Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

C |

|---|

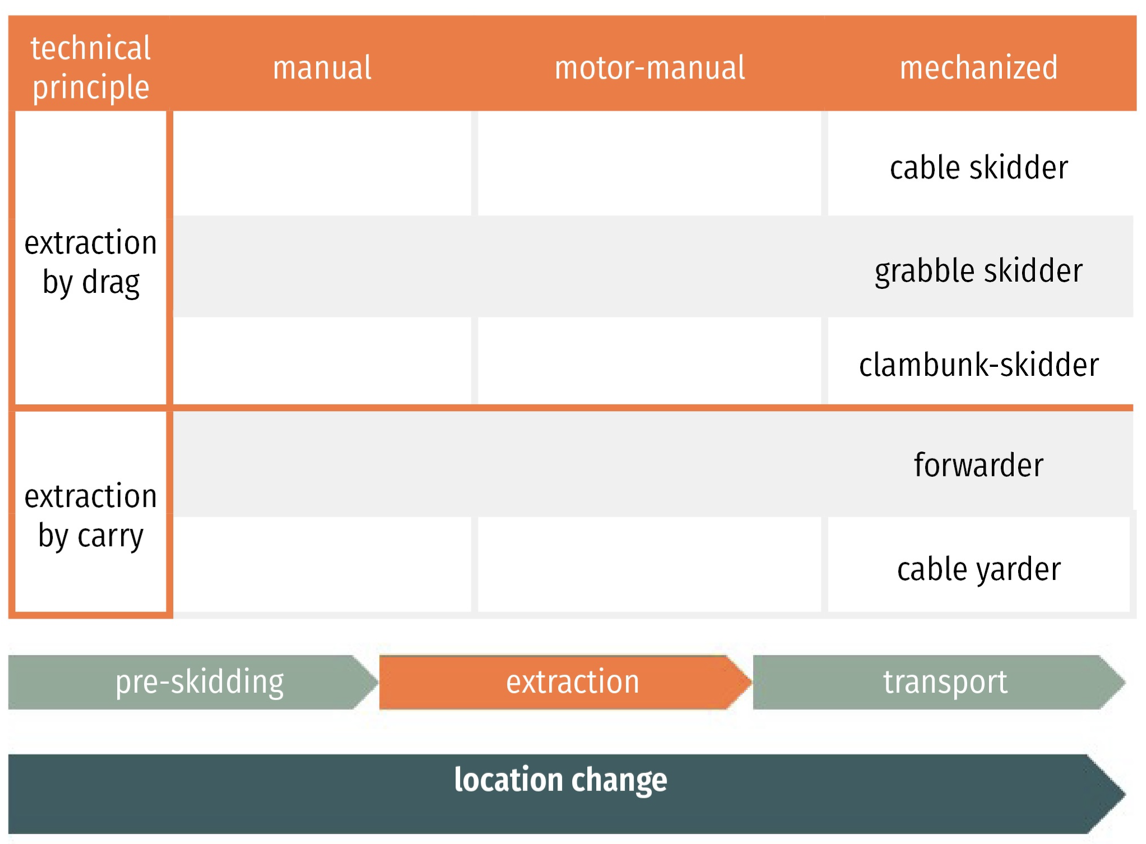

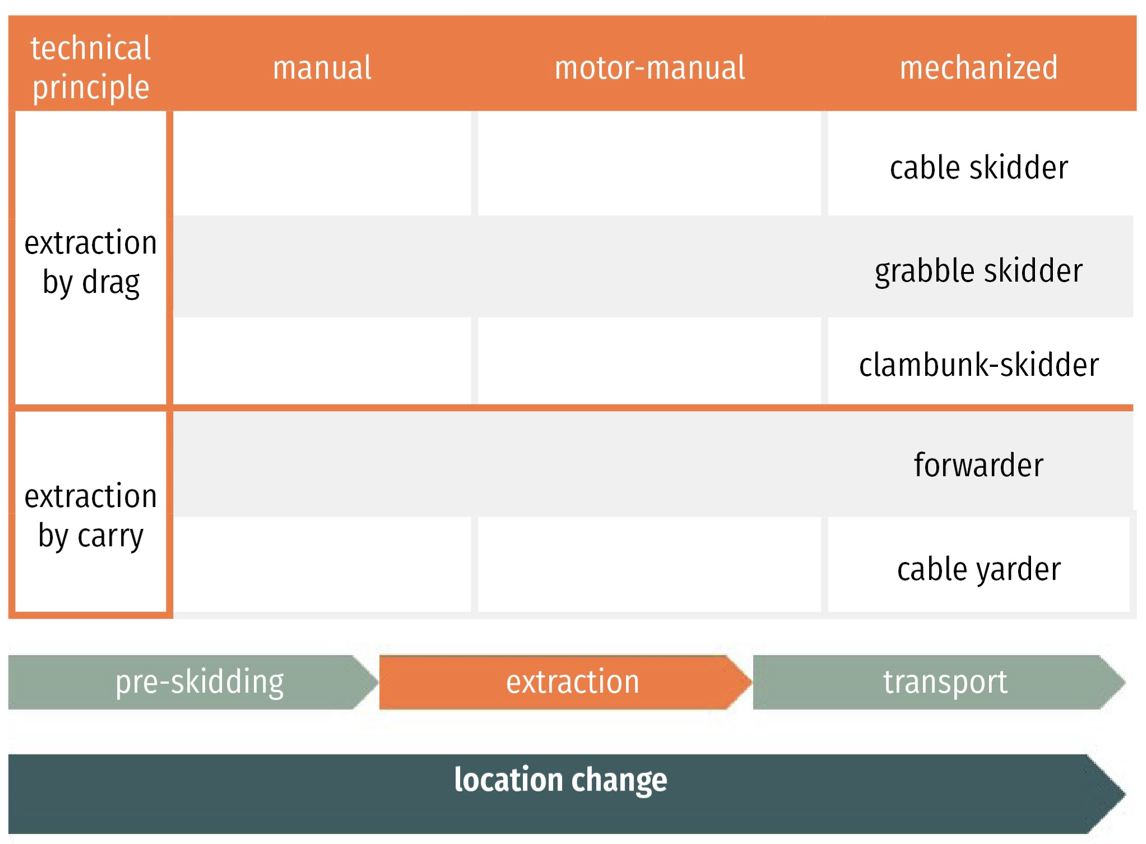

Cable skidder

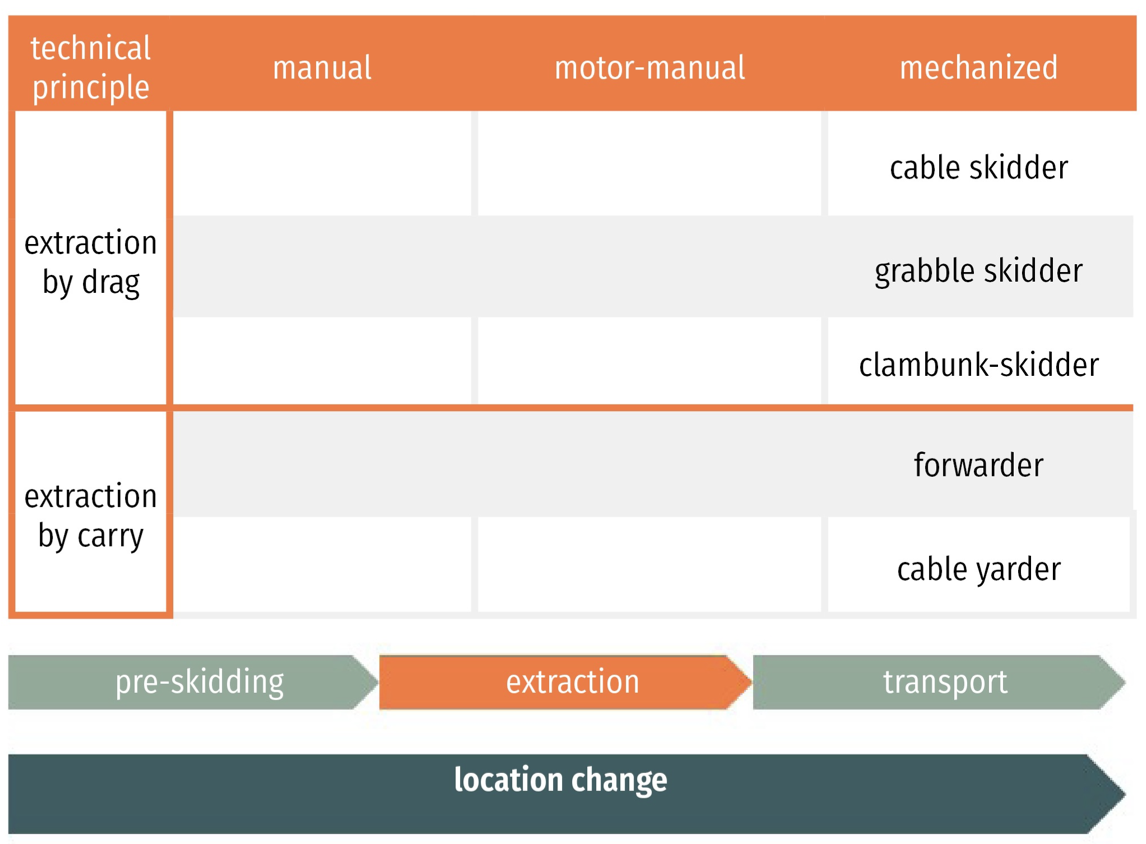

The cable skidder is a machine used for the extraction of trees. Driving on rubber tires or caterpillars it is specialized to off-road conditions. The cable skidder extracts full trees and tree length from the trail (buffer 21 & 22) to the forest road (buffer 31 & 32). Instead of a cable, trees can be dragged by a grapple skidder, clam-bunk skidder, or loaded with a loading crane to a forwarding trailer, forwarder. Another possibility for extraction on un-accessible terrain is the cable yarder or the helicopter. It contains a single or double winch with reeling functions. With the cable given by the winch the load can be compiled and hold. The extraction of the load takes places in a dragging movement. Since the cable skidder is a self-propelled machine, the work with the cable skidder is declared as simple mechanized work.  (Photo BOKU)  | |

Cable yarderThe cable yarder is a machine used for the extraction of trees. Other machines that can be used for this sub-process are the cable skidder, grapple skidder, clam-bunk skidder, skidder with a loading crane, farm tractor equipped with a forwarding trailer, and forwarder. The cable yarder extracts full trees and tree lengths from the stand (buffer 11 & 31) to the forest road (buffer 12 & 32). The extraction takes place in a carrying movement. Therefore, a cable is stretched between the tower of the cable yarder, and a standing tree or a second, mobile tower. On this cable a carriage is riding which lifts the load into the air and carries it along the cable line. To have an undisturbed transportation of the load the cable yarding system is erected on corridors, which are free from trees. The extraction with a cable yarder is soil friendly because the cable yarder does not move itself during the extraction process and the load is in the air during the transit. So, the corridor underneath the cable line does not experience any load. The negative aspect of the cable yarder is the time-consuming assembly and dismantling, which makes this extraction option expensive. The cable yarder is primarily used in the mountains and in other rough terrain. Working with the cable yarder is considered as simple mechanized work. (See PR1-B03 and B07) (Photo BOKU)  | |

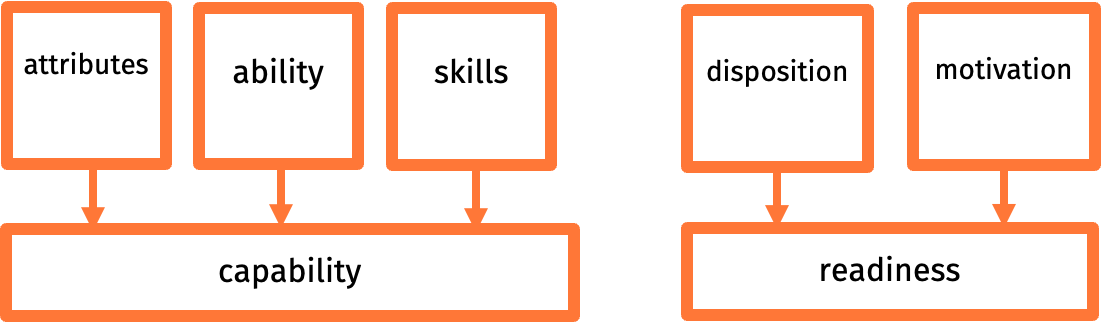

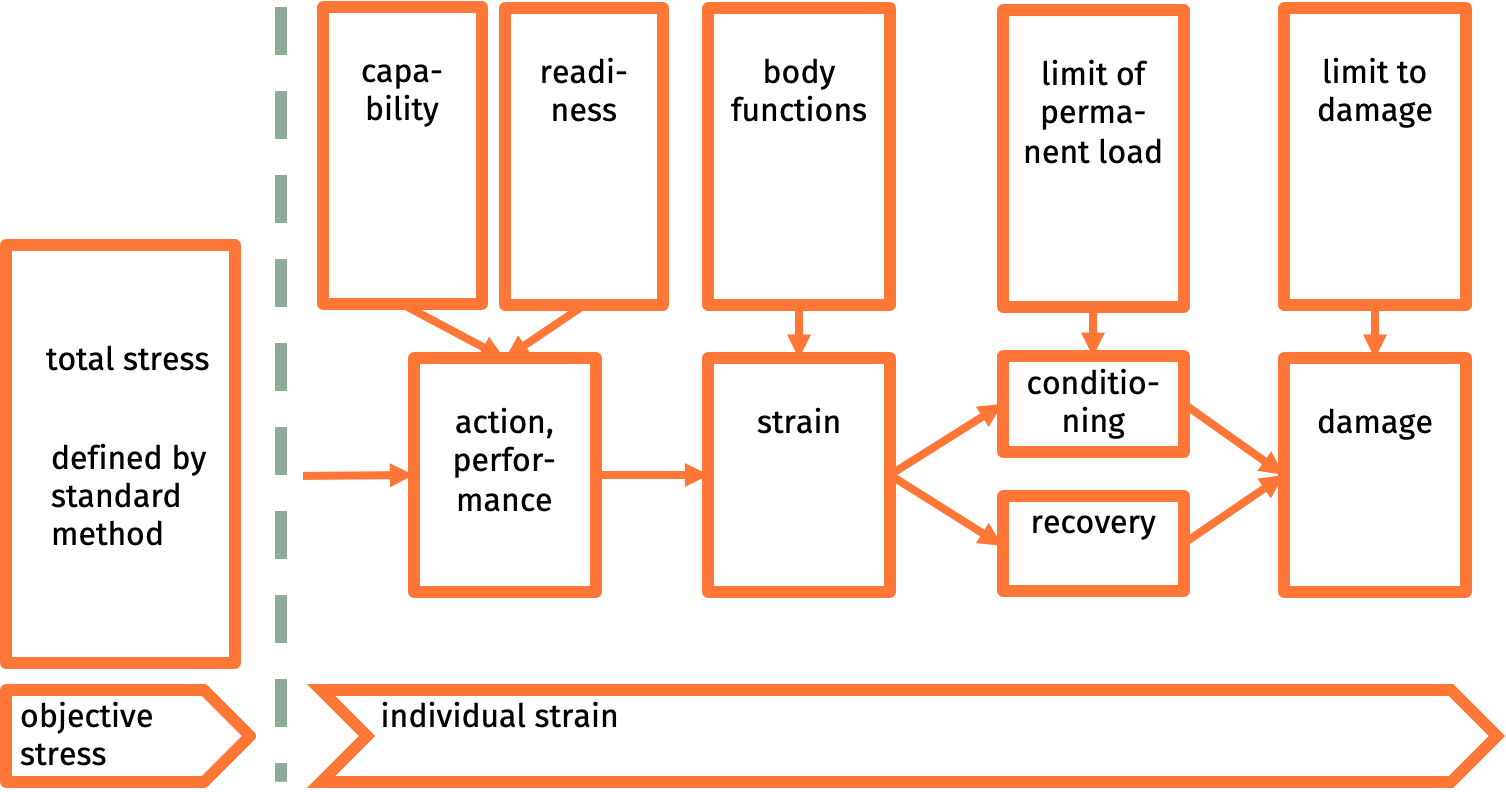

Capability of a workerErgonomics follows a very simple basic model that derives from physics: When you impact a body with a certain stress, the body will react with a corresponding strain. Since a standard method causes a stress that is typical for this standard method, the strain as a reaction to this typical stress situation should be typical, too. The intensity of the strain, however, is not the same. It depends on the worker: his personal attributes, his abilities and his skills (together they form the capability for work). And it varies due to the actual disposition and motivation (together called readiness for work), and his health. If the strain overruns the permanent work load, breaks are necessary for his personal recovery to avoid acute or chronic damage. The capability of a person is a combination of attributes, abilities, and skills. If the capability fits the demands of the standard method, the strain is low. If not, strain will keep accumulating… Thus, the strain can differ from person to person, though the job is the same. (See more under TDiv PR1-E04)  | |

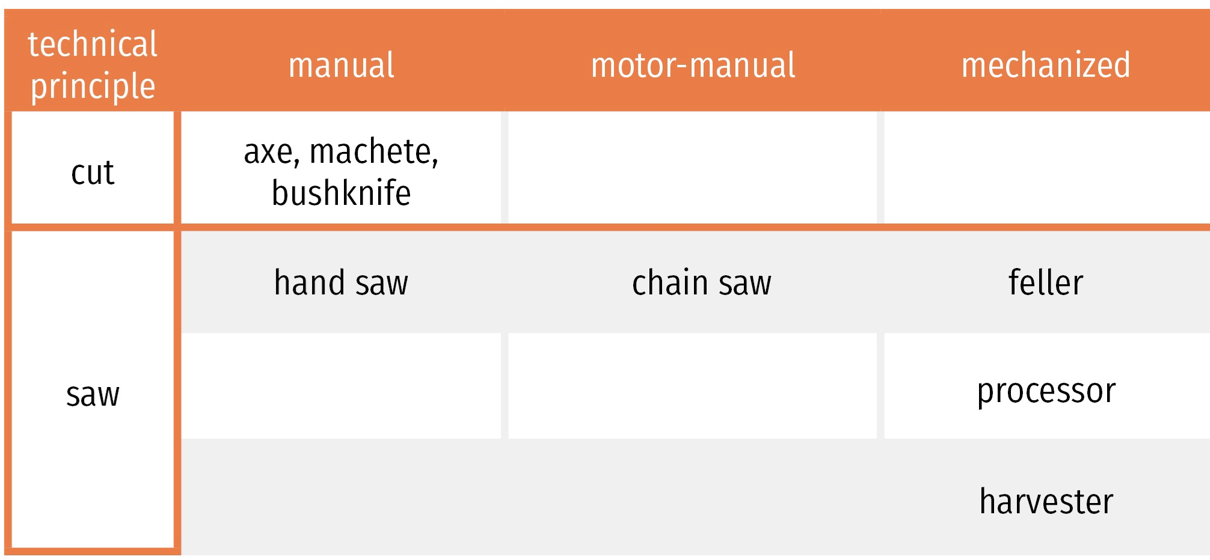

ChainsawA chainsaw is a motorized tool that it used to saw off a complete tree from its roots (buffer 10 to 11). Furthermore, it can be used for delimbing (buffer 11 to 12) and to cross-cut trees into logs (buffer 12 to 13). The alternative commonly used in forestry for the felling sub-process is the feller and for the felling - pre-skidding - delimbing sub-processes the harvester. The sawing movement is performed by a saw chain, which runs over a chainsaw bar. Due to the motor of the chainsaw, the user does not need to apply force for the movement of the saw itself. Therefore, working with the chainsaw is by far easier than working with an axe or a hand saw. Since the chainsaw is mechanically driven but must be held in position by a human being, the work with the chainsaw is classified as motor-manual work. (See PR1-B03 and B07)  | |

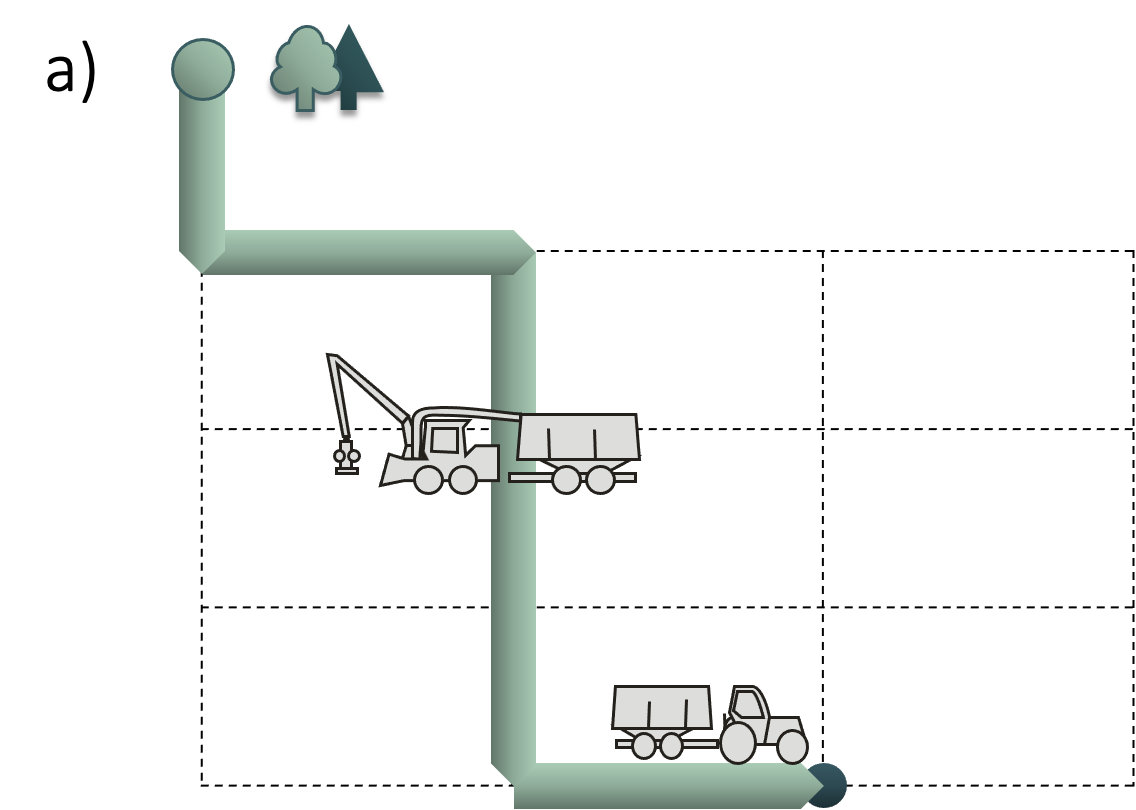

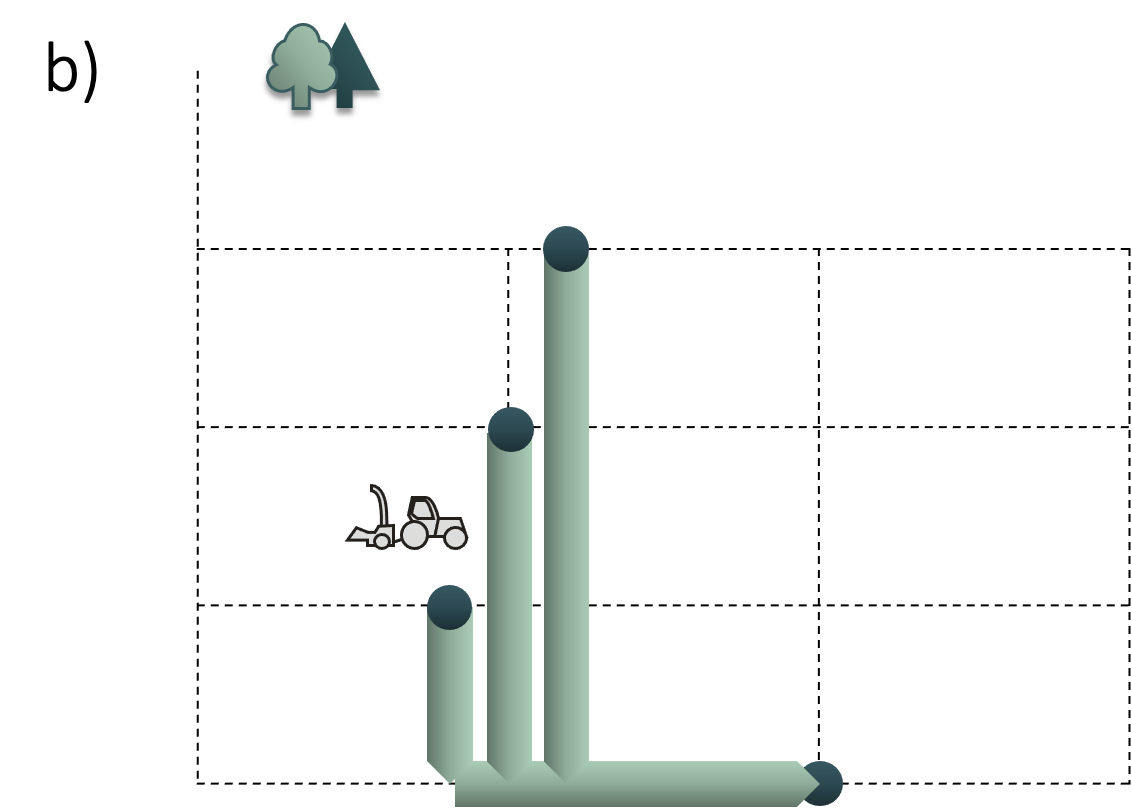

Chip methodThe chip method is one of four different functional groups of harvesting methods. The others are fulltree, tree length and cut-to-length method. With chip methods, the wood is chipped before it reaches the forest road. The two most common alternatives are: An integrated feller-chipper (a) fells the trees and chips them in a single pass. Chips are blown into a container, carried by the feller-chipper or by an auxiliary vehicle. Or the trees are felled, moved to the trail and chipped there (b). (See more at TDiv PR1-B07)   | |

Clam-bunk skidder

The clam-bunk skidder is a rubber-tired or tracked machine used for the extraction of trees. Other machines that can be used for this sub-process are the cable skidder, grapple skidder, skidder with a loading crane, farm tractor equipped with a forwarding trailer, forwarder, and cable yarder. The cable skidder extracts full trees and tree length from the trail (buffer 21 & 22) to the forest road (buffer 31 & 32). Therefore, the clam-bunk skidder is equipped with an integrated loader that lifts one end of the tree lengths into an inverted clam. The clam holds the load during the extraction process, resulting into a dragging movement of the load. Like all skidders, the work with the grapple skidder is declared as advanced mechanized work. (See PR1-B03 and B07)

| |

Compatibility, ecologicalCompatibility, ecological see ecological compatibility | |

Compatibility, societalCompatibility, societal see societal compatibility | |

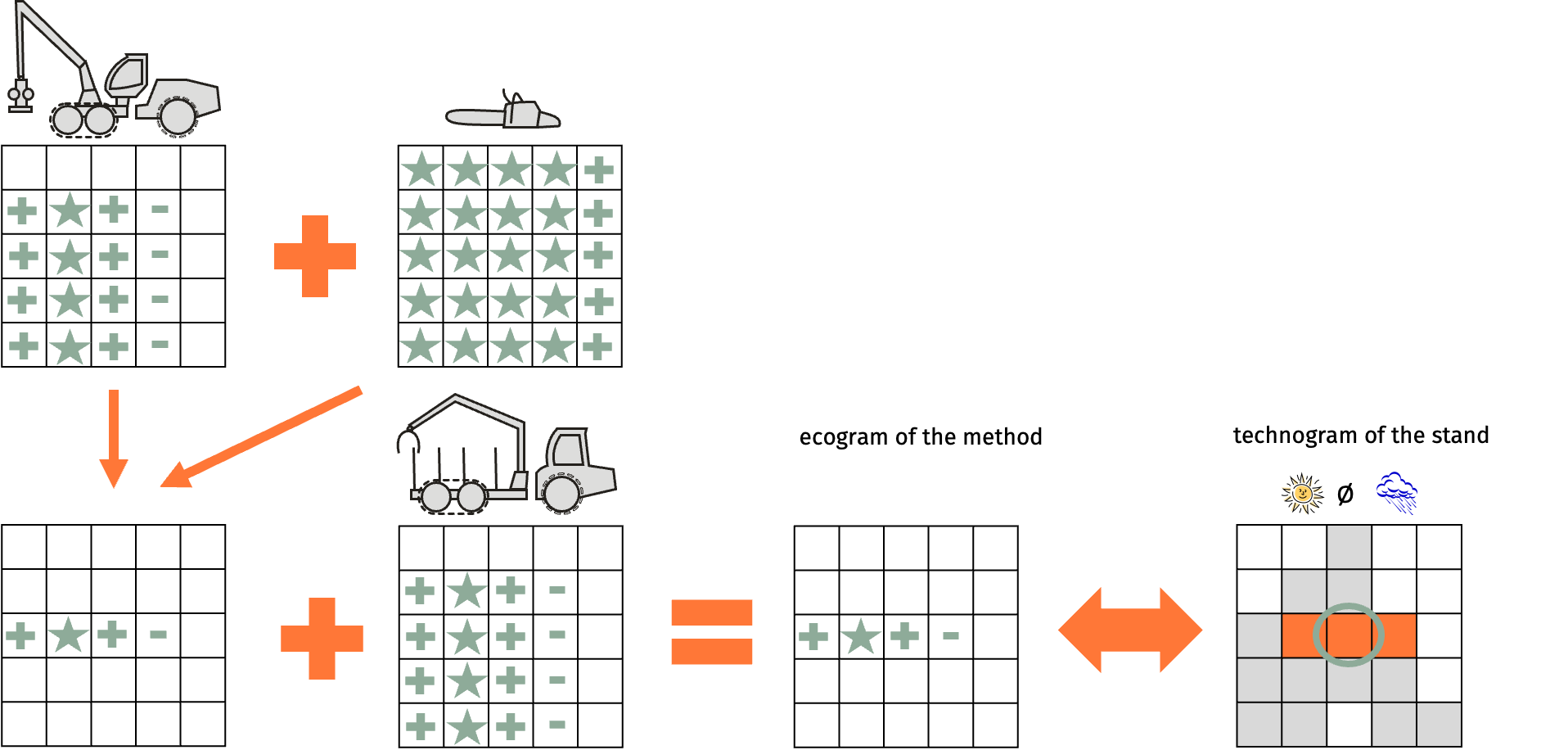

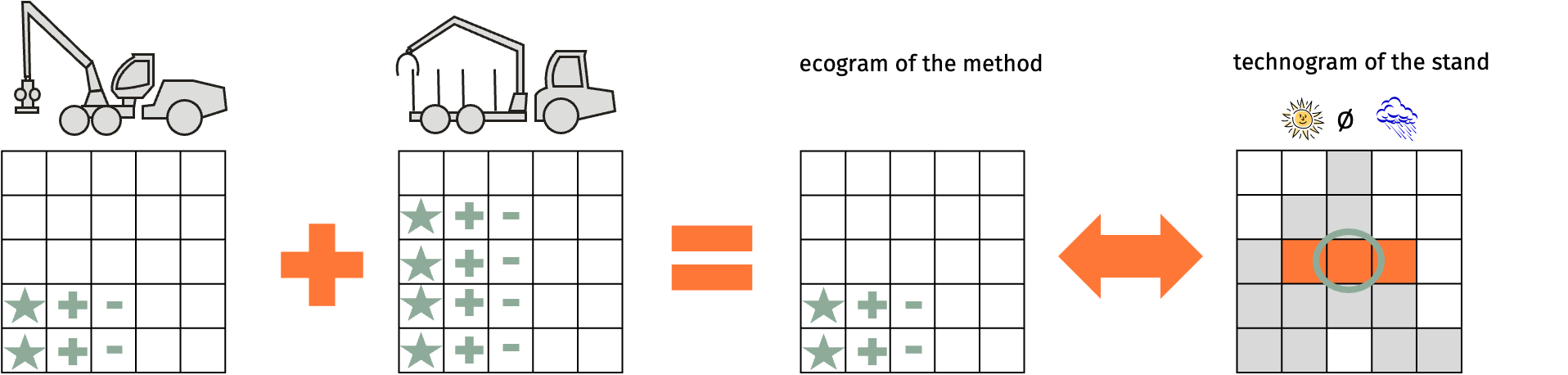

Composed ecogramIn Technodiversity, the compatibility of a working method is expressed with the help of an ecogram. But since the working method in nearly all cases is a composition of two or more sub-processes, the ecogram of the method must be composed by the ecograms of the sub-processes, too. For example, we have a fully mechanized ctl-method with harvester and forwarder. Since the reach of the harvester is limited by the length of its crane, it needs to drive near to each harvest tree. As long as the harvester may drive offroad (=P1), this is no problem. But when we demand that the machine remains on trails that also will be used in future (say permanently), the trails should not be spaced further than twice the length of the crane, normally 20 m (=P2). The assessment is very good on dry soil and less with increasing humidity. Before the forwarder comes, short logs are stored alongside the trail. So directly, the distance of the trails doesn’t matter for this machine (but indirectly it does: the wider the distance the higher the volume that must be transported on one trail and therefore the higher the impact to the soil there). The compatibility concerning soil moisture is the same as with the harvester. To combine these two ecograms, we introduce the “bottle-neck-rule”: For each field in the ecogram, the worst assessment of all procedural steps is used as final assessment for the total method. Both, harvester and forwarder are assessed in a similar way for the T-classes, but the harvester goes only for P1 and P2. So, the total method also is only compatible for P1 (driving without binding at permanent lines) and P2 (trails with 20 m distance). We see that this method does not fulfil the demands of the forest owner that are expressed in the technogram.  In another example, a working method is composed by three sub-processes: felling with the chainsaw, processing by machine and extraction by a forwarder fitted with bogie tracks. Each sub-process has its own suitability that can be expressed by a typical ecogram. Thus, first we must look at the ecograms of each sub-process. The worker with his chainsaw is compatible nearly everywhere. The ecogram shows mostly star symbols, only under very wet conditions the walking can be limited. The processor (here a harvester that is working on the trail), is mainly limited by the moisture; since the trees are pre-skidded to the trail it can be used under all P-classes (except P5). Both sub-processes together only make sense at a trail distance of 40 m. Therefore, the processing of this method is only reasonable at P-class 3 (=40 m). The assessment whether the process is very good, good or limited compatible, depends on the worst case; here the processor (again following the bottle-neck principle). The forwarder drives on the trails, too. Since the logs are pre-skid, it can be used under all P-classes P1-P4 (except P5). The common ecogram of the total method again is a combination of the ecograms of processing and extraction under observing the bottle-neck principle. When – like in this example – the technogram of the stand demands for the fields P3-T2, -T3, and -T4, this method is well compatible under normal and dry conditions. (See more at TDiv PR1-D05) | |

ConditioningErgonomics follows a very simple basic model that derives from physics: When you impact a body with a certain stress, the body will react with a corresponding strain. Since a standard method causes a stress that is typical for this standard method, the strain as a reaction to this typical stress situation should be typical, too. The intensity of the strain, however, is not the same. It depends on the worker: his personal attributes, his abilities and his skills (together they form the capability for work). And it varies due to the actual disposition and motivation (together called readiness for work), and his health. If the strain overruns the permanent work load, it may have two consequences: On one hand the body is pushed to improve its capacities. We use this effect for active training and conditioning. But on the other hand, acute or chronic damage can occur. Therefor breaks for recovery are necessary and should actively be provided by the employer. (See more under TDiv PR1-E04) | |