Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

H |

|---|

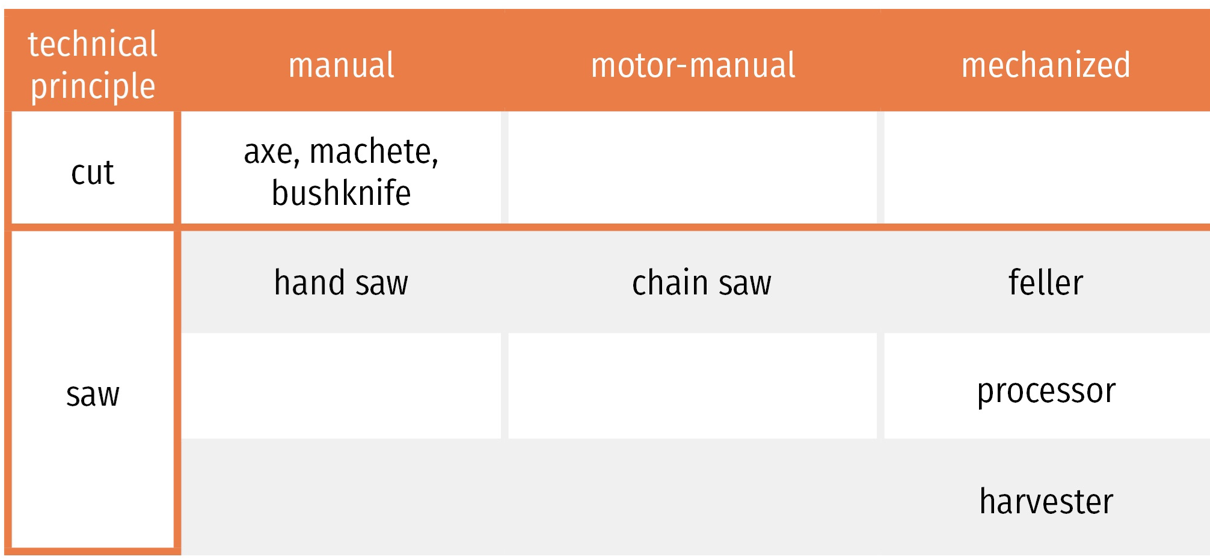

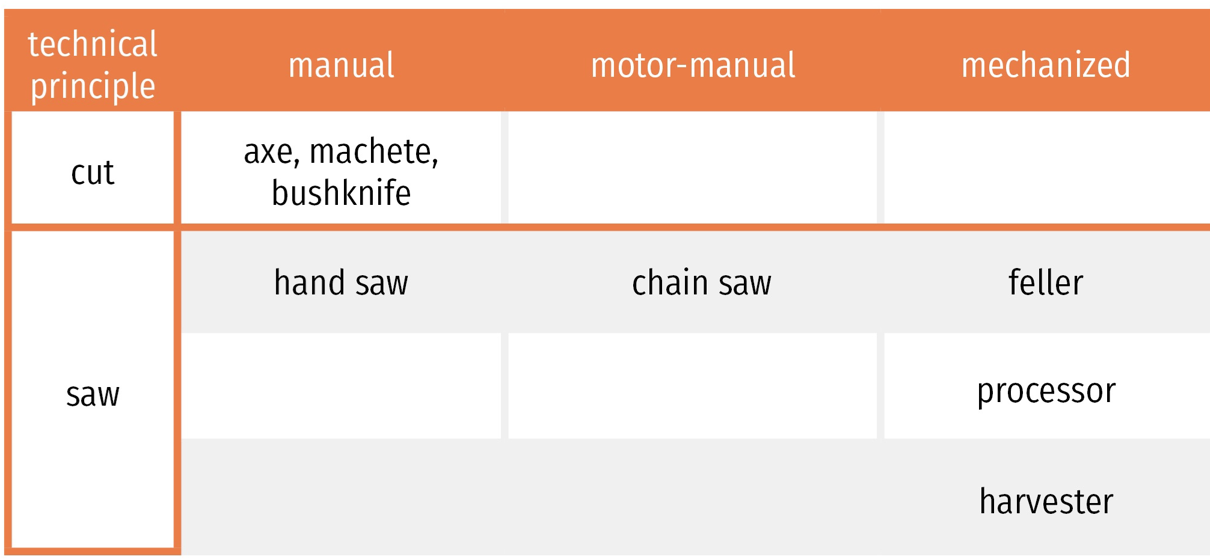

Hand sawThe hand saw is used as a tool for dividing an object by sawing it. Characteristic for the hand saw used in forestry are the bar handles at each side of the saw blade. As an alternative to the axe the hand saw is operated by two people, each standing at a handle. By alternately pulling the hand saw a kerf is formed in the complete tree which leads to the felling of the tree at a certain point (buffer 10 to 11). Since only human force is needed to saw with the hand saw, it is assigned to the manual work. Other harvesting tools, the use of which is assigned to manual work, are the axe, the machete, and the bush knife. (See PR1-B03)  | |

HandlingHandling is one of the auxiliary functions of harvesting. It does not directly change the state of the working object or its position, but brings the tools, machines and objectives together. A very effective tool for handling is a crane with a hydraulic grip that allows the operator to stay apart from the object and therefore out of the risk zone. Though handling is a very effective and efficient area for improving the working site, it is not mentioned intensively in Technodiversity. (See more at TDiv PR1-B01) | |

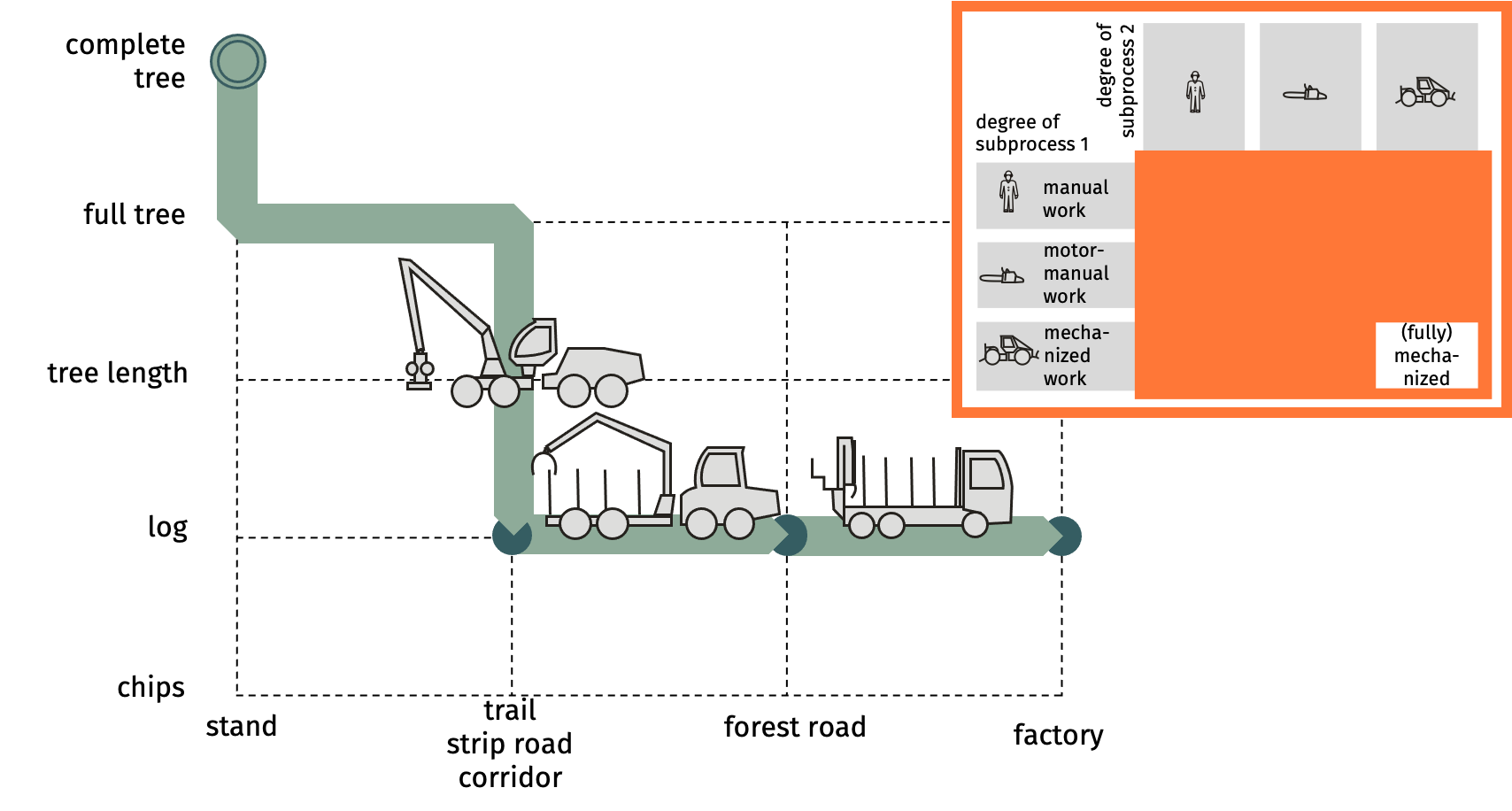

HarvesterThe harvester is a self-propelled machine that takes over all partial steps of the timber harvest, which are felling, delimbing, measuring, cross-cutting and bunching (buffer 10 to 21, 22 or 23). There is no other machine that combines all these sub-processes. Along the crane it takes over a short pre-skidding as well (buffer 21 to 22). The harvester is a widely used instrument in wood harvesting.

(Photo BOKU) Depending on whether the harvester is having the same felling and processing unit (all functions can be performed with one grab of the tree), or the processing unit is separate from the felling unit (functions need to be performed with more than one grab of the tree), the harvester is called one- or two-grip-harvester. Since today most machines on the market are one-grip-harvesters, this differentiation gets less important. Currently, other prototypes are being

tested in addition to the classic harvester construction. They differ from the

classic model in the way they move, which should enable these models to be used

in very steep terrain or to minimize the soil compaction of the harvester (See lecture

B06: Harvester Highlander (Konrad, Austria), Prototype walking machine

(Plustech Oy, Finland) or Prototype Portalharvester (TU Dresden, Germany)).

(Photos PLUSTECH and TUD) Since every step of timber harvest is executed by the harvester and the operator only needs to control the movements, the work with the harvester is classified as mechanized work. (See PR1-B03 and B07) | |

HarvestingHarvesting is one of the main functions of harvesting. The term has two meanings: As a general term it includes felling of trees, processing to a transportable product and the extraction from the forest to the customer. As a more precise term it only points to the change of state of the product, while the extraction is not included. In this narrow sense the harvesting includes the sub-functions felling, delimbing, topping, cross-cutting or bucking and chipping. All other sub-functions except the felling is called processing as well. (See more at TDiv PR1-B01) | |

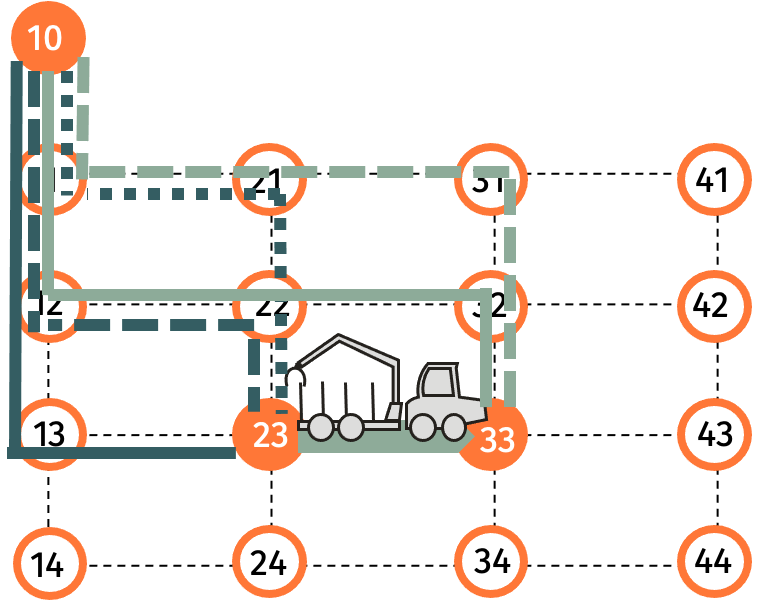

Harvesting chainDifferent sub-processes can be assembled into a full chain, when the end of the foregoing sub-process matches the needs of the following sub-process. In the functiogram, such a so-called ‘buffer’ is symbolized by a dark button. In real life, when we plan any job, we know where it begins and where it should end. Between these two poles we have a lot of options to reach this aim. But as soon as we define one specific sub-process, the list of viable sub-processes becomes much shorter. For example, we want to fell trees and process them into short logs, which are stored at the forest road. This means that we start with buffer 10 and end up at buffer 33. Here we have more than 5 options to reach this goal. But when we decide to use a forwarder for the extraction tasks, the degree of freedom decreases, because the forwarder is specialized for extraction from 23 to 33 (it is good for short logs). To finalize the method, we only need to fill the gap between buffers 10 and 23. Then, out of our initial more than 5 options, only 3 are left. (See more at TDiv PR1-B07)

| |

Harvesting methodIn Technodiversity, we prefer to visualize harvesting methods by a functiogram. For naming we have found following convention: The noun describes the functional group of harvesting like full tree method, tree length method, cut-to-length (ctl) method or chip method. An adjective declares the degree of mechanization like (fully) manual method, partly motor-manual method, (fully) motor-manual method, partly mechanized method, and fully mechanized method. As an example, the functiogram shows the fully mechanized ctl-method. (See more at TDiv PR1-B06 and B07) | |

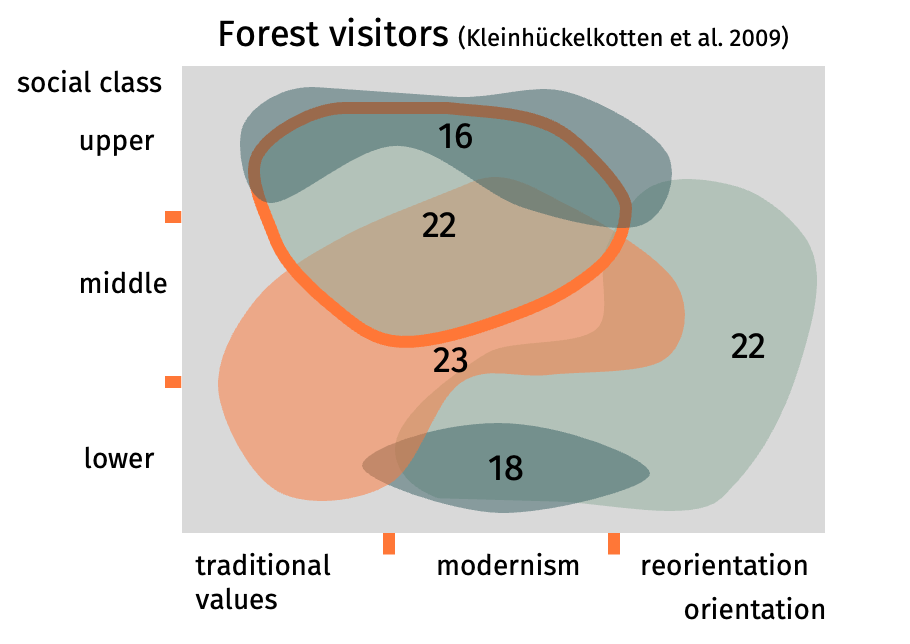

Holistic forest friendsIn a study from 2009, Kleinhückelkotten et al. have found five different groups of people who use the forests for recreation. One of them are the holistic forest friends, the others are ecological forest romantics, pragmatical distant persons, self-centered forest users, and indifferent persons. About 22% of the sample was classified as holistic forest friends. These people like natural forest structures and believe that modern forestry will assure sustainable yield of products and sustainable forest functions. This group is relatively comfortable with forest technology. (See more under TDiv PR1-E02) | |

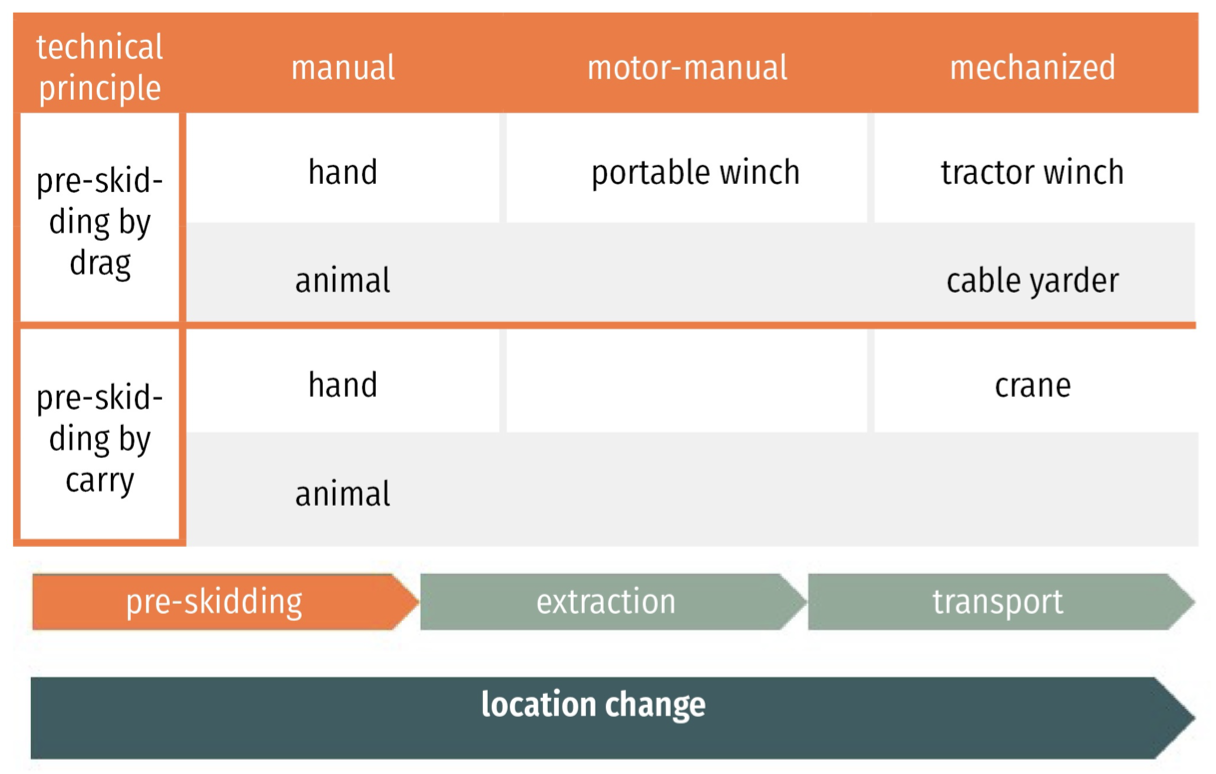

HorseThe horse or mule is a tool being used for the pre-skidding of full trees (buffer 11 to 21) and tree length (buffer 12 to 22) and for the pre-skidding and skidding of logs (buffer 13 to 23 or 33). Horses work on more or less flat terrain and drag the load, while mules are used in steep terrain and prefer to carry the logs. The work with the horse or mule is classified as manual work. A classic combination in which the horse/ mule is being used is the “Tree length method using chainsaw, horse, and tractor” also known as “Partly mechanized tree length method”. (See PR1-B03 and B07)  (Photos CNR)  | |