Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

L |

|---|

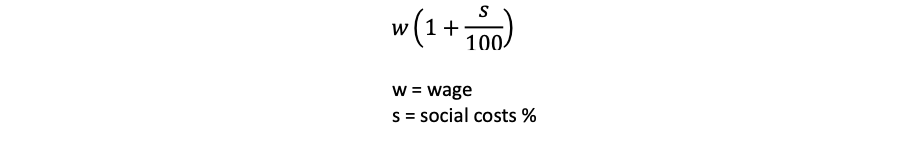

Labor costsLabor costs are a part of the cost calculation with the engineering formula. They consider the wage costs of the operator plus all additional costs. Here we should be careful: If the operator only works with that machine, we can take the total costs of this worker (including assurance etc.) over the year and divide them by the same time of productive utilization “m” as we have for the machine. However, a driver or worker often operates two or more machines, in which case it is easiest to calculate his/her costs per hour and then conduct all the machine cost calculation on an hourly basis. As we stated before, labor costs have two main components: • w = gross wage • s = social costs thatmust be covered by the employer like insurance, wage costs during unproductive times due to holidays, traveling expenses etc. (but not his taxes). They are normally indicated as percentage of the gross wage. The percentage of social costs is highly variable from country to country. In Germany, e. g., it depends mainly on the company: • in private forest companies it is about 80-110 % • in public forest administrations it often reaches 130 %. (See more at TDiv PR1-C02)

| |

Laws for forest operationsSee rules and laws for forest operations

| |

Localizesee localizing | |

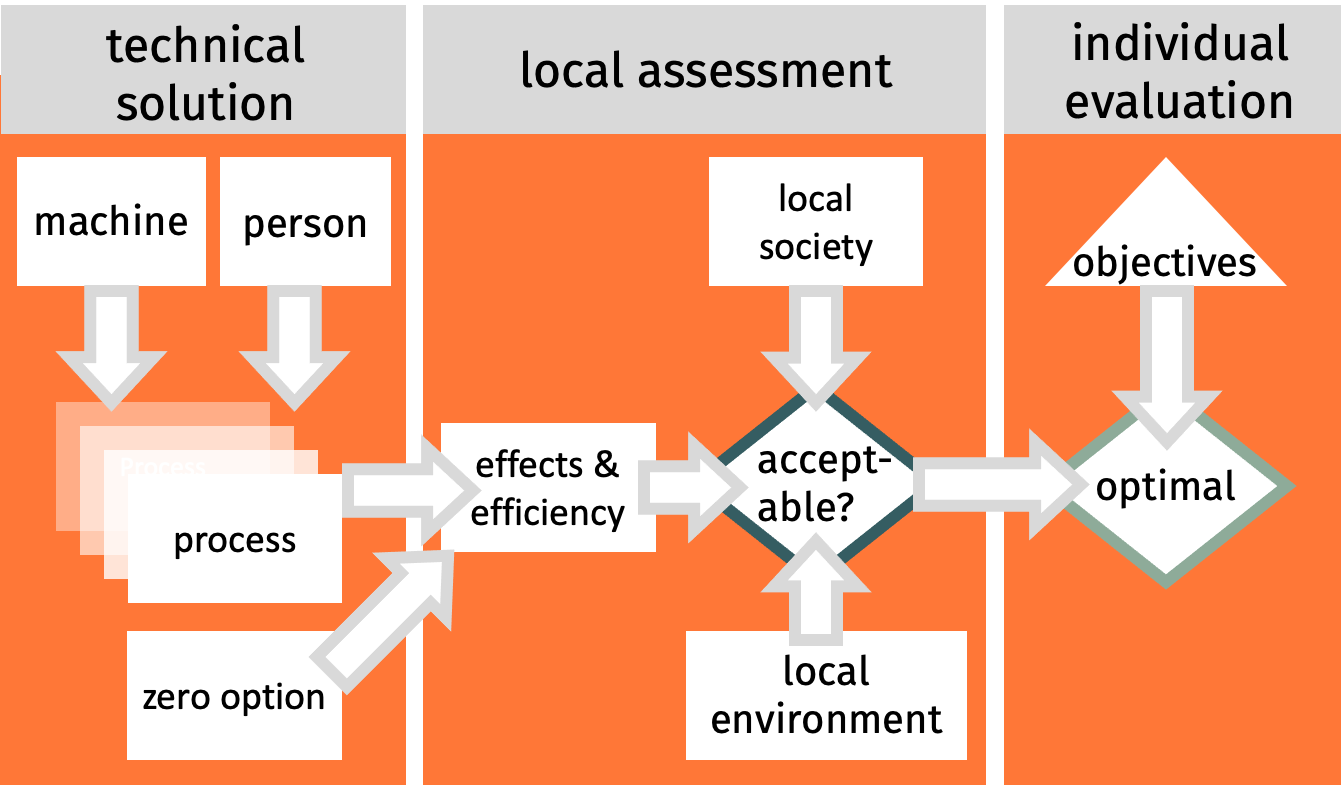

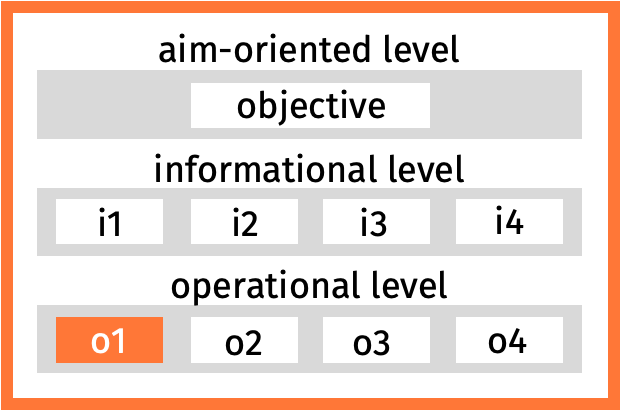

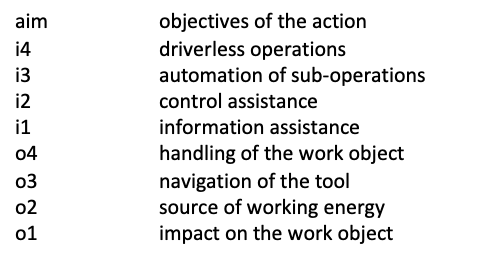

LocalizingLocalizing is the second step of the three-step-model of decision-making in forest technology. The first step is functionalizing and the third one is individualizing. The second step checks for any local constraints to their deployment and leads to the exclusion of non-compatible options. The criteria are the economic suitability for the company (effectiveness and efficiency), the ecological suitability for the local environment (ecological compatibility and eco-efficiency), and the social suitability for the local population (societal compatibility and ergonomics). (See more under TDiv PR1-A04 and C… for economy, D… for ecology and E… for social aspect) | |

M |

|---|

Manner of workingFor any operational method, the tools and machines as well as the working steps are fixed. But sometimes the worker does not exactly what he is asked to do. Maybe he invents his own sequence of steps or he works in a way that conflicts with any safety rules – then we call it the manner of working. Since the worker is the one who has the most experience with the working situations, it can happen that his manner of working leads to an improvement of the standard operational method. But if he breaks any legal limits or safety rules, then this manner cannot be accepted. (See more under TDiv PR1-E03) | |

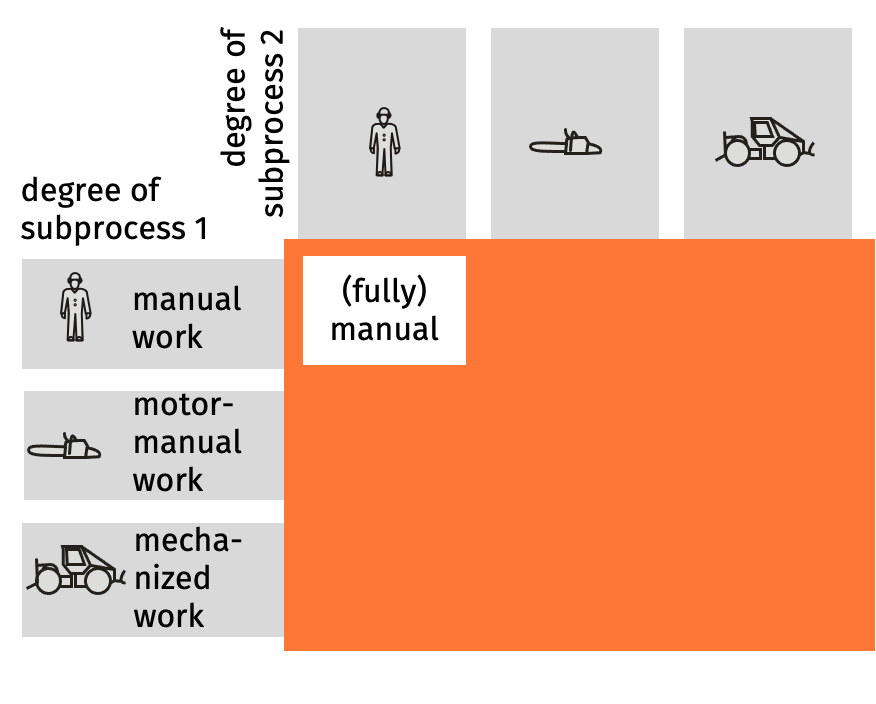

Manual methodIn Technodiversity, the total harvesting process normally is seen as a combination of several sub-processes. Each sub-process has a certain degree of mechanization. The degree of mechanization of the total method is given by the combination of these single degrees. There are five degrees of mechanization: (fully) manual method, partly motor-manual method, (fully) motor-manual method, partly mechanized method, fully mechanized method. If there is no power equipment in any sub-process, say both sub-processes are done by manual work, the method is a fully manual method. Fully manual methods are not unusual in developing economies or in part-time work. The word fully underlines the character of the process, but it can be missing. (See more under TDiv PR1-B04 an d B05)

| |

Manual WorkThe term manual work describes the degree of mechanization of a technical operation. Other degrees are motor-manual work and mechanized work.

| |

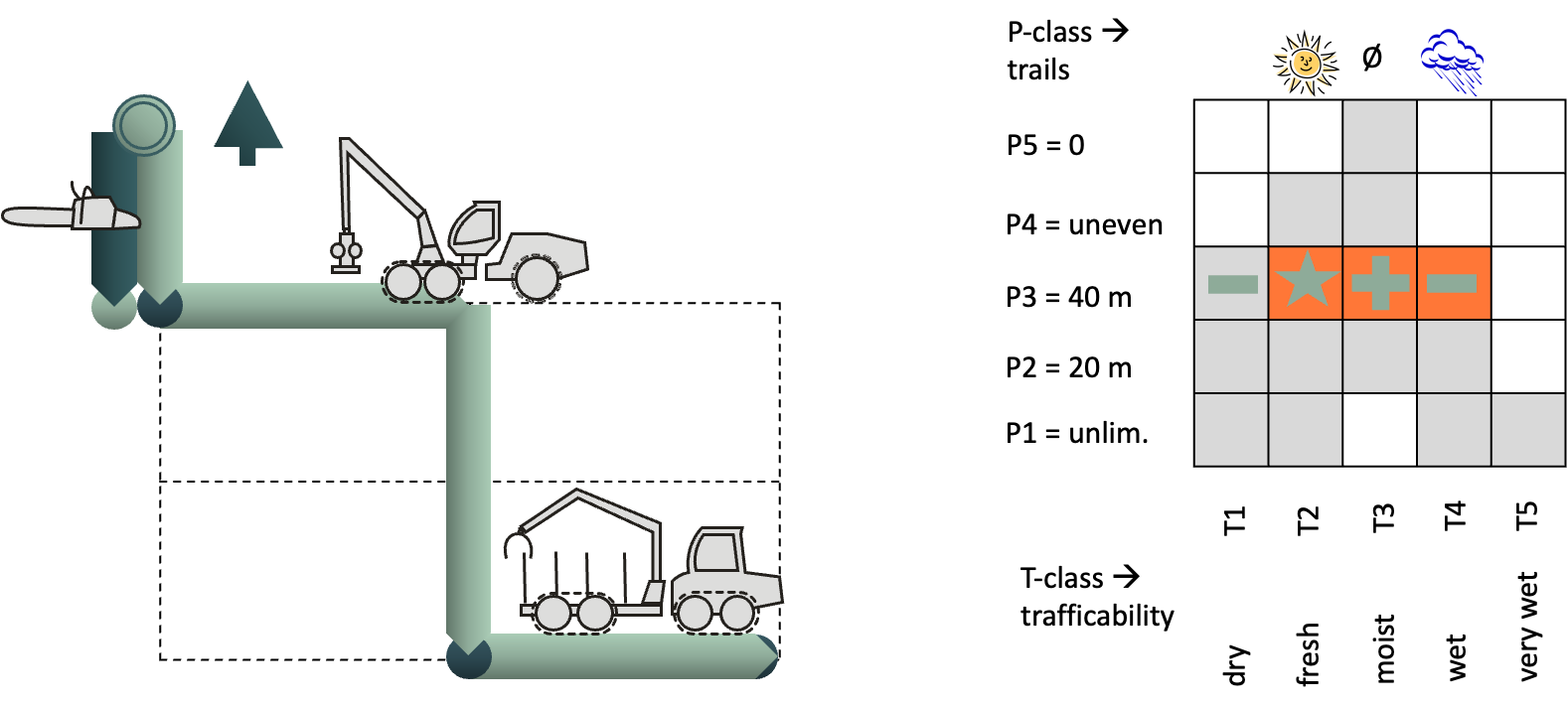

Matching technogram and ecogramIn Technodiversity, a graphical method to find the optimal harvesting method is supposed. The technical conditions of the forest stand are represented by the technogram with the sides T-class (trafficability due to the moisture of the soil) and P-class (productivity of the stand). Each stand falls exactly into one field, in the example it is T3-P3; but under dry or wet conditions it can move to left (dryer, T2) or right (wet, T4). As one possible harvesting method, the functiogram of a almost fully mechanized ctl-method with bogie-tracks is shown. In the ecogram, it has its optimum at T2-P3, but is good under T3-P3 and limited under T4-P3 and T1-P3. Matching both graphs shows that the method is very good under dry conditions, but also good under normal conditions in this stand. In combination with the ecograms of other technical options, this may be a basis to select the optimal option. (See more at TDiv PR1-D04)  | |

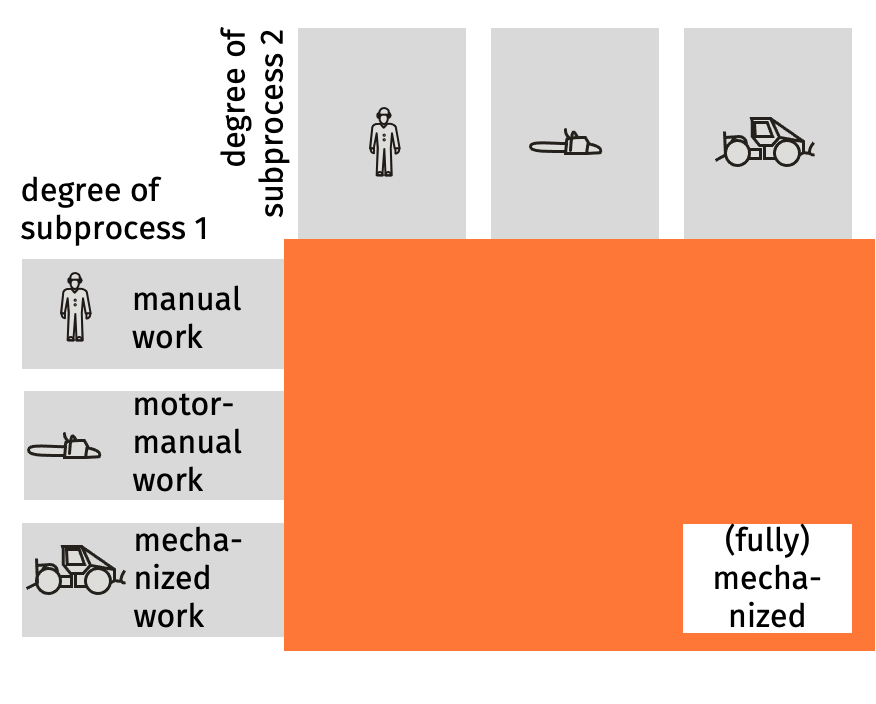

Mechanized methodIn Technodiversity, the total harvesting process normally is seen as a combination of several sub-processes. Each sub-process has a certain degree of mechanization. The degree of mechanization of the total method is given by the combination of these single degrees. There are five degrees of mechanization: (fully) manual method, partly motor-manual method, (fully) motor-manual method, partly mechanized method, fully mechanized method. If all sub processes are done with self-propelled machines, the method is a fully mechanized method or easier: mechanized method. Typically, that occurs when the harvester-forwarder team or the feller-buncher and skidder team are employed. (See more under TDiv PR1-B04 and B05) | |