Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

F |

|---|

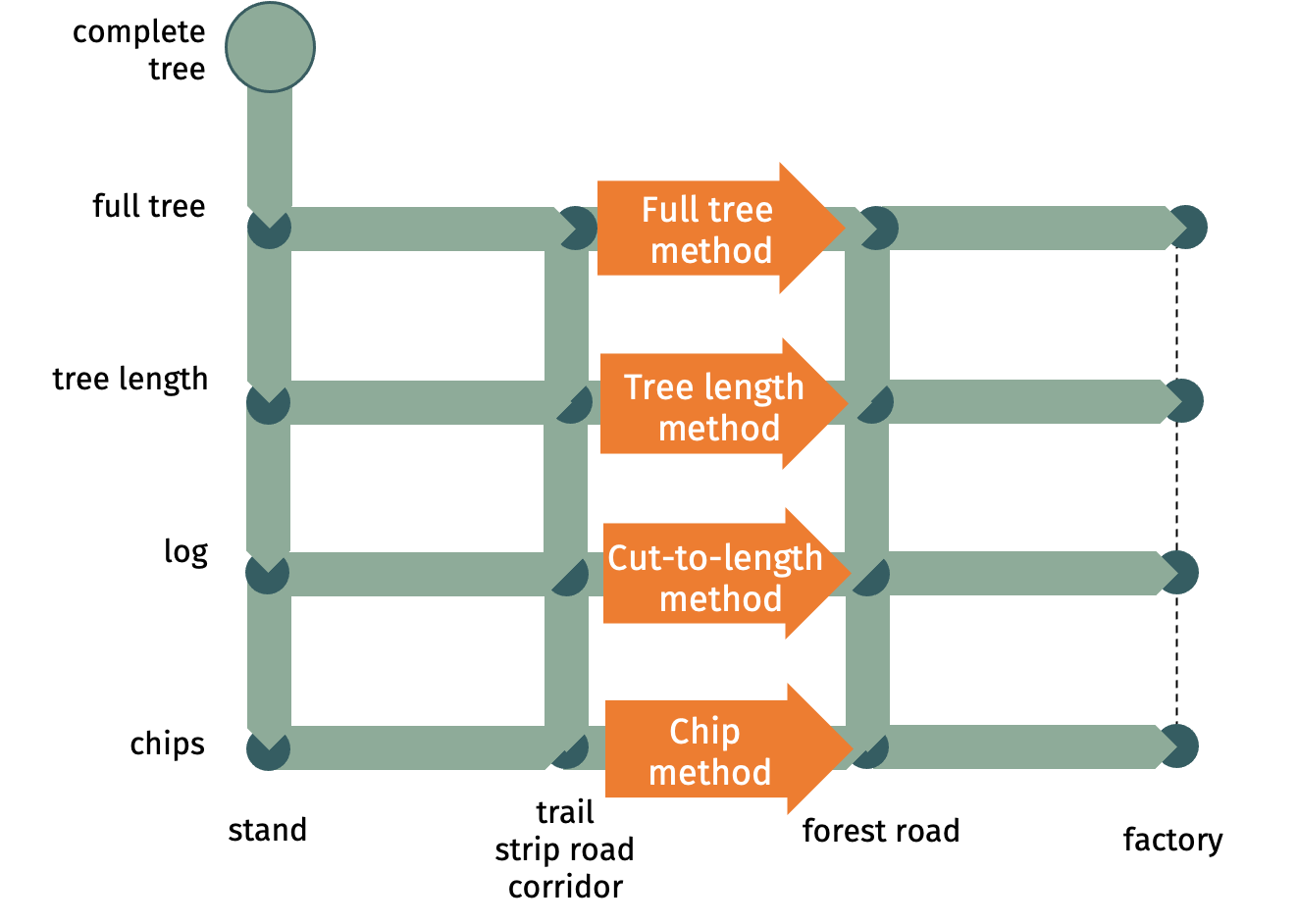

Functional groupsDue to the confusing number of different harvesting methods, there is a need to define functional groups of them where some crucial attributes are the same. One possibility that is often used in practice is to subdivide the methods by the form in which the tree arrives at the forest road: - as a full tree = full tree method - as a tree length = tree length method - as a short log = short wood or cut-to-length method - or as chips = chip method. (See more at TDiv PR1-B07)  | |

FunctionalityFunctionality describes whether any systems functions in a way that it fulfils the demands. In our technical context, it may be seen as synonym for economic effectiveness. | |

FunctionalizeFunctionalize see functionalizing | |

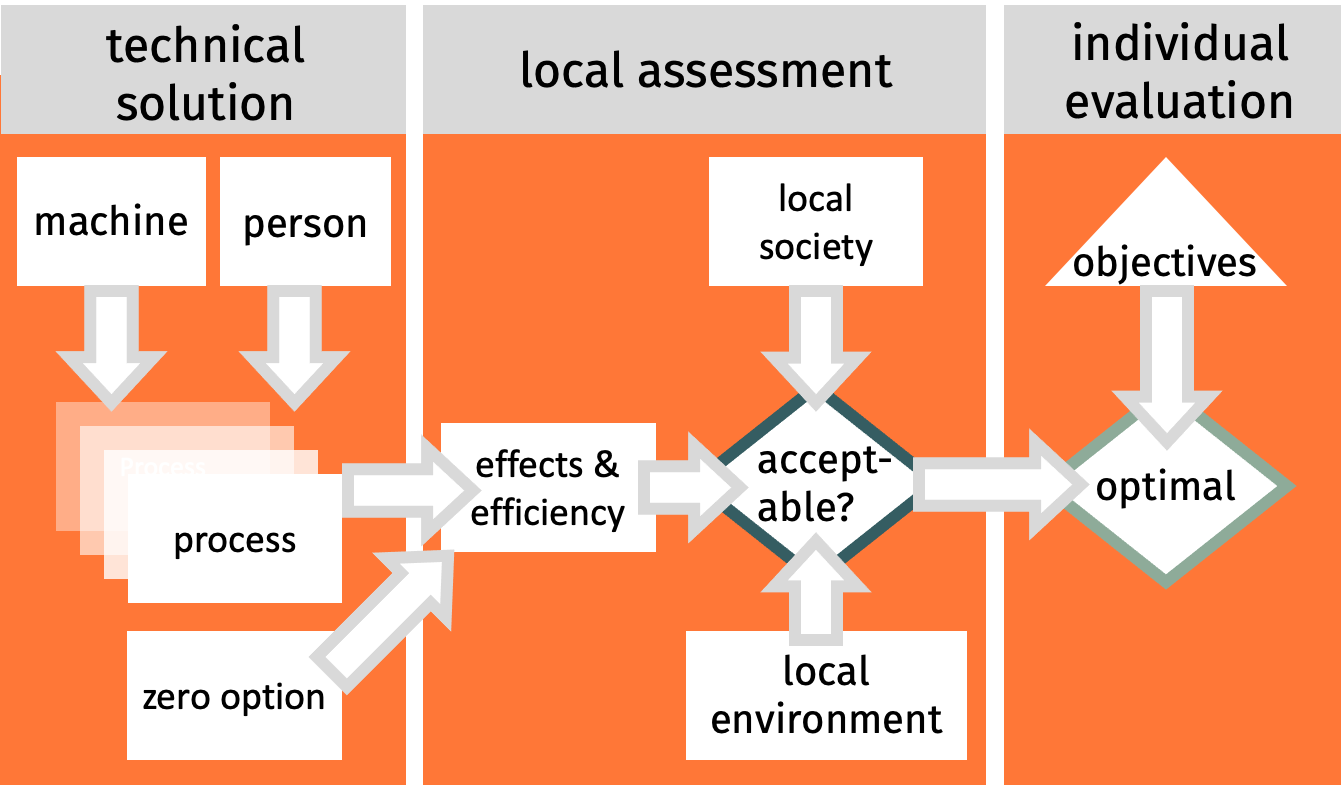

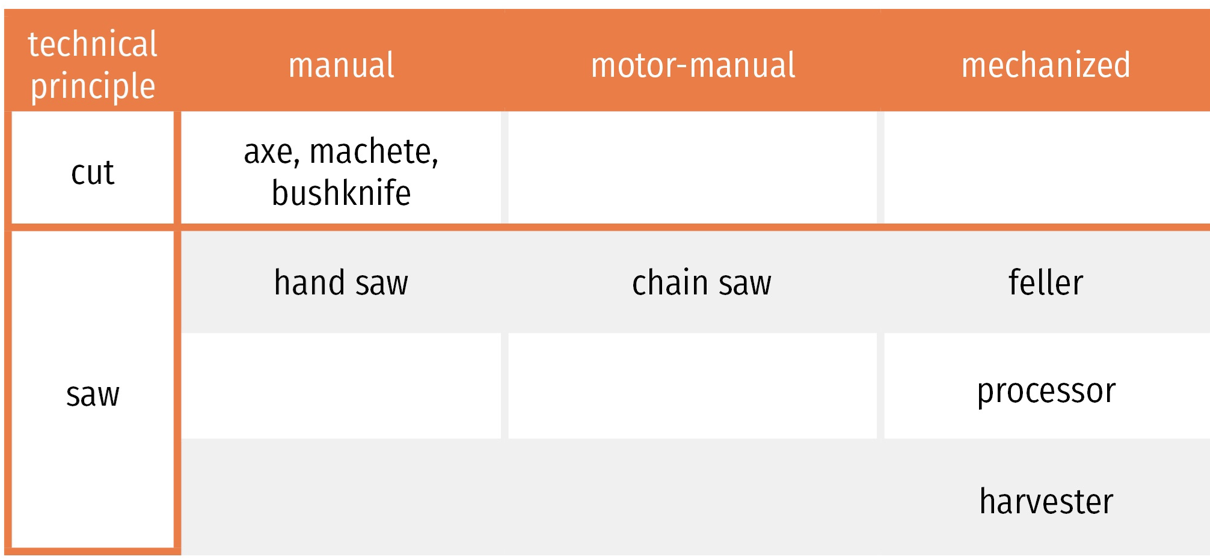

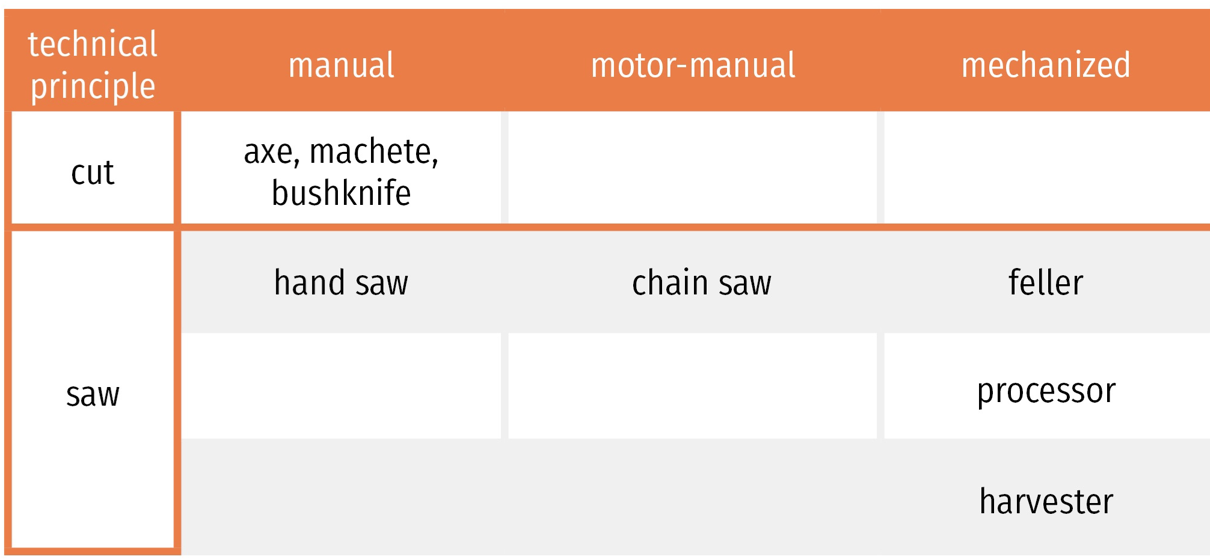

FunctionalizingFunctionalizing is the first step of the three-step-model of decision-making in forest technology. The second step is localizing and the third one is individualizing. The first step aims at finding and designing all harvesting processes that can work under local conditions and technical constraints of the stand. Here, machines that are available and operators, who are available, are combined to working methods that can be assumed to do the demanded job. In order to expand the search space as large as possible, several options should be selected that differ greatly from one another (different machines, different degrees of mechanization etc.). And one option should never be forgotten: the option to do nothing, the so-called zero-option. (See more under TDiv PR1-A04 and TDiv PR1-B01 to B07)

| |

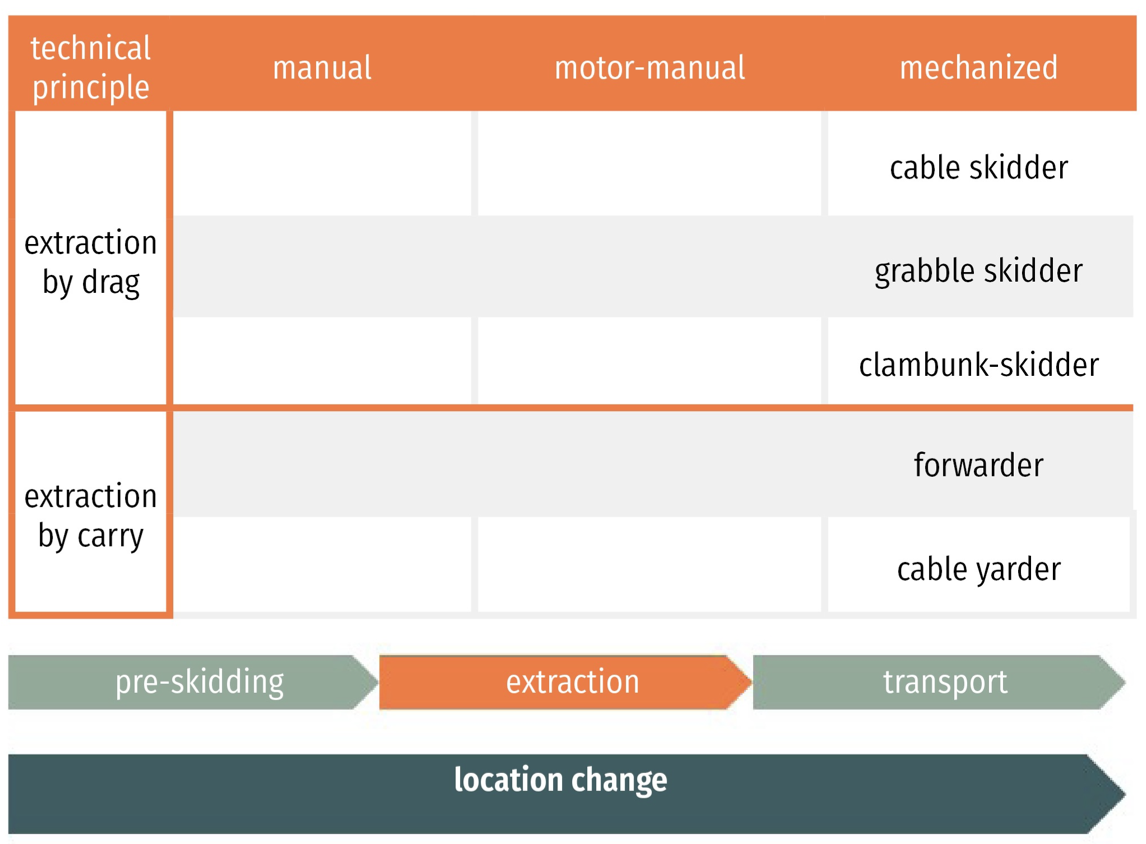

Functions of harvestingFunctions can be divided into two groups: Main functions and auxiliary functions. Main functions influence directly the working object. Again, we have two sub-groups: those that change the state of the object and those that change its position. Auxiliary functions help to manage the process, but don’t have a direct input to the working object. On to highest level, we have two auxiliary functions: the handling that is a more physical sub-process and the steering that operates the process and deals with data. In tree harvesting operations, the main functions are the harvesting and the extraction. Though the auxiliary functions are important, too, in Technodiversity they will not be treated further. | |

G |

|---|

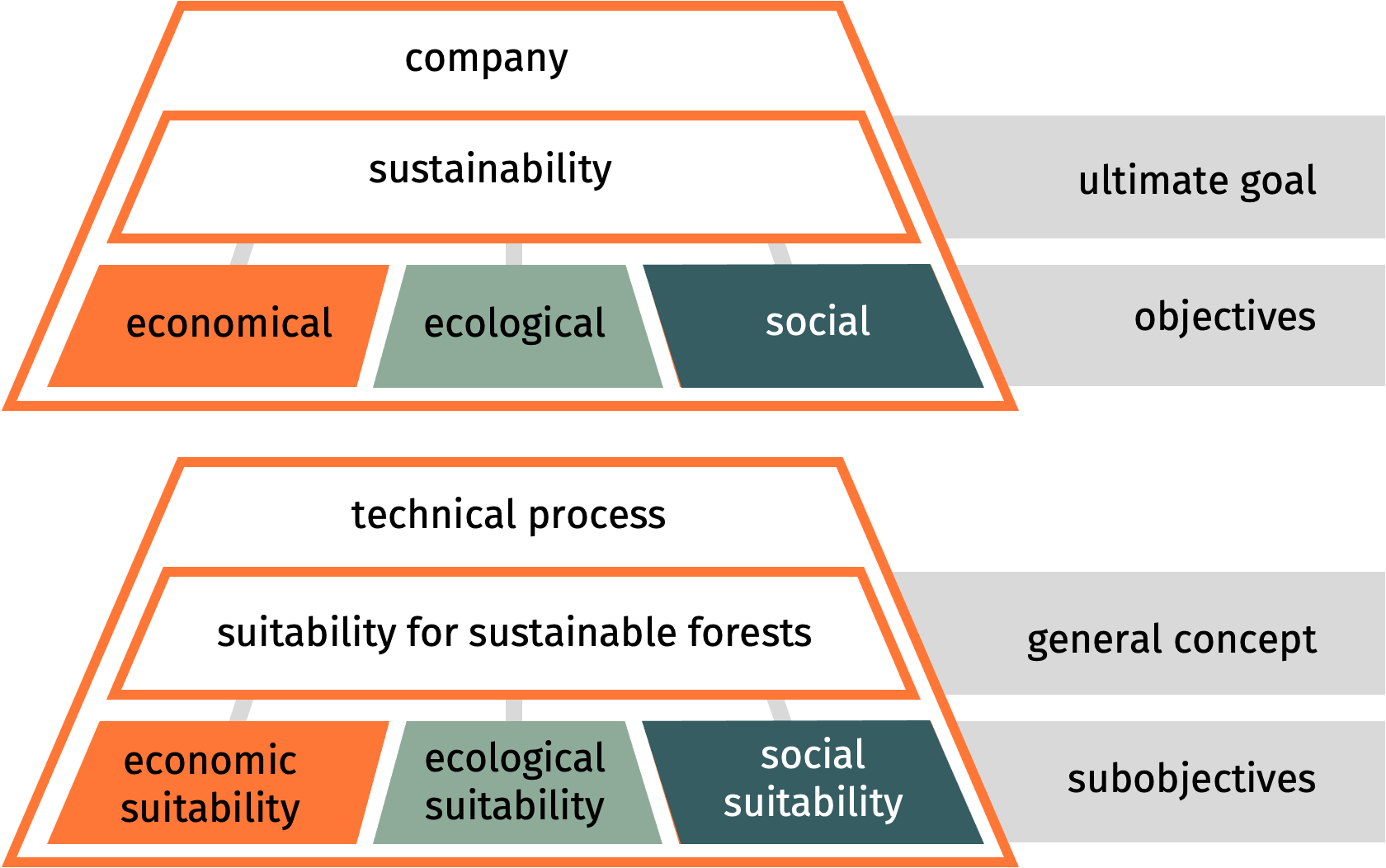

General conceptGeneral concept is a guideline for a company that gives a certain drive to the operations in a field. For example, a forest company may have different general concepts for silviculture, for hunting, for nature conservation activities, e.g. For technical operations, it should also formulate a general concept. Like the ultimate goal for the total company, the general concept has two dimensions: · For internal decision-making situations it clarifies priorities or preferences between the sub-objectives or partial objectives. Thus, it improves the transparency and operationality of the decision-making process in this field. · For external use it should explain with simple words the focus how this company sees its operations. It can be regarded like a motto that explains the typical behavior of the company. (See more at PR1-A03)  | |

Grapple skidderThe grapple skidder is a rubber-tired or tracked machine used for the extraction of trees. Other machines that can be used for this sub-process are the cable skidder, clam-bunk skidder, farm tractor equipped with a forwarding trailer, forwarder, and cable yarder. The grapple skidder is mainly used to extract full trees from the trail (buffer 21) to the forest road (buffer 31). In contrast to the clam-bunk skidder, the grapple skidder assembles and holds its load with a hydraulic grapple, that opens downwards. Like all skidders, the work with the grapple skidder is declared as advanced mechanized work. (See PR1-B03 and B07)  (Photo CNR)  | |

H |

|---|

Hand sawThe hand saw is used as a tool for dividing an object by sawing it. Characteristic for the hand saw used in forestry are the bar handles at each side of the saw blade. As an alternative to the axe the hand saw is operated by two people, each standing at a handle. By alternately pulling the hand saw a kerf is formed in the complete tree which leads to the felling of the tree at a certain point (buffer 10 to 11). Since only human force is needed to saw with the hand saw, it is assigned to the manual work. Other harvesting tools, the use of which is assigned to manual work, are the axe, the machete, and the bush knife. (See PR1-B03)  | |

HandlingHandling is one of the auxiliary functions of harvesting. It does not directly change the state of the working object or its position, but brings the tools, machines and objectives together. A very effective tool for handling is a crane with a hydraulic grip that allows the operator to stay apart from the object and therefore out of the risk zone. Though handling is a very effective and efficient area for improving the working site, it is not mentioned intensively in Technodiversity. (See more at TDiv PR1-B01) | |

HarvesterThe harvester is a self-propelled machine that takes over all partial steps of the timber harvest, which are felling, delimbing, measuring, cross-cutting and bunching (buffer 10 to 21, 22 or 23). There is no other machine that combines all these sub-processes. Along the crane it takes over a short pre-skidding as well (buffer 21 to 22). The harvester is a widely used instrument in wood harvesting.

(Photo BOKU) Depending on whether the harvester is having the same felling and processing unit (all functions can be performed with one grab of the tree), or the processing unit is separate from the felling unit (functions need to be performed with more than one grab of the tree), the harvester is called one- or two-grip-harvester. Since today most machines on the market are one-grip-harvesters, this differentiation gets less important. Currently, other prototypes are being

tested in addition to the classic harvester construction. They differ from the

classic model in the way they move, which should enable these models to be used

in very steep terrain or to minimize the soil compaction of the harvester (See lecture

B06: Harvester Highlander (Konrad, Austria), Prototype walking machine

(Plustech Oy, Finland) or Prototype Portalharvester (TU Dresden, Germany)).

(Photos PLUSTECH and TUD) Since every step of timber harvest is executed by the harvester and the operator only needs to control the movements, the work with the harvester is classified as mechanized work. (See PR1-B03 and B07) | |