Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

S |

|---|

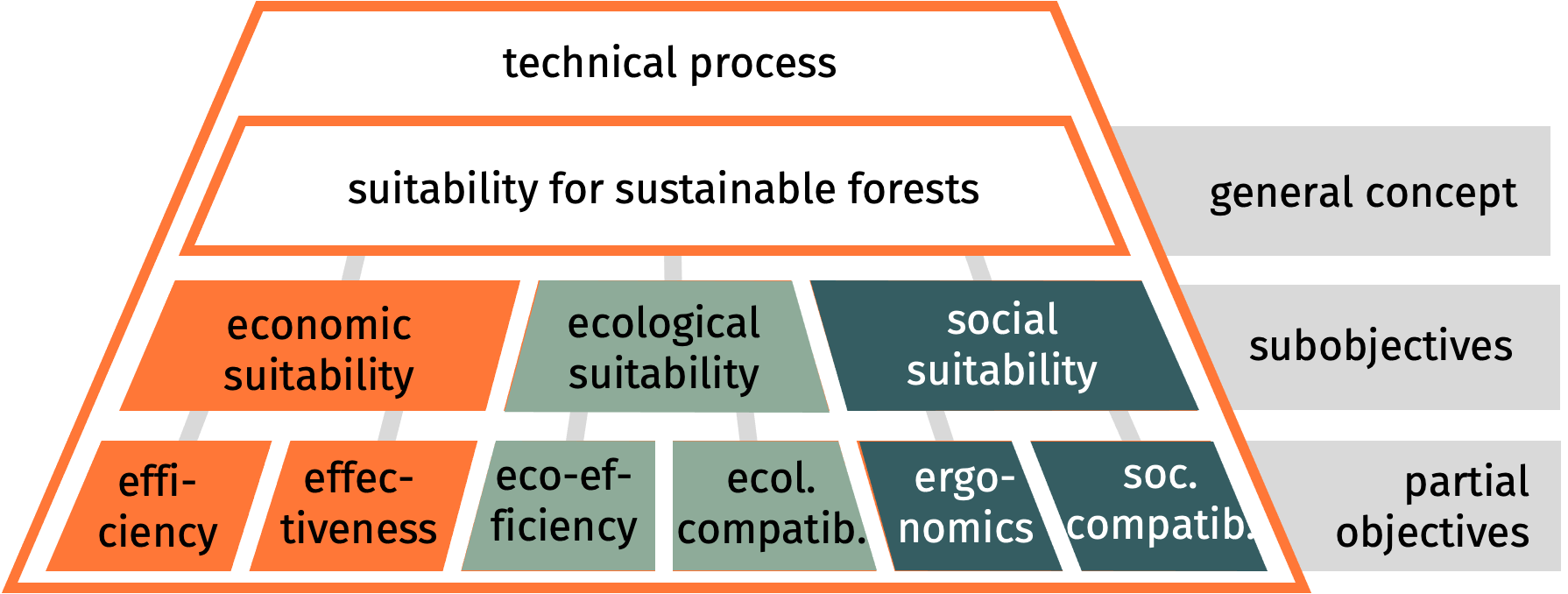

Societal compatibilitySocietal compatibility is a partial objective for decision-making. It wants to avoid disturbances that can occur in conflict with the needs and demands of the public. In forestry people enter the forests to recreate and enjoy their life and feel disturbed by forest operations. Cultural needs of the local population can be disturbed by technical activities, too. A third criterion may be the wish of local people to be employed by the forest company in order to earn money. As criteria in Technodiversity, we use the S-classes for societal needs. Together with its twin ergonomics we can assess the social suitability that is one sub-objective to find the optimal option. Parallel to the social suitability we also should look at the economic and the ecological suitability. For more information about systematics of decision-making, look at objectives and three-step model of optimization. (See more under TDiv PR1-A03, PR1-E02, and -E04)  | |

Societal demand for recreationSee recreation | |

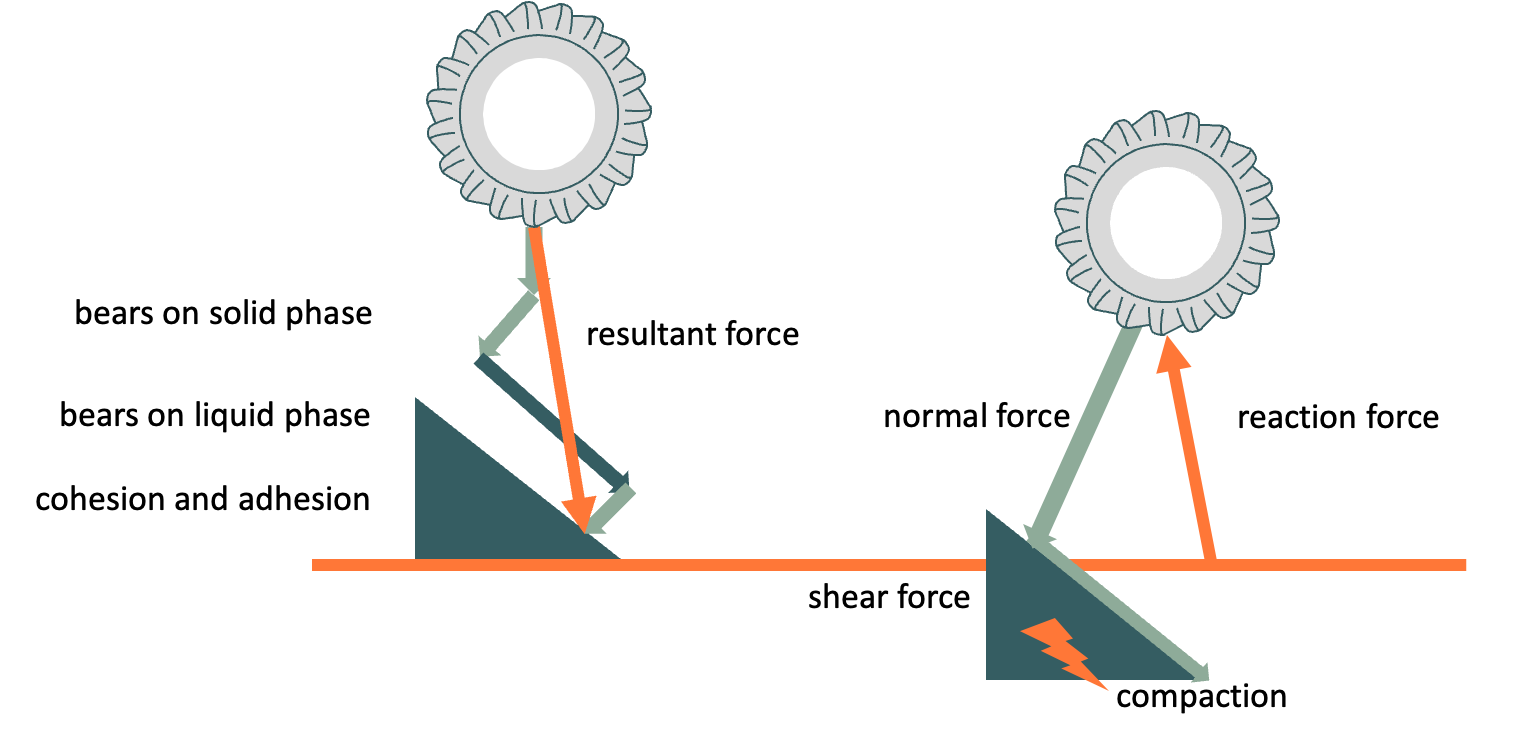

Soil damageThe model of soil damage of Technodiversity acts on the assumption of tree soil states: A) Untouched forest soil: biologically healthy and productive B) Trafficable trail: compacted by former traffic and strong enough for future traffic C) Destroyed trail: impacted by former traffic in a way that is no longer usable. By traffic, a soil moves from untouched soil (A) to trafficable trail (B). After traffic, maybe it has a chance to find back to state (A) by biological (worms, roots…) and physical (frost) influences. As long as this happens in a reasonable time, we call it elastic deformation. But very often the traffic with our heavy machines causes a plastic deformation, which means that no natural regeneration will happen in a reasonable time period. This must not be regarded as damage as long as the technical function of the trail has priority for the owner. Because the compacted trail can be used for future harvesting operations, too, as long as it keeps its technical functionality. This has the advantage that next time the rate of compacted soil will not increase. To reach this, we demand for permanent trails as a central idea of eco-efficiency. For the question, how much of the soil is allowed to be fixed for technical purposes, no absolute answer can be found. This depends on the decision of the owner. Consequently, any further degradation of the soil towards destroyed trail (state C) must be avoided. There are two tactics: To stop the operation immediately when critical signs occur or to shape the harvesting system in a way that the likelihood of any damage is minimized. But sometimes the trail will be destroyed in a way that no more traffic can happen on it. Then it should be repaired by technical means (road construction) to recover the technical functionality. (See more at PR1-D02) | |

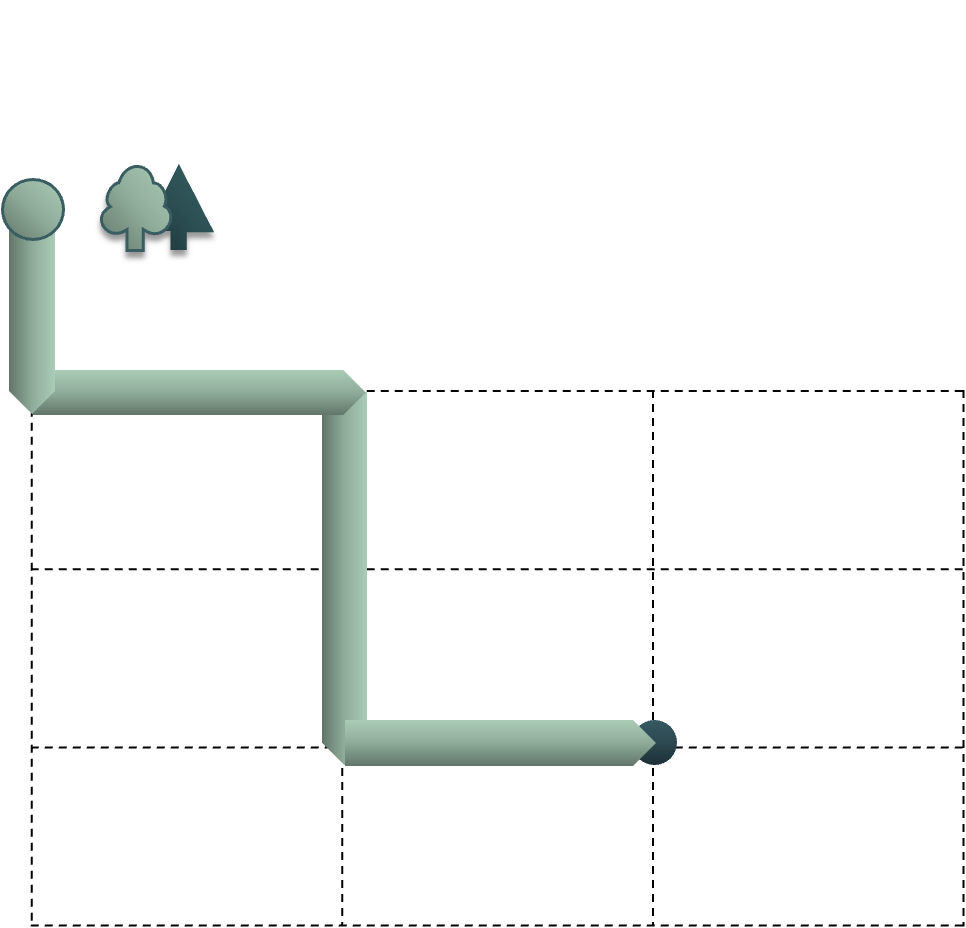

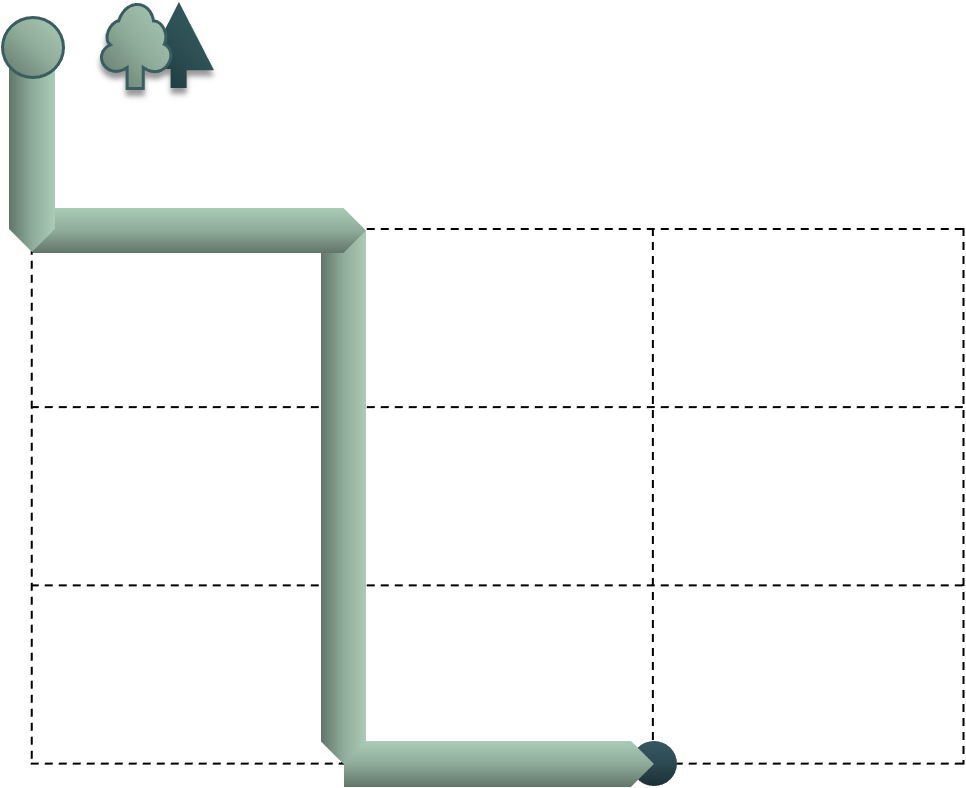

Solutions for „harwarding“ of short logsOne option which can only be executed by a special machine is the “harwarding” of short logs. In this case a special machine, the harwarder, fells the tree, delimbs it, cross-cuts it into logs and skids the logs to the forest road (buffer 10 to 33). All these sub-processes are done in one step without a buffer to interrupt. Since all the sub-processes are done by the harwarder, it is assigned to the mechanized work.

| |

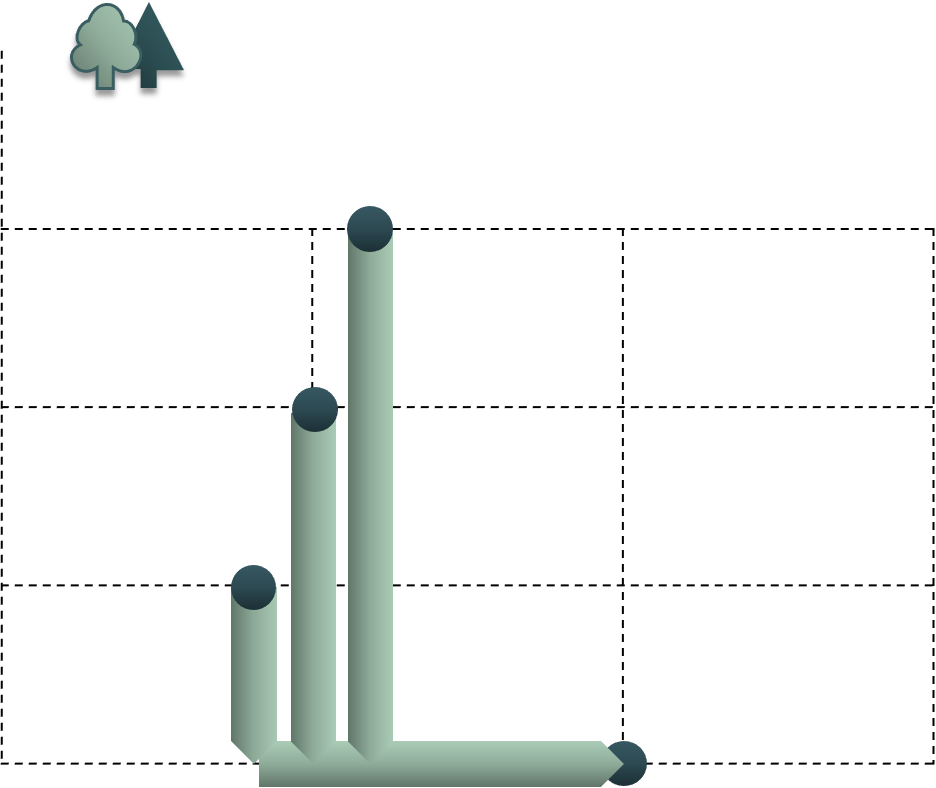

Solutions for chipping at the forest roadTo produce chips (= chipping) at the forest road, full trees (buffer 31 to 34), tree lengths (buffer 32 to 34) or short logs (buffer 33 to 34) can be used. The chipping is a mechanized work and can be executed by a chipper.   | |

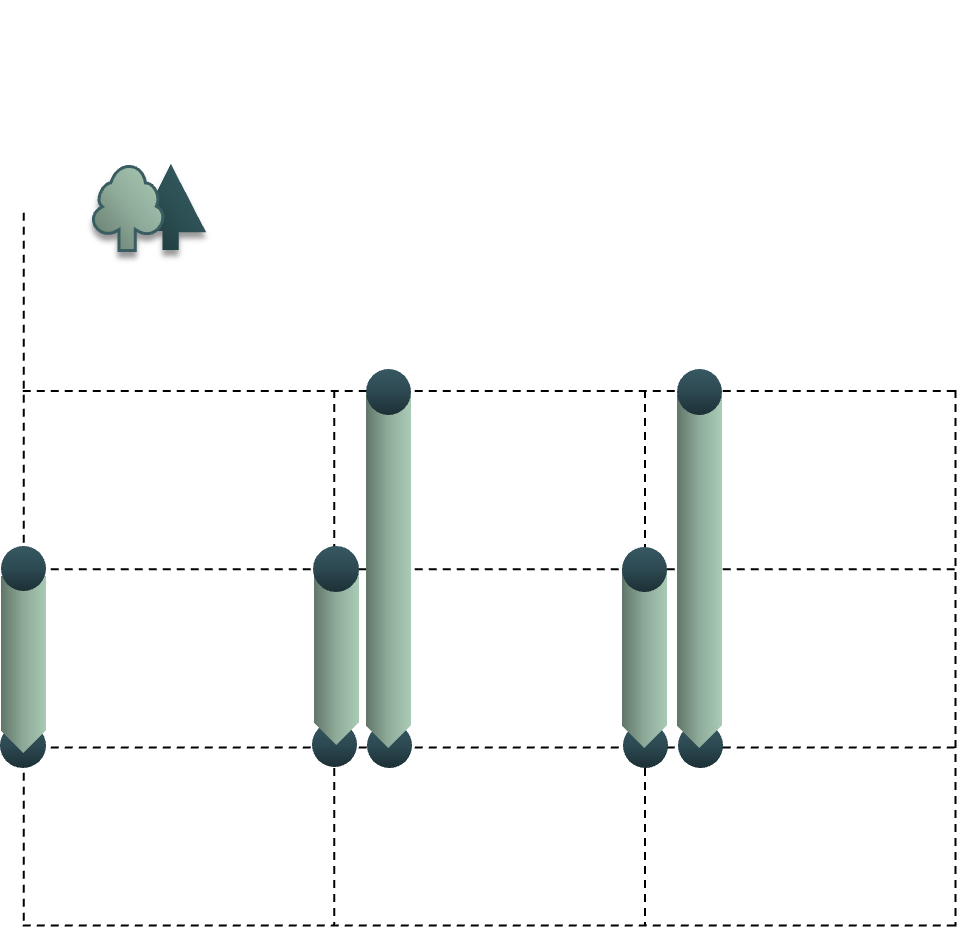

Solutions for chipping on the trailTo produce chips (= chipping) on the trail, full trees (buffer 21 to 24), tree lengths (buffer 22 to 24) or residues (buffer 23 to 24) can be used. The chipping is a mechanized work and can be executed by a chipper.   A specialized option is a biomass-harvester. This machine fells the tree and directly forms chips out of it (buffer 10 to 24).

| |

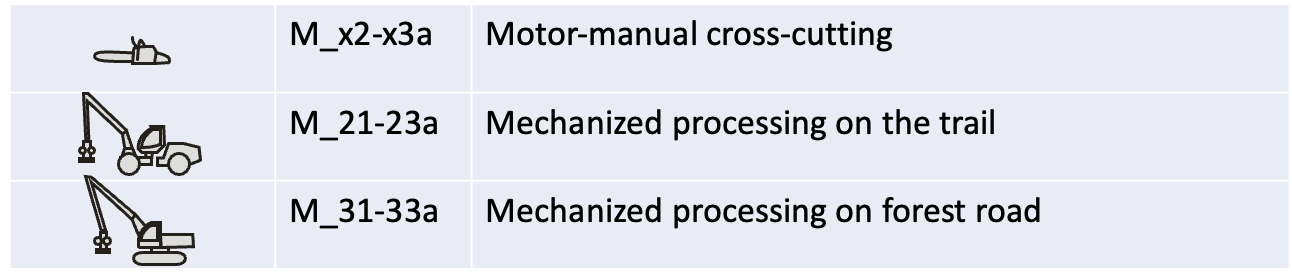

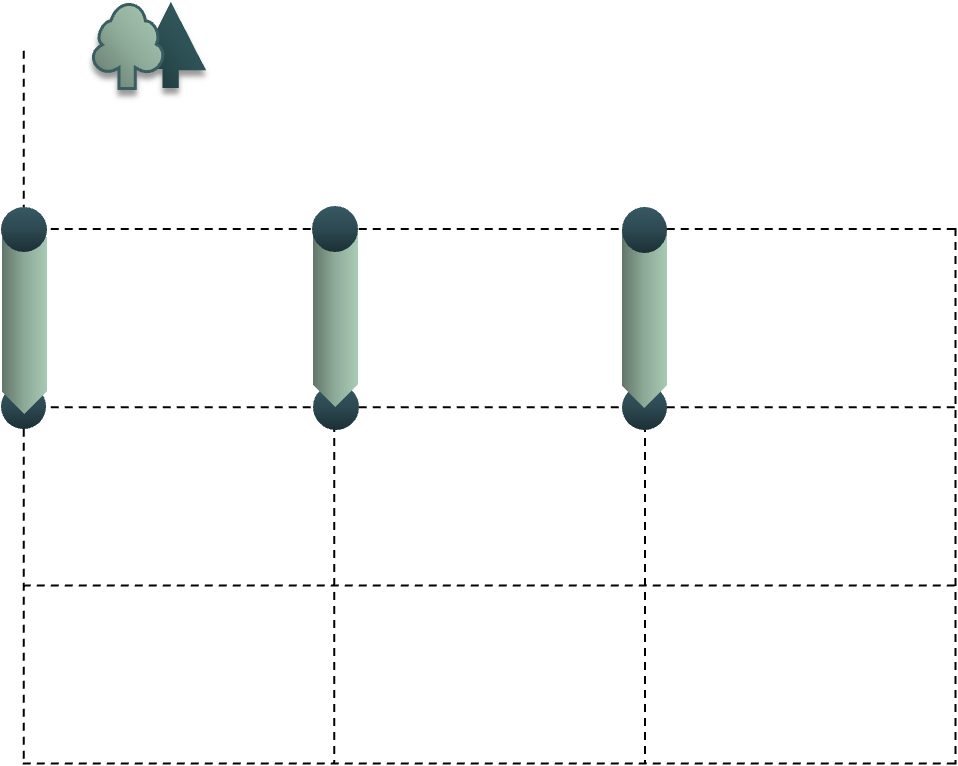

Solutions for cross-cuttingThe sub-process of cross-cutting describes the transformation from tree lengths or a full tree into short logs. It can be carried out either in combination with the delimbing of the tree or detached from the delimbing as a single function. If the tree is delimbed and cross-cut in one step, this is usually done on the trail (buffer 21 to 23) or the forest road (buffer 31 to 33). The combination of delimbing and cross-cutting is executed mechanically with a processor ( can also be executed with a harvester) on the trail or the forest road. If the tree length is cross-cut as a single function, it can be done either in the stand (buffer 12 to 13) or on the trail (buffer 22 to 23) or the forest road (buffer 32 to 33). Usually it is done motor-manually with a chainsaw.   | |

Solutions for delimbingDuring the sub-process of delimbing, a full tree is converted into a tree length by cutting of the top of the tree and the branches. If the tree is only delimbed, this is usually done motor-manually with the chainsaw. Depending on where the full tree is located, delimbing can be performed either in the stand (buffer 11 to 12), on the trail (buffer 21 to 22) or the forest road (buffer 31 to 32).

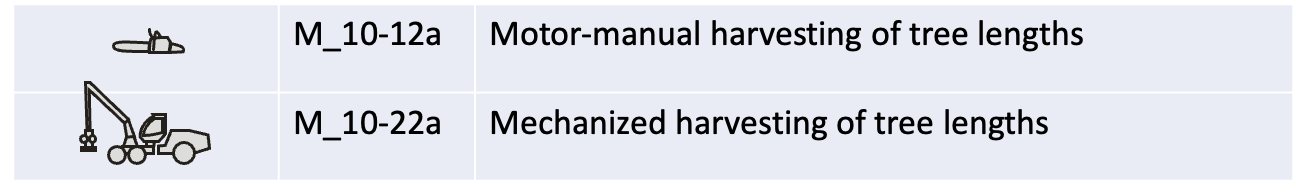

The sub-process of delimbing can also be carried out in combination with the felling of the tree. This combined option of felling and delimbing can be executed mechanically by a harvester or motor-manually with a chainsaw. While the tree that is felled and delimbed motor-manually remains in the stand (buffer 10 to 12) after the process, the tree that is felled and delimbed mechanically is lifted onto the trail during the process (buffer 10 to 22).   | |

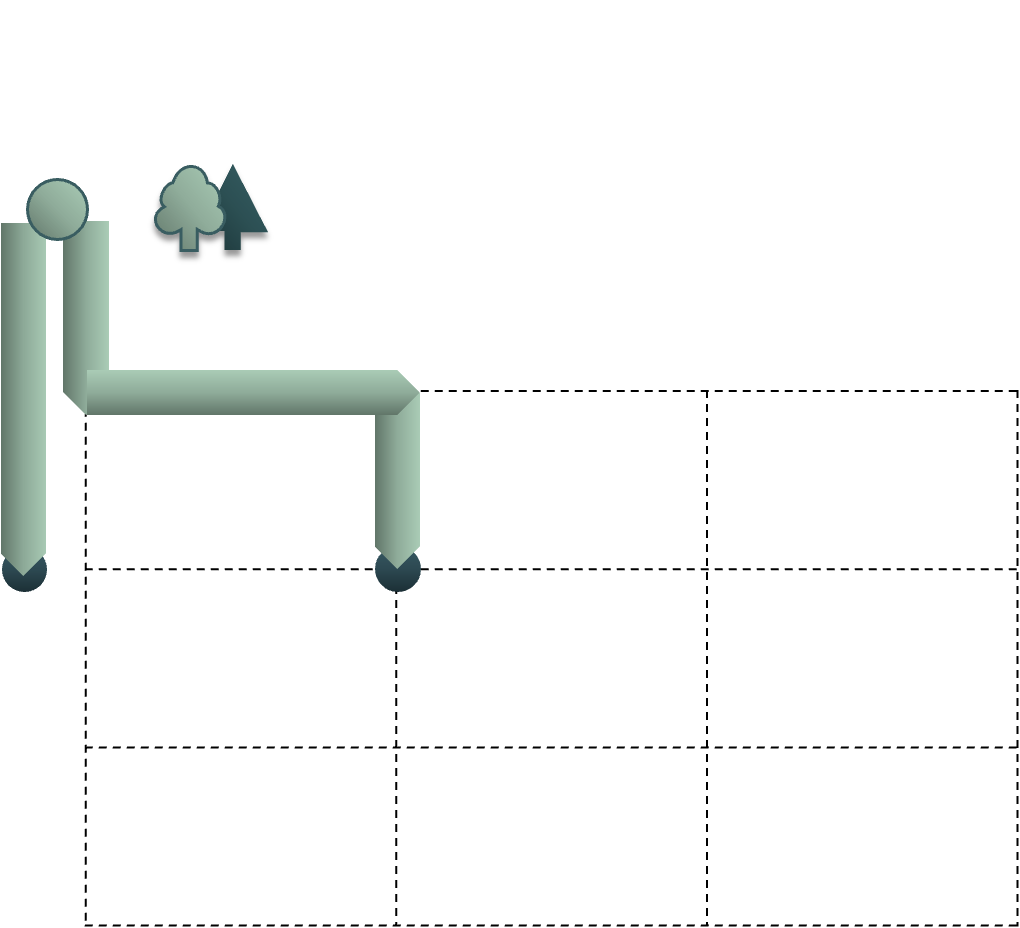

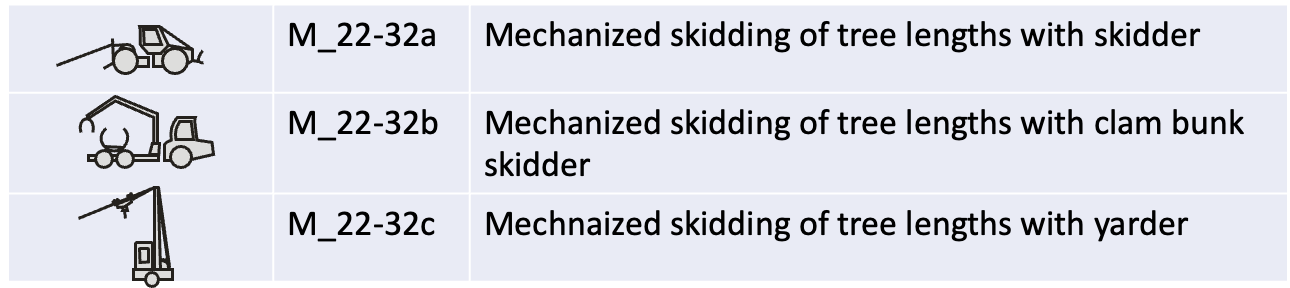

Solutions for extracting (skidding) tree lengthsDuring the sub-process of extracting/ skidding, the tree lengths are moved from the trail (buffer 22) to the forest road (buffer 32). Usually, the extracting is executed mechanically. Often used machines are the cable skidder and clam-bunk skidder. In both cases, the transport of the tree lengths is carried out in a dragging movement. The cable skidder can also be used not only for the skidding of tree lengths but also for the combined sub-processes of pre-skidding and skidding (see “Solutions for pre-skidding and skidding of tree lengths”).   | |