Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

W |

|---|

Winch | |

Working methodA working method describes a special working process. In contrast to the term process, which only describes what actually happens, the working method has a more normative implication: It declares, which system elements are combined, and in which steps they are concatenated. The most important information is: what kind of tool or machine is used, what are the inputs and for which outputs do we aim? When we look mostly on the worker: how he must behave, what he has to do, when and in which sequence should he go on, we call it operational method. But sometimes the worker does not exactly what he is asked to do. Maybe he invents his own sequence of steps or he works in a way that conflicts with any safety rules – then we call it the manner of working. (See more under TDiv PR1-E03) | |

Working processSee process | |

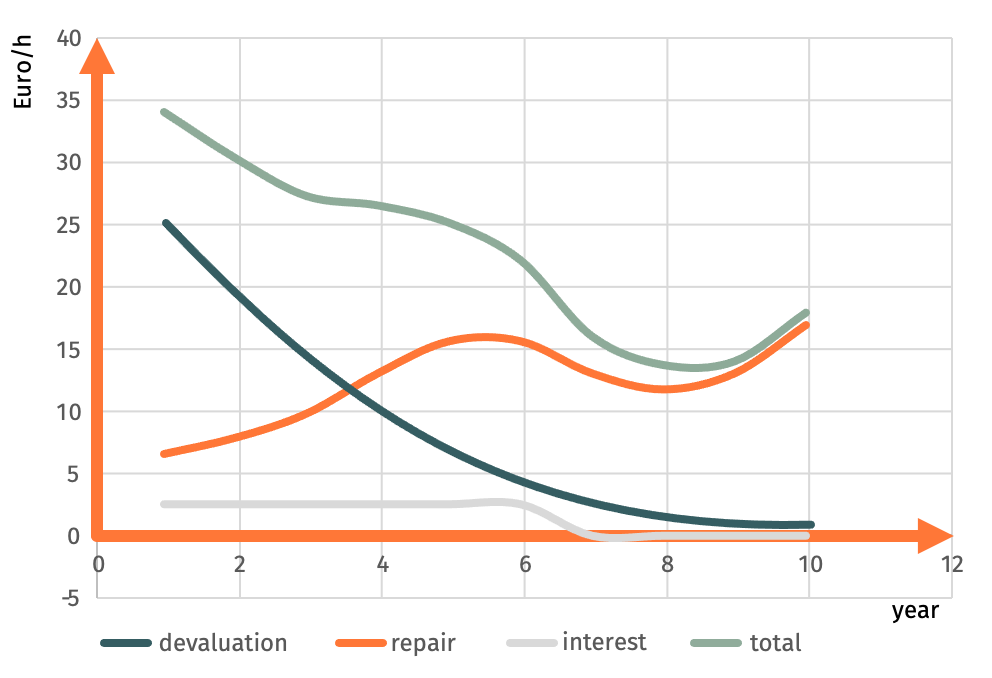

Written-off machineCost calculations normally are made for new machines, because the investment is very high and needs precise planning for pay-back. Written-off machines are old machines that are working longer than it was planned. Consequently, some cost elements, that are important at new machines, go here for zero. The depreciation and interest costs, for example, can very low or zero, but the costs for repair and maintenance are increasing. Experiences show that the repair and maintenance costs (R&M) are not unlimited. Very often there is a period, when R&M costs remain stable or even decrease for a few years, before they increase again. This is because the owner decides to stop investing in the machine and only use it for as long as it makes sense to do so.This machine can be a risk for him, but as long as it works it is cheap. For a company that is working professionally under a high market pressure, the risk to interrupt the work due to an old machine breaking down is too high. This company tends to work with new machines only for a short period that may match the depreciation period.Then it will sell the machine on the second-hand market. The company that buys this machine pays a low price. Depreciation and interest are low. While the costs for fuel and lubricants may be more or less the same, and also the drivers have comparable costs. But the costs for repairs and maintenance can be doubled until the total cost is equal to that of a new machine. This is the reason, why machines often find a second life in smaller companies with lower work performance, where the owners repair their machines themselves. (See more at TDiv PR1-C05)  | |