Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

S |

|---|

Solutions for extraction of short logsThe extraction of short logs describes the transportation of the logs from the trail to the forest road (buffer 23 to 33). It is a mechanized work, usually done by a forwarder or a tractor with a trailer.   | |

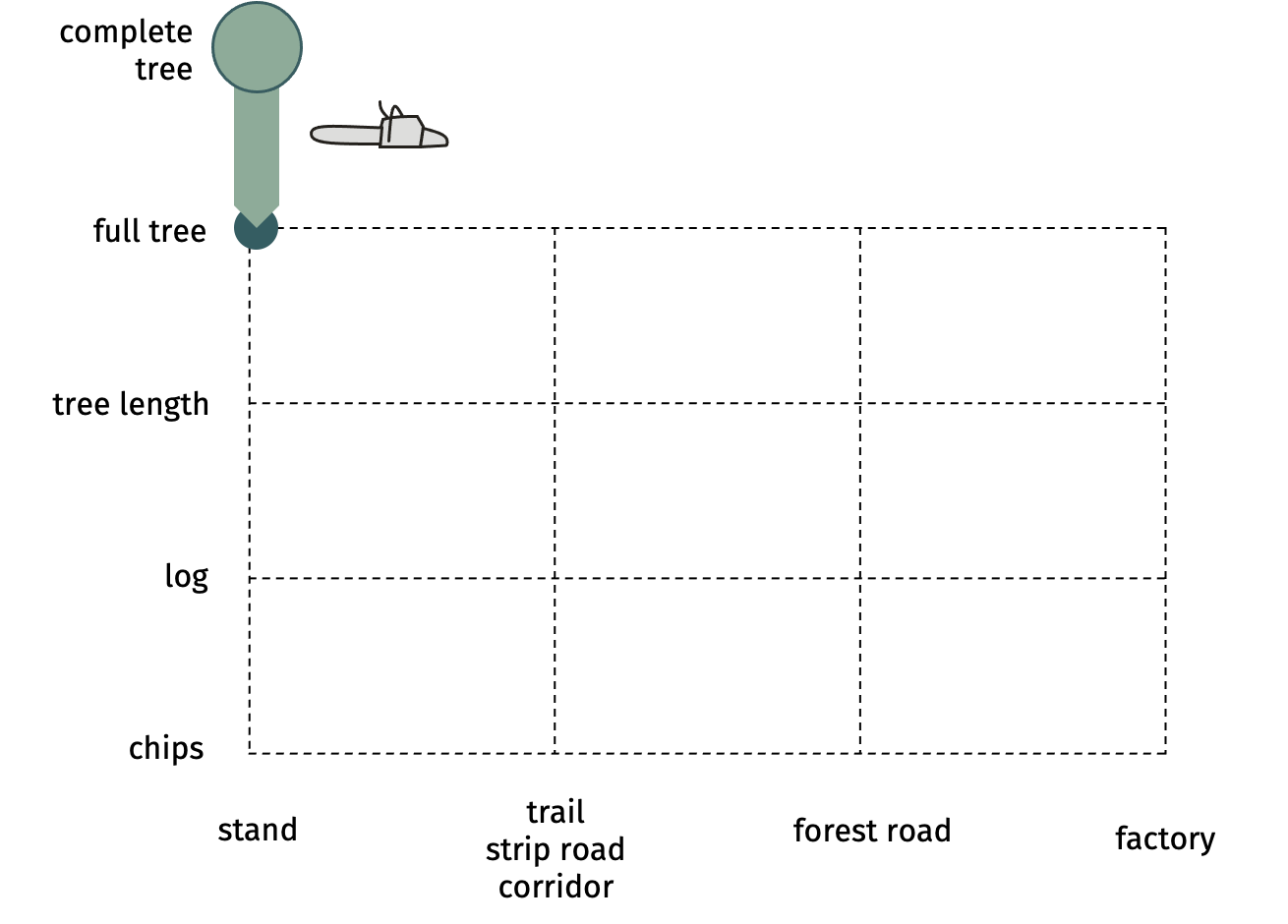

Solutions for fellingFor the subprocess of felling there are two options common. The complete tree can be either just felled or felled and then directly hauled. If the tree is only felled, the subprocess normally is performed motor-manually with a chainsaw. After felling, the full tree remains in the stand (buffer 10 to 11). | |

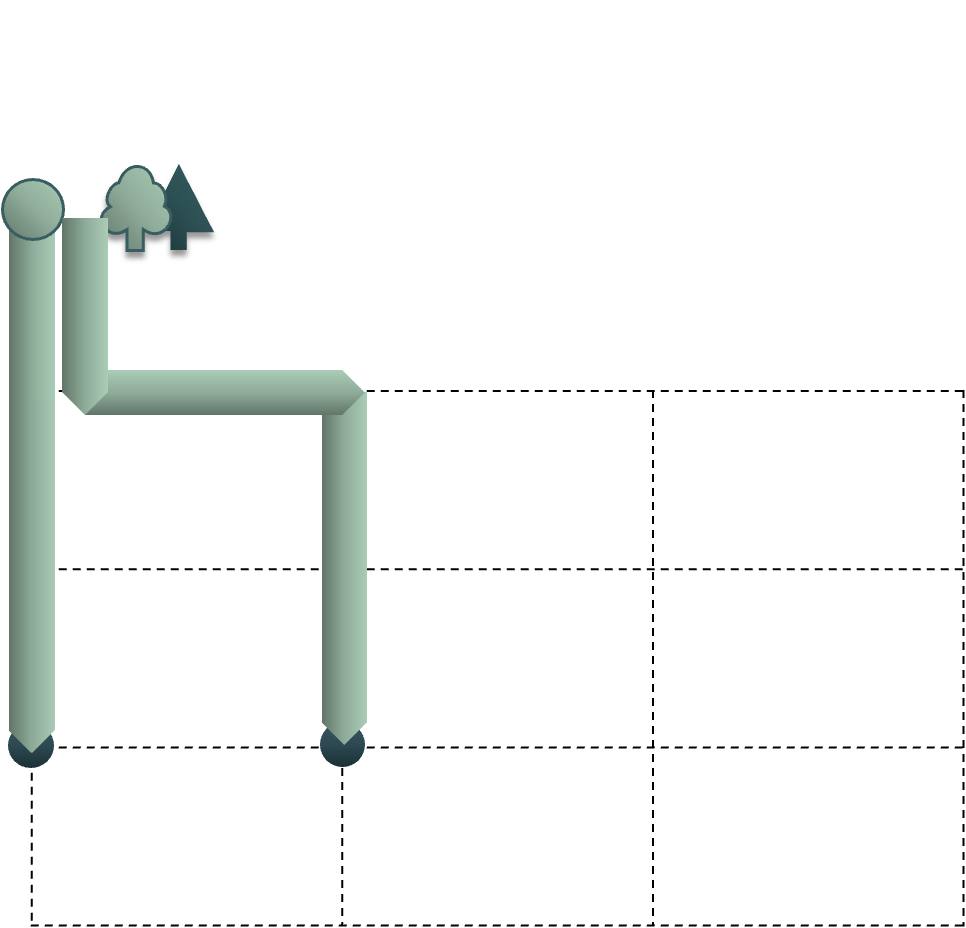

Solutions for felling and processing short logsThe felling and processing (= harvesting) of short logs can also be executed in one step. Without a buffer to interrupt the process, the complete tree is felled, branches are removed, and the tree is topped and cross-cut. This process can be done motor-manually with a chainsaw or mechanically with a harvester. If the harvesting takes place motor-manually, the logs remain in the stand near the stump (buffer 10 to 13). If the harvesting is done mechanically, the stem is lifted onto the trail during the process (buffer 10 to 23).   | |

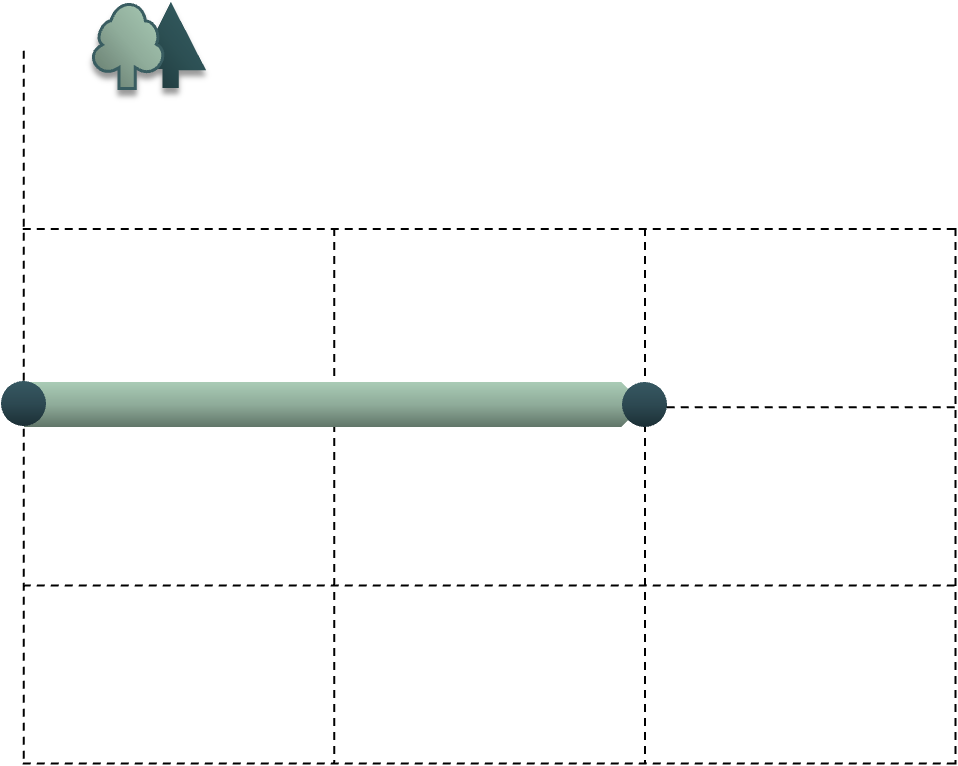

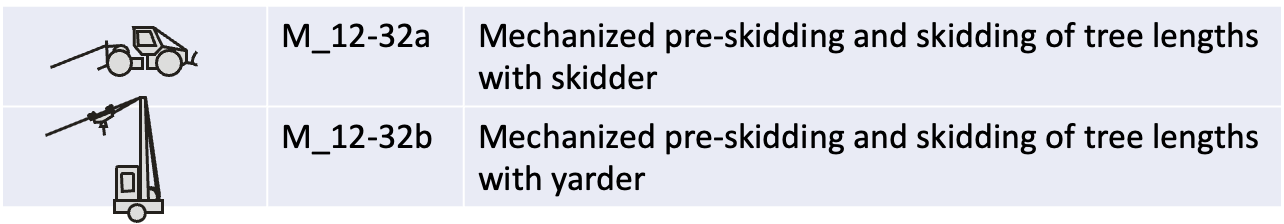

Solutions for pre-skidding and skidding of tree lengthsIn some cases, the sub-process of pre-skidding is not necessary and can be skipped. Then, the tree lengths are skidded directly from the stand (buffer 12) to the forest road (buffer 32). This may be the case, if there are no regulations for the machines to stay on a permanent trail or if the technology of the machines makes the sub-process of pre-skidding unnecessary. Machines which can skid tree lengths directly are for example the cable yarder or the cable skidder. While the cable yarder skids the tree lengths in a carrying movement to the forest road, the cable skidder needs to drag the tree lengths.   | |

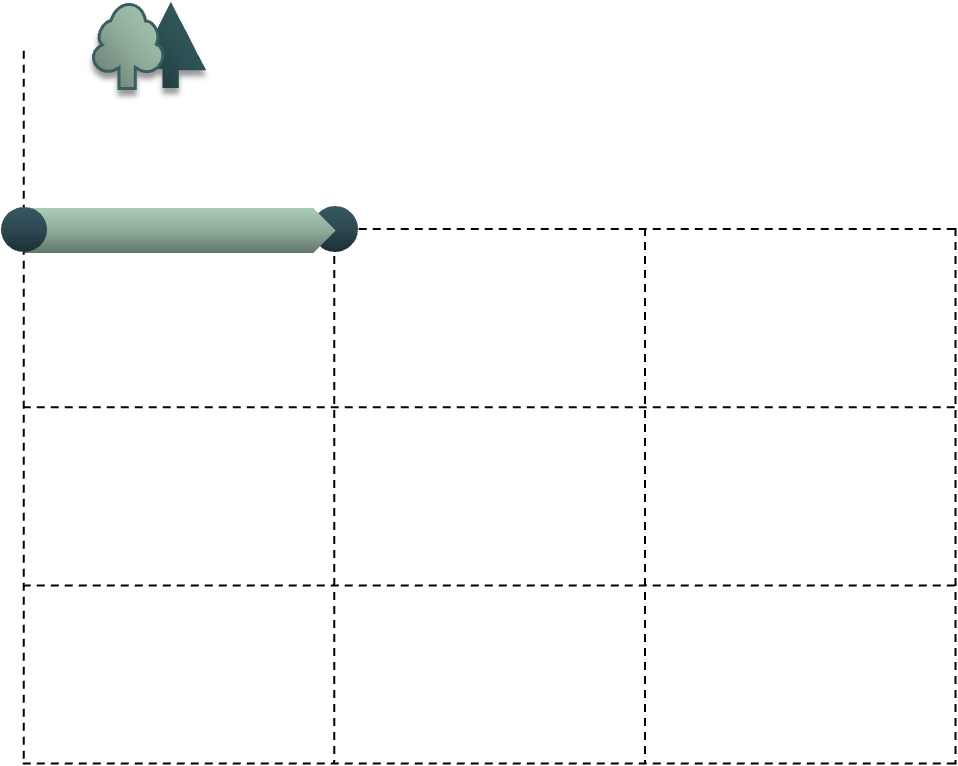

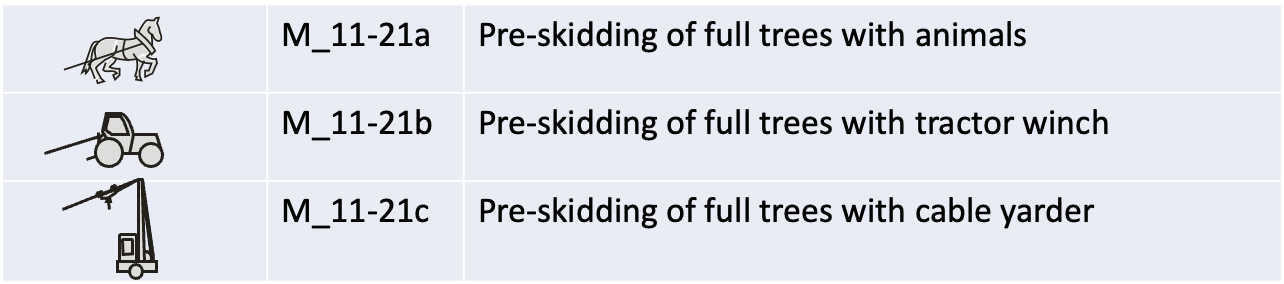

Solutions for pre-skidding full treesThe pre-skidding of full trees can be performed either by animals (horse) or as mechanized work by machines. As machines usually a tractor winch or a cable yarder are taken for the subprocess of pre-skidding. While the tractor winch and horse can only drag the full tree from the stand (buffer 11) to the trail (buffer 21), the cable yarder is able to carry the full tree to the trail.   | |

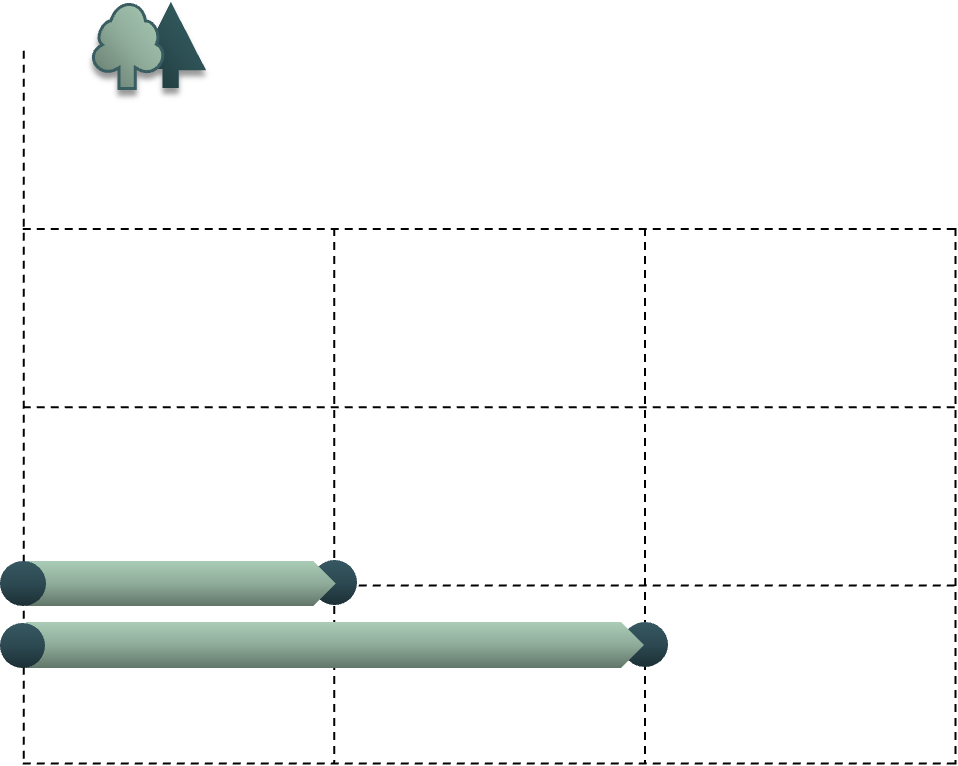

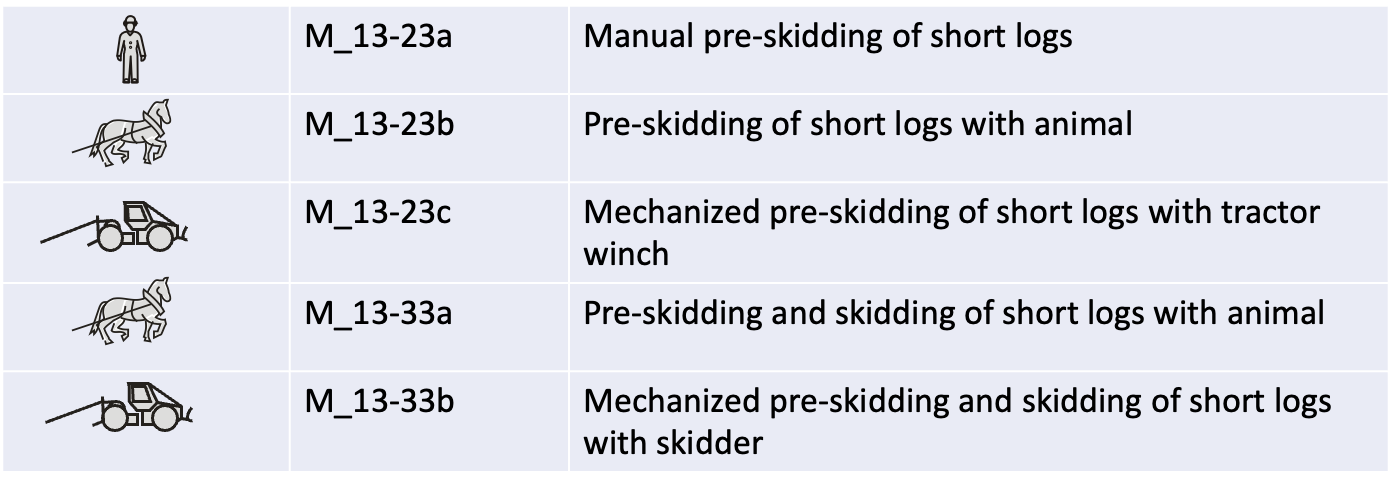

Solutions for pre-skidding short logsDuring the pre-skidding of short logs, the short logs are moved from the stand onto the trail (buffer 13 to 23). In special cases, the short logs can also be skidded directly from the stand to the forest road (buffer 13 to 33). Due to the “light” weight of the short logs, there are a lot of options possible for pre-skidding them. They can either be carried manual by a person or a mule or dragged by a horse. Another option is to pre-skid the logs mechanically with a cable skidder. The cable skidder and horse can also be used for the direct skidding of logs from the stand to the forest road.   | |

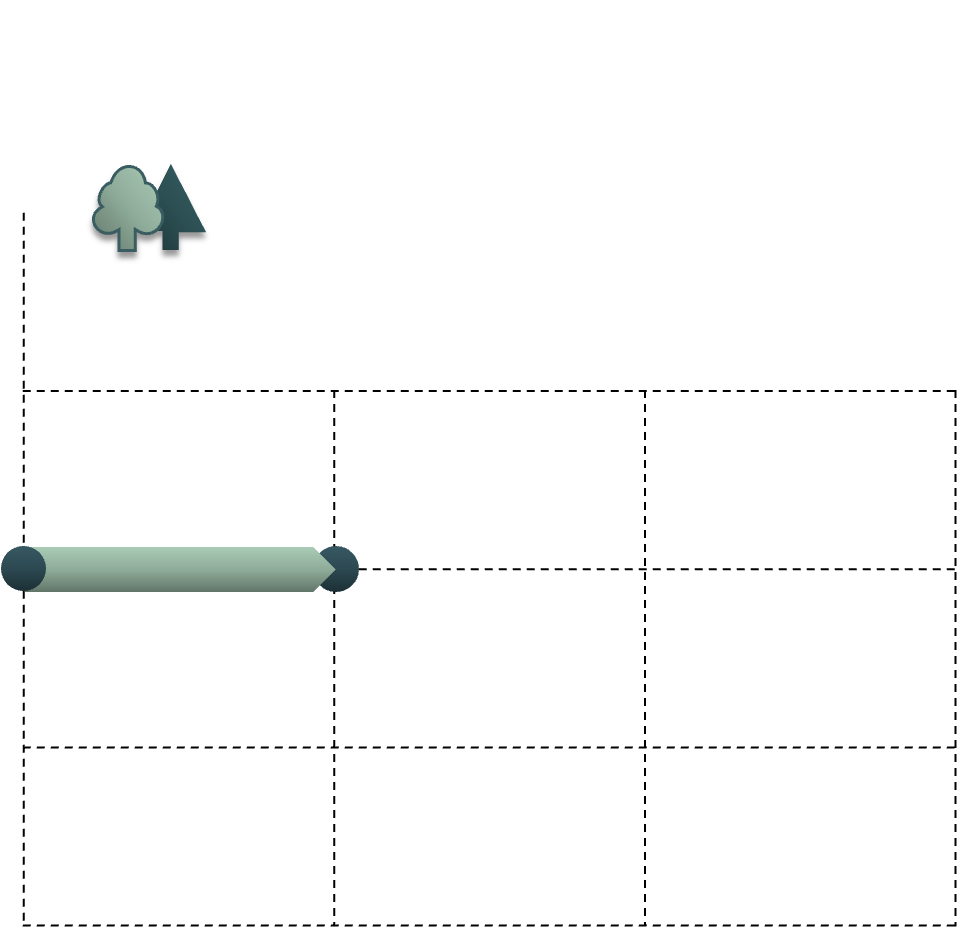

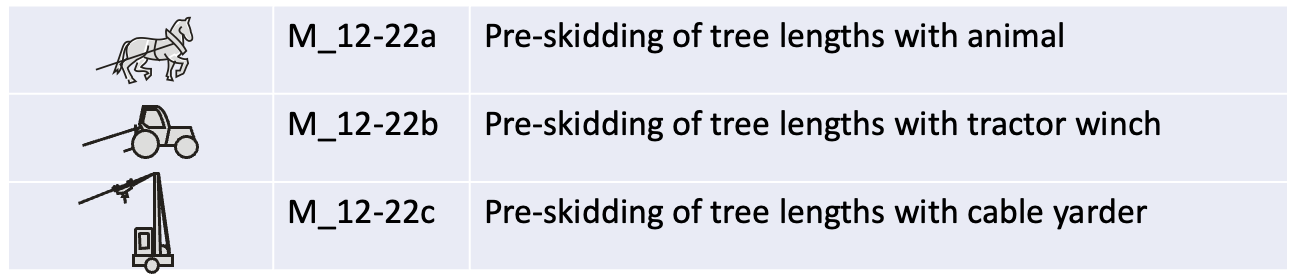

Solutions for pre-skidding tree lengthsThe pre-skidding of tree lengths (stem without branches and crown) can be performed either manual by animals (horse) or as mechanized work by machines. The most common options for the pre-skidding of tree lengths are the use of a horse, tractor winch or cable yarder. While the tractor winch and horse can only drag the tree length from the stand (buffer 12) to the trail (buffer 22), the cable yarder is able to carry the tree length to the trail (buffer 22).   | |

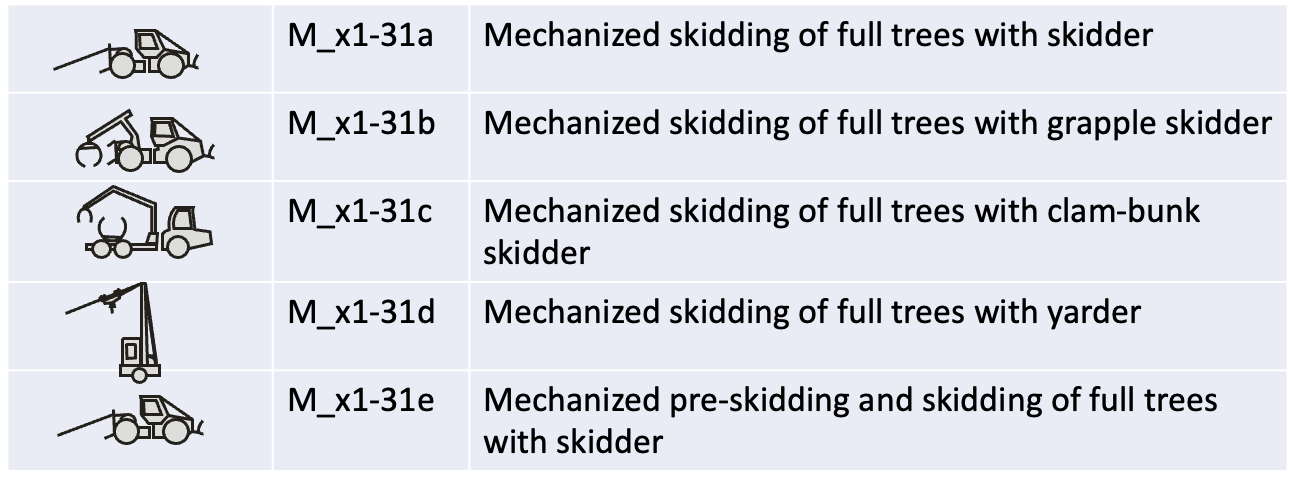

Solutions for skidding full treesThe skidding of full trees is commonly a mechanized sub-process. For the extraction of full trees several options are available. The clam-bunk skidder and grapple skidder are normally used only for the skidding from the trail (buffer 21) to the forest road (buffer 31). Whereas the cable yarder and the cable skidder can be taken not only for the skidding but also for the pre-skidding of full trees (buffer 11 to 31). The transportation of the full tree by cable skidder, grapple skidder or clam-bunk skidder is executed in a dragging movement, the transportation with the cable yarder in a carrying movement.  options described in this glossary are  | |

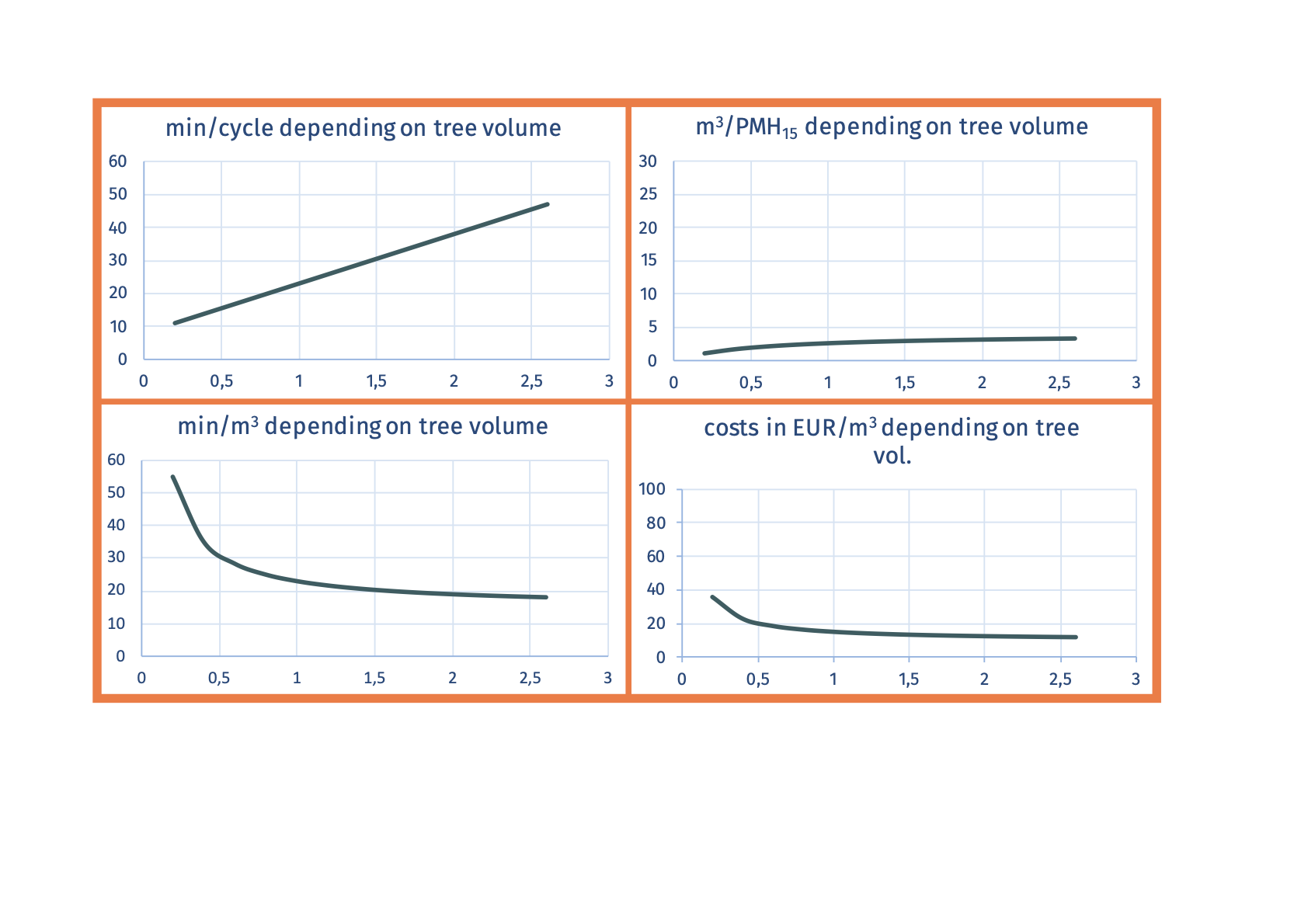

SP-10-11 motor-manual felling with chainsawCutting tree at the base with chainsaw and fell it in a predefined pattern. | |

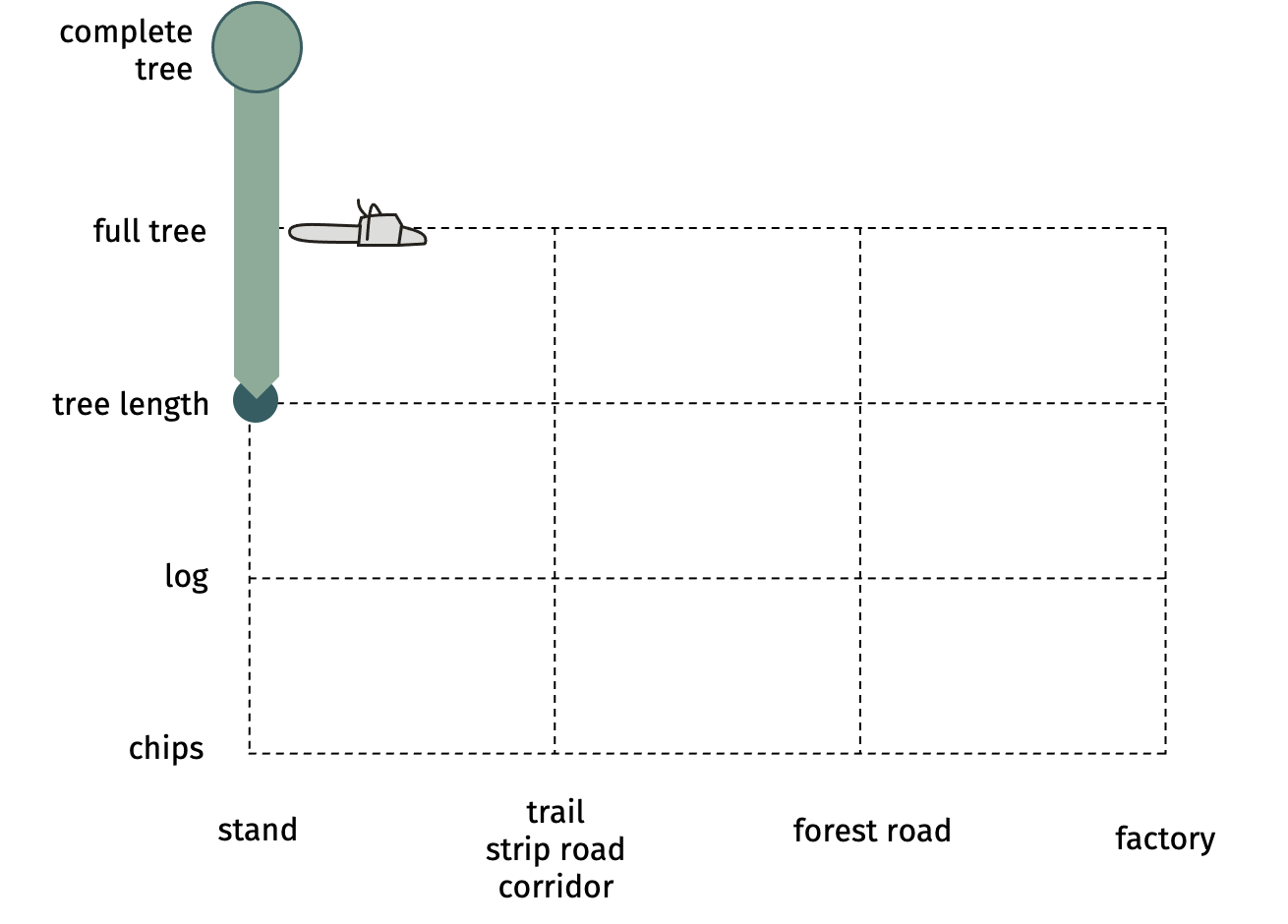

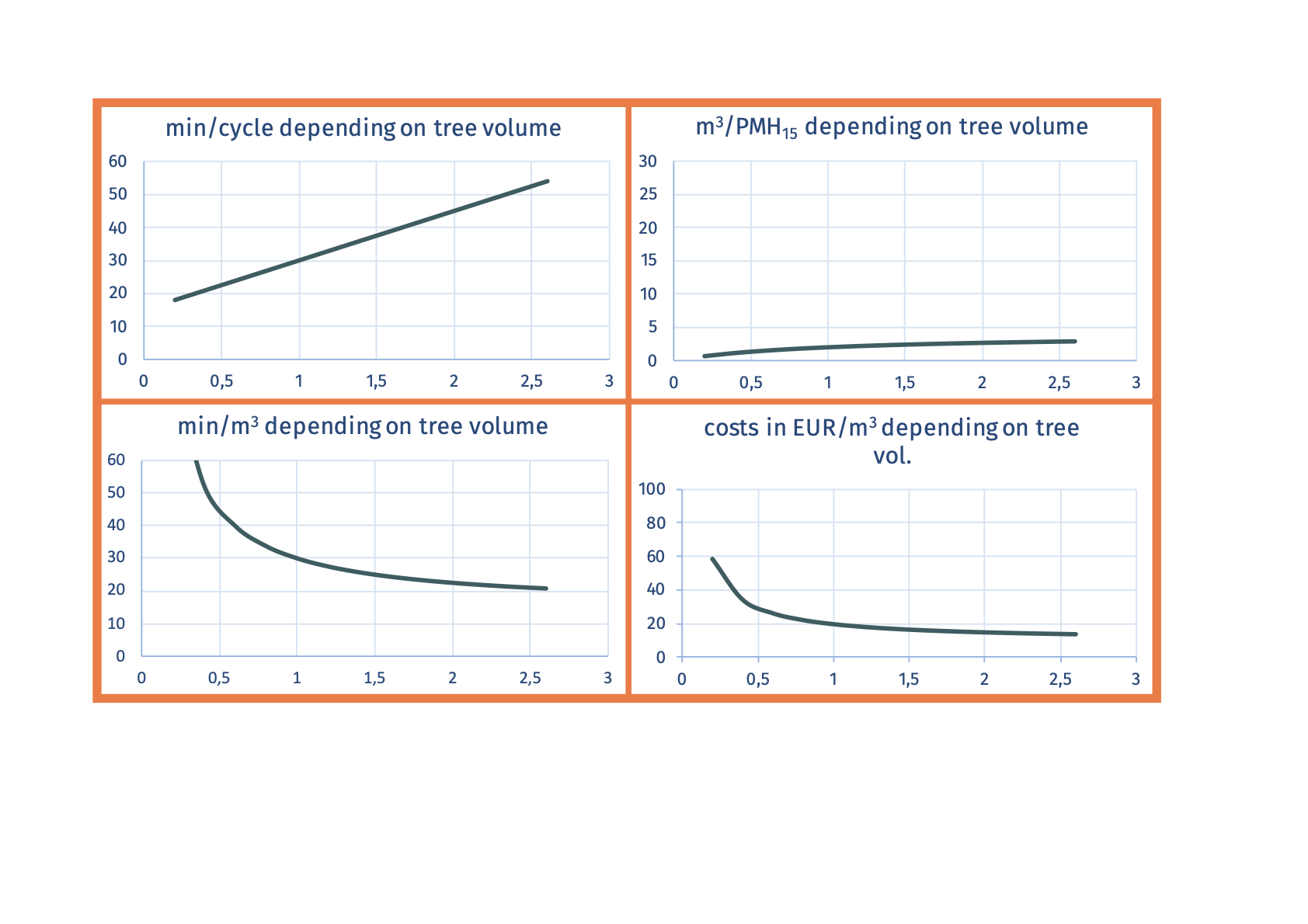

SP-10-12 motor-manual harvesting of tree lengthFelling,

directly followed by delimbing and topping at the predefined diameter. Important:

felling direction in order to minimize the damage in stand at the pre-skidding

and extraction operations Functiogram:

Advantages

Example

Social suitability:

| |