Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

Special | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | ALL

C |

|---|

ControllingControlling is one of the auxiliary functions of harvesting. It does not directly change the state of the working object or its position, but steers these operations and deals with the data (logistics). In Technodiversity, controlling is not mentioned intensively; but nevertheless here a great potential for innovations and efficiency is covered. (See more at TDiv PR1-B01) | |

Cost calculationBefore a decision maker decides to buy a machine, e. g., he should estimate the probable costs and earnings and calculate the net income. The earnings normally depend on the market and cannot be influenced. So, the cost side is that one, where the decision maker can ‘earn or burn money’. In some cases, the cost of any future operation can be assessed very easily, because the decision maker has his own experience.But very often, he must estimate the costs based on very foggy data. They are unclear, because the costs will occur in future, for example in the next 6 years. We sub-divide cost calculations due to the time when we make them: pre-calculation, interim-calculation and post-calculation. (See more at TDiv PR1-C01 and PR1-C02)

| |

Costs per hour | |

CoverageEconomic effectiveness asks whether the result of an action fulfils the objective, in this case the economic goal. Sometimes, when it is not possible to measure the grade of fulfilment, it must be estimated. But sometime the fulfilment can be measured - like with coverage. Imagine that you have a forest stand, which is opened-up with trails that have a distance of 40 meters. One option that you have selected is the standard combination of harvester and forwarder. The problem is that the crane outreach is only 10 m and only 50 % of the stand can be harvested. So, the effectiveness of this solution is 50 %. You might add a worker with chainsaw, who fells those trees, which are outside the crane reach, towards the trail. Now, all trees can be reached and harvested. The effectiveness climbs up to 100 %.It often happens, that some technical options cover less than 100 %. Therefore, coverage is one attribute to measure the effectiveness. (See more at TDiv PR1-C01)  | |

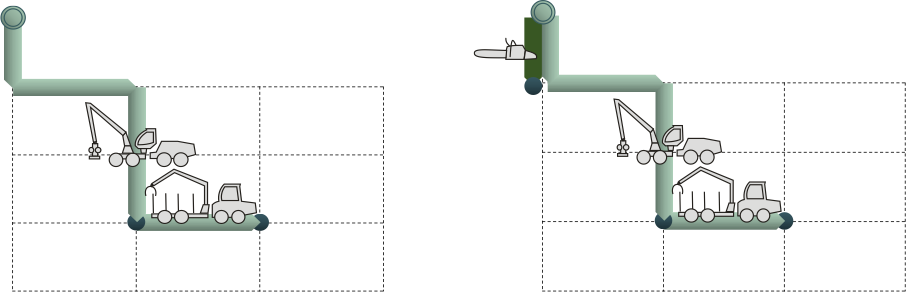

Cut-to-length methodThe cut-to-length (ctl) method is one of four different functional groups of harvesting methods. The others are fulltree, tree length and chip method. The character of ctl-methods is that the trees are brought to the forest road in form of short logs. There are several ways to do it: (a) Trees are converted into logs directly in the stand (i.e., felling-delimbing-crosscutting in a smooth single pass). Or (b) trees can be delimbed inside the stand right after felling, but they are crosscut into logs after the stem lengths have been pre-skidded to the trail. Or (c) one may pre-skid full trees to the trail and perform there the delimbing and cross-cutting – so they are extracted as logs. After extraction (d), the logs can be transported directly to the factory as such or turned into chips before transport. (See more at TDiv PR1-B07)  | |

D |

|---|

Deformation of soilSee plastic and elasticdeformation

of soil | |

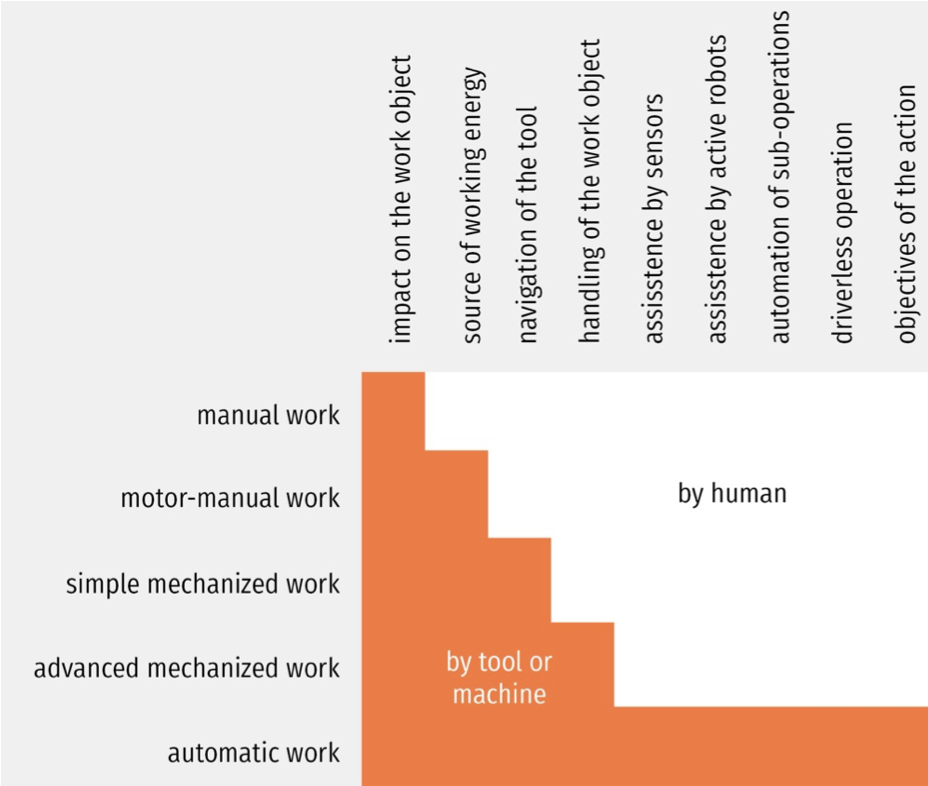

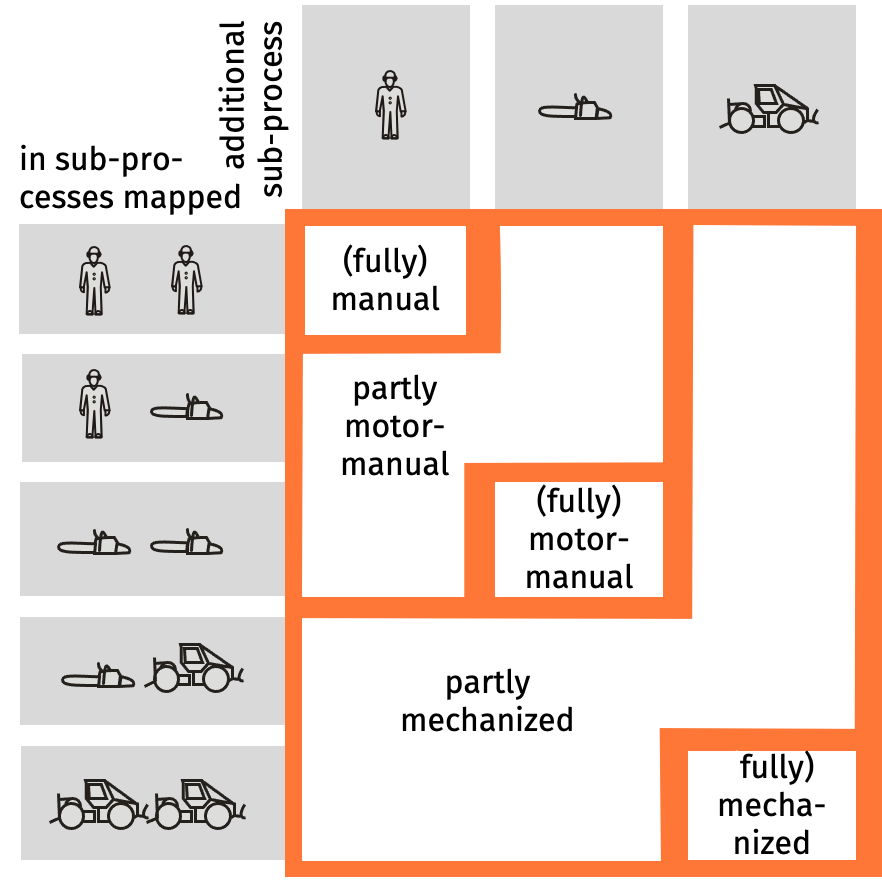

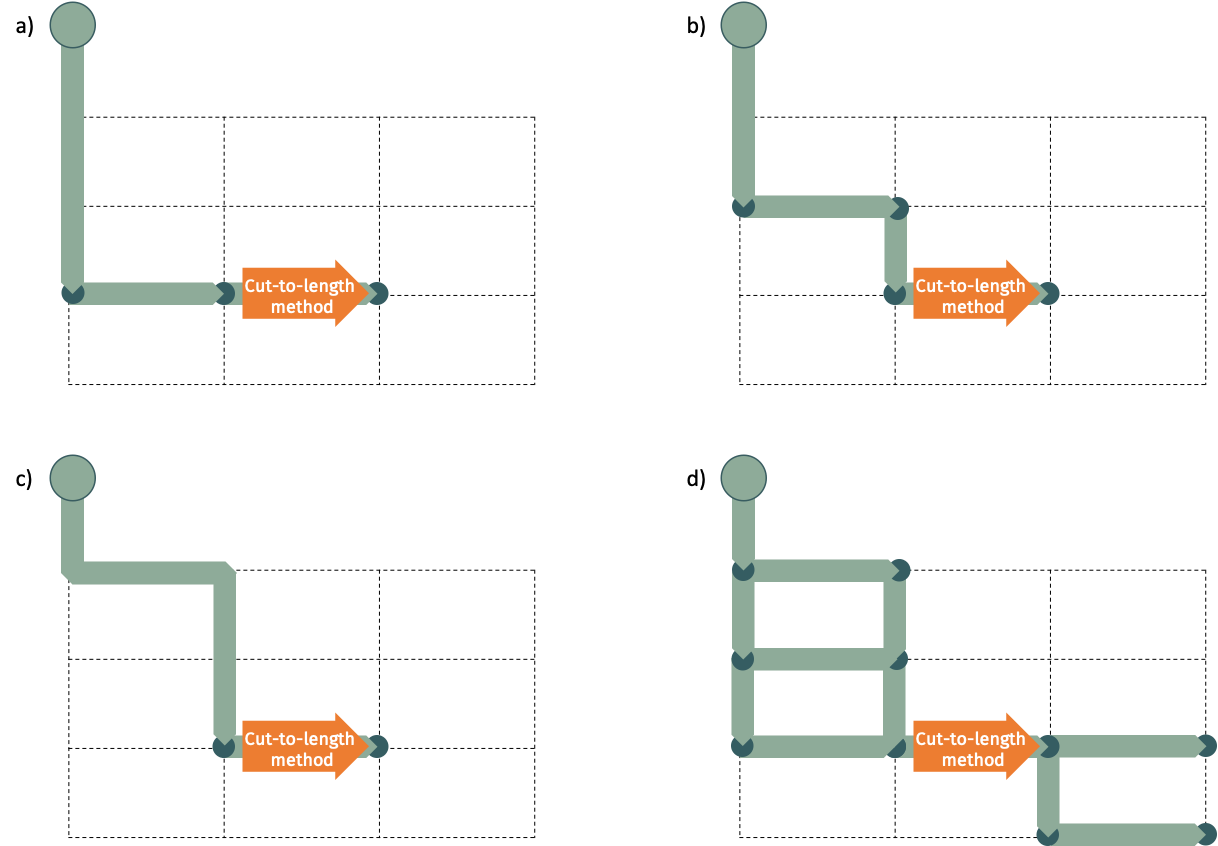

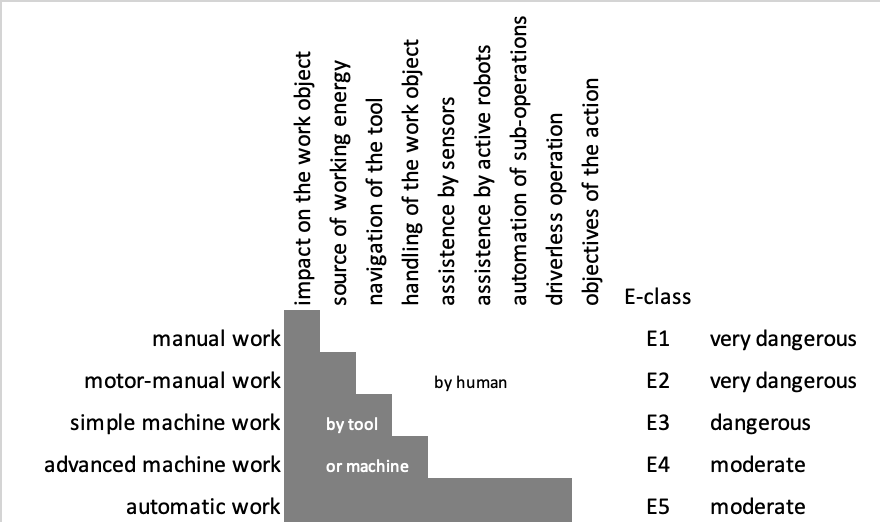

Degree of mechanizationThe term "degree of mechanization" is commonly used, but the content of this term varies extremely. After a long discussion, the authors of "Technodiversity" have agreed to the following, complex definition: In case of one single subprocess It can have three degrees:

In case of two sub-processes: Normally, a total harvesting process is a combination of two or more sub-processes. Since each sub-process has its degree of mechanization, we want to characterize the total process by a degree of mechanization, too. This is easy, if the degrees are equal. Then we have a fully manual, a fully motor-manual, or a fully mechanized method. If the degrees differ, we take the name of the highest degree and add the adjective "partly".  In case of more than two sub-processes As long as only two sub-processes are combined, the degree can easily be found. But in some cases, there are more than two sub-processes combined. In this cases, we first look for the degree of mechanization of two sub-processes and then add the degree of mechanization of the third sub-process. The terms of the degree of mechanization are the same as with two sub-processes.

"Almost fully mechanized": In some cases, we need a more differentiated description. Let's explain it with an example: When the distance between trails is wider than 20 m, the harvester that is instructed to stay on the trail cannot fell all trees, because its crane is not long enough. In that case a worker with his chainsaw fells those trees beyond harvester reach towards the trail. Later, the harvester picks the full trees up and processes them. Here, the most important machines are harvester and forwarder, forming a fully mechanized method. But due to the felling with chainsaw as an additional sub-process, the degree of the total process would turn to partly mechanized. We have the feeling that does not well represent the reality. Consequently, if the sub-process with the lower degree of mechanization is only necessary for a smaller subset of working objects, we can express it with “almost fully mechanized”. | |

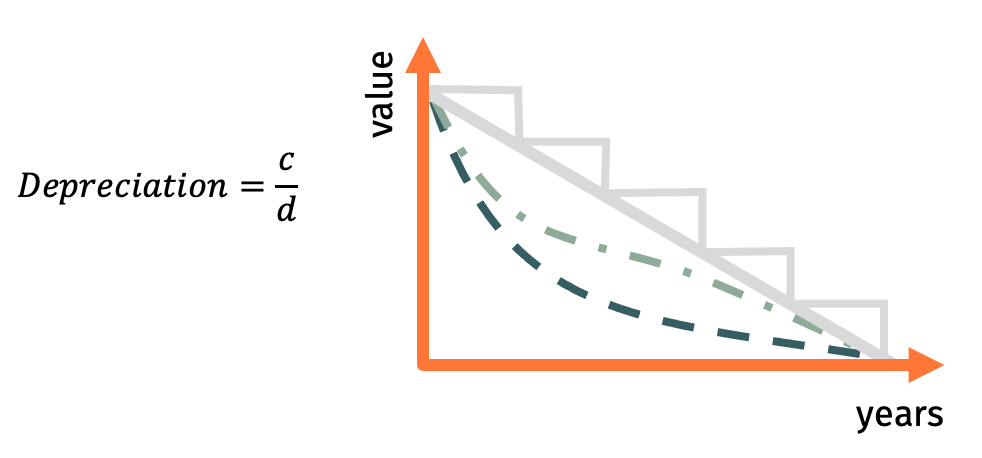

DepreciationDepreciation is a part of the cost calculation with the engineering formula. It considers the loss of value of a working system during its life span. Imagine you plan to buy a machine. It is very expensive, so the decision should be made carefully. If you intend to get a loan from the bank, you need a plan to pay the money back within a certain time. That means: Hour by hour you must put aside a certain sum, which you will transfer to your bank at the end of the month.We call this depreciation. The lifetime of a tool or machine is limited. There are several reasons for decay: • Technical decay (obsolescence) depends on technical progress: when new and better machines appear, your old machine may be no longer competitive. • Technical aging (wear) happens when parts of the machine become thin, stiff, inflexible, and break, i.e. • In some situations, we have only limited use of a machine, afterwards we will not need it any longer. • Or the machine suffers from a “fashion change”, when your technology will become unfashionable, and nobody will be interested in this technology any longer. Depreciation is the response to the progressive loss of value of your machine. During this time, we must pay back the initial investment. If we did not borrow the money from the bank, we have taken it from the “investment pool” of our company. We have only changed money into a machine with the same value. When the value of the machine decreases, we must pay back into this pool in order to stay as “rich” as before. A third argument for depreciation deals with taxes: Since the taxes are based on the win, we should not forget the hidden costs by the daily devaluation of our equipment. How do we calculate depreciation? • First, we decide how many years the machine will be used. • Then we ask, whether it will be possible to sell the old machine at the end of the utilization time. But be careful there! Normally there is some residual value, but we may want to assume that it is 0 and use it as a silent reserve to compensate the higher price for a new machine – due to inflation and technical development. • The annual depreciation now is calculated as the initial investment minus the assumed residual value divided by the number of years. This is called linear depreciation. In fact, real devaluation is not linear (here implied with red or green) but in practical term a linear solution is good enough and it is easier to calculate. (See more at TDiv PR1-C02) | |

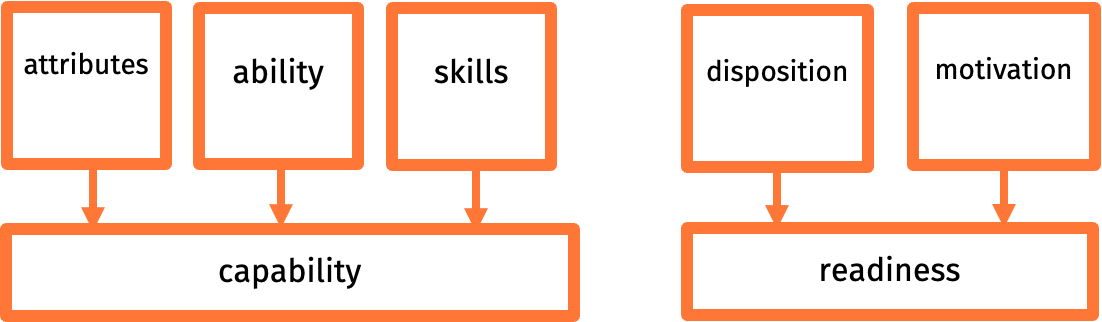

Disposition of a workerErgonomics follows a very simple basic model that derives from physics: When you impact a body with a certain stress, the body will react with a corresponding strain. Since a standard method causes a stress that is typical for this standard method, the strain as a reaction to this typical stress situation should be typical, too. The intensity of the strain, however, is not the same. It depends on the worker: his personal attributes, his abilities and his skills (together they form the capability for work). And it varies due to the actual disposition and motivation (together called readiness for work), and his health. If the strain overruns the permanent work load, breaks are necessary for his personal recovery to avoid acute or chronic damage. We know that there are days when the same job feels hard, and days when it feels much easier. So, for the same individual the strain can differ. This partly depends on the health, conditioning, tiredness, hunger and time of the day. We call these organic reasons disposition. (See more under TDiv PR1-E04)

| |

E |

|---|

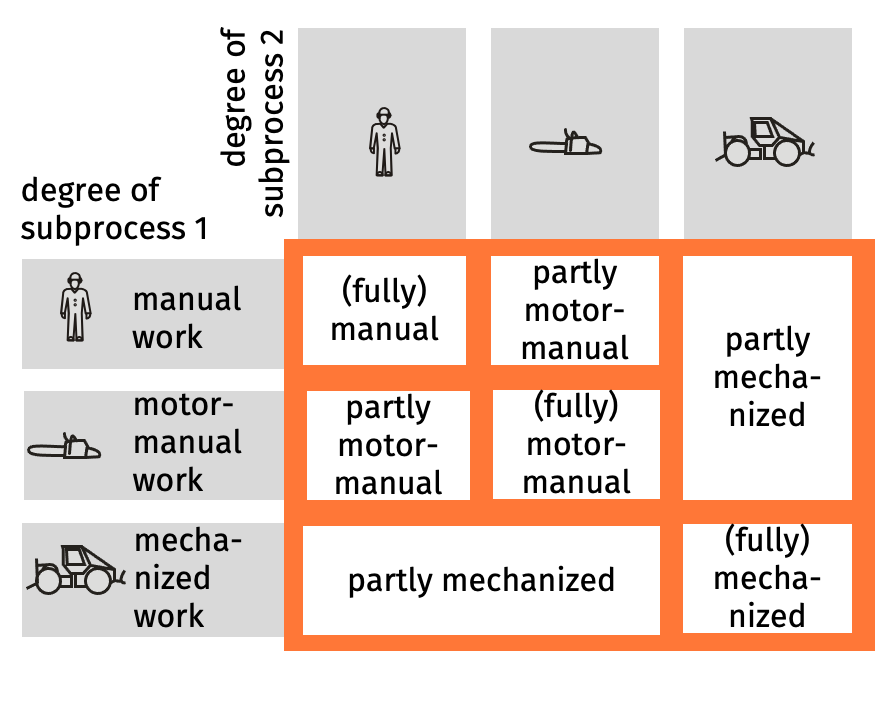

E-class for ergonomics and safetyFor Technodiversity, we introduce an E-class to specify the complex influence of the standard working method on the strain of work. The question is, are there any categories that correspond with the special capabilities of the persons? Concerning physical stress, we can deduce them from the degree of mechanization. These categories correspond with the risk of an accident, too. In general, work safety improves as we progress through the various degrees of mechanization.  | |