Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Spécial | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | Tout

S |

|---|

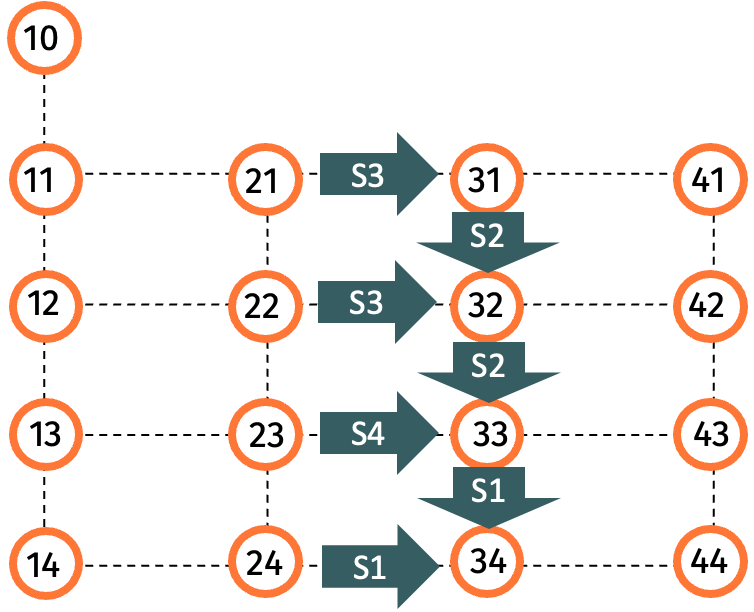

S-classesPublic recreation can get in conflict with harvesting operations. Based on SINUS-milieus, different user groups are found that have very different needs and expectations to the forest owner. But all forest visitors have one common need: they use the forest roads as their access to the forest and don’t want to be disturbed. If we keep the roads clear for people to move on them, this can help to improve the acceptance of forest techniques and operations. Thus, the forest roads take over the role as a key factor for the acceptance of techniques by the forest visitors. Based on the functiogram, we can define five S-classes for societal compatibility: S1 chipping of wood on the forest road of storing of chips there with noise, dust, and trash on the ground = arrow ending at 34; S2 processing round wood on the forest road with impact to the road = arrow down ending at 32 or 33; S3 unloading and loading of tree lengths or full trees along the forest road with skidding on the floor = arrow from 22 to 32 or 21 to 31; S4 unloading and loading of short wood along the forest road, only picking up of products = arrow from 23 to 33; S5 perfect, no contact with forest roads. (See more at TDiv PR1-E02)  | |

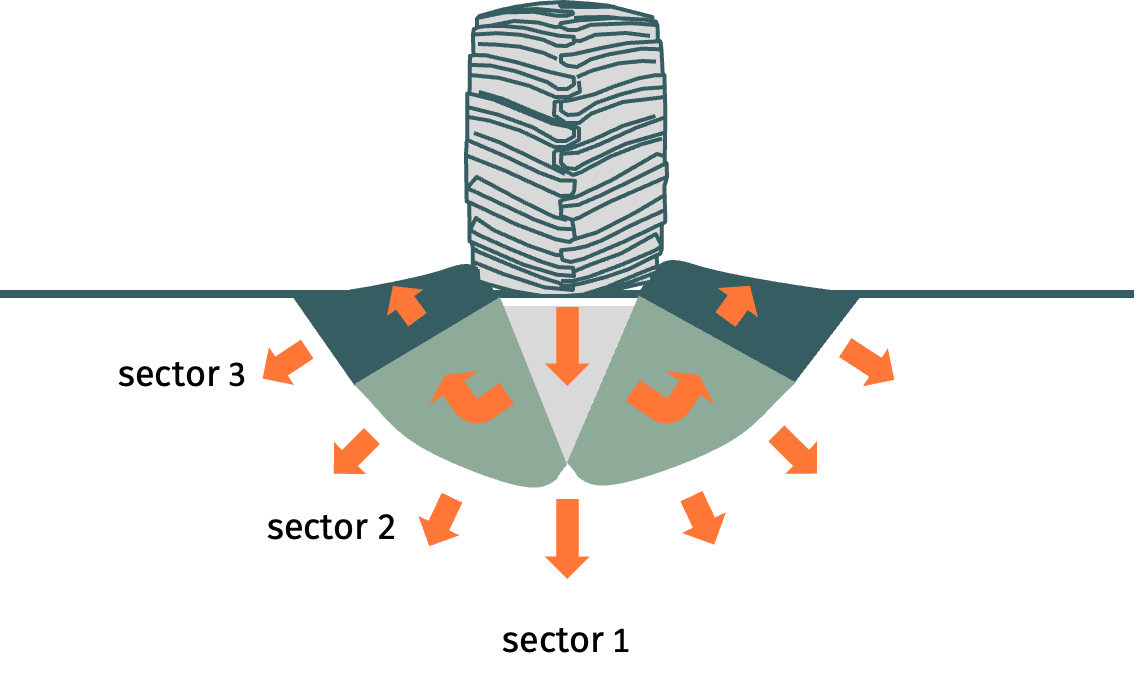

Sectors under wheelUnder a wheel, the load is covered by the soil. Inside the soil, zone of the same pressure (isobars) can be drawn like onion peels. Directly under the wheel the forces follow gravity and form a compaction. But to the left and right of the main vertical push, the soil can relax against the neighboring soil particles; the vectors turn around. The parts of the soil near the surface give way to the pressure and are lifted. Thus, ruts are not only the result of compaction, but also of lateral lifting of the soils beneath the ruts. (See more at PR1-D02)  | |

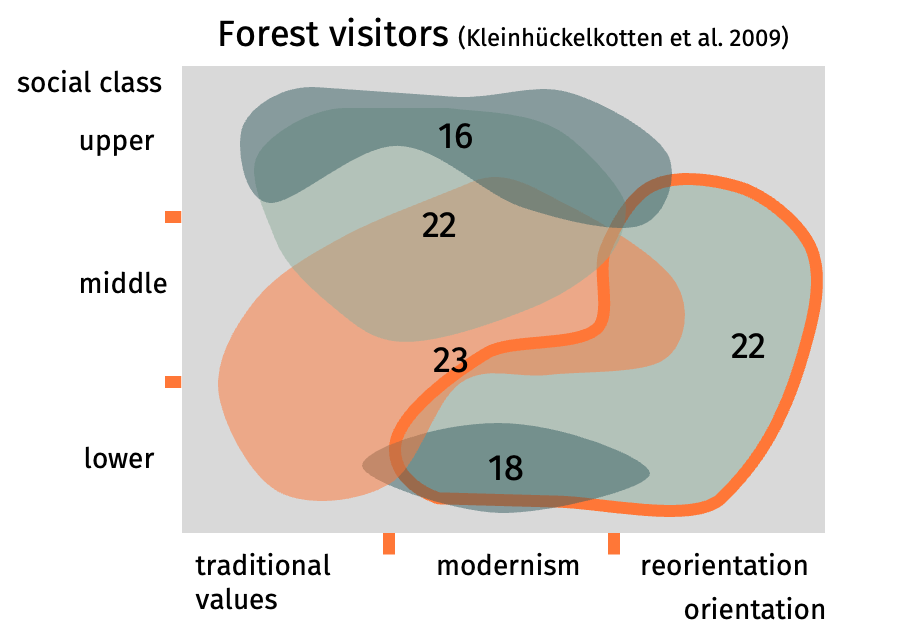

Self-centered forest usersIn a study from 2009, Kleinhückelkotten et al. have found five different groups of people who use the forests for recreation. One of them are the self-centered forest users, the others are holistic forest friends, ecological forest romantics, pragmatical distant persons, and indifferent persons. In the study, 22% have been characterized as self-centered forest users. For them, the forest is no more than a backdrop for their hedonistic activities, such as playing sports, picnicking etc. They regard any limitations as the unacceptable restriction of their freedom. As such, they are not amenable to restrictions caused by forest activities, regardless of harvesting methods and technology. (See more under TDiv PR1-E02)

| |

Side-effectsSee risks and side-effects | |

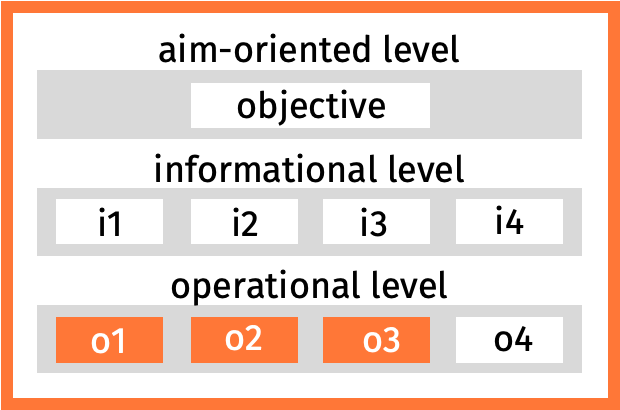

Simple mechanized workThe term mechanized work describes the level of mechanization of a technical operation. Other levels are manual work and motor-manual work. Mechanized work can further be divided into simple, advanced and automatic work. Simple mechanized work offers increased power and mobility, but all auxiliary functions are done by humans. Example: a cable skidder, which can move larger loads than a human can, and does that at a higher speed. But the attachment of the logs must be done manually by the operator. (See more at TDiv PR1-B04)

| |

Skiddingsee solutions for skidding | |

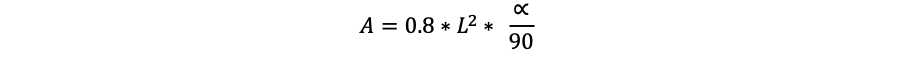

Skidding damageSkidding damage happens during the extraction. It can be caused by the machine or the skidded log. Animals seldom bump into trees, because they fear to be wounded. Machines have no sensors to protect from damage, only the driver should have. Therefore, in dense stands the moving pattern of the machine has an influence to the likelihood of a damage: Curves can be tricky, when the rear axle has a shorter turning radius than the front axle as it is common with Ackerman steering. Conventional machines like farm tractors and trucks have Ackerman steering. Dedicated forestry machines often have an articulated frame, where the two half-frames are connected by a central hinge. In that case, the rear wheels follow exactly the same track as the front wheels. The risk to damage trees is much lower. Another cause of damage is that the superstructure of a forest machine (like cabin, loading boom and basket) bumps against neighboring trees because of uneven floor. If the machine is fitted with bogies, the deflection of the chassis is only half as high then without bogies, so the danger of accident decreases. Damage to the stand can be caused by long logs, too. The area of the danger zone depends on the length of the log and the angle 𝛂 between log axis and strip road.  This formula says that the length has the most important influence on the danger zone. Thus, Systems that transport short logs make less damage to the forest stands. (See more at PR1-D01)

| |

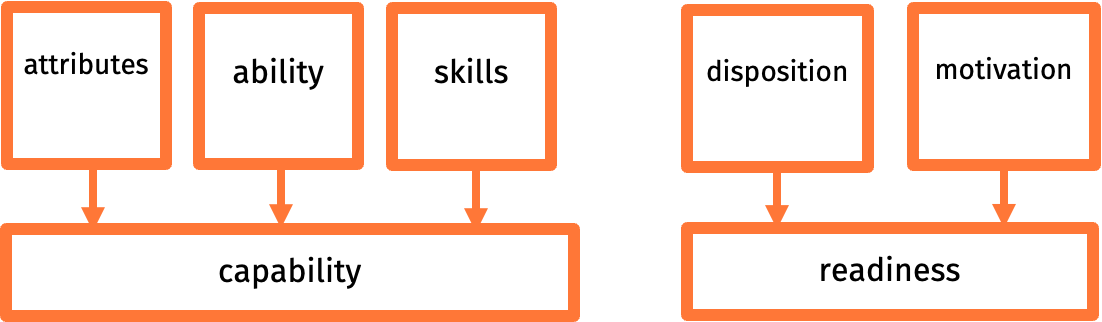

Skills of a workerErgonomics follows a very simple basic model that derives from physics: When you impact a body with a certain stress, the body will react with a corresponding strain. Since a standard method causes a stress that is typical for this standard method, the strain as a reaction to this typical stress situation should be typical, too. The intensity of the strain, however, is not the same. It depends on the worker: his personal attributes, his abilities and his skills (together they form the capability for work). And it varies due to the actual disposition and motivation (together called readiness for work), and his health. If the strain overruns the permanent work load, breaks are necessary for his personal recovery to avoid acute or chronic damage. Most jobs require a certain technique. Skilled persons can reach results that will never be possible for unskilled persons. (See more under TDiv PR1-E04)  | |

Social efficiencySocial efficiency see ergonomics | |

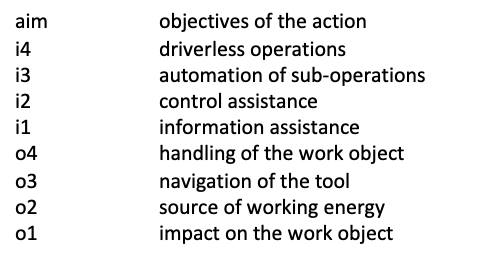

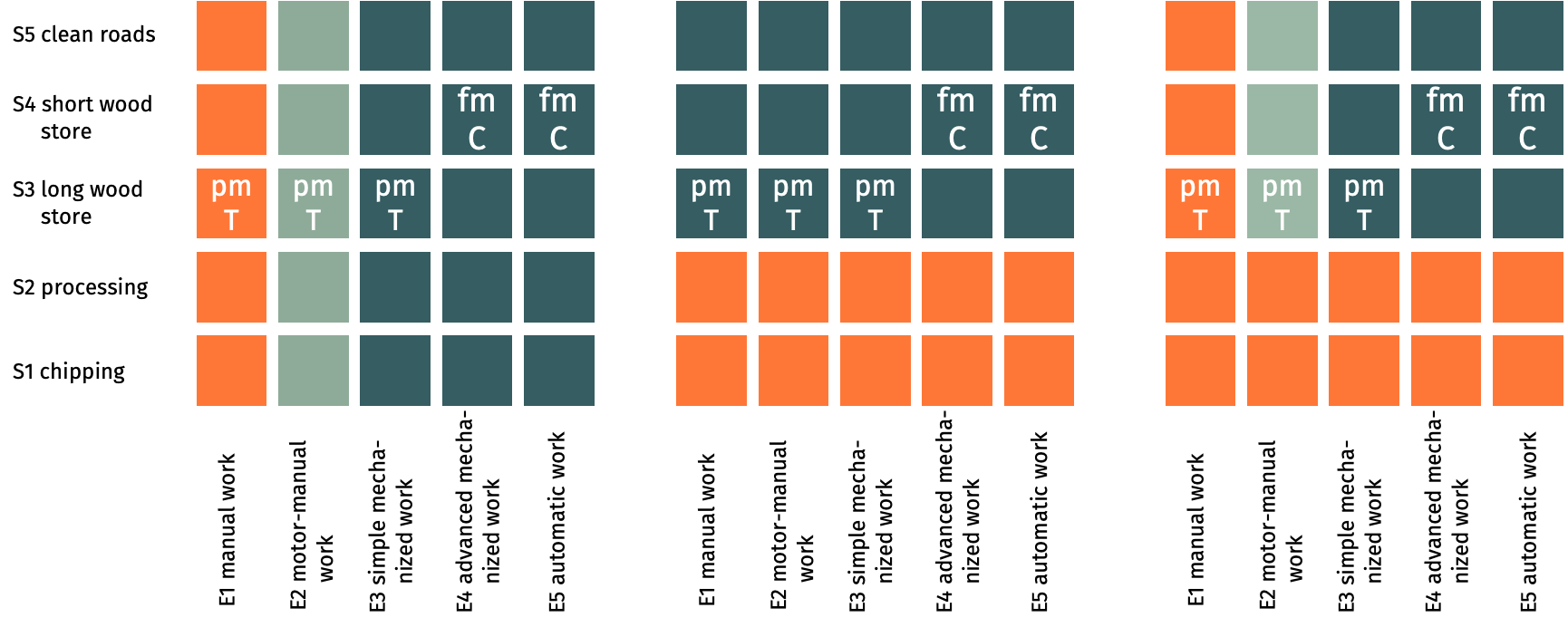

Social suitabilitySocial suitability is one sub-objective of the decision-making process. It corresponds with the social objective of the company in a means-end-relationship: The means should be developed in a way that it fulfills the end that is given by the objective of the company. The social suitability is subdivided into ergonomics and societal compatibility. On the same level are two competing sub-objectives: the economic and the ecological suitability. The relationships between them can be organized by the general concept for technical operations that is given by the company. The societal compatibility deals with the needs of the local society, within which the forest company operates. It is achieved by matching the different demands for recreation, heritage, employment etc. In Technodiversity, we have invented the S-class. Ergonomics, however, is focused on the wellbeing of the workers employed by the forest company, which is responsible for the working sites and methods. Employers must plan and conduct their operations in a way that minimizes the risk for the operators to suffer an accident or become ill. In Technodiversity, we have invented the E-class. Now we combine the assessments for ergonomics and societal compatibility in a 5x5-table, on x-axis the E-class and on y-axis the S-class. As an example, a fully mechanized CTL method with harvester and forwarder falls into the S-class S4 and E-classes E4 (forwarder) and E5 (harvester). Another option, a partly mechanized tree-length method with horse and tractor, falls in S-class 3 and E-classes E1 (horse), E2 (chainsaw), and E3 (tractor). Now the decision maker can mark his individual preferences. Here we chose traffic light colors to represent green (okay), yellow (limited), red (not acceptable). For example, one decision maker might feel uncomfortable with manual work due to safety concerns and prefer mechanized work, instead. Then he marks E1 with red, E2 with yellow, and the other columns with green (left table). Concerning compatibility with recreational needs (in the middle), our decision-maker may want to avoid processing on the forest road. Loading operations, however, could be accepted without constrains. Consequently, S1 and S2 are not acceptable, but all other S-classes are okay for this decision maker. When we combine those assessments (right table), at each intersection the less desirable color is dominant (comparable with the bottle-neck-rule). In our example we see, that the fully mechanized cut-to-length method with harvester and forwarder (fC) fits well to the societal assessment of this company. The partly mechanized method fails, due to the critical assessment of manual and motor-manual work. (See more

under TDiv PR1-A03, -E01, -E04, and E05)  | |