Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

F |

|---|

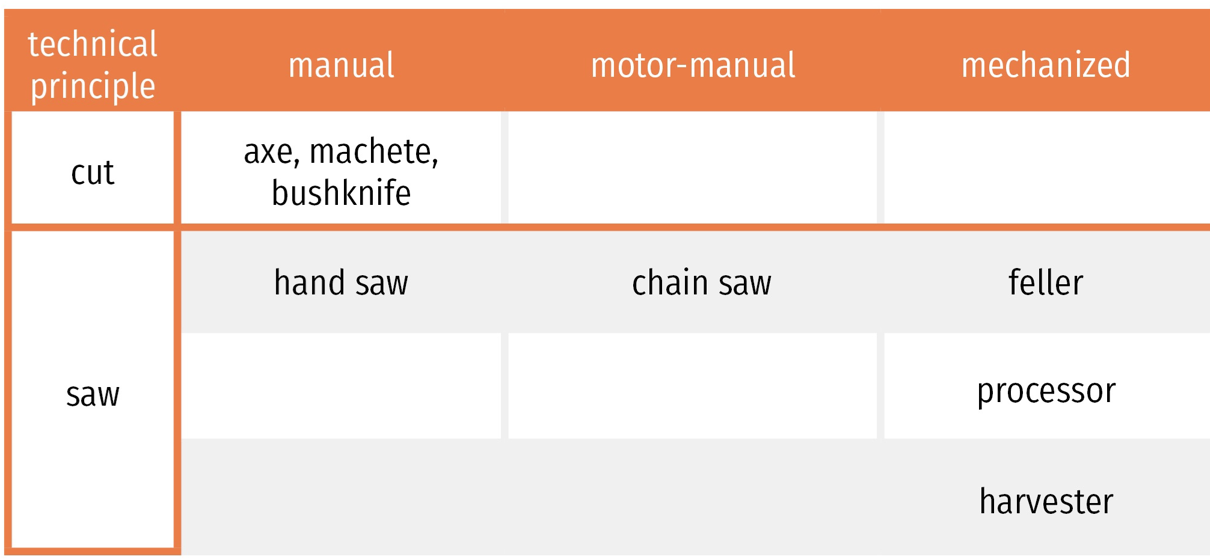

FellerThe feller is a self-propelled machine which is designed to fell trees (buffer 10 to 21). Alternatives, which are commonly used in forestry for the sub-process of felling, are the chainsaw as a tool, and the harvester as a machine. The feller itself can only take over the function of felling and pre-skidding over the distance of the crane length, further steps must be performed by other forest machines e.g., the processor. A shear or saw device, which is attached to the end of the feller´s hydraulic arm, cuts the tree off from its roots and bunches the full trees. Since all the steps of felling are executed by the feller and the human only needs to control the movements, the work with the feller is classified as advanced mechanized work. (See PR1-B03 and B07)

| |

Felling | |

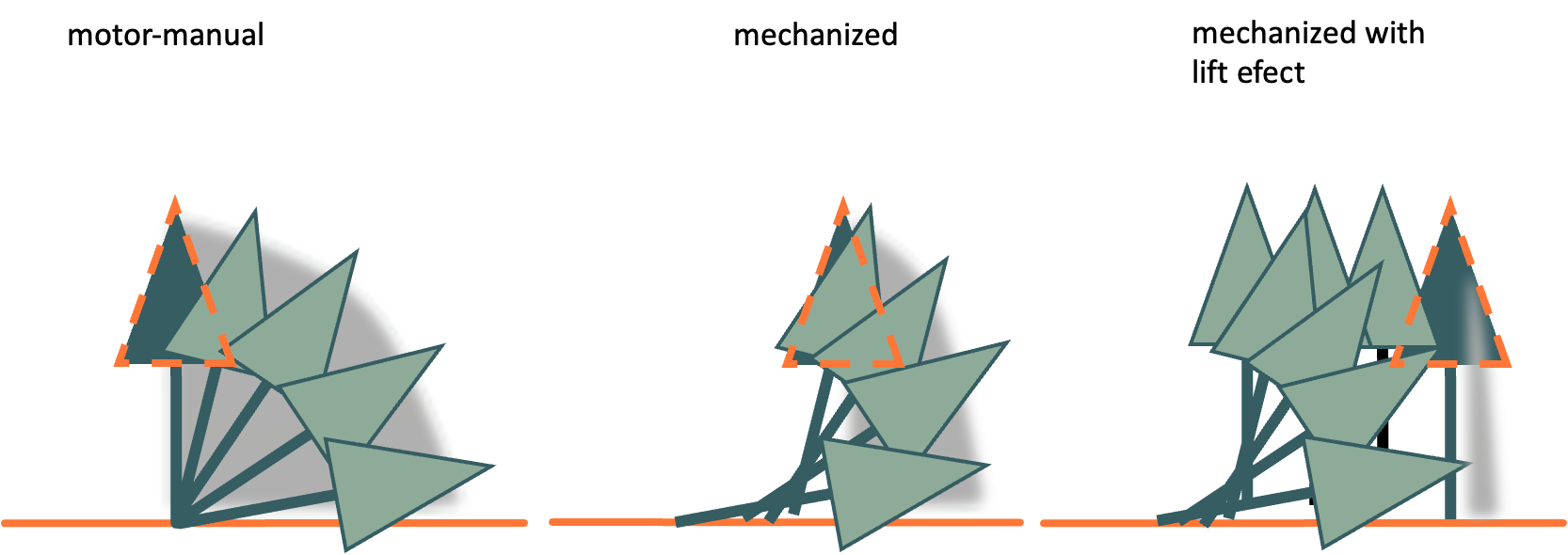

Felling damageA felling damage happens by the felling and processing of a tree to the tree itself and to neighboring trees and values. With motor-manual felling (a), the tree falls down forming a quadrant. The axis of this movement originates at the aptly, called “hinge”. As it falls, the tree develops a high dynamic force.Any obstacle in its way is in serious danger. If another tree is hit, it will be broken or wounded. If that occurs, a damage has been inflicted on the environment - not to the human being itself. Very often, this devaluation is not important: yet, if the injured tree is particularly valuable, then an important financial damage has also occurred. With machine felling (b) – using a feller or a harvester – , the tree is cut from its root, lifted a little bit and pulled towards the machine position. As a result, the wide tree crown falls mostly in the void left by the cut tree – where now there is little that could be damaged. Experience shows that by this procedure, the risk of inflicting felling damage to the remaining stand has turned nearly to zero. If the machine is strong enough to lift the tree upright (c), it can move it out of the stand and lay it down where there is no risk of damaging anything. This procedure is applied when the driver wants to spare clumps of regeneration developing under the cut tree. This proves that machines are able to reduce site damage, opposite to the common feeling of public, provided that the driver is sufficiently competent and careful. (See more at PR1-D01)  | |

Flexible decision makingSee rosette | |

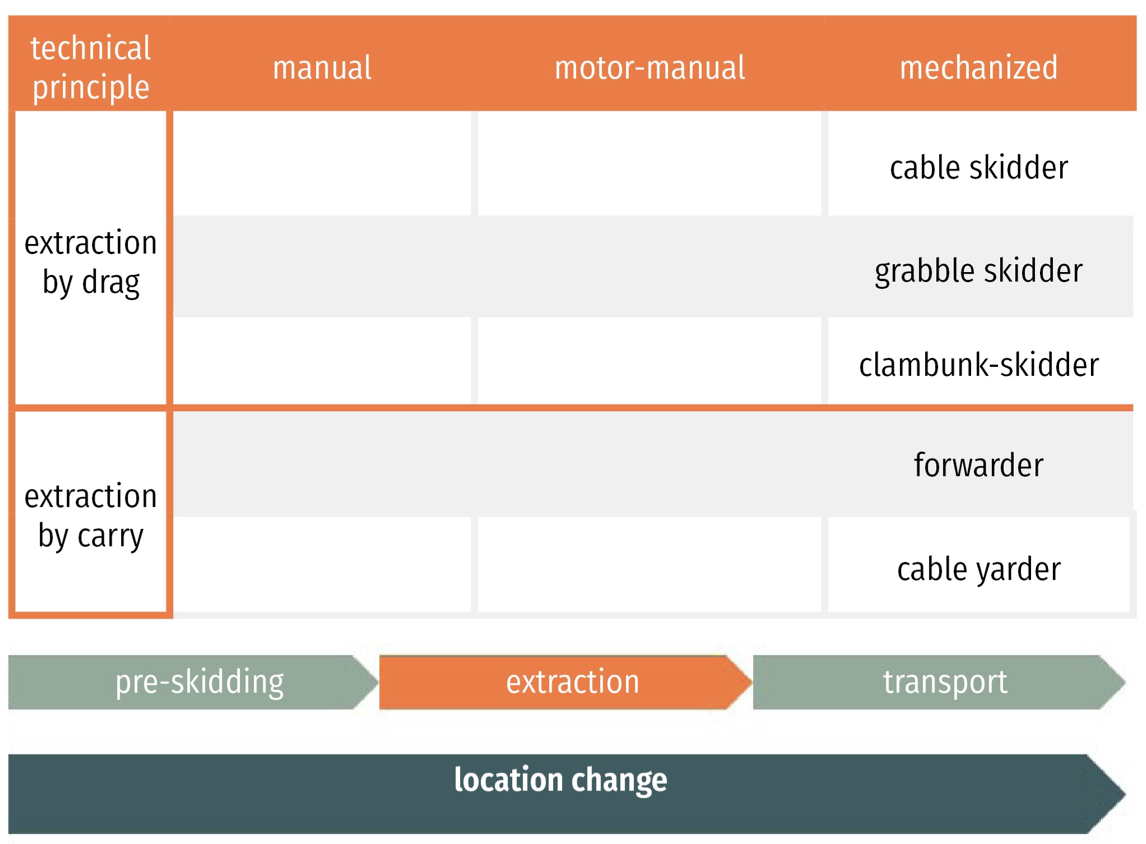

ForwarderThe forwarder is a rubber-tired or tracked machine used for the extraction of trees. Other machines that can be used for this sub-process are the cable skidder, grapple skidder, clam-bunk skidder, farm tractor equipped with a forwarding trailer, and cable yarder. The forwarder is mainly utilized for the extraction of short logs with a maximum length of 6 m (so called crane length). An integrated grapple loader lifts the logs onto the forwarder, where the logs are held by stanchions. Since the load does not touch the ground during the transportation process from the trail (buffer 32) to the forest road (buffer 33), this type of extractions is assigned to the carrying extraction. The forwarder is commonly used in combination with a harvester. The combination of both machines is called “fully mechanized cut to length method” or short “cut to length method”. A farm tractor equipped with a forwarding trailer is also used in some cases as a substitute for the forwarder. The work with the forwarder is described as advanced mechanized work. (See PR1-B03 and B07)

| |

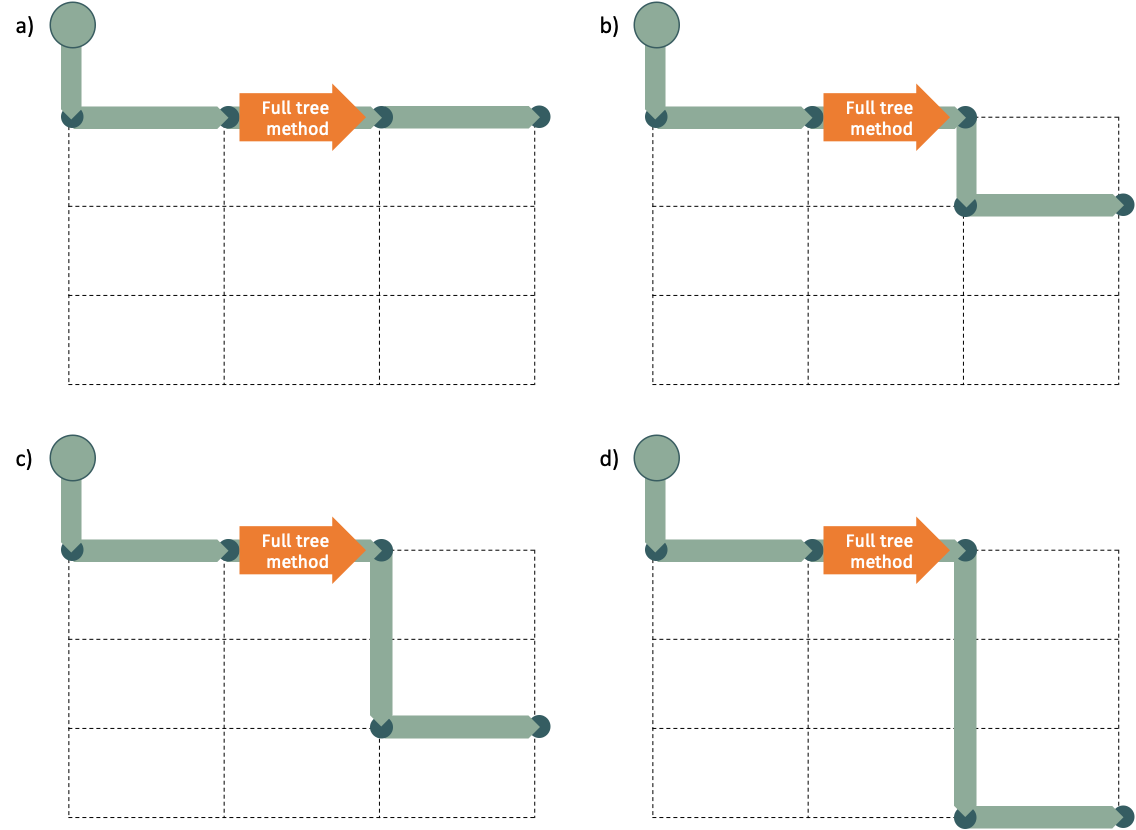

Full tree methodThe full tree method is one of four different functional groups of harvesting methods. The others are tree length, cut-to-length and chip method. With the full tree method, trees are cut down and then taken as full trees to the forest road. There (a) they can be loaded on special trailers and transported as full trees to the factory. Otherwise (b), once at the forest road, trees are delimbed and topped and transported to the factory as tree lengths. Or (c) they could also be crosscut at pre-defined lengths and transported to the factory as logs. Or finally (d), the logger opts for chipping the whole trees rather than delimbing and crosscutting them. (See more at TDiv PR1-B07)  | |

Fully manual methodSee manual method | |

Fully mechanized method | |

Fully motor-manual method | |

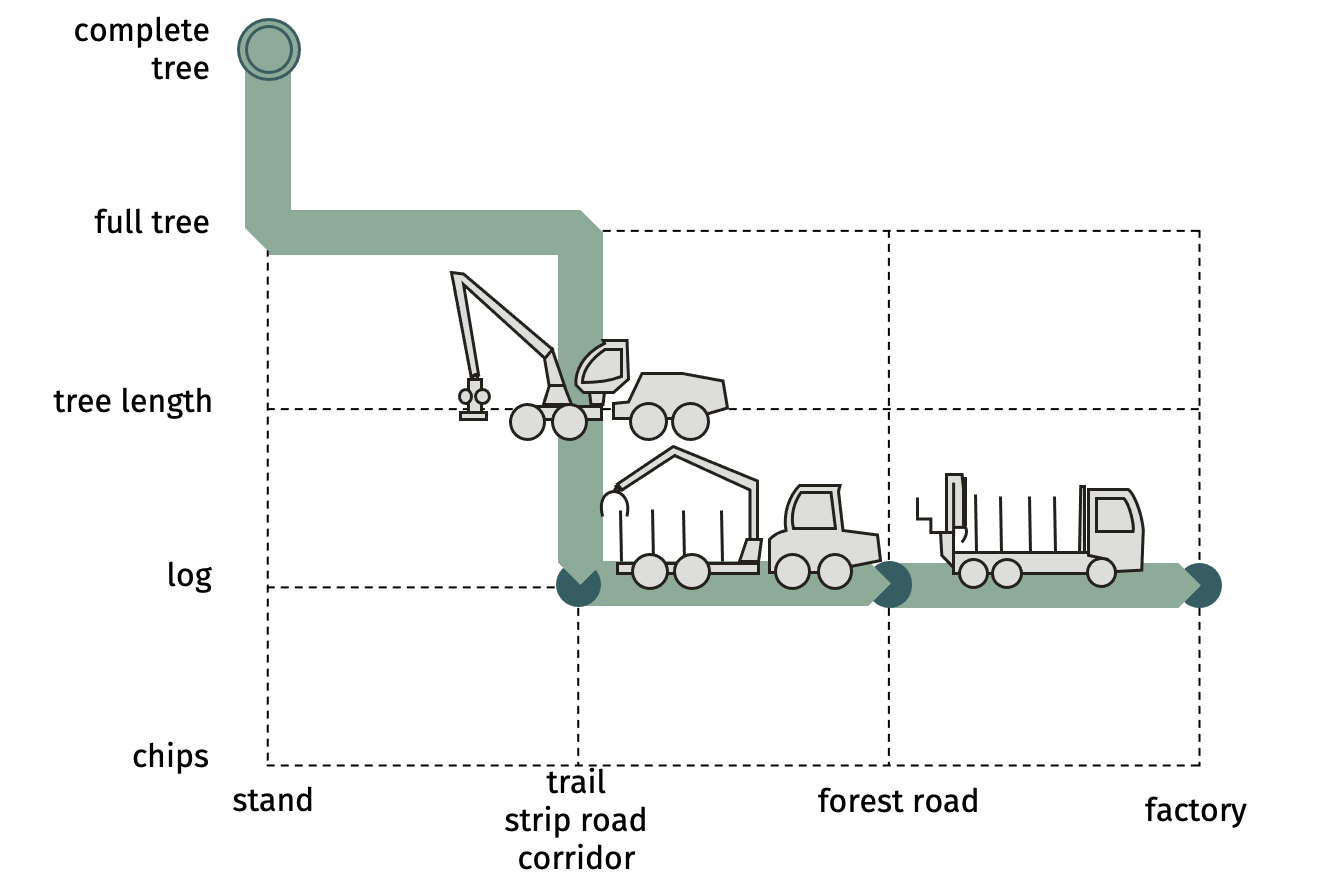

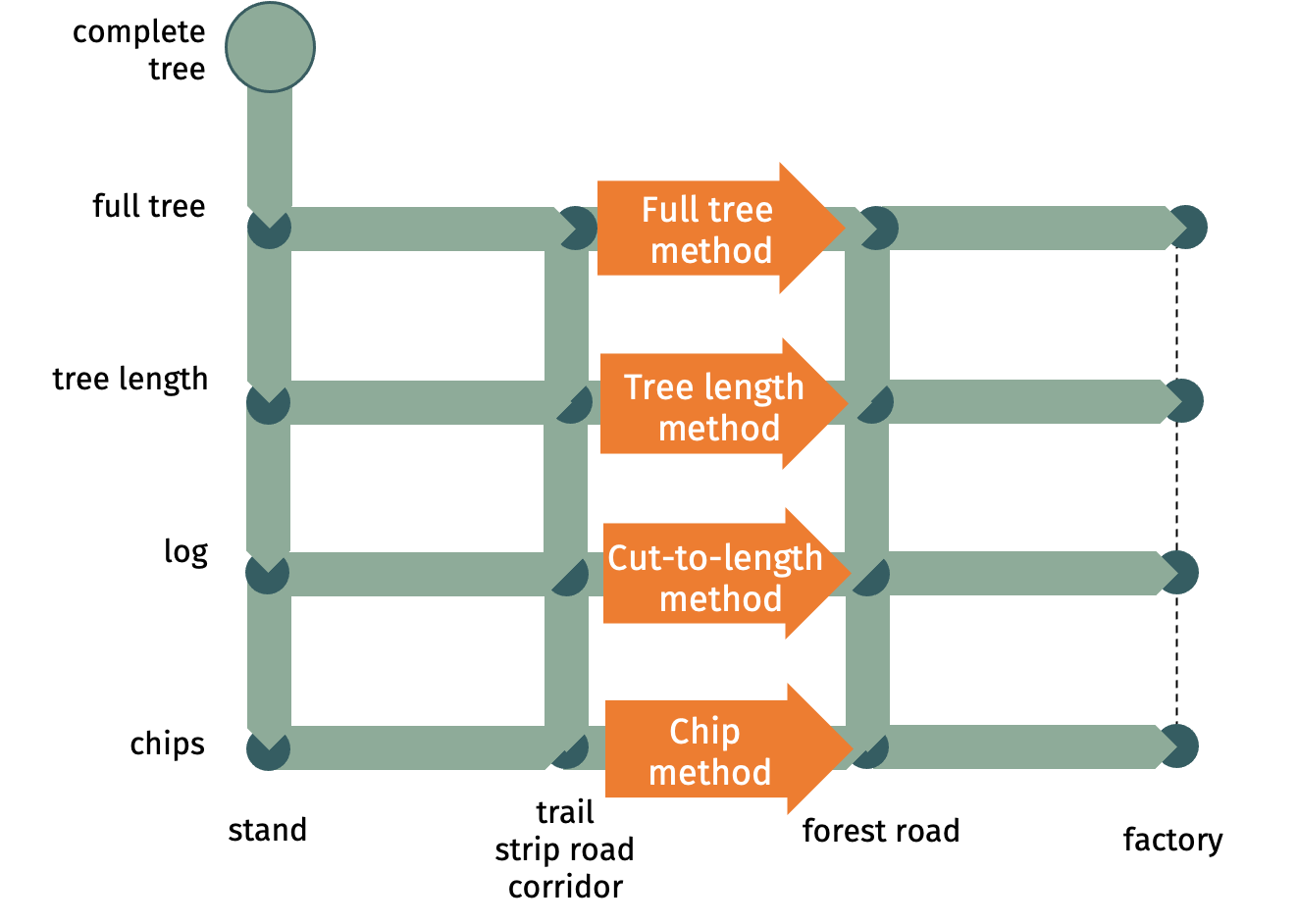

FunctiogramThe functiogram is one possibility to describe a harvesting method in forestry. In Technodiversity, it is used as standard visualization for processes and methods. From LÖFFLER et al. we have adopted the columns, where the location of the action is visualized: • Stand • Strip road, trail, corridor • Forest road • Factory From top to down we added the steps leading to state change:

In combination of both, we get a ‘road map’ of different paths, through which we can step forward from the top left corner (the complete tree) to the comfortable right end (i.e., the desired product). Technical operations are expressed by colored arrows. Each sub-process ends up with a buffer that is expressed by a dark button. Normally a process is a combination of two or more sub-processes that are concatenated. Each sub-process can be named by a pictogram of the most important actor like a machine, an animal or a hand-tool. If necessary, additional information can be made by pictures or words. As one example, the fully mechanized method with harvester and forwarder is shown here. The harvester performs the following tasks: fells the tree, moves the full tree to the trail (pre-skidding), delimbs the tree and cross-cuts it into shorter logs. Finally, the logs are stored alongside the trail as a small pile – i.e., a buffer (dark button). Later on, the forwarder loads the logs, carries them along the trail to the landing at the forest road and unloads the logs. Here again a buffer is formed (second dark button). The truck loads the logs and delivers them to the user plant. On the basis of a functiogram, the harvesting method can be subsumed under one of the following functional groups: full-tree method, tree-length method, cut-to-length method or chip method. The combination of the degrees of mechanization of each sub-process gives the degree of mechanization of the total method. In our example, we have a fully mechanized cut-to-length method. (See more at TDiv PR1-B06)

| |

Functional groupsDue to the confusing number of different harvesting methods, there is a need to define functional groups of them where some crucial attributes are the same. One possibility that is often used in practice is to subdivide the methods by the form in which the tree arrives at the forest road: - as a full tree = full tree method - as a tree length = tree length method - as a short log = short wood or cut-to-length method - or as chips = chip method. (See more at TDiv PR1-B07)  | |

FunctionalityFunctionality describes whether any systems functions in a way that it fulfils the demands. In our technical context, it may be seen as synonym for economic effectiveness. | |

FunctionalizeFunctionalize see functionalizing | |

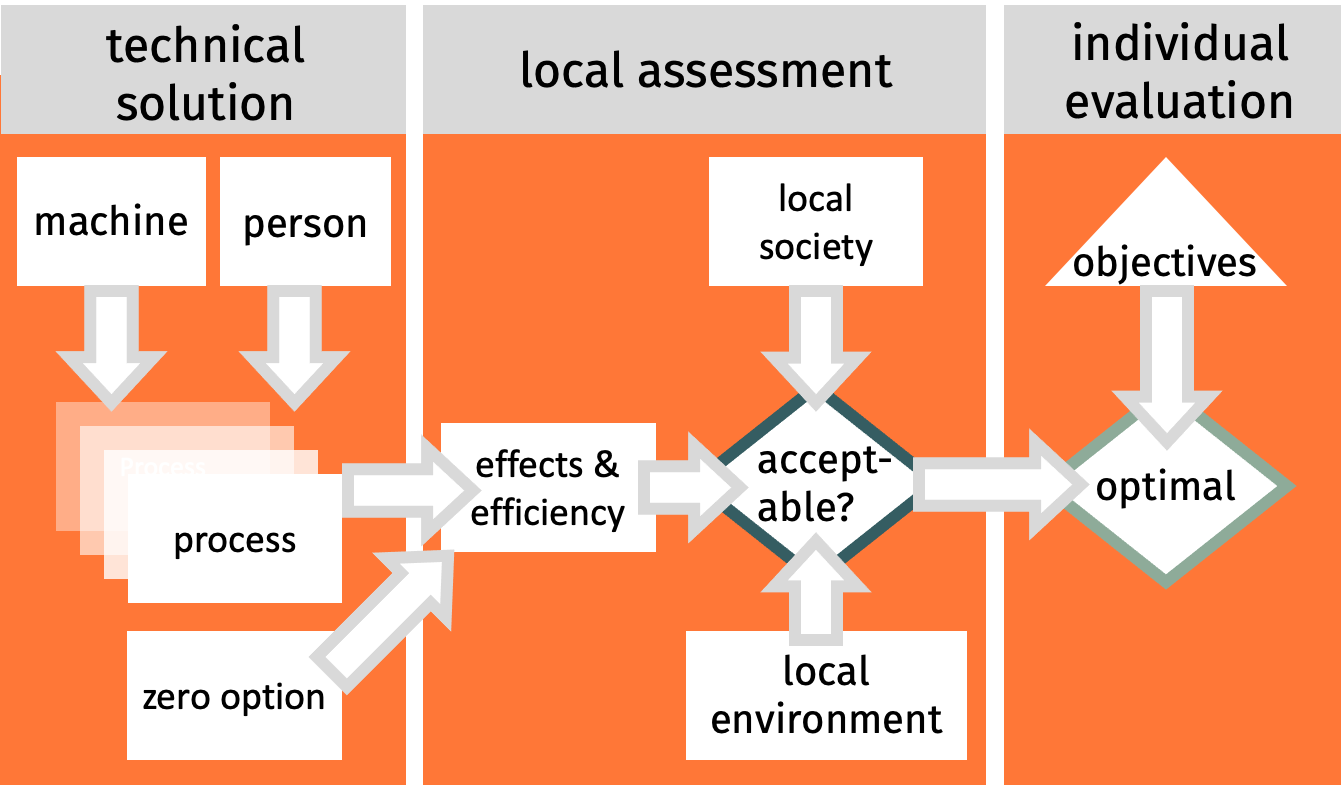

FunctionalizingFunctionalizing is the first step of the three-step-model of decision-making in forest technology. The second step is localizing and the third one is individualizing. The first step aims at finding and designing all harvesting processes that can work under local conditions and technical constraints of the stand. Here, machines that are available and operators, who are available, are combined to working methods that can be assumed to do the demanded job. In order to expand the search space as large as possible, several options should be selected that differ greatly from one another (different machines, different degrees of mechanization etc.). And one option should never be forgotten: the option to do nothing, the so-called zero-option. (See more under TDiv PR1-A04 and TDiv PR1-B01 to B07)

| |

Functions of harvestingFunctions can be divided into two groups: Main functions and auxiliary functions. Main functions influence directly the working object. Again, we have two sub-groups: those that change the state of the object and those that change its position. Auxiliary functions help to manage the process, but don’t have a direct input to the working object. On to highest level, we have two auxiliary functions: the handling that is a more physical sub-process and the steering that operates the process and deals with data. In tree harvesting operations, the main functions are the harvesting and the extraction. Though the auxiliary functions are important, too, in Technodiversity they will not be treated further. | |