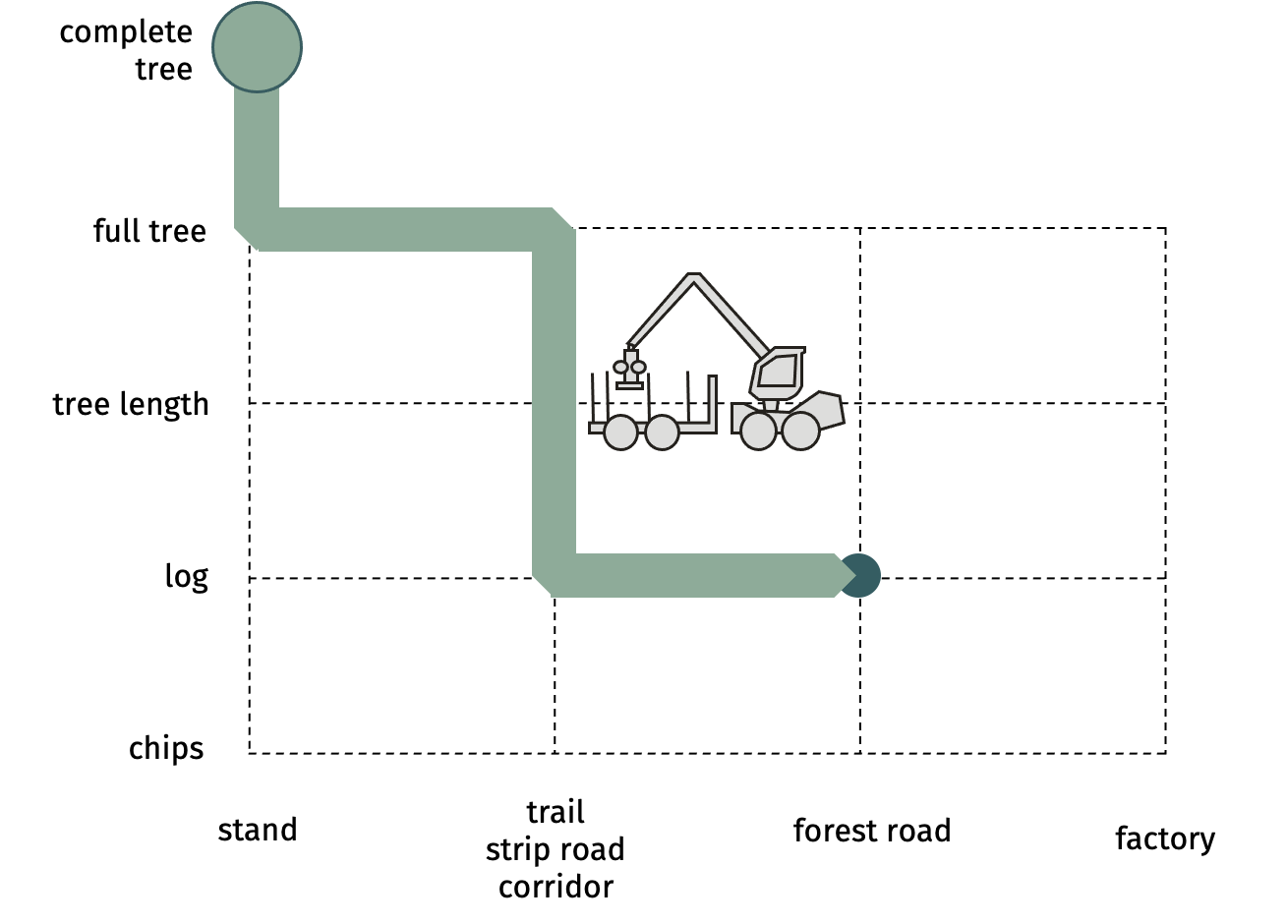

SP-10-33 mechanized harvesting and forwarding with harwarder

Advantages

Example:

Ecograms

Social suitability:

| |

SP-10-34 mechanized felling and chipping with biomass harvesterOne single machine cuts and chips whole trees in one single passage. This system is applied to SRC plantations and the most popular units are based on powerful (≥300 Kw) foragers

Example:

Ecograms

Social suitability:

Literature: Spinelli et al. 2009, 2011 and many others | |

SP-11-12 delimbingsee SP-x1-x2 delimbing | |

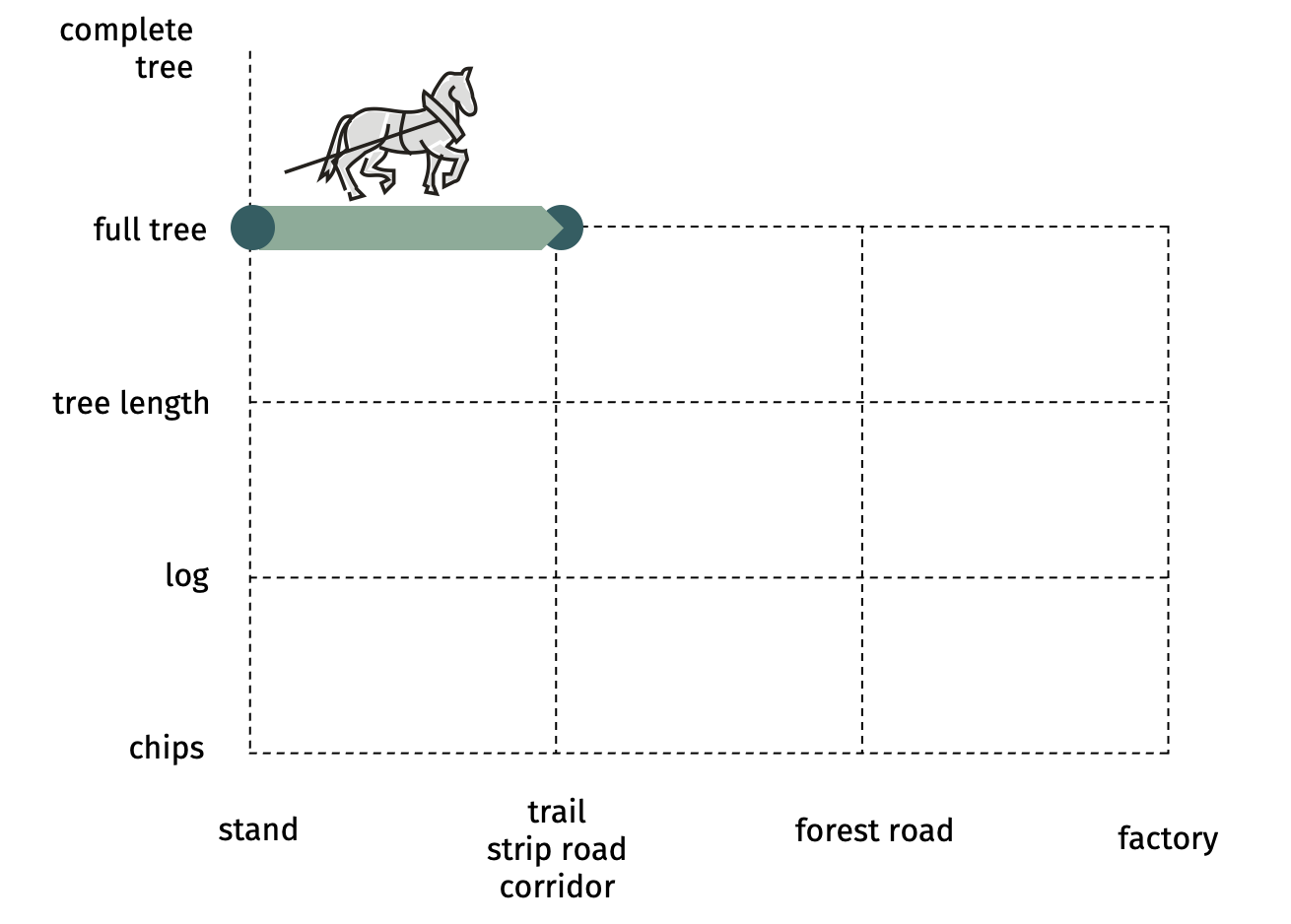

SP-11-21 pre-skidding of full trees with animalsAfter felling, trees are pre-skidded to a strip road using animals, and most commonly draught horses. Different breeds are available in different regions, but the most popular are heavy breeds like French Percherons, Belgian Ardennes, or Italian TPR.  Advantages

Main use

Example:

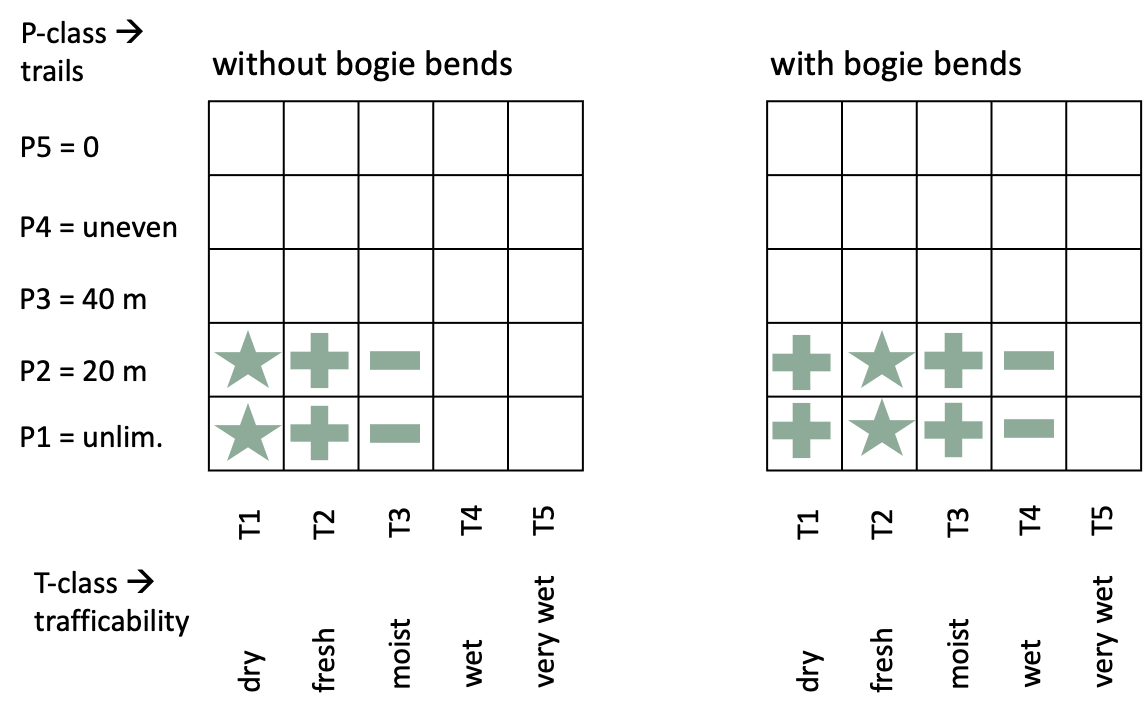

Ecogram

Social suitability:

Literature: Baigent C. 1984. Clydesdale logging. LIRO Technical Release 6, 4 pp. De Paul M., Bailly M. 2005. À propos de la pression exercée par les pneus, chenilles et sabots. Forêt Wallonne 78: 21-33. De Paul M., Lombaerde F., Jourez B. 2006. Approche économique du cheval en forêt. Forêt Wallonne 81: 15-25. Harstela P., Tervo L. 1981 Bunching of timber by winches and horse. Folia Forestalia 466, 20 pp. In Finnish. Hedman L. 1987. Tools and equipment for horse logging. Small Scale For 1: 10-17. Hedman L. 1988. Skidding with horse to strip road. Small Scale For 2: 15-19. Leinert S. 1979 Einsatz veraltungseingener pferde beim vorrücken von schwachholz. Forsttechnische Informationen 1: 4-6. Magagnotti N., Spinelli R. 2011 Integrating animal and mechanical operations in protected areas. Croatian Journal of Forest Engineering 32: 489-499. Magagnotti N., Spinelli R. 2011 Financial and energy cost of low-impact wood extraction in environmentally sensitive areas. Ecological Engineering 37: 601-606. McNamara D, Kaufman J. 1985. Can horses compete with tractors? State of California, For. Dept., Sacramento, CA. For. Note 95, 7 p. Pynn L. 1991. Logging with horse power. Can Geogr 3: 31-35. Shresta S, Rummer R, Dubois M. 2005 Utilization and cost of log production from animal logging operations. Int J For Eng 16: 167-180 Shresta S, Lanford B., Rummer R, Dubois M. 2008 Soil disturbances from horse/mule logging operations coupled with machines in the Southern United States. Int J For Eng 19: 17-23 Schroll E. (Editor) 2008 Holzrücken mit pferden – Handbuch für die waldarbeit mit pferden. Starke Pferde Verlag, Lemgo, Germany. In German. Snoeck B. 2000. Ces chevaux « qui traînent au bois ». Forêt Wallonne 46: 12-23. Thérer Y. 2006. Situation du débardage au cheval en Région Wallonne, enquête auprès de débardeurs. Forêt Wallonne 82: 18-27. Toms C., Dubois M., Bliss J., Wilhoit J., Rummer B. 2001 A survey of animal-powered logging in Alabama. South J Appl For 25: 17-24 | |

SP-11-21 pre-skidding of full trees with tractor winchPre-skidding of full trees from the felling site to the strip road with a winch that is mounted or attached to a tractor. Advantages

Limitations, threshold

Main use

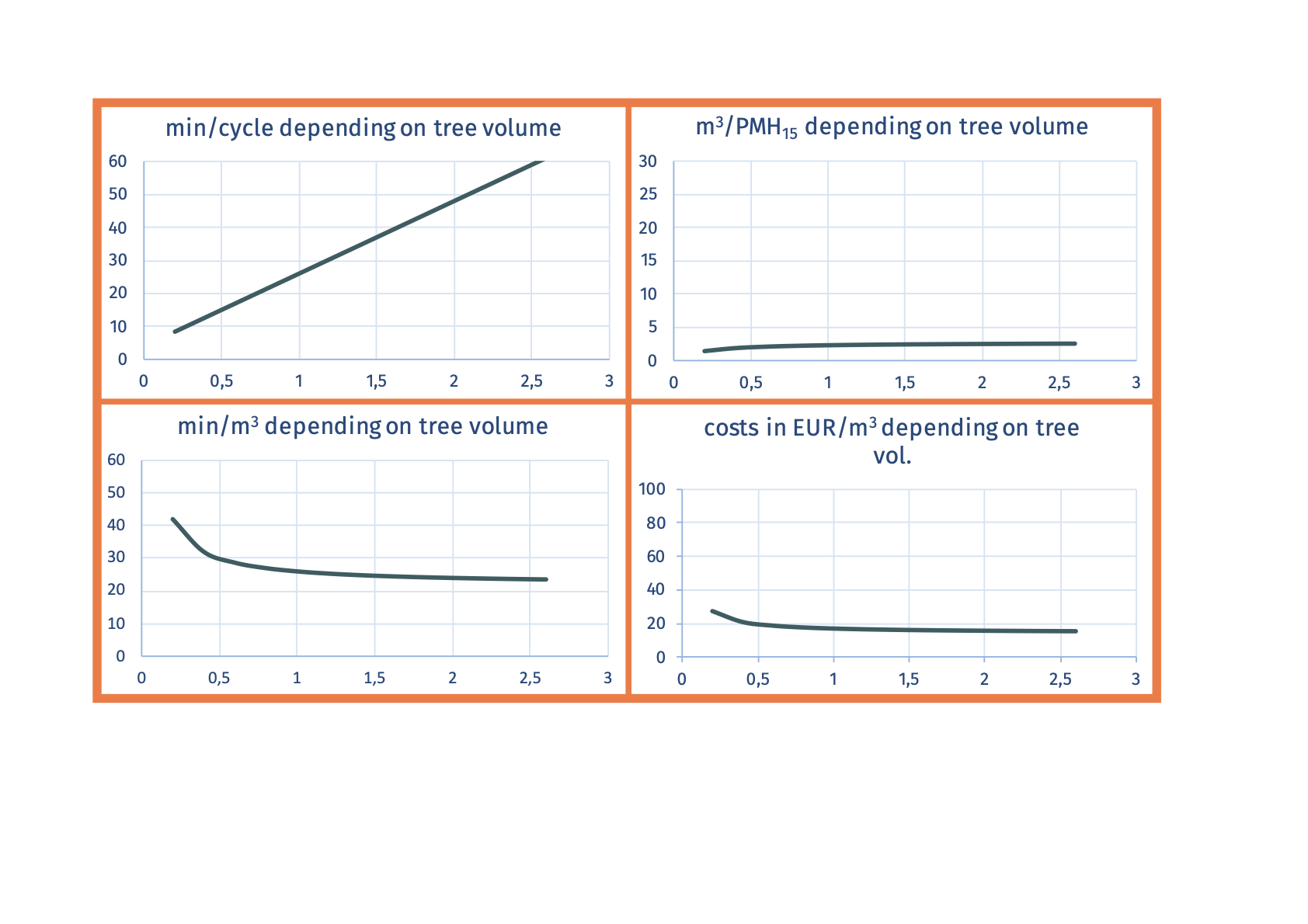

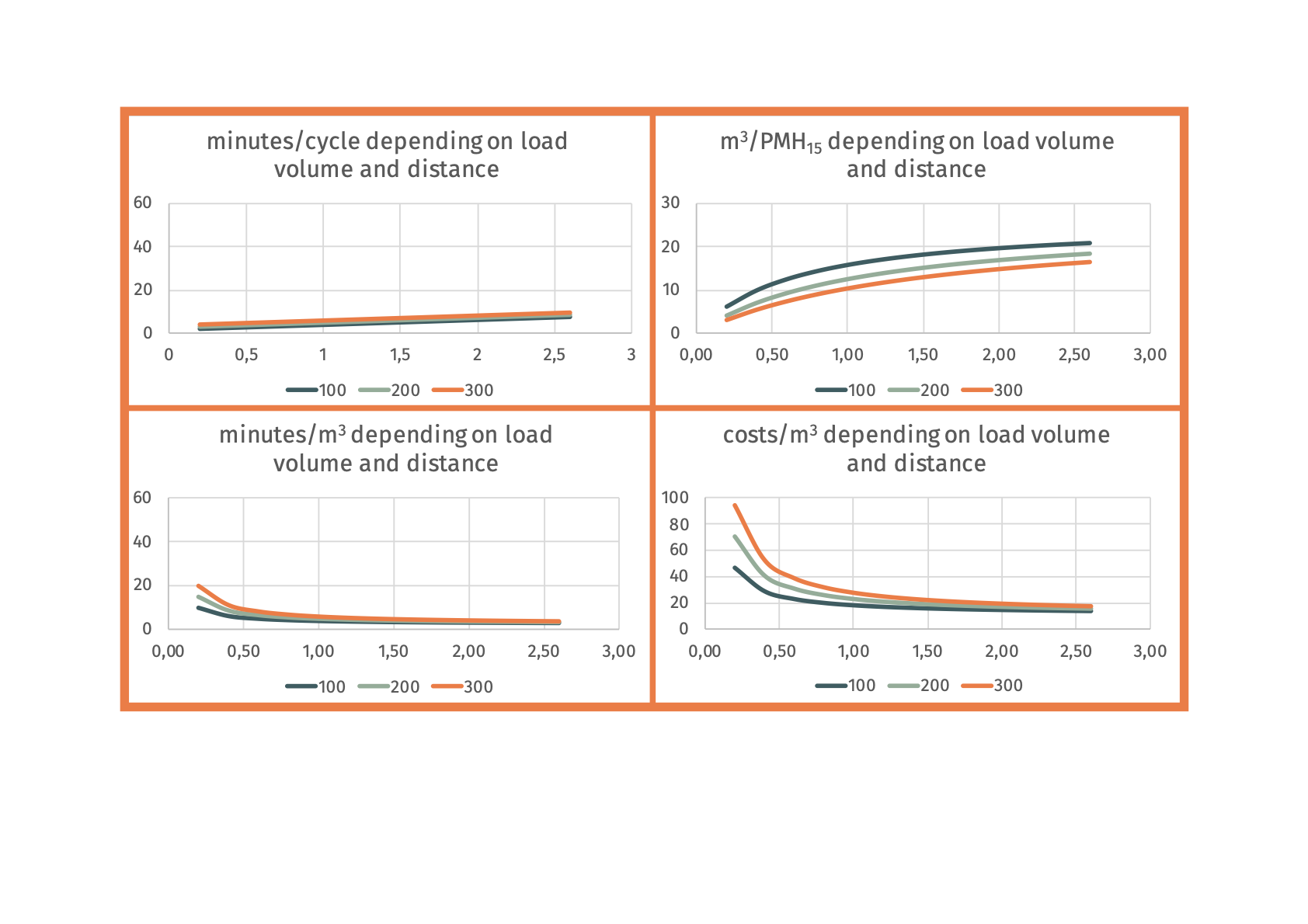

Winching performance depends on many factors, but mostly on extraction distance and tree size. However, extraction distance and tree size have the strongest effect on cycle time, productivity and pre-skidding cost.

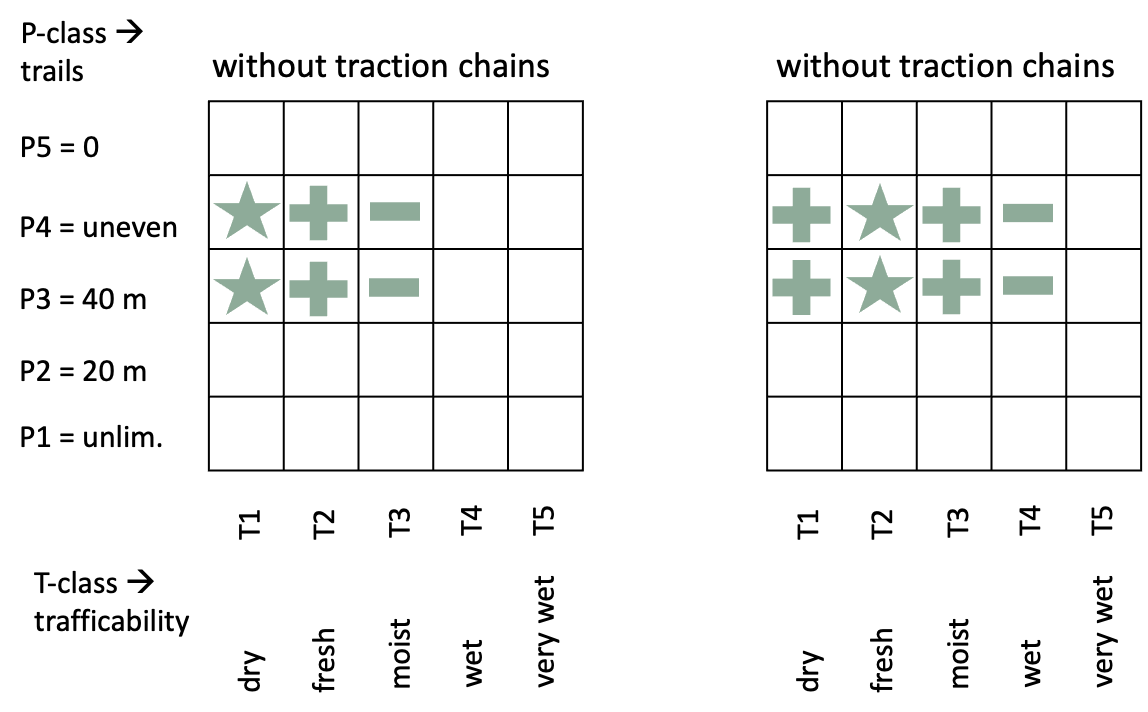

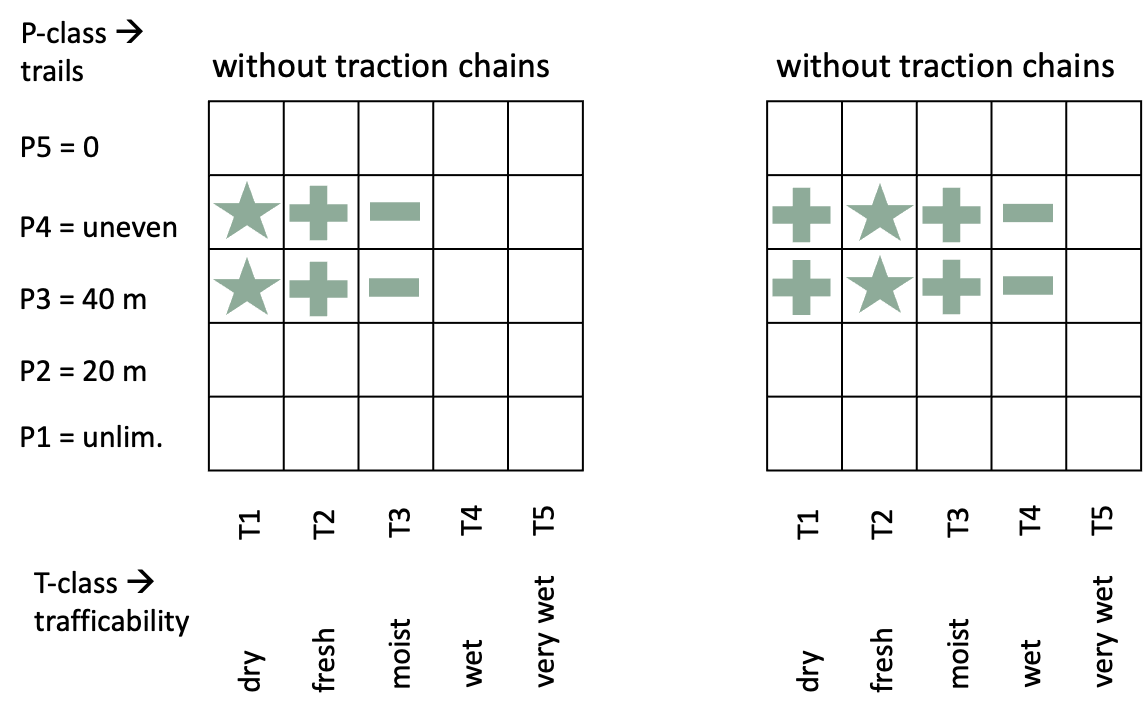

Since winch pre-skidding is extremely sensitive to distance, it should be used on very short distances, only. If tree volume is large enough, then one can obtain acceptable results also on medium distances, up to 50 m. Ecograms

Social suitability

Literature: Dekking J. 1984 Goliat, a small tractor with tracks. IEA/FE/CPC7 Report, 17 pp. Dunnigan J. 1993 Braided KevlarTM Cable: Trials in Skidding Wood With an ATV. Field Note FN-022. FERIC. Pointe Claire, Quebec, Canada. Ewing R. 2001 Use of a portable capstan winch and associated hand tools in manual thinning. FERIC Advantage Reports, 28: 4 p. Ewing R. 2003 Harvesting riparian zones using cable skidders equipped with Spectra synthetic-fibre mainlines. FERIC Advantage Reports, 20: 6 p. Harstela P., Tervo L. 1981 Bunching of timber by winches and horse. Folia Forestalia 466, 20 pp. In Finnish. Hill S. 1991 D4H tractor and towed arch in radiate clearfell. LIRA Report 16, 8. 4 p. Horvat D, Spinelli R, Šušnjar M. 2005 Resistance coefficients on ground-based winching of timber. Croatian Journal of Forest Engineering 30: 3-11 Leek N. 1976 Bunching with Radiotir 740 in thinnings. Nederlands Bosbouw Tijdschrift 48: 151-157. Magagnotti N., Spinelli R. 2012 Replacing steel cable with synthetic rope to reduce operator workload during log winching operations. Small Scale Forestry 11: 223-236. Picchio R., Magagnotti N., Sirna A., Spinelli R. 2012 Improved winching technique to reduce logging damage. Ecological Engineering 47: 83-86. Prebble R. 1986. Evaluation of the Logquip smart arch. LIRA Report 11, 5. 4 p. Pritchard N. 1986. The Logquip smart arch for small crawler tractors. LIRA Report 8. 4 p. Ryans M. 1980 Evaluation of the Agri-Winch: a farm tractor-mounted logging winch. FERIC Tech. Rep. TR41. 18 p. Spinelli R, Magagnotti N 2012 Wood extraction with farm tractor and sulky: estimating productivity, cost and energy consumption. Small-scale Forestry 11: 73-85. TDB 2002 ATC timber sulky. Information Note ODW 9.04, Ae Village, UK. 5 p. Turner T., Huyler N. Bousquet D. 1988 Farm Tractor Skidding Costs in Relation to Profitability of a Fuelwood Harvesting System. Nort.h J Appli For 5: 207-210 Vaughan L. 1988 Thinning with small crawler tractors. LIRA Report 13, 26. 6 p. Zeĉić Z., Krpan A., Vukuŝić S. 2005 Productivity of Holder 870 tractor with double drum winch Igland 4002 in thinning beech stands. Croatian J For Eng 26: 49-56. | |

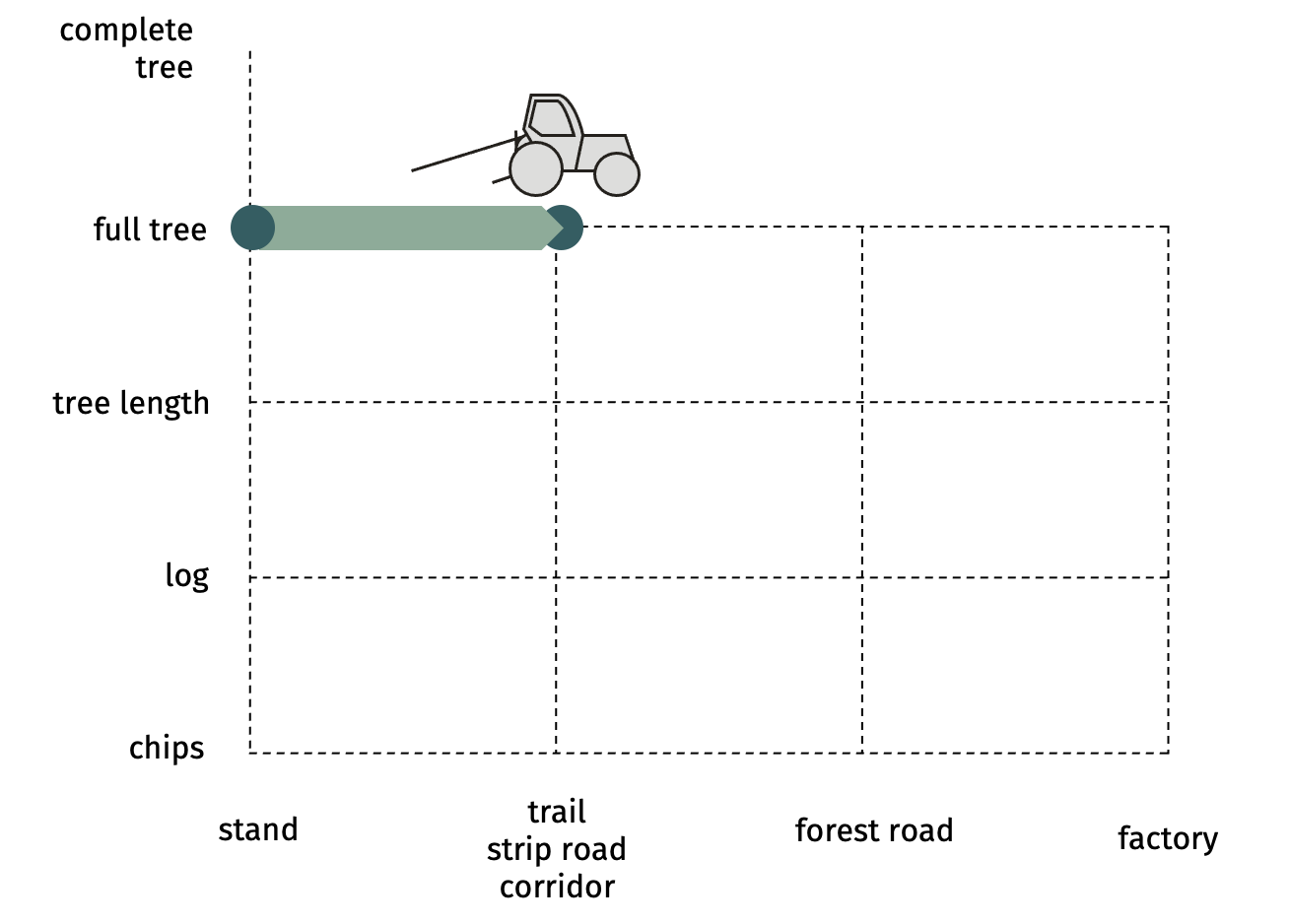

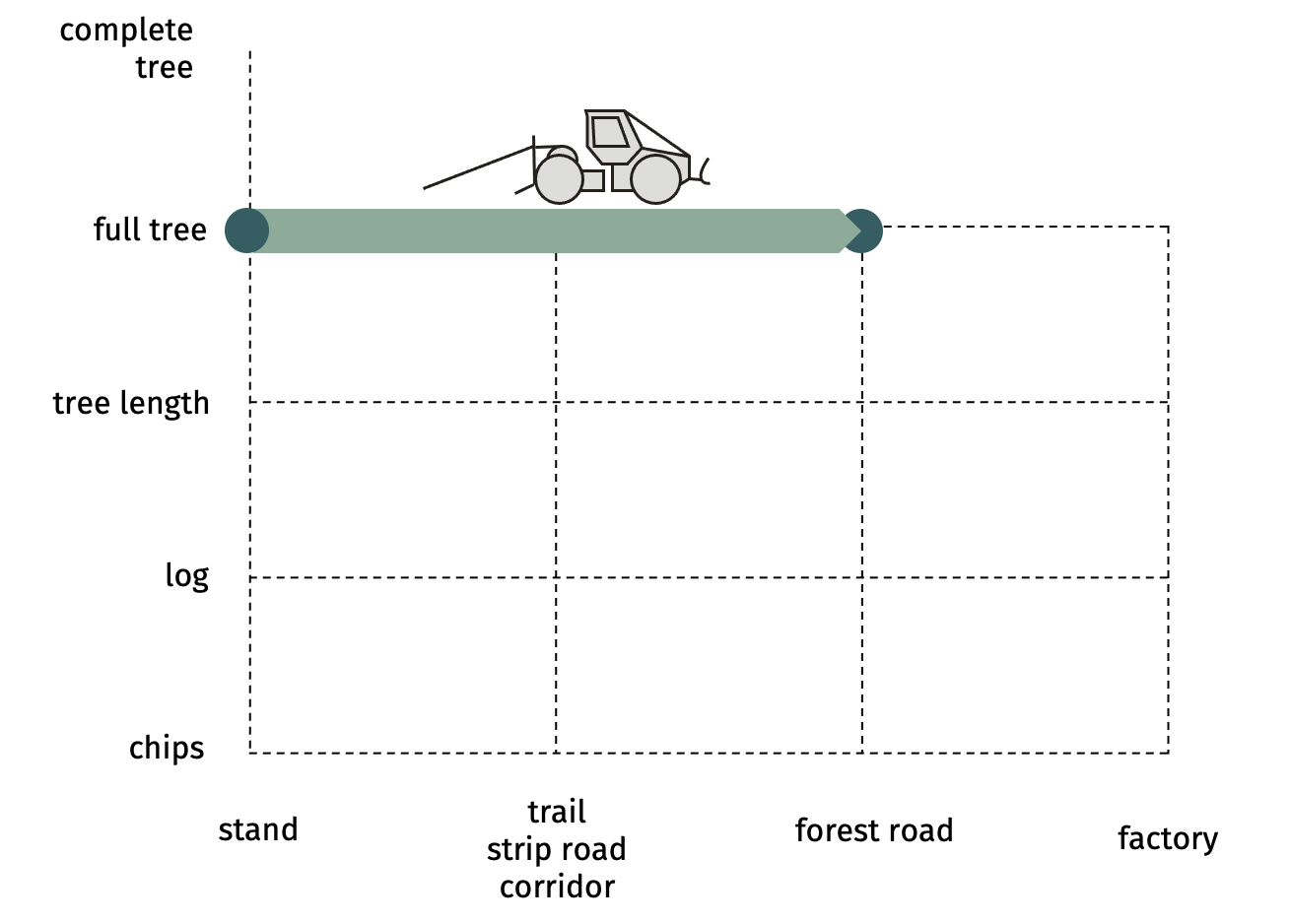

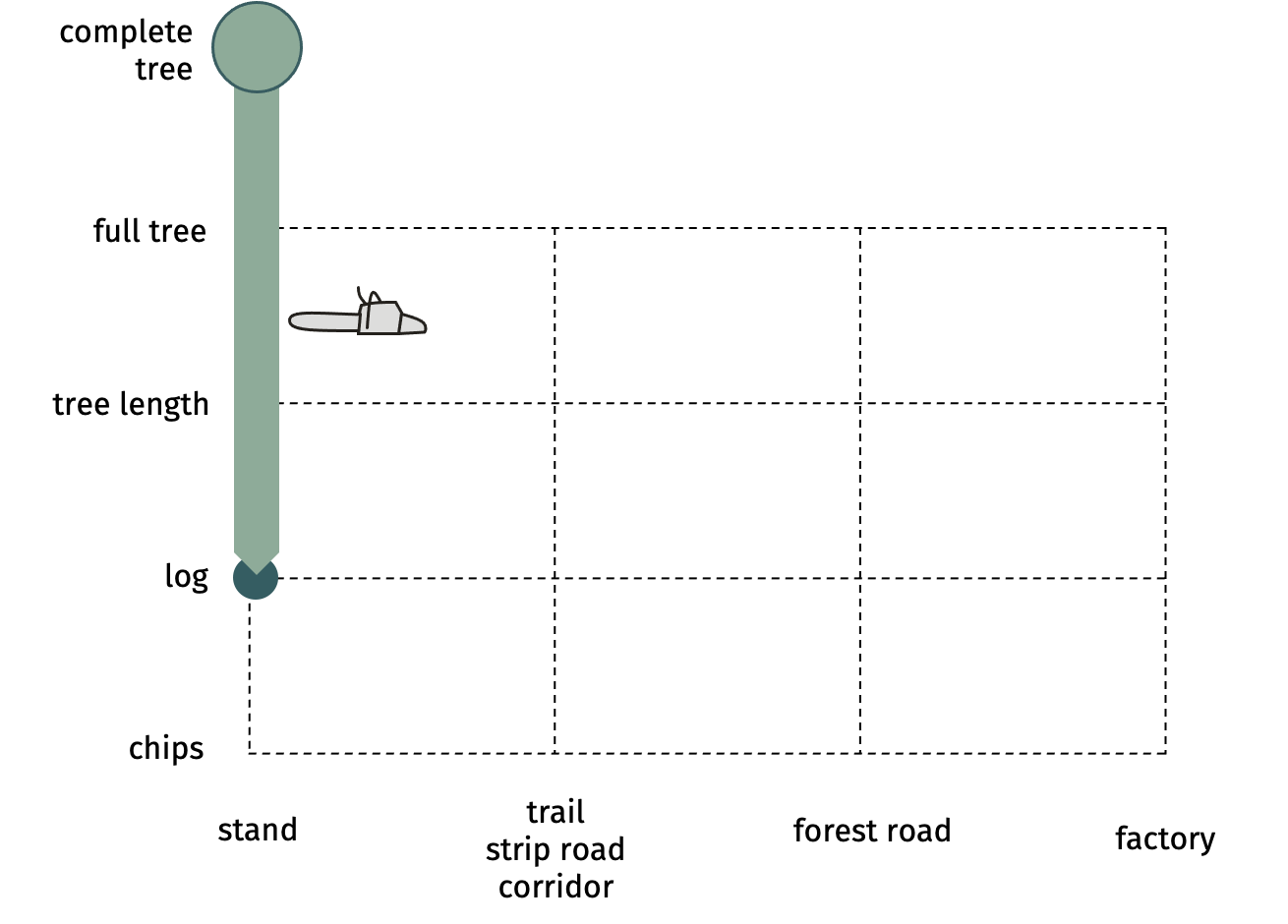

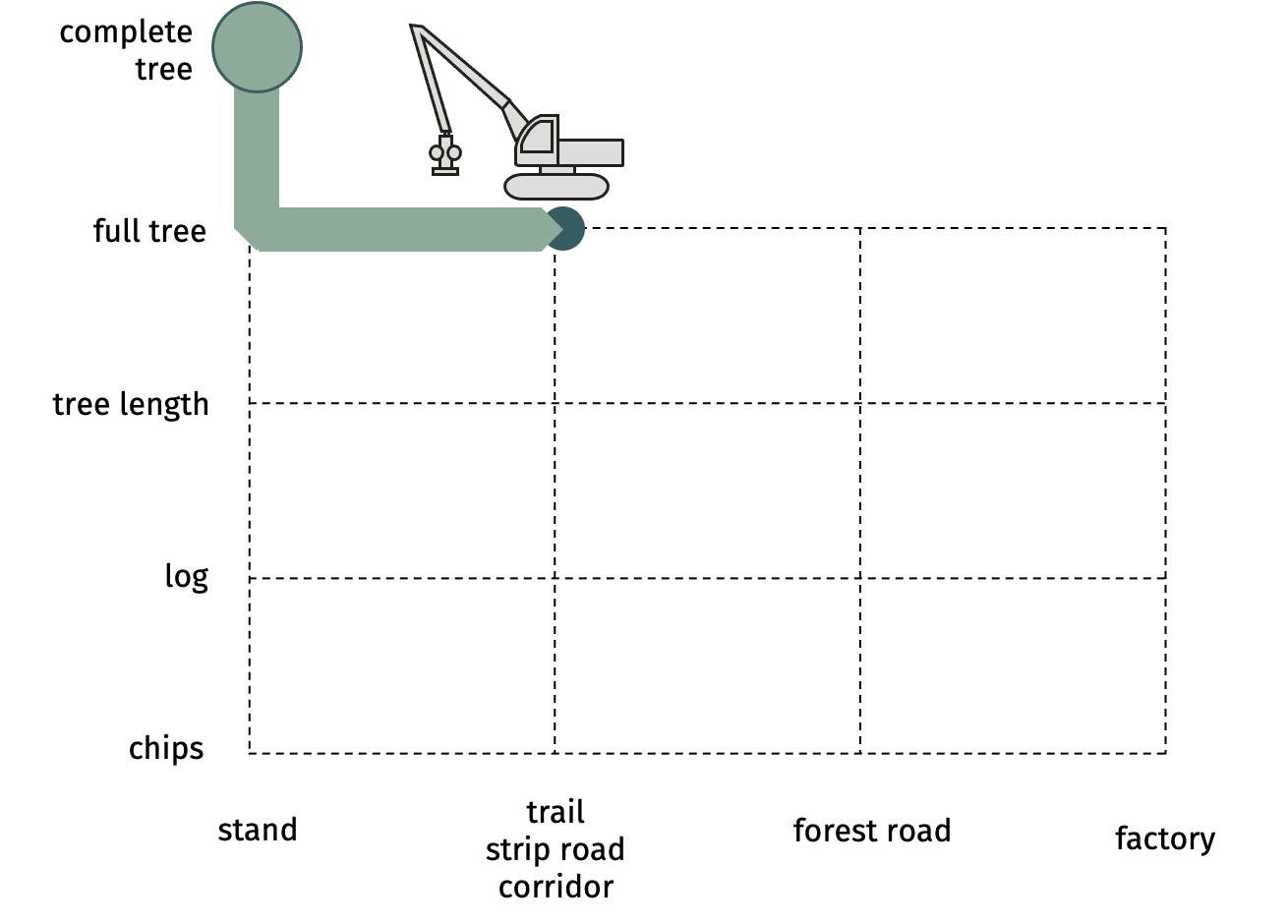

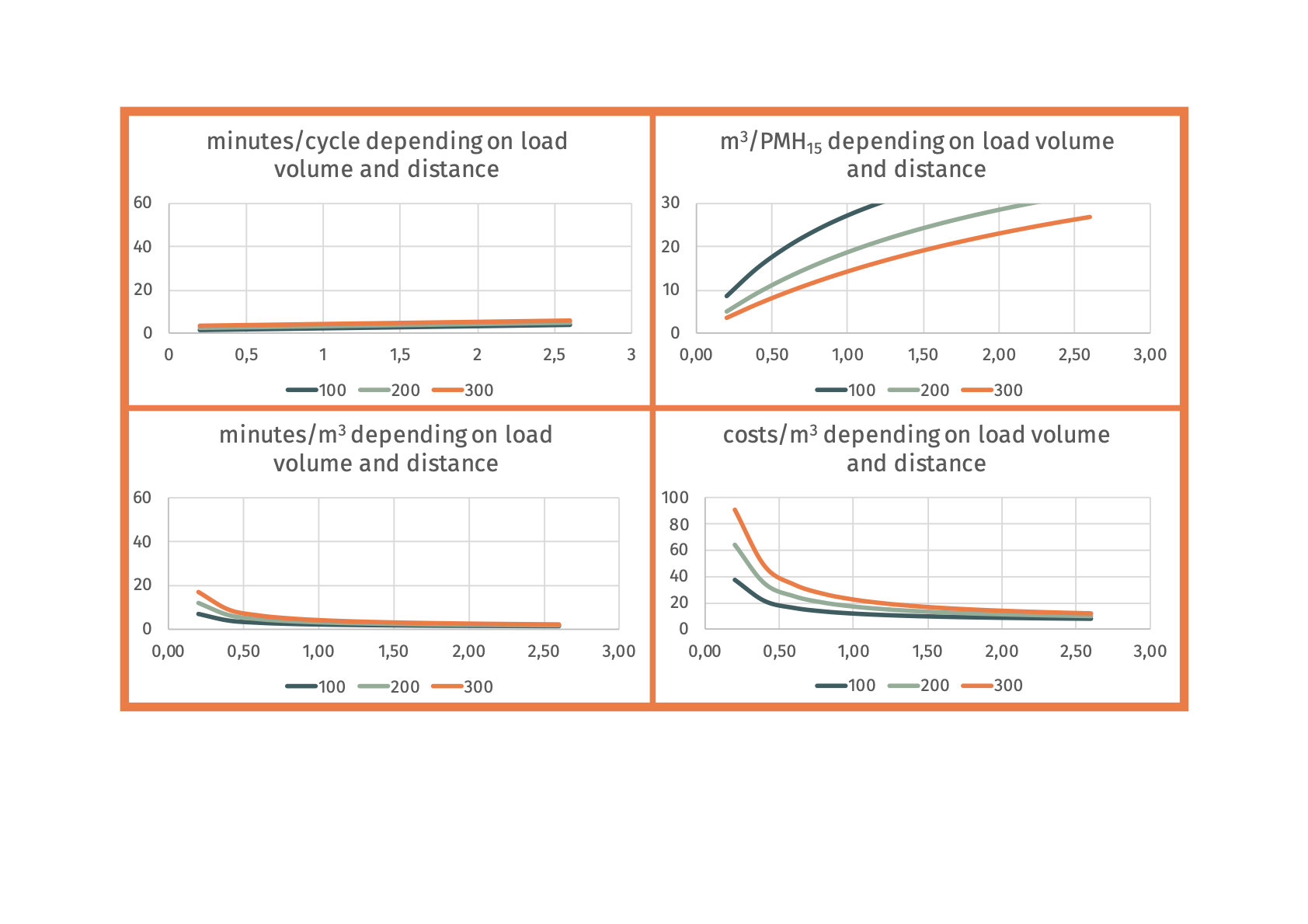

SP-11-31 pre-skidding and skidding of full trees with a tractorFelled trees are pulled to a trail by means of a tractor winch and collected; when some full trees are collected, the tractor extracts them to the forest road and unloads alongside the road. Functiogram

Advantages

Limitations. thresholds

Main use

Example:

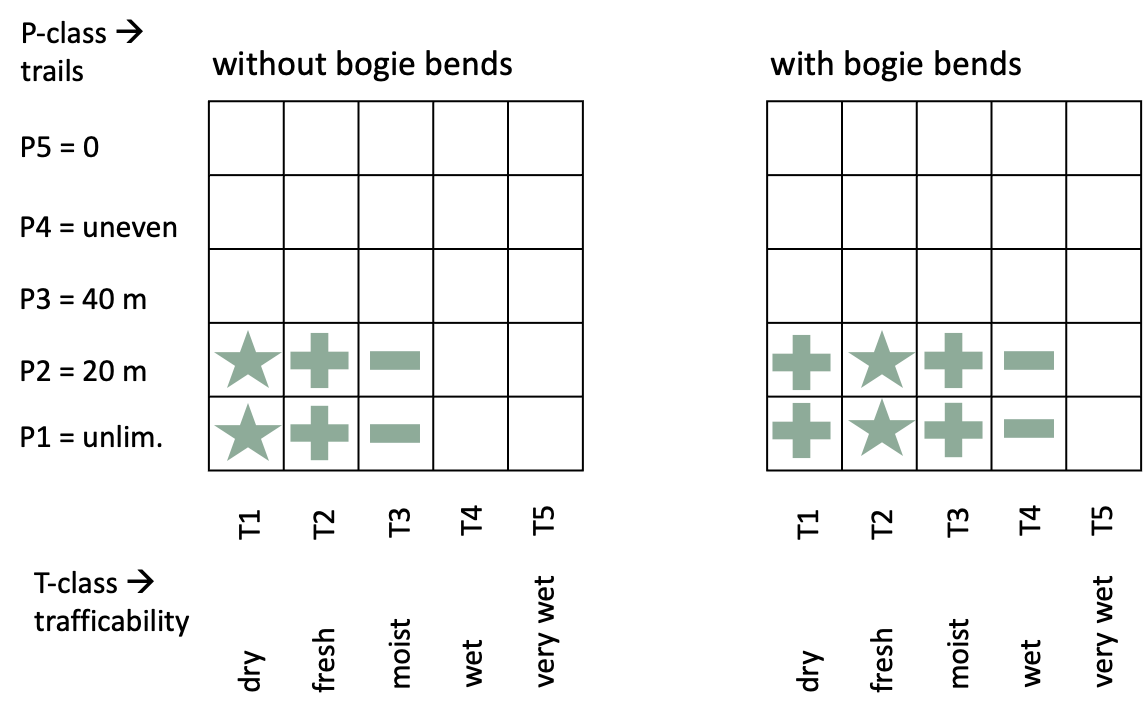

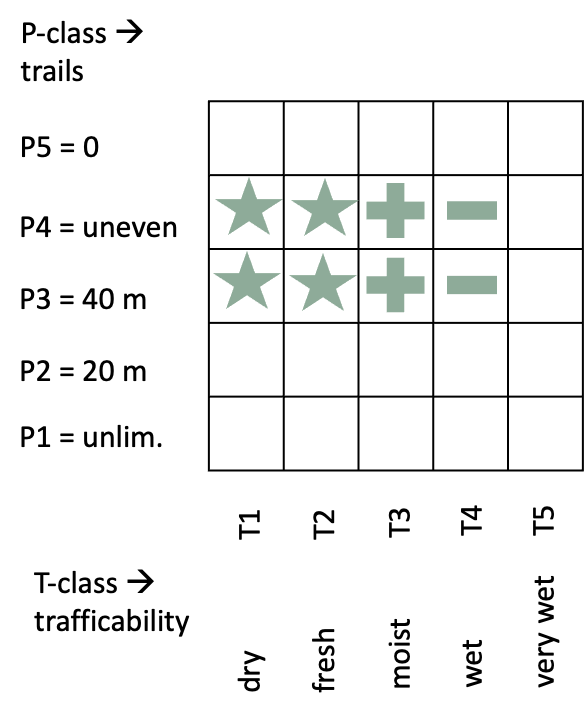

Ecograms

Social suitability:

| |