Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Caratteri speciali | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | TUTTI

Pagina: 1 2 (Successivo)

TUTTI

M |

|---|

Manner of workingFor any operational method, the tools and machines as well as the working steps are fixed. But sometimes the worker does not exactly what he is asked to do. Maybe he invents his own sequence of steps or he works in a way that conflicts with any safety rules – then we call it the manner of working. Since the worker is the one who has the most experience with the working situations, it can happen that his manner of working leads to an improvement of the standard operational method. But if he breaks any legal limits or safety rules, then this manner cannot be accepted. (See more under TDiv PR1-E03) | |

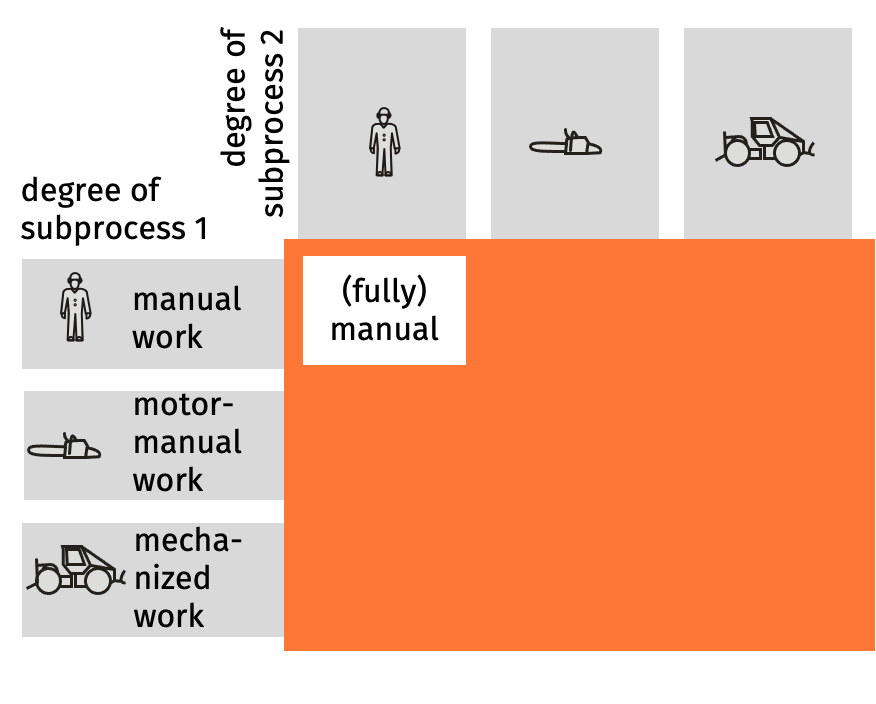

Manual methodIn Technodiversity, the total harvesting process normally is seen as a combination of several sub-processes. Each sub-process has a certain degree of mechanization. The degree of mechanization of the total method is given by the combination of these single degrees. There are five degrees of mechanization: (fully) manual method, partly motor-manual method, (fully) motor-manual method, partly mechanized method, fully mechanized method. If there is no power equipment in any sub-process, say both sub-processes are done by manual work, the method is a fully manual method. Fully manual methods are not unusual in developing economies or in part-time work. The word fully underlines the character of the process, but it can be missing. (See more under TDiv PR1-B04 an d B05)

| |

Manual WorkThe term manual work describes the degree of mechanization of a technical operation. Other degrees are motor-manual work and mechanized work.

| |

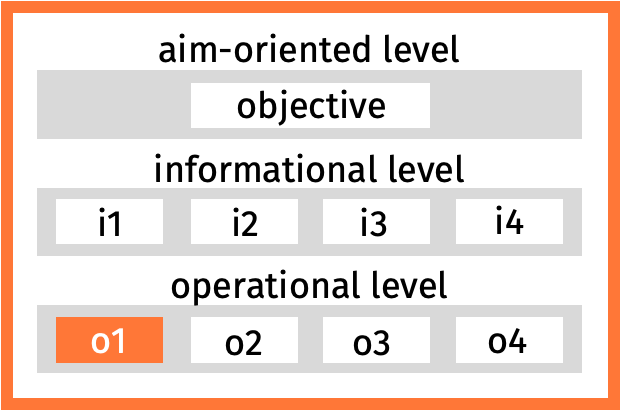

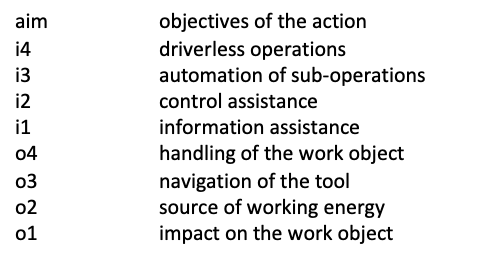

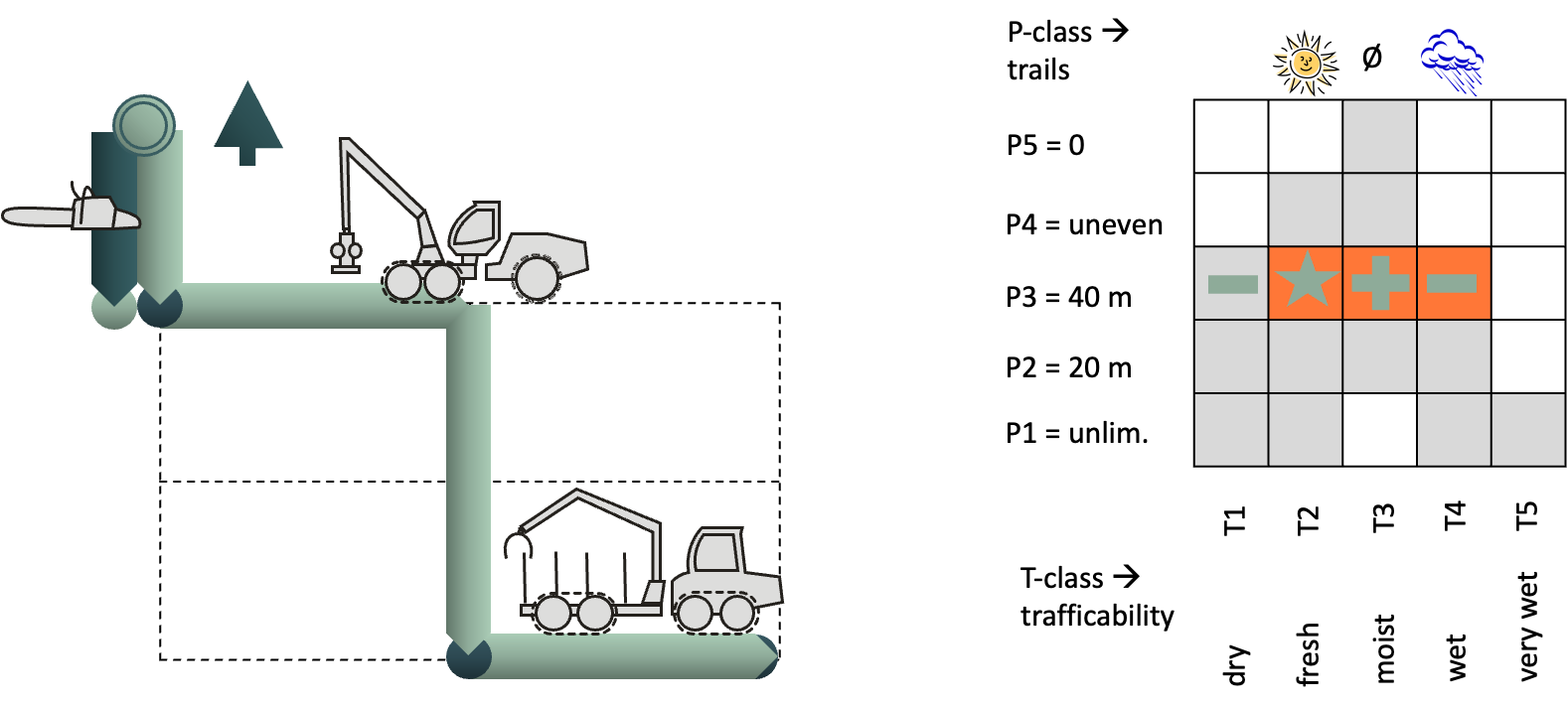

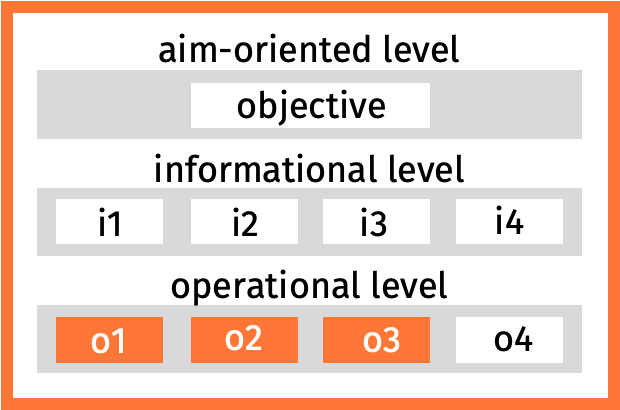

Matching technogram and ecogramIn Technodiversity, a graphical method to find the optimal harvesting method is supposed. The technical conditions of the forest stand are represented by the technogram with the sides T-class (trafficability due to the moisture of the soil) and P-class (productivity of the stand). Each stand falls exactly into one field, in the example it is T3-P3; but under dry or wet conditions it can move to left (dryer, T2) or right (wet, T4). As one possible harvesting method, the functiogram of a almost fully mechanized ctl-method with bogie-tracks is shown. In the ecogram, it has its optimum at T2-P3, but is good under T3-P3 and limited under T4-P3 and T1-P3. Matching both graphs shows that the method is very good under dry conditions, but also good under normal conditions in this stand. In combination with the ecograms of other technical options, this may be a basis to select the optimal option. (See more at TDiv PR1-D04)  | |

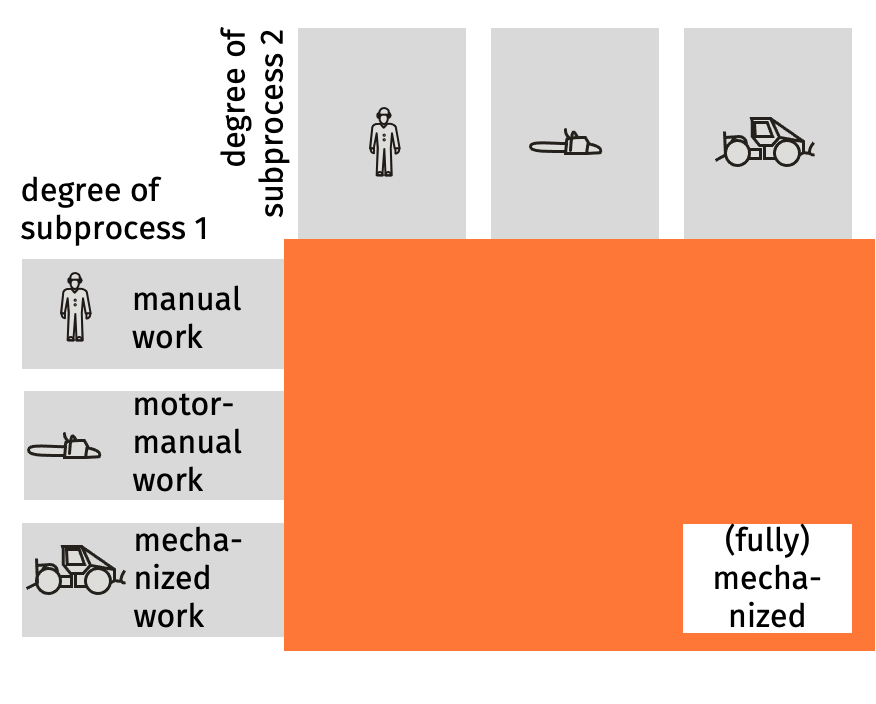

Mechanized methodIn Technodiversity, the total harvesting process normally is seen as a combination of several sub-processes. Each sub-process has a certain degree of mechanization. The degree of mechanization of the total method is given by the combination of these single degrees. There are five degrees of mechanization: (fully) manual method, partly motor-manual method, (fully) motor-manual method, partly mechanized method, fully mechanized method. If all sub processes are done with self-propelled machines, the method is a fully mechanized method or easier: mechanized method. Typically, that occurs when the harvester-forwarder team or the feller-buncher and skidder team are employed. (See more under TDiv PR1-B04 and B05) | |

Mechanized workWhen the engine is no longer portable but needs a carrier, we call that mechanized work. Because the weight of the machine is no longer limited by the weak carrying power of humans, the machine can be developed without any mass restrictions. Currently we observe a steady increase of machine weight, in the pursuit of higher power and efficiency. But that does not go without any ecological consequences… Mechanized work can be further subdivided into simple mechanized work, advanced mechanized work and automatic work. (See more at TDiv PR1-B04)   | |

MethodSee working method | |

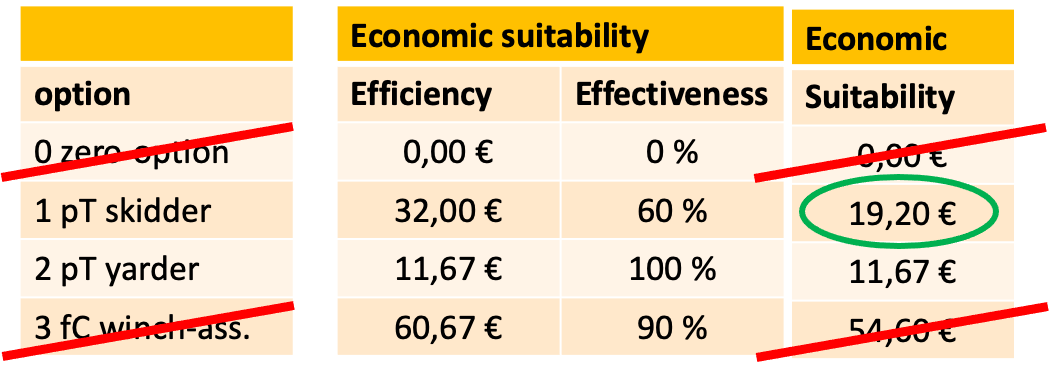

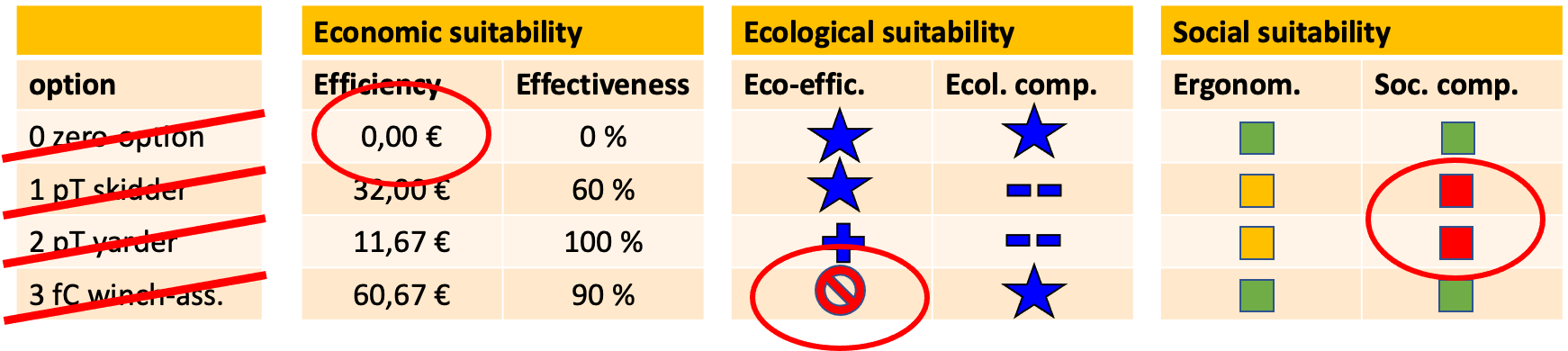

Minimax-ruleThis is one option to find the best option. Others are the monetarization, utility analysis, AHP, and optimality curves, for example. This method for decision making is a very simple one that is common in real life. Here, the decision-maker first eliminates any option that fails a certain criterion. After the elimination process, all surviving options are considered acceptable.Next step is focusing on that single criterion that is the most important for the decision-maker. In real life, it often will be the monetary efficiency. If so, the decision-maker will select that one among the surviving options that offers the highest income. Given an example, the decision-maker has got a problem:Option 3 does not fulfill the ecological compatibility requirement because it needs a higher trail density than is considered acceptable. Options 1 and 2 score quite low in terms of societal compatibility due to the activities on the forest roads. And the income of the zero-option does not fulfill the economic expectations. At the end, no option is good enough.  The decision-maker now has two possibilities: to look for better options or to lower his demands. For example, if he decides that societal compatibility is not so crucial, then options 1 and 2 become viable. Since these two options have “survived”, he must find the one among them that offers the highest net income. That is option 1, pT skidder. However, the effectiveness of option 1 is low. One has to correct the theoretical income with the coverage (economic effectiveness).After that operation, the edge of option 1 (pT skidder) decreases, but it still remains the most profitable.

| |

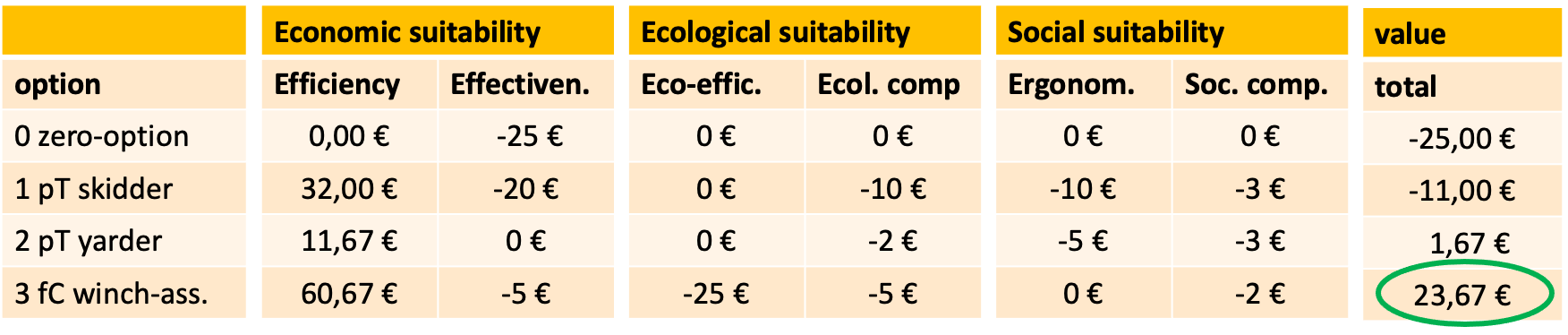

MonetarizationThis is one option to find the best option. Others are the minimax-rule, utility analysis, AHP, and optimality curves, for example. Some economists point out, that evaluations deal with values. And values should be quantified in terms of currency, so that the easiest end is to add all values… That amounts to transfer any assessments to Euros or dollars. There are some models to do this in a fairly scientific way. Taking an example, we must invent some estimated figures. If those are accepted, then option 3 is best, and option 2 seems to be surprisingly good, too. But in some cases, we pass the limits of fairness and modesty. How to calculate the value of human health? …or of eco-efficiency? So, for as attractive this idea may sound, in practice it generates significant controversies.  (See more under PR1-F04) | |

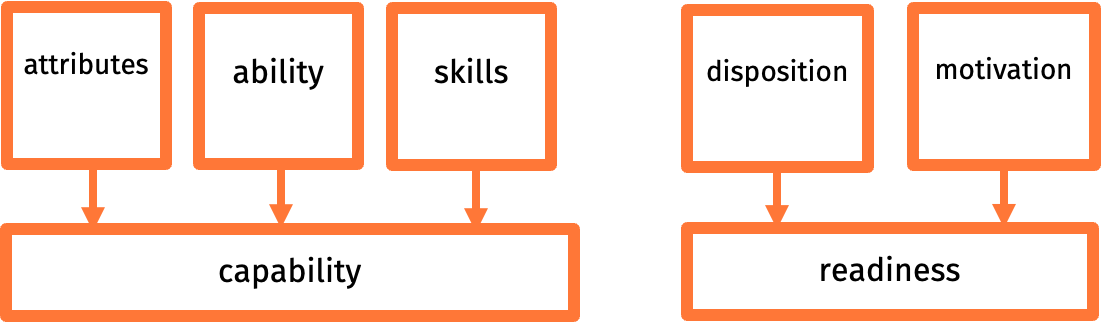

MotivationErgonomics follows a very simple basic model that derives from physics: When you impact a body with a certain stress, the body will react with a corresponding strain. Since a standard method causes a stress that is typical for this standard method, the strain as a reaction to this typical stress situation should be typical, too. The intensity of the strain, however, is not the same. It depends on the worker: his personal attributes, his abilities and his skills (together they form the capability for work). And it varies due to the actual disposition and motivation (together called readiness for work), and his health. If the strain overruns the permanent work load, breaks are necessary for his personal recovery to avoid acute or chronic damage. We know that there are days when the same job feels hard, and days when it feels much easier. Besides the organic disposition, the motivation of the worker is crucial for the strain. Motivated workers experience their work easier and suffer less from strain symptoms. Disposition and motivation together form the readiness for work. While capability is the potential of any given person, readiness is the percentage of that potential actually activated. (See more under TDiv PR1-E04)

| |

Pagina: 1 2 (Successivo)

TUTTI