Technodiversity glossary is a result of the ERASMUS+ project No. 2021-1-DE01-KA220-HED-000032038.

The glossary is linked with the project results of Technodiversity. It has been developed by

Jörn Erler, TU Dresden, Germany (project leader); Clara Bade, TU Dresden, Germany; Mariusz Bembenek, PULS Poznan, Poland; Stelian Alexandru Borz, UNITV Brasov, Romania; Andreja Duka, UNIZG Zagreb, Croatia; Ola Lindroos, SLU Umeå, Sweden; Mikael Lundbäck, SLU Umeå, Sweden; Natascia Magagnotti, CNR Florence, Italy; Piotr Mederski, PULS Poznan, Poland; Nathalie Mionetto, FCBA Champs sur Marne, France; Marco Simonetti, CNR Rome, Italy; Raffaele Spinelli, CNR Florence, Italy; Karl Stampfer, BOKU Vienna, Austria.

The project-time was from November 2021 until March 2024.

@ | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | Alle

N |

|---|

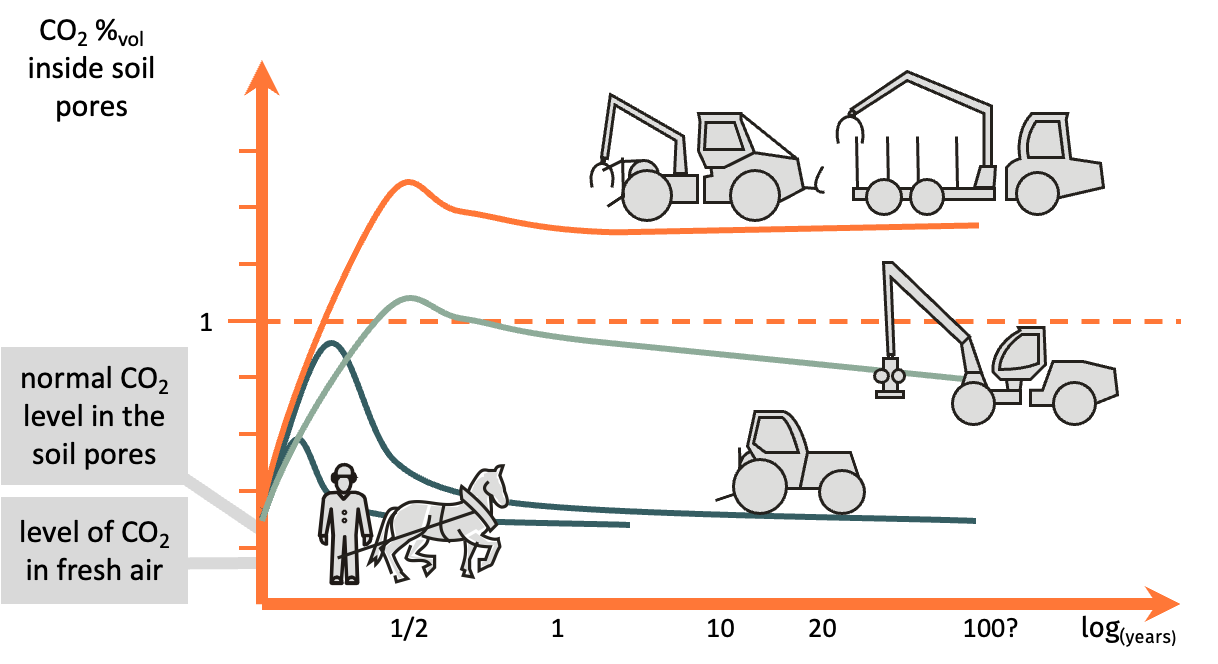

Natural regeneration of soilAny compaction of a soil can be recovered by physical power (like frost or mechanical lifting) or by biological activities (roots, micro-organisms, worms…). Biological activities get their power by life processes that depend on breathing. Due to this reason, the measurement of carbon dioxide (CO2) in the pores is a valid indicator for biological actions. In biologically active soils the percentage (on volume) of CO2 is about 0,3%, a bit higher than in the outside air. Directly after traffic we observe a quick increment of CO2 in the soil pores.But after a couple of hours the percentage of CO2 can go down again. We believe that in this case the pores in the soil are opened again by biological activities from all directions.Thus, though the specific soil pressure may be high, when the affected volume of soil is small and the lateral area is large as we have it with human footprints or animal steps, then recovery happens very quickly. When a light tractor (< 5 t) drives on the soil, the impact is higher. For the first few months, the percentage of CO2 is significantly higher, but there is a tendency to recovering during the first year. Of course, much depends on the gross weight of the tractor, the number of passes, the soil type, the moisture… so, driving with tractors seems to approach the limits. When a harvester, which has a gross weight > 15 tons, drives on the soil, the impact is so high, that the percentage of CO2 increases in the first few months and may exceed the 1,0 %vol threshold. Over several years there is no clear tendency towards recovery. This tendency gets clear as soon as heavy forest machines drive on the soil several times. Here the soil shows no tendency for recovery. (See more at PR1-D02)  | |

Normative levelOn the normative level of decision-making, persons like the owner of the company, the forest owner or in case of a state forest the parliament defines the objectives of all actions. Since in most cases there are more than one objective, collaborators need a guideline how to deal with competing or contradicting objectives. Very often a general guideline is given for external advertisement as well as for the internal communication, where this guideline allows all decision-makers in the company to streamline their decisions with the wishes of the top-management. (see more in TDiv PR1-A05)  | |

O |

|---|

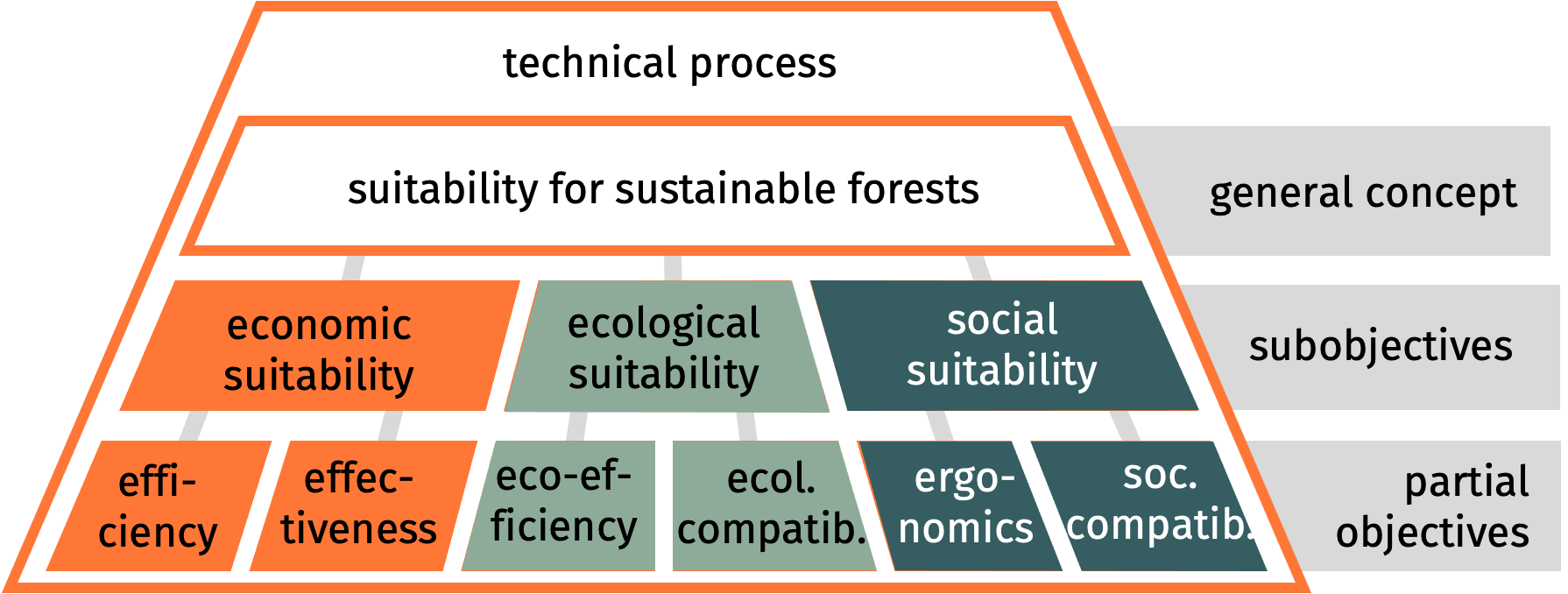

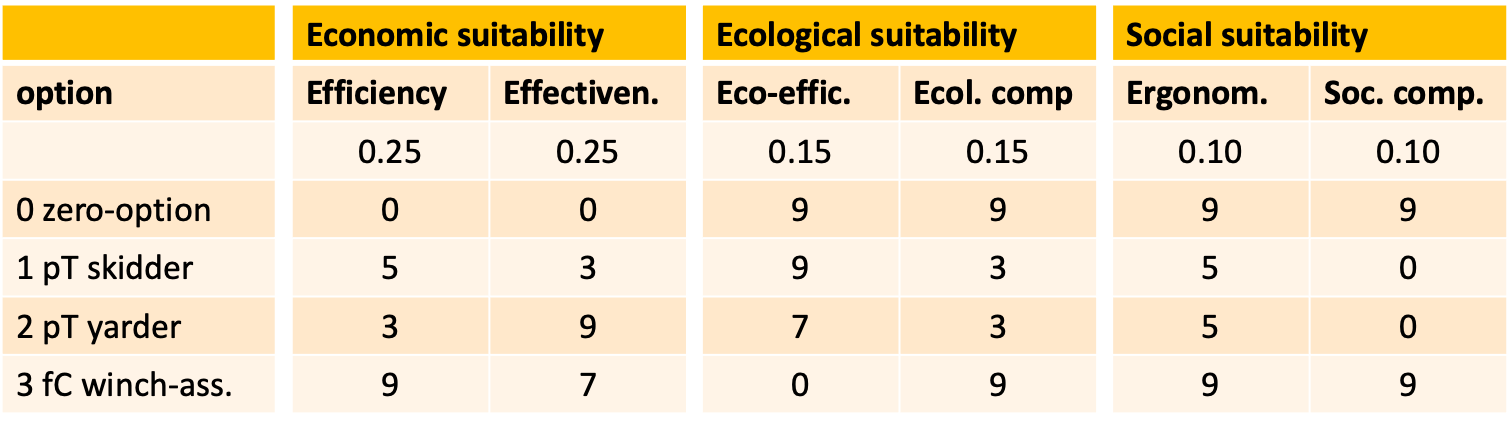

ObjectivesObjectives of forest operations depend on the objectives of the decision-making body, which normally is the forest owner. He follows his individual set of objectives, only. In a first glance we can assume that there will be an overarching task to maximize the income of the owner. But things should be differentiated a bit more: · The material objective of any forest and herewith also for every forest owner is to care about the forest and to deliver services and goods in a sustainable way. This defines the typical character of this branch, its restrictions and limitations. · The manager of the forest must regard all these limitations. But inside these restrictions and natural limitations, different options are given to optimize the success. Choosing the best option is the original job of the manager. But what is the best? Here the overarching task may be to maximize the income of the owner, but in some cases, there are diverging priorities. The success of the manager is measured on the background of this formal objective. So, not only one objective is followed but a set of more than one. Normally we work with three objectives, economy, ecology and social aspect. The relationship between them can be fixed with an ultimate goal that is typical for the forest owner resp. company. Since the objectives and the ultimate goal are valid for all actions of the company (like silviculture, hunting, nature conservation and harvesting, e.g.), they must be broken down for each field. For each objective we are looking for one corresponding sub-objective that defines the suitability of the means to reach the objective. So, the sub-objectives for forest operations are economic suitability, ecological suitability and social suitability. Each sub-objective can further be subdivided into two partial objectives, the effectiveness and the efficiency. Thus, at the end we have exactly 6 partial objectives that in common describe the suitability of operational options. We call this step the assessment as the objective part of the decision-making process. Like we have seen with the ultimate goal, also the sub-objectives can be brought to a relationship by the help of a general concept. A well-developed general concept for forest operations declares the priorities and preferences of sub-objectives and partial objectives in order to find a final evaluation of the best option. (See more in TDiv PR1-A02 and A03).  | |

Operational methodOperational method describes a special aspect of a working method. While the working method gives an overview on machine, input and output of the method, the operational method concentrates on the work of the operator. It asks what he has to do, in which sequence he must go on, what he must look for… But sometimes the worker does not exactly what he is asked to do. Maybe he invents his own sequence of steps or he works in a way that conflicts with any safety rules – then we call it the manner of working. (See more under TDiv PR1-E03) | |

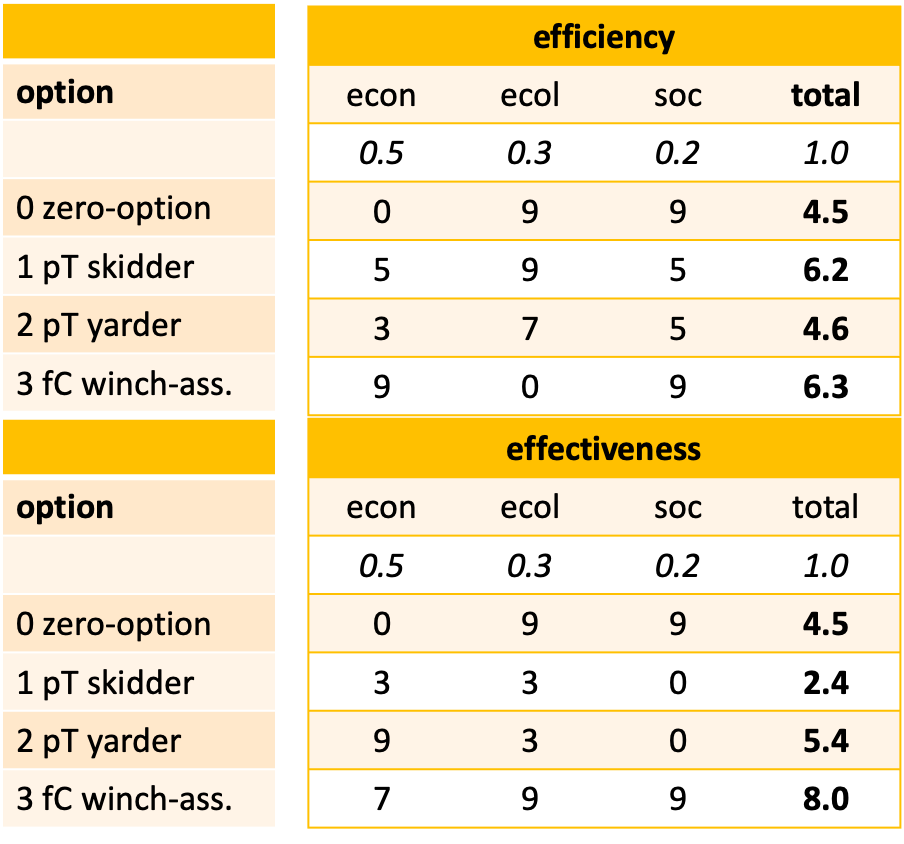

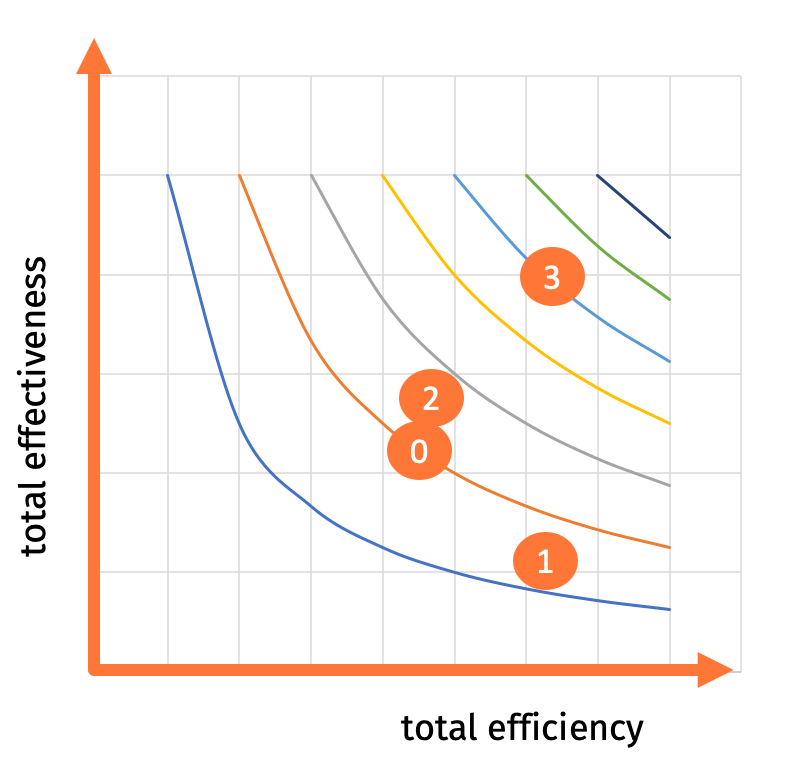

Optimality curvesThis is one method to find the best option. Other methods are minimax rule, monetarization, utility analysis, and AHP, for example. This method that has been developed at Harvard University. With this method the efficiency and the effectiveness of each option are compared against each other. This works well when there is only one

effectiveness and one efficiency. Since we have three criteria, we need to

adapt it a bit:

Here, we use the the same example as with the other decision making methods and also the same weights.  Now, we combine the assessments to one effectiveness and one efficiency.   Option 3 is located on the highest optimality curve, while option 1 is the worst option. (See more under PR1-F04) | |

P |

|---|

P-classes for productivityFrom the Saxonian technological map we know the idea to expand the distance between permanent trails when the soils has a high sensitivity. In Technodiversity, the decision about the distance between skid trails is made by the forest owner. This socio-economic approach gives the full freedom to him, asking: How much of the site’s productive potential are you willing to sacrifice to the technical function?” Depending on the answers, we introduce five so-called P-classes (for productivity, but it does not only depend on the productivity): P1: At a stand with low value (rocks, pure sand), any possible damage of traffic is not as important for the owner. Here, traffic may happen. P2: At a medium-value stand, where the advantages of fully mechanized methods are dominant, up to 20% of compacted soil is acceptable. P3: At a high value forest stand, where the owner sees the biological needs prior to technical needs, compaction should stay under 10%. P4: At a stand with a very high value, the technical considerations should be restricted to a minimum, say roundabout 5 %. P5: Finally, at a stand with an extreme high value, no machine traffic on the floor is accepted. When we assume that a trail has a width of 4 m, then this corresponds with following patterns of opening-up: P1: driving is accepted without any permanent pattern = “unlimited” P2: trails with “20 m” distance P3: trails with “40 m” distance P4: trails on old given routes, mostly >80 m distance = “uneven” P5: no driving with machines outside constructed roads at all. These P-classes form the Y-axis oft the technogram of a stand as well as the ecogram of harvesting methods. (See more at TDiv PR1-D04) | |

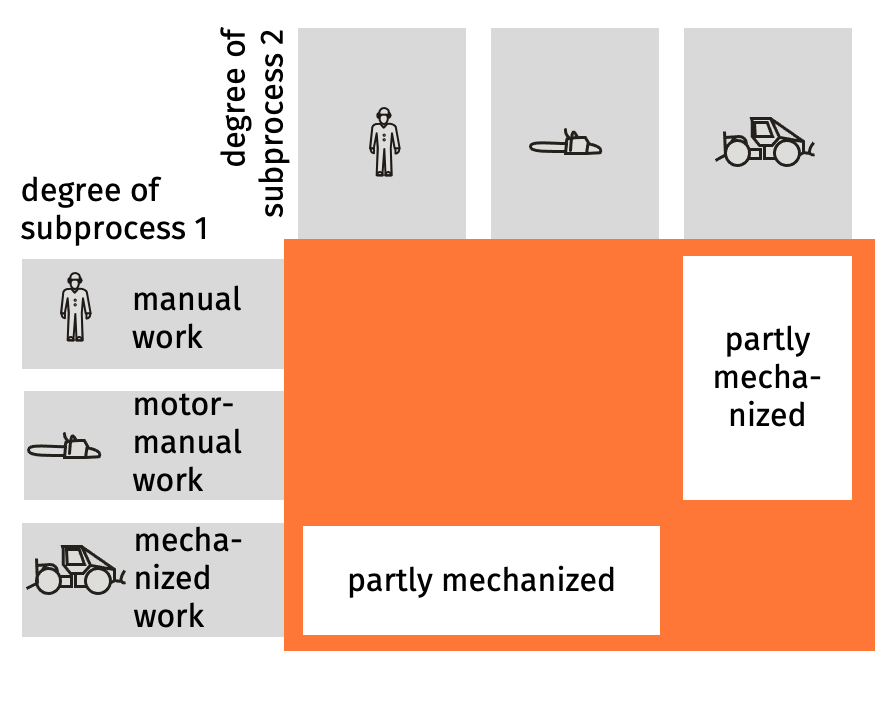

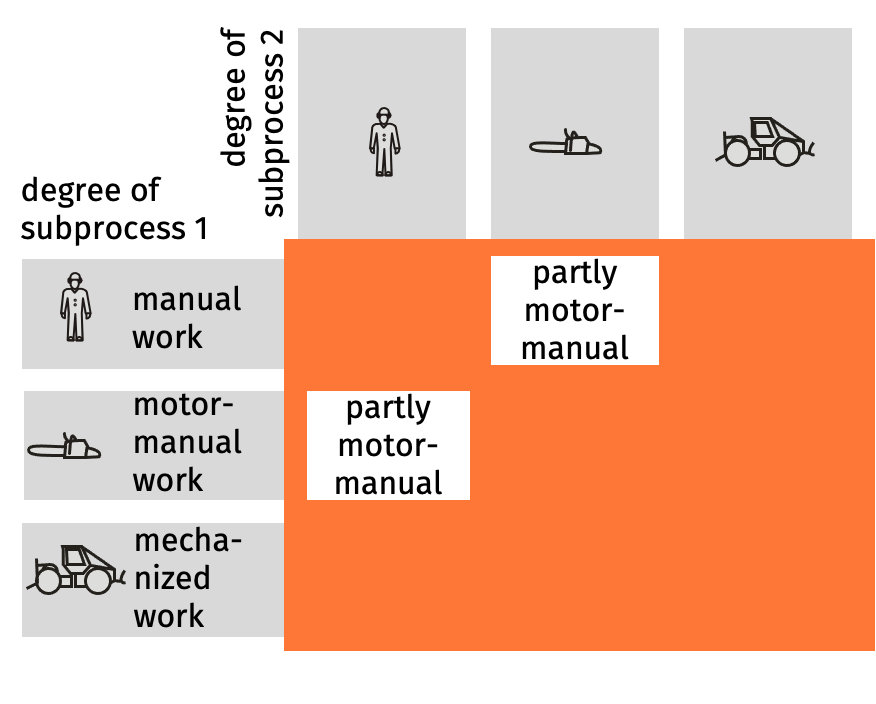

Partly mechanized methodIn Technodiversity, the total harvesting process normally is seen as a combination of several sub-processes. Each sub-process has a certain level of mechanization. The degree of mechanization describes the combination of these levels. There are five degrees of mechanization: (fully) manual method, partly motor-manual method, (fully) motor-manual method, partly mechanized method, fully mechanized method. If one sub-process is done by manual or motor-manual work and the other by mechanized work, then the method is a partly mechanized method. Examples are: chainsaw and skidder, chainsaw and forwarder, or hand tool and tractor. (See more under TDiv PR1-B04 and B05) | |

Partly motor-manual methodIn Technodiversity, the total harvesting process normally is seen as a combination of several sub-processes. Each sub-process has a certain level of mechanization. The degree of mechanization describes the combination of these levels. There are five degrees of mechanization: (fully) manual method, partly motor-manual method, (fully) motor-manual method, partly mechanized method, fully mechanized method. If one sub-process is done by manual work and the other by motor-manual work, then the method is a partly motor-manual method. Examples are: chainsaw and horse or chainsaw and extraction by hand. (See more under TDiv PR1-B04 and B05)  | |

PerformanceSee system performance | |