Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

T |

|---|

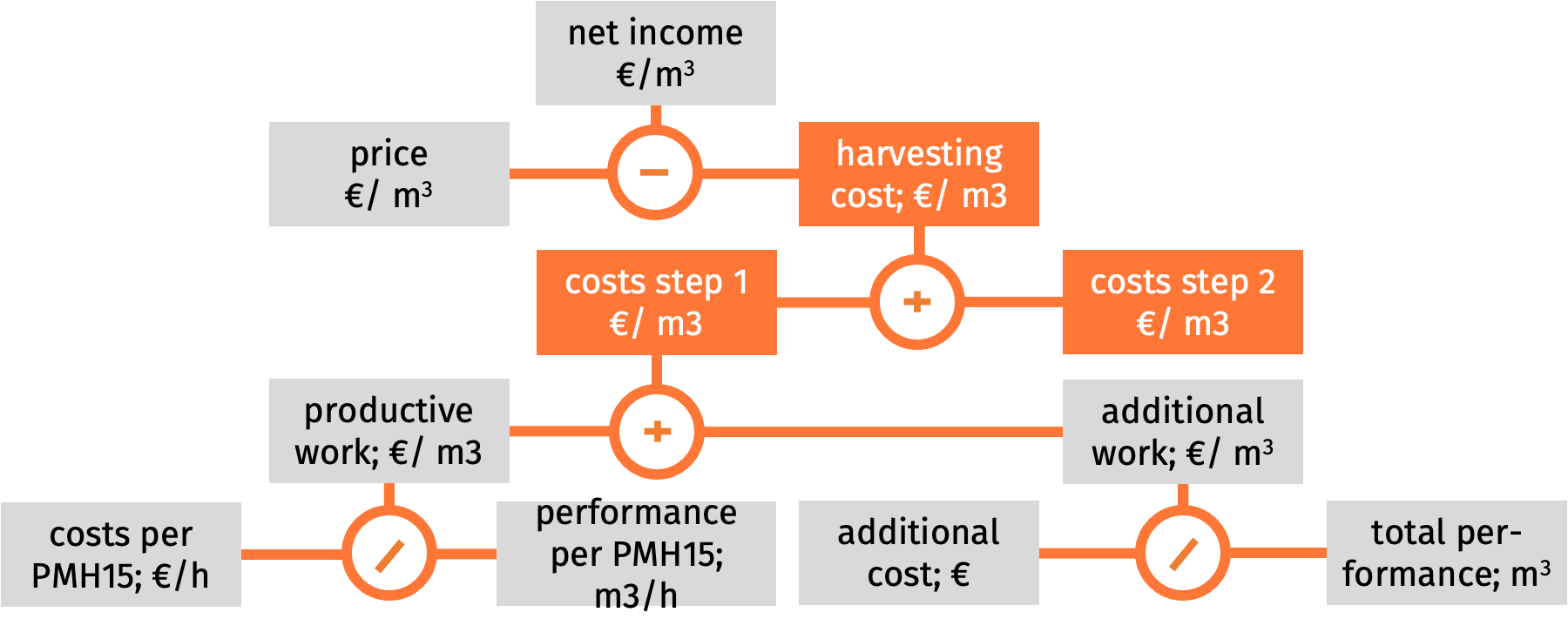

Total system costsTotal system costs are a part of the cost calculation. Since most processes are composed by two or more sub-processes, their costs must simply be added, too. But there are some exceptions. In a case, where one sub-process must wait for another one, the productivity of the total system is defined by the productivity of the slowest sub-process. (See more at TDiv PR1-C05)

| |

Tractor winch

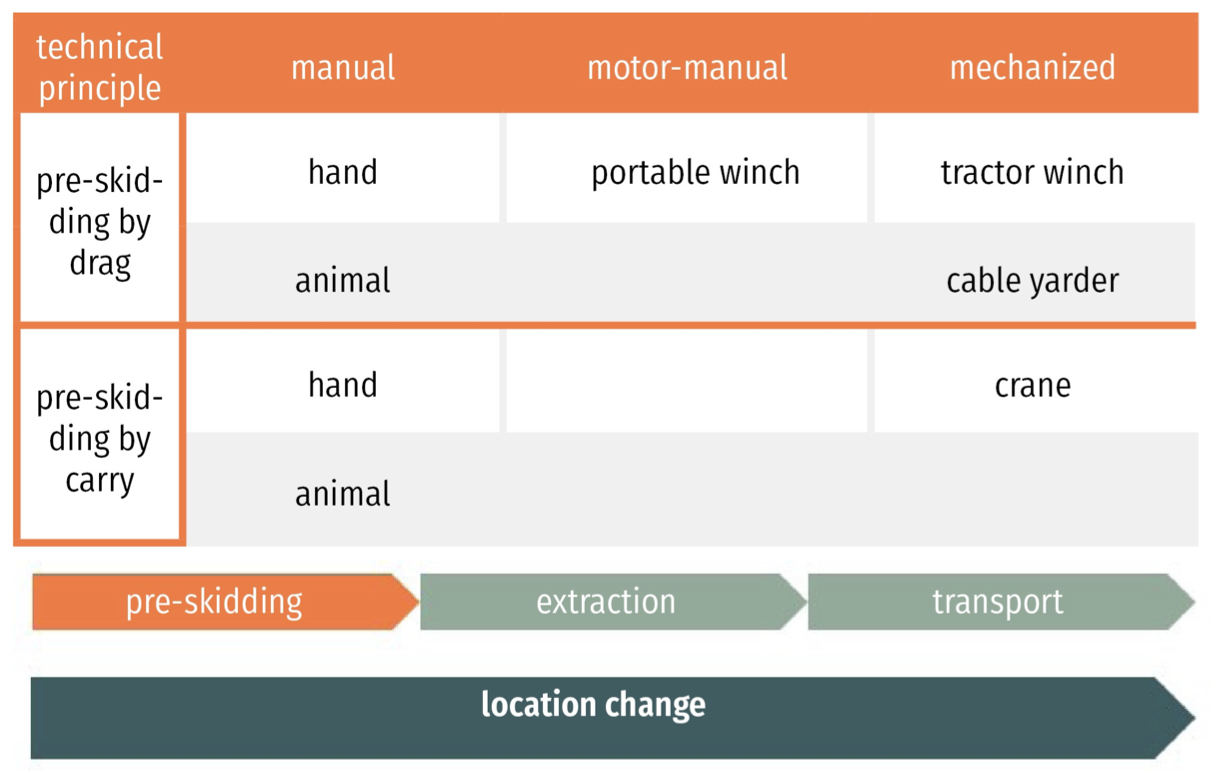

A tractor winch is used for pre-skidding full trees, tree length and logs from the stand (buffer 11, 12 or 13) to the trail (buffer 21, 22 or 23). Alternatives are the horse in flat terrain or the mule in steep terrain or the portable winch. Like the portable winch, the tractor winch reels in or pays out cable. In contrast to the portable winch, the tractor winch is located on a tractor and therefore does not have to be tight to a standing tree to perform its dragging function. Also different from the portable winch, the tractor winch manages to drag more than just one tree length/ full tree/ log out of the stand. The work with the tractor winch is declared as simple mechanized work. (See PR1-B03 and B07)  (Photo BOKU)  | |

Trafficability | |

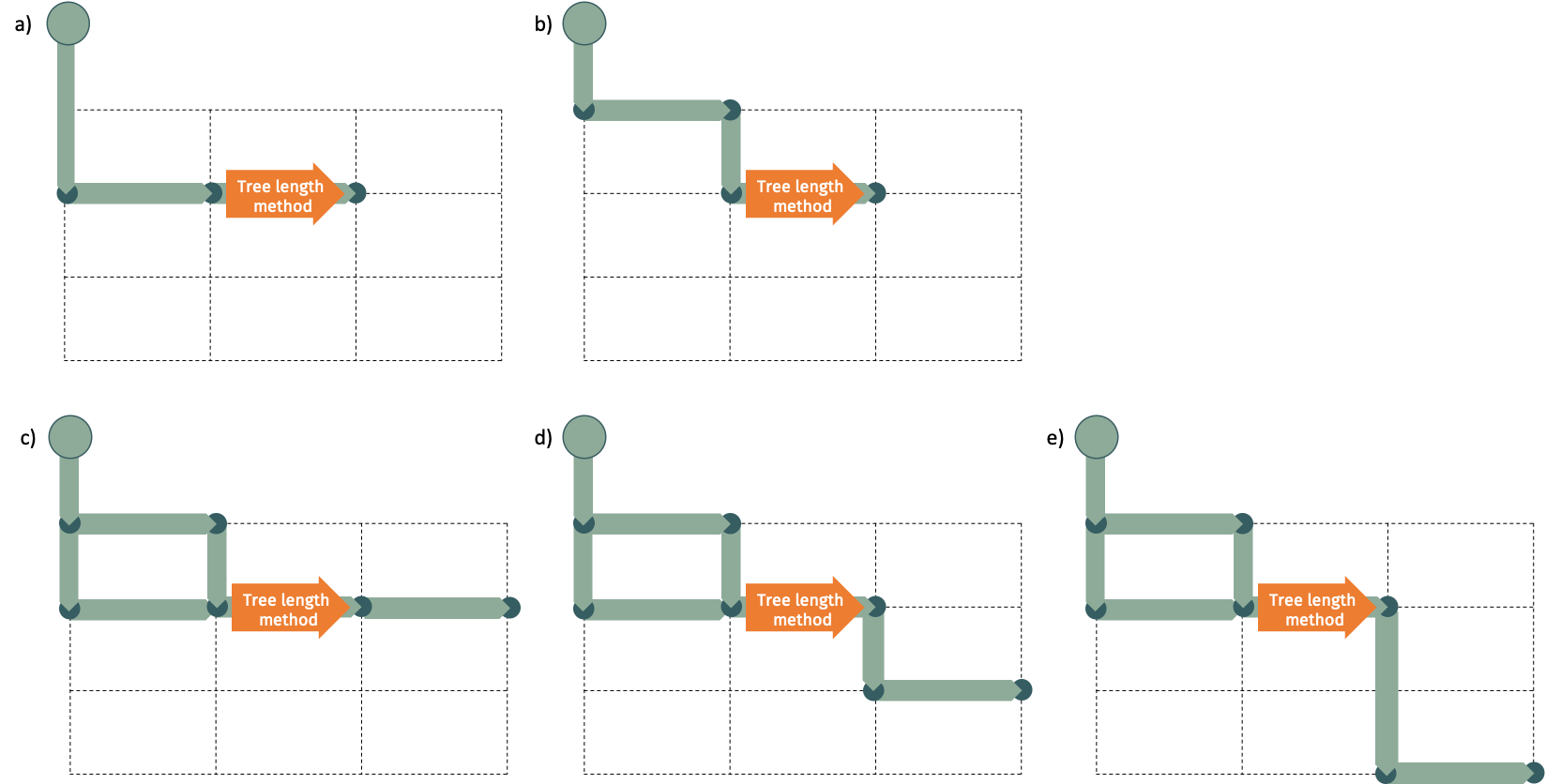

Tree length methodThe tree length method is one of four different functional groups of harvesting methods. The others are fulltree, cut-to-length and chip method. With the tree length method, two beginnings are possible: (a) Either the tree is delimbed at the felling site and moved as a tree length all the way to the forest road. Or (b) it is felled, pre-skidded to the strip road as a full tree and delimbed there, prior to extraction to the forest road. In both cases, the tree reaches the forest road as a tree length. Once at the forest road, the tree length can be transported to the factory as such (c), or cross-cut into logs before transport (d) or even chipped at the roadside and transported as chips (e). (See more at TDiv PR1-B07)  | |

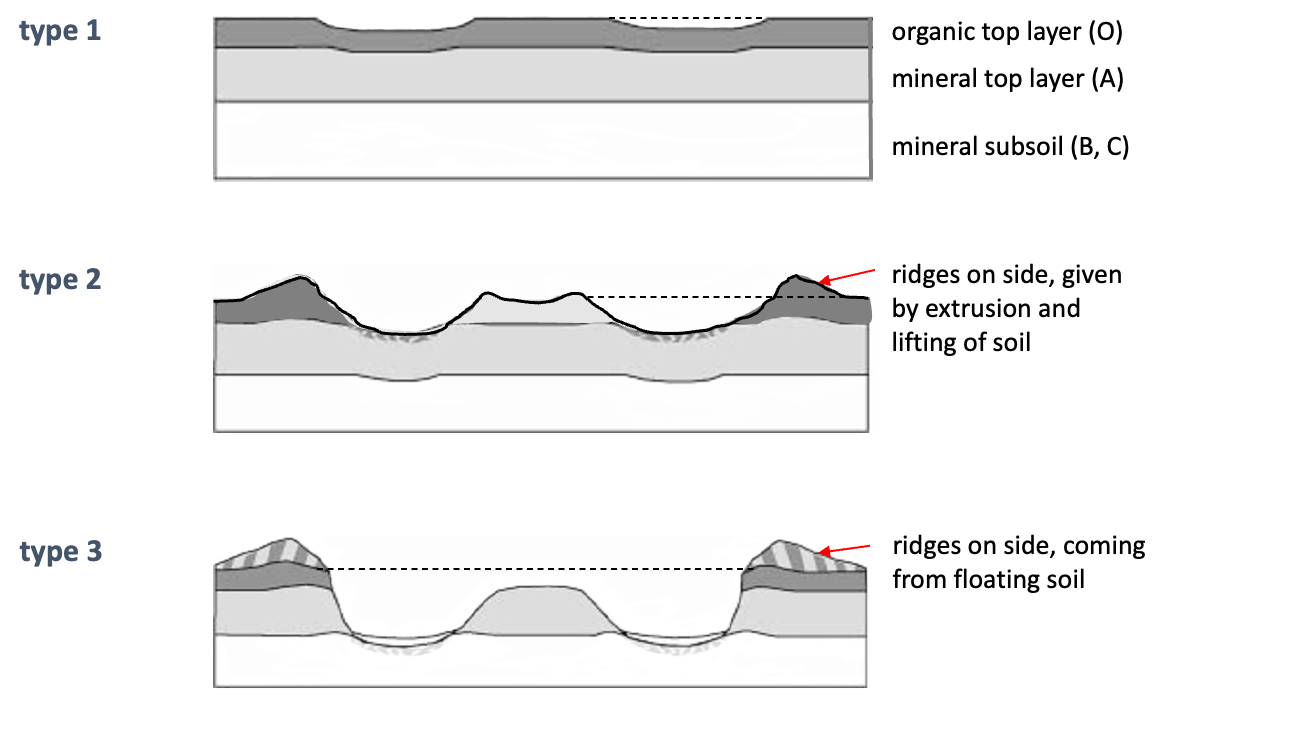

Types of ruts on trailsDue to machine traffic, soils react in different ways to compaction. The Eidgenössische Forschungsanstalt WSL (Switzerland) has classified ruts on trails according to three types: With type 1, we can see small ruts that witness to some degree of compaction, but there are no ridges on the sides. This type of rut is very stable and allows for further passages. With type 2, ridges appear at the sides of the ruts: they derive from the soil being pushed aside by the wheel. This type is stable, too, but the ridges are a warning that we are close to the limit and must be very careful. With type 3, new ridges appear that derive from semi-liquid soil flowing out of the ruts. This is a clear indicator that traffic must be stopped. (See more at TDiv PR1-D03)  | |

U |

|---|

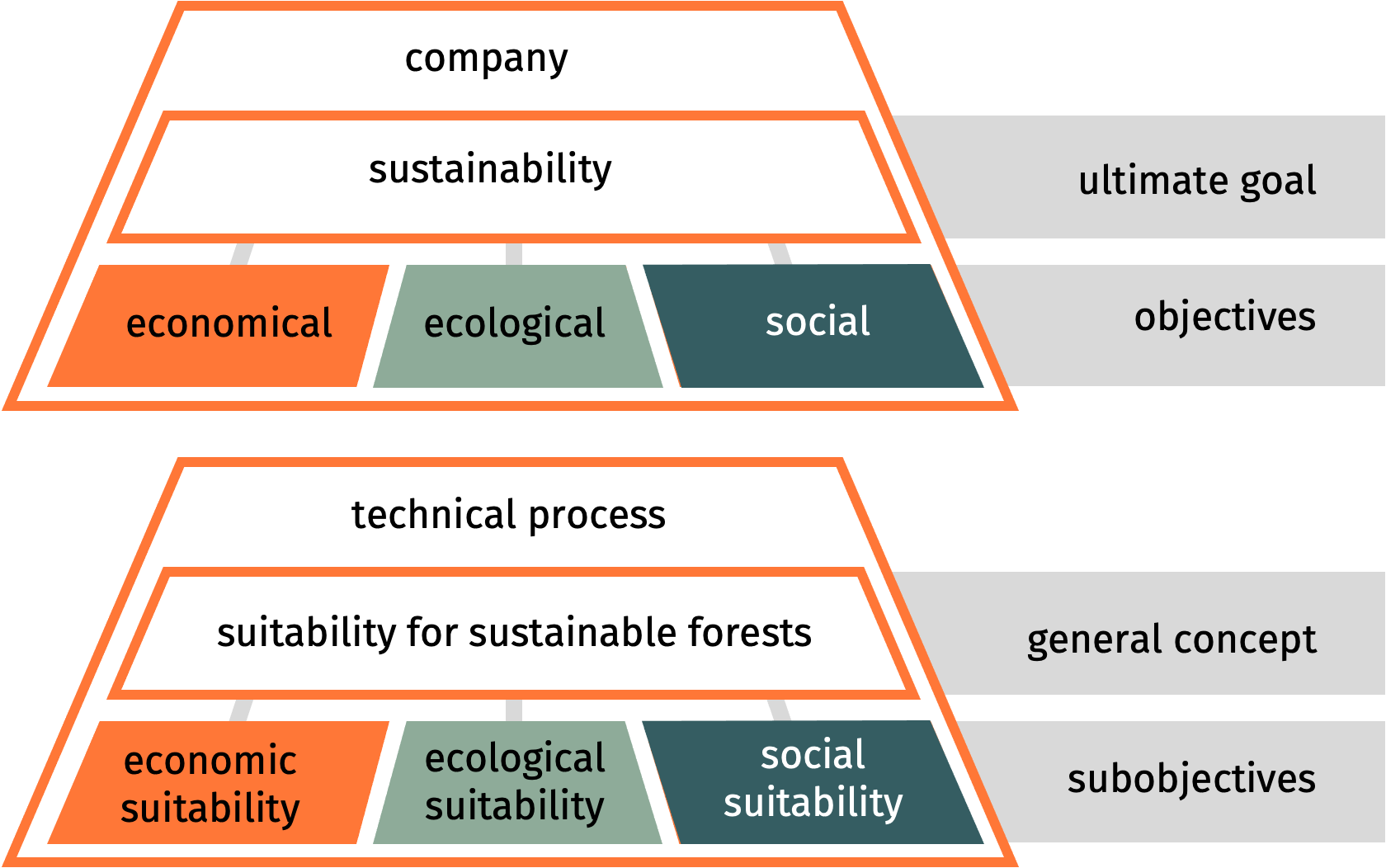

Ultimate goalThe Ultimate goal is an overall concept of a company. It has two dimensions: · For internal decision-making situations it clarifies priorities or preferences between the economic, ecological and social objectives. Thus, it improves the transparency and operationality of the decision-making process. · For external use it explains with simple words the focus how this company sees itself. It can be regarded like a motto that explains the typical behavior of the company. (See more at PR1-A03)

| |

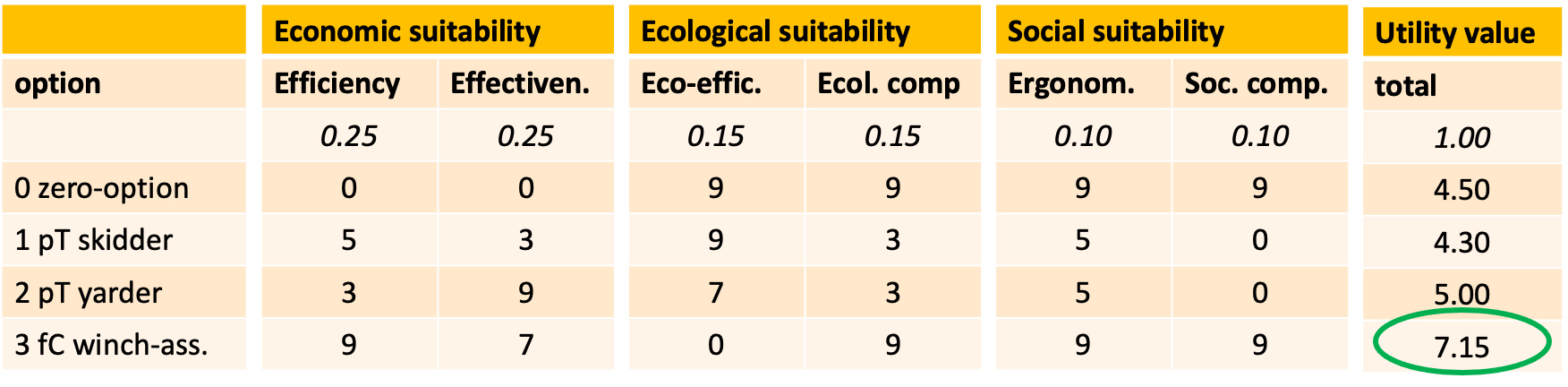

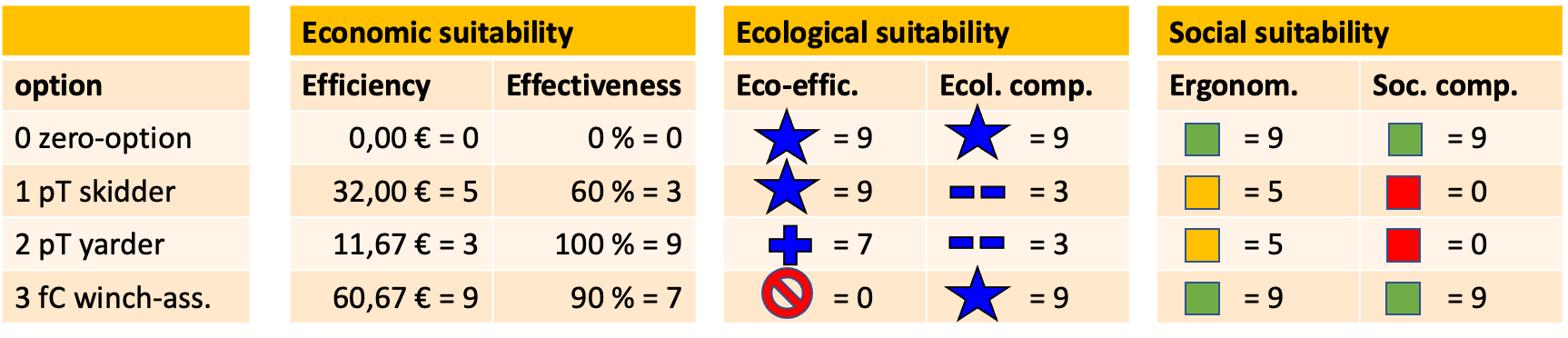

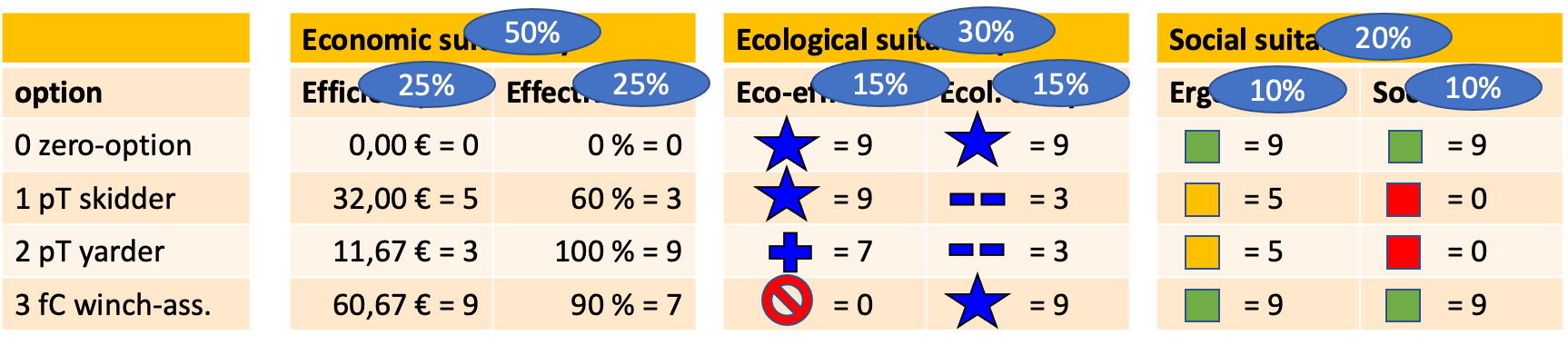

Utility analysisThis is one option to find the best option. Others are the minimax-rule, monetarization, AHP, and optimality curves, for example. This method for decision making is really old (Zangemeister 1973). Here, one common scale of values is used, that is not based on monetary values. Instead, one uses scores like in school. Every criterion must be rated according to those scores.Next, one gives a weight to every criterion according to its relative importance. The sum of weights should be 1.0 Finally, each score is multiplied by the respective weight and then summed up. The option with the highest score will be the favorite. Let’s take an example. Here we introduce a value scale with scores that allow a rough assessment like:

Then we need some weights for the different criteria. It is easier to weigh the three main pillars first, for example

…and then the two sides of optimality (i.e. effectiveness and efficiency). Multiplying them, you get the weight. In our example we balance effectiveness and efficiency by 50/50 %.  The result is quickly told: again, option 3 CTL (hC winch-assist) wins, option 1 is a bit worst than the zero-option. No option is really bad, but also no option is extraordinarily good (the range of values is between 4.3 and 7.15). This is one of the disadvantages of this method: It equalizes all options near the center.

Scientists do not rate this analytical method too high, because it has a couple of mathematical bugs, that make it unscholarly. One of the most relevant critics at the utility analysis is, that it uses mathematical operations that are not rational. In particular, the scores 0-9 are data on an ordinary scale, which only knows “more”, “equal” and “less”. Operations like adding or multiplying may not be done. But it has one advantage: It allows for a transparent decision-making process. (See more at PR1-F04) | |

V |

|---|

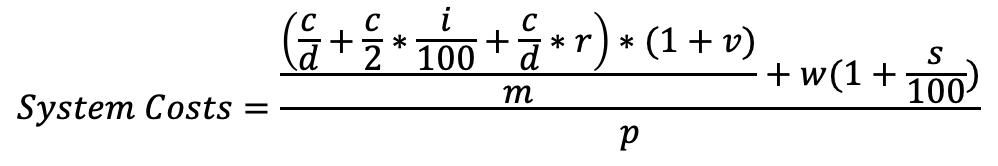

Variable costsVariable costs are a part of the cost calculation with the engineering formula. They consider those costs that only occur when the system is working. When it stands by, these costs are zero. But when the machine works, it consumes energy in the form of fuel or electricity, plus other consumables like hydraulic oil, lubricants, and so on. It is not too difficult to calculate these costs per hour. With fuel, we multiply consumption (liters per hour) with the price per liter, for example. For a general approximation, one can also take the sum of fixed costs and multiply it with nay estimated factor. With expensive machines it is roughly 10%, and it climbs up to 50% with simple machines like the chainsaw. (See more at TDiv PR1-C02)

| |

W |

|---|

Winch | |

Working methodA working method describes a special working process. In contrast to the term process, which only describes what actually happens, the working method has a more normative implication: It declares, which system elements are combined, and in which steps they are concatenated. The most important information is: what kind of tool or machine is used, what are the inputs and for which outputs do we aim? When we look mostly on the worker: how he must behave, what he has to do, when and in which sequence should he go on, we call it operational method. But sometimes the worker does not exactly what he is asked to do. Maybe he invents his own sequence of steps or he works in a way that conflicts with any safety rules – then we call it the manner of working. (See more under TDiv PR1-E03) | |